Silicon-containing acrylic-acid-modified epoxy ester resin and paint thereof

A technology of epoxy acrylate and epoxy resin, which is applied in the field of epoxy resin, can solve the problems of short baking time, achieve fast drying speed, avoid the risk of paint falling off, and meet the requirements of deep processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Synthesis of Acrylic Epoxy Resin:

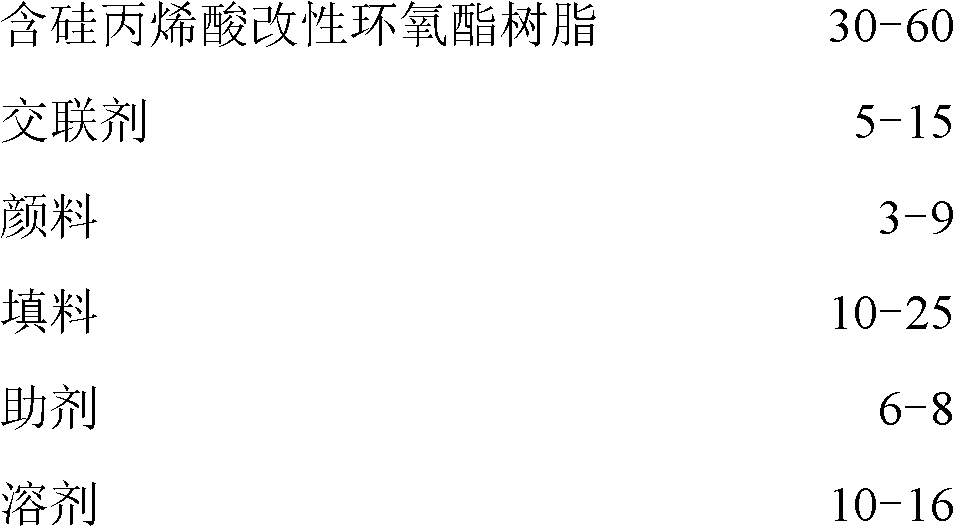

[0045] Synthesize epoxy acrylate resin by composition and component (all by weight) listed in Table 1.

[0046] Table 1

[0047]

[0048] In a four-necked flask equipped with a thermometer, a stirrer and a condenser, add epoxy resin, oleic acid and linoleic acid, add 0.1% catalyst, heat up to 185°C, stop the reaction when the acid value is less than 4mgKOH / g, and cool down to Add acrylic acid at 100°C, stop the reaction when the acid value is less than 4mgKOH / g, and prepare epoxy acrylate resin.

[0049] Synthesis of Silicon-Containing Acrylic Modified Epoxy Ester:

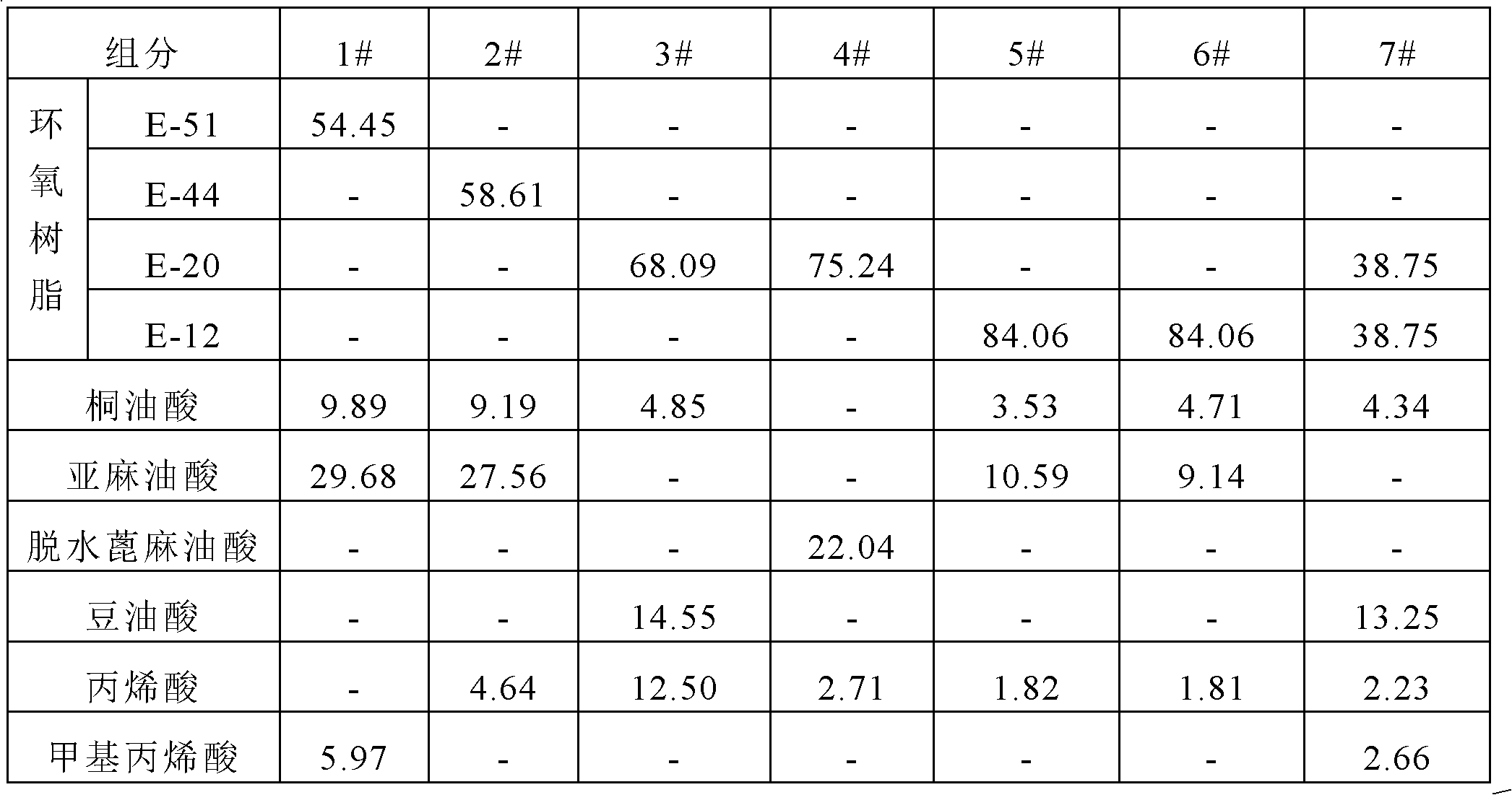

[0050] Take a certain amount of the above-mentioned acrylate epoxy resin, add silicon-containing acrylic acid monomers to free-radical copolymerization, and synthesize the silicon-containing acrylate epoxy resin. The acrylic monomers used are mixed from various monomers, and the compositions and amounts used in each embodiment are listed in Table 2 (all calculated b...

Embodiment 2

[0055] The synthetic method of epoxy acrylate resin is the same as that in Example 1, and one or more of E-51, E-44, E-20 and E-12 can be used as reactants for epoxy resin. The synthesis of silicon-containing acrylic acid-modified epoxy ester is also carried out with reference to the method of Example 1. The organosilicon monomer can use vinyl trichlorosilane, methyl vinyl dichlorosilane, vinyl triethoxysilane, gamma-methyl One or more of acryloyloxypropyltrimethoxysilane and trifluoropropylmethyldichlorosilane. If benzoyl peroxide (BPO) is used as the initiator, the reaction temperature should be kept at 115°C-125°C.

Embodiment 3

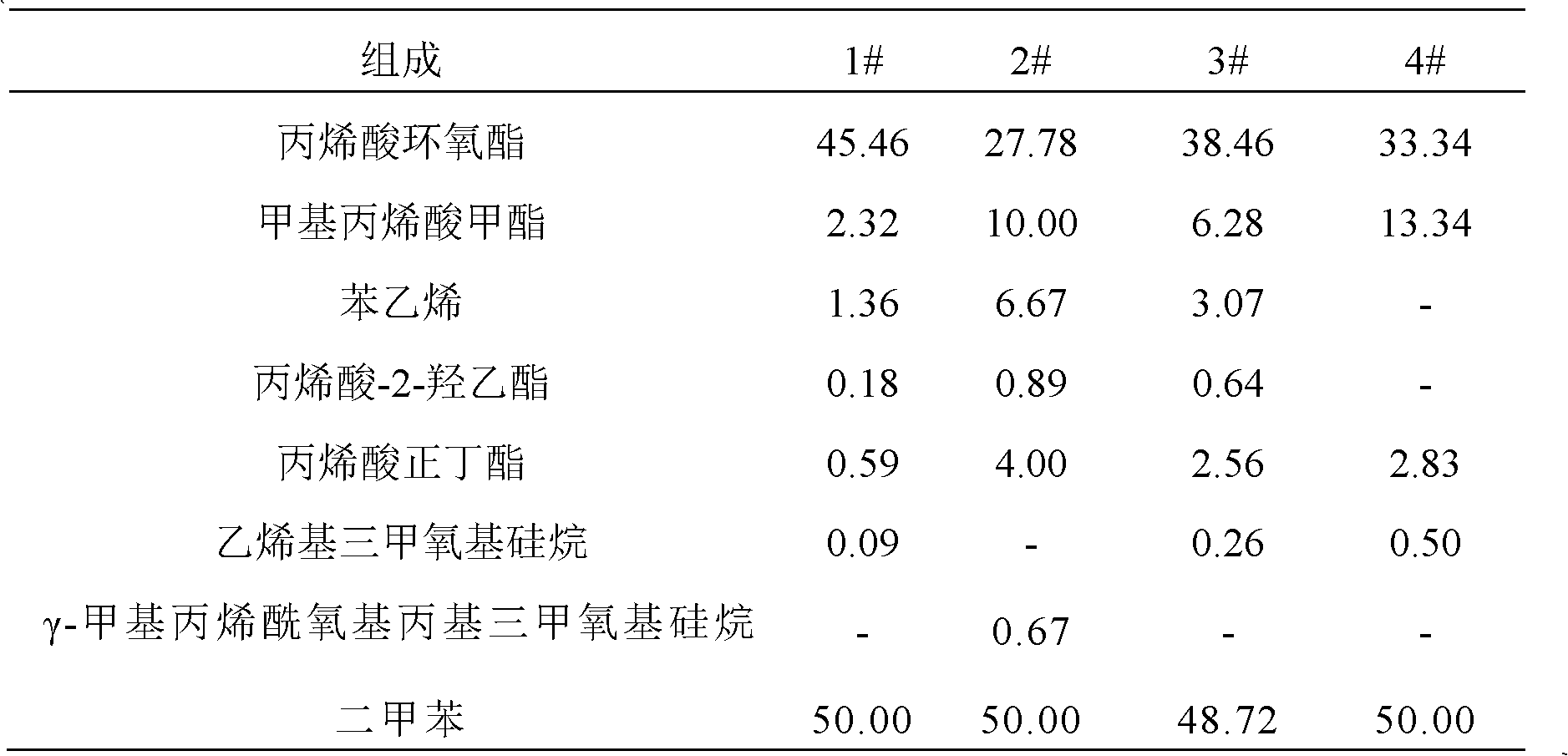

[0057] Preparation of silicon-containing acrylic modified epoxy ester colored glass curtain coating

[0058] According to the ratio of each component raw material listed in Table 3, mix silicon-containing acrylic modified epoxy ester, pigment, and filler at high speed for 30 minutes, grind to a fineness of 25 μm, and then add crosslinking agent, solvent and additives Stir evenly, filter, measure and pack after passing the inspection.

[0059] The anti-skinning agent is selected from methyl ethyl ketone oxime, butyraldehyde oxime or dipentene. The alcohol solvent is propanol or butanol, etc. Use trimethylbenzene, naphtha or raffinate as the high boiling point solvent.

[0060] Preparation Process:

[0061] At the production site, the glass curtain coating was diluted with solvent xylene to the construction viscosity, sprayed on the glass surface, baked at 130°C-160°C for 5-7min, and tested performance after 24 hours off-line as shown in Table 4.

[0062] table 3

[0063] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com