Punch mechanism used for removing longan stones and separating longan pulp and processing method using the punch mechanism to remove longan stones and separate longan pulp

A processing method and technology of longan meat, applied in the direction of fruit pitting device, application, peeling of vegetables or fruits, etc., can solve the problems of time-consuming and laborious, large loss of pulp, irregular shape of longan meat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

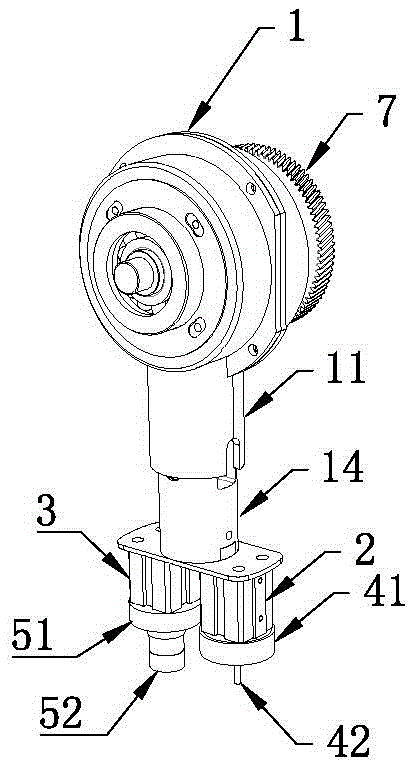

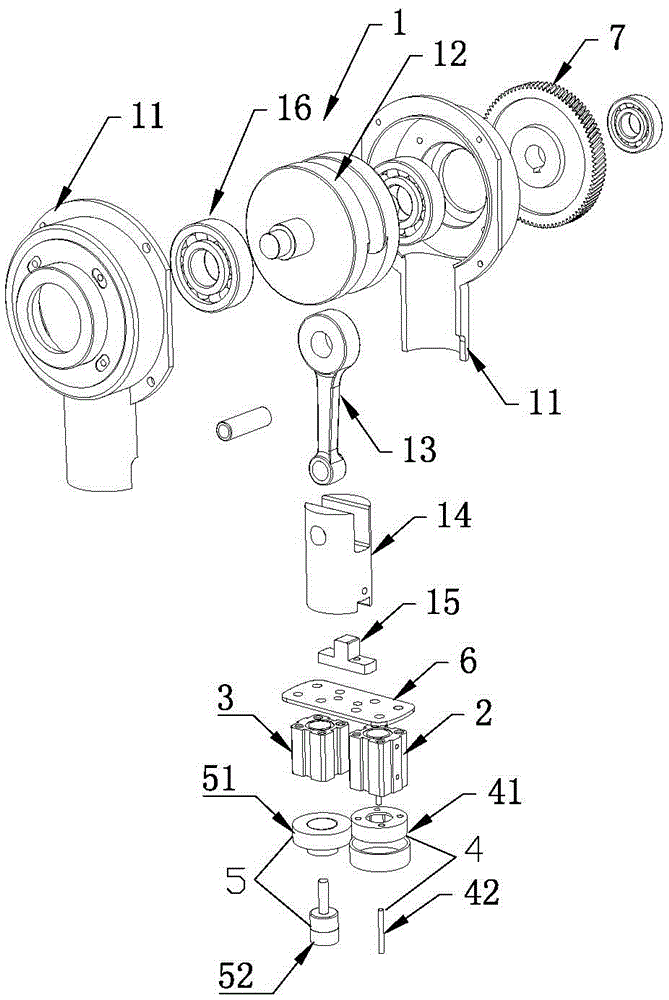

[0037] The punch mechanism for longan core removal and meat removal of this embodiment, such as figure 1 with figure 2 As shown, it includes the core punch 4 used to push the longan core from the longan flesh, the core punch 5 used to push the longan flesh out of the longan shell, the core cylinder 2, the deflesh cylinder 3 and the driving The crankshaft connecting rod mechanism 1 in which the core cylinder 2 and the defleshing cylinder 3 reciprocate up and down, the cylinder rod of the coreless cylinder 2 is connected with the core punch 4, and the cylinder rod of the deflesh cylinder 3 is connected with the core strip punch 5.

[0038] The core removal punch 4 includes a core removal upper punch 41 and a punch pin 42 arranged at the bottom of the core removal upper punch 41 for pushing out longan cores. The core removal upper punch 41 is fixedly connected to the cylinder of the core removal cylinder 2 . The meat removal punch 5 includes a meat removal upper punch 51 and a pus...

Embodiment 2

[0047] The processing method of using the punch mechanism of embodiment 1 to remove the cores and flesh of longan includes the following steps:

[0048] Step a, pre-processing steps before denuclearization:

[0049] a1. The longan is located at the core removal station. Cut the longan flesh and the longan shell together from the center of the bottom of the longan to form an opening so that the longan core can be pushed out of the longan flesh without causing damage to the longan flesh;

[0050] a2. Applying an expanding force from the inside to the outside of the longan flesh, so that the longan flesh and the longan core are stretched and become loose. The loose state between the longan flesh and the longan core is beneficial to the longan core in the next de-nucleation step It is easier to be pushed out of the longan flesh, and the part closely connected with the longan core will not be torn due to the impulse of the core punch 4 to push out the longan core, which reduces the loss r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com