Paint for zipper puller, paint spraying method and paint-sprayed puller

A zipper and paint technology, which is applied in the field of clothing accessories, can solve the problems of long spraying time, the slider cannot be pulled, and the production cost is increased, and achieves the effect of saving spraying time, improving the fullness of the slider, and improving the spraying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

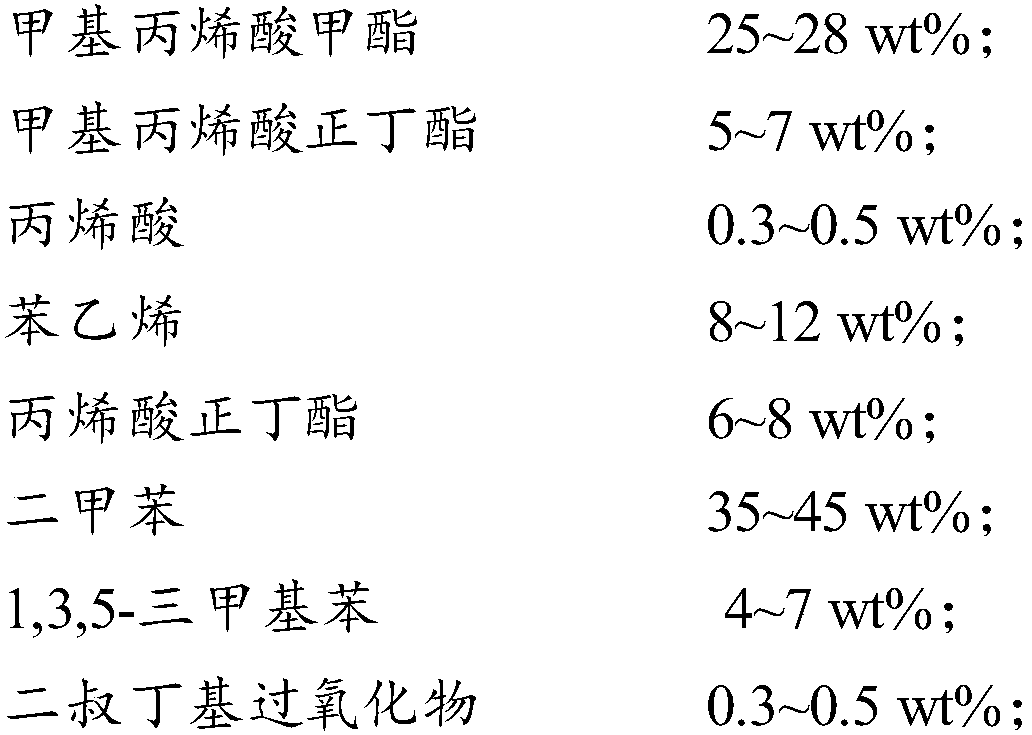

[0092] 27wt% methyl methacrylate, 6wt% n-butyl methacrylate, 0.4wt% acrylic acid, 9wt% styrene, 7.1wt% n-butyl acrylate, 45wt% o-xylene, 5wt% The 1,3,5-trimethylbenzene and 0.5wt% of di-tert-butyl peroxide were reacted in a reactor at 125° C. for 5 hours to obtain an acrylic resin.

[0093] The acrylic resin 65wt%, titanium dioxide 15wt%, triethylhexyl phosphoric acid 5wt%, octadecyltrimethicone 1wt%, durene 9wt%, novolac epoxy resin 1wt%, urea-formaldehyde resin 4wt% % Stir and mix at normal temperature to obtain the paint for zipper sliders.

[0094] Formulation of thinner:

[0095] 20 wt% of propylene glycol methyl ether acetate, 50 wt% of durene and 30 wt% of o-xylene.

[0096] Painting steps:

[0097] a) The rough slider is first degreased, then phosphorized with phosphoric acid with a mass concentration of 35% for 90 seconds, and then baked at 120° C. for 40 minutes to obtain a pretreated rough slider, which is placed in a paint spraying machine. b) Put the above-men...

Embodiment 2

[0100] 27wt% methyl methacrylate, 6wt% n-butyl methacrylate, 0.4wt% acrylic acid, 9wt% styrene, 7.1wt% n-butyl acrylate, 45wt% o-xylene, 5wt% 1,3,5-trimethylbenzene and 0.5wt% di-tert-butyl peroxide were reacted in a reactor at 125° C. for 4 hours to obtain an acrylic resin.

[0101] The acrylic resin 73wt%, titanium dioxide 10wt%, triethylhexyl phosphoric acid 5wt%, octadecyltrimethicone 1wt%, durene 4wt%, novolac epoxy resin 2wt%, urea-formaldehyde resin 5wt% % Stir and mix at normal temperature to obtain the paint for zipper sliders.

[0102] Formulation of thinner:

[0103] 20 wt% of propylene glycol methyl ether acetate, 50 wt% of durene and 30 wt% of o-xylene.

[0104] Painting steps:

[0105] a) The rough slider is first degreased, then phosphorized with phosphoric acid with a mass concentration of 35% for 90 seconds, and then baked at 120° C. for 40 minutes to obtain a pretreated rough slider, which is placed in a paint spraying machine. b) Put the above-mentioned ...

Embodiment 3

[0122] 26wt% methyl methacrylate, 7wt% n-butyl methacrylate, 0.3wt% acrylic acid, 12wt% styrene, 8wt% n-butyl acrylate, 40wt% p-xylene, 6.4wt% 1,3,5-trimethylbenzene and 0.3wt% di-tert-butyl peroxide were reacted in a reactor at 125° C. for 5 hours to obtain an acrylic resin.

[0123] The acrylic resin 60wt%, titanium dioxide 10wt%, polyether modified organopolysiloxane 10wt%, stearic acid monoglyceride 0.5wt%, durene 15wt%, bisphenol F type epoxy resin 1.5wt% %, 3wt% of melamine formaldehyde resin were stirred and mixed at normal temperature to obtain the paint for zipper sliders.

[0124] Formulation of thinner:

[0125] 20 wt% of propylene glycol methyl ether acetate, 50 wt% of durene and 30 wt% of p-xylene.

[0126] Painting steps:

[0127] a) The rough slider is first degreased, then phosphorized with phosphoric acid with a mass concentration of 35% for 90 seconds, and then baked at 120° C. for 40 minutes to obtain a pretreated rough slider, which is placed in a paint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com