A kind of pipe anti-scratch polyurethane coating and preparation method thereof

A technology of polyurethane coatings and pipes, which is applied in the field of polyester coatings, can solve the problems that cannot meet the requirements of pipeline scratch resistance coatings, impact resistance, poor adhesion, rusty steel plates, etc., and achieve stability over time and salt spray resistance The effect of good performance and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A preparation method for pipeline anti-scratch polyurethane coating, comprising the following steps:

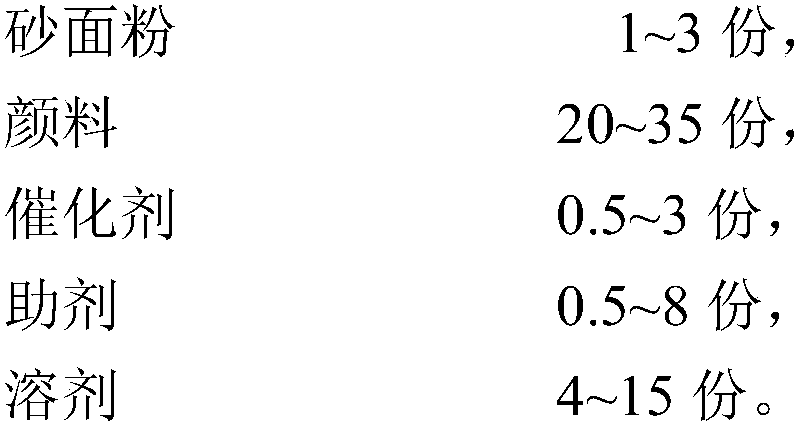

[0061] 1) Mix 25-30 parts of polyester resin, 1-3 parts of dispersant, 20-35 parts of coloring pigment, and 0.1-1 part of anti-sedimentation additive, add 4-10 parts of solvent, and grind to obtain slurry;

[0062] 2) Add 15-20 parts of polyester resin and 8-13 parts of amino resin to the slurry, mix; add 10-20 parts of isocyanate, add 0.2-1.5 parts of wax additive, 0.2-0.3 parts of acid catalyst, organic tin 1-2 parts of catalyst, 0.5-1.5 parts of defoamer, 1-3 parts of sand flour (polymethyl methacrylate, commercially available, such as produced by Dongguan Longhai Chemical Co., Ltd., model 3678), to obtain scratch-resistant polyurethane for pipes coating.

[0063] The solid percentage of polyester resin is 60-70%, the solid percentage of amino resin is 70-100%, the solid percentage of isocyanate is 70-90%; the ratio of polyester amino group is 2-5, and the ratio of...

Embodiment 2

[0069] A preparation method for pipeline anti-scratch polyurethane coating, comprising the following steps:

[0070] 1) Mix and grind 25 parts of polyester resin, 2 parts of dispersant, 22 parts of coloring pigment, 0.1-1 part of anti-sedimentation aid, and 4-10 parts of solvent to obtain slurry;

[0071] 2) Add 15 parts of polyester resin, 12 parts of amino resin, 18 parts of isocyanate, 0.2 parts of wax additive, 1.5 parts of sand flour, 0.2-0.3 parts of acid catalyst, 1-2 parts of organotin catalyst, disinfectant Mix 0.5-1.5 parts of foaming agent and 0-5 parts of solvent to obtain scratch-resistant polyurethane coating for pipes; wherein, the sand flour is polymethyl methacrylate, the particle size of the sand flour is 40 μm, and the specific gravity is 1.7 g / ml .

[0072] The polyester resin solid content is 60%, the amino resin solid content is 70%, and the isocyanate solid content is 70%; the polyester amino ratio is 2.9, the polyester isocyanate ratio is 1.9, the pigm...

Embodiment 3

[0075] A preparation method for pipeline anti-scratch polyurethane coating, comprising the following steps:

[0076] 1) Mix and grind 30 parts of polyester resin, 2 parts of dispersant, 35 parts of coloring pigment, 0.1-1 part of anti-sedimentation aid, and 4-10 parts of solvent to obtain slurry;

[0077] 2) Add 20 parts of polyester resin, 10 parts of amino resin, 12 parts of isocyanate, 0.2 parts of wax additives, 1.5 parts of sand flour (polymethyl methacrylate, the particle size of sand flour is 30 μm, and the specific gravity is 1.5g / ml), 0.2-0.3 parts of acid catalyst, 1-2 parts of organic tin catalyst, 0.5-1.5 parts of defoamer, 0-5 parts of solvent, and mix to obtain scratch-resistant polyurethane coating for pipes;

[0078] The polyester resin solid content is 60%, the amino resin solid content is 70%, and the isocyanate solid content is 70%; the polyester amino ratio is 4.3, the polyester isocyanate ratio is 3.6, the pigment-base ratio is 0.8, and the sand-color rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com