Acrylic-modified alcohol acid-epoxy ester hybrid resin and paint thereof

A technology of epoxy resin and alkyd resin, applied in the direction of coating, can solve the problem of unable to meet the needs of the process, and achieve the effect of good acid and alkali resistance and water resistance, smooth and flat board surface, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Synthesis of acrylic modified alkyd-epoxy ester hybrid resin:

[0051] Step 1: Prepare epoxy ester: as shown in Table 1, put epoxy resin E-12, soybean oil acid, linoleic acid and zinc oxide into the reactor, add 40kg of reflux xylene, and heat to 150℃-160℃. When there is no abnormality in the motor, start the stirring. When the temperature is 180℃-200℃, keep for 4 hours and start to detect the acid value and viscosity. When the acid value is less than or equal to 4mgKOH / g, it is the end of the reaction. While diluting with xylene to the solid content of (50±1)%, while controlling the viscosity to 100s-250s (coating four cups, 25℃), filter the material for use;

[0052] Step 2: Prepare alkyd resin: as shown in Table 1, mix soybean oil, linseed oil and glycerin into the reactor, heat to about 120°C, add lithium hydroxide, continue to heat up to 240°C-250°C, keep for 1 hour-3 Hours until the alcoholysis is clear (by alcoholysis: 95% ethanol = 1:3), cool down, put in phthalic a...

Embodiment 2

[0057] Synthesis of acrylic modified alkyd-epoxy hybrid resin:

[0058] Step 1: Prepare epoxy ester: as shown in Table 2, put epoxy resin E-20, soybean oil acid, tung oleic acid, linoleic acid and zinc oxide into the reactor, add 40 kg of reflux xylene, and heat to 180°C-200 Measure the acid value and viscosity at ℃ for 4 hours. When the acid value is less than or equal to 10mgKOH / g, it is the end of the reaction. Discharge the material to the diluting kettle. While cooling, dilute with xylene until the solid content is (50±1)%. Adjust the viscosity to 100s-250s, filter for use;

[0059] Step 2: Preparation of alkyd resin: as shown in Table 2, mix soybean oil, linseed oil and glycerin into the reactor, heat to about 120°C, add lithium hydroxide, continue to heat up to 240°C-250°C, keep warm for about 1h until alcohol Decompose thoroughly (by alcoholysis: 95% ethanol=1: 3), cool down, put in phthalic anhydride and 40kg reflux xylene, keep at 170℃-190℃ for 4 hours-5h, start to detec...

Embodiment 3

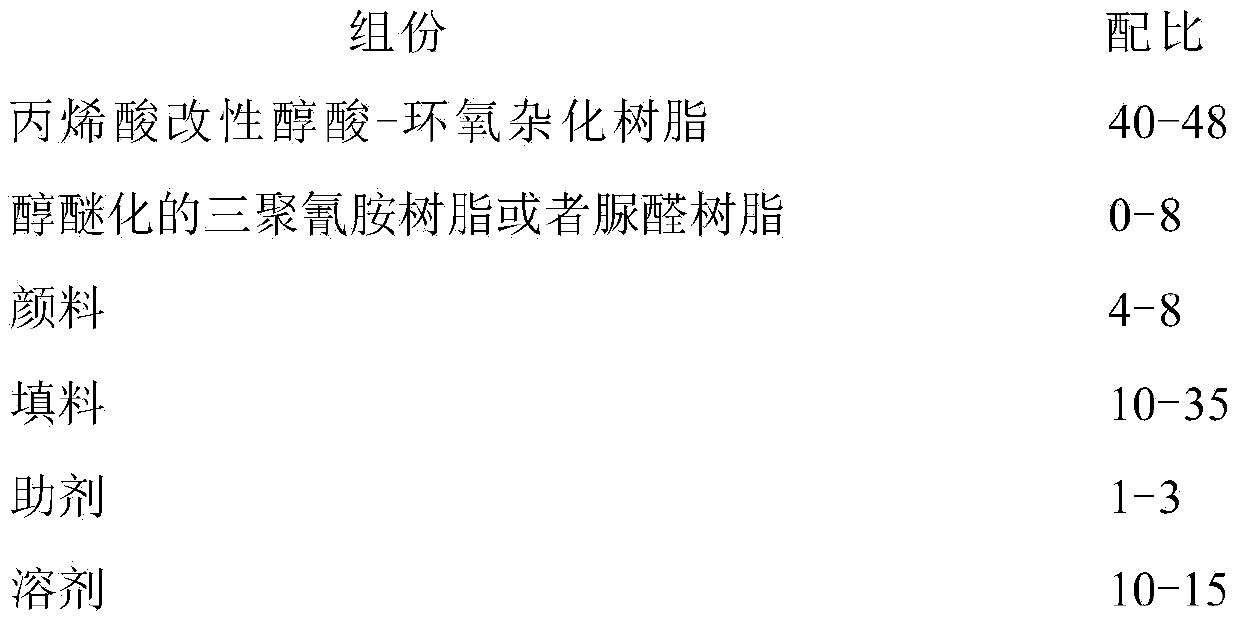

[0065] Preparation of mirror back curtain coating (primer)

[0066] According to the ratio of each component raw material listed in Table 3, the acrylic modified alkyd-epoxy hybrid resin, anti-skinning agent, pigment, and filler were mixed and dispersed at high speed for 30 minutes, and then pulverized by a sand mill to a fineness of Below 25μm, add cross-linking agent, solvent and auxiliary agent and stir evenly. After passing the inspection, filter, measure and package.

[0067] Table 3 Primer ingredients list (weight percentage)

[0068]

[0069] Those skilled in the art can choose the type and dosage of the suitable drier according to actual needs and the guidance of textbooks or experimental manuals. In this embodiment, the drier is one or more of naphthenic acid metal soap and isooctanoic acid metal soap.

[0070] Those skilled in the art can choose the type and dosage of the suitable anti-skinning agent according to actual needs and the guidance of textbooks or experimental ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com