A kind of soft fixture and its special feeding mechanism

A technology of feeding mechanism and soft material, applied in conveyors, conveyor objects, applications, etc., can solve the problems of loss of pulp, time-consuming and laborious, and poor appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

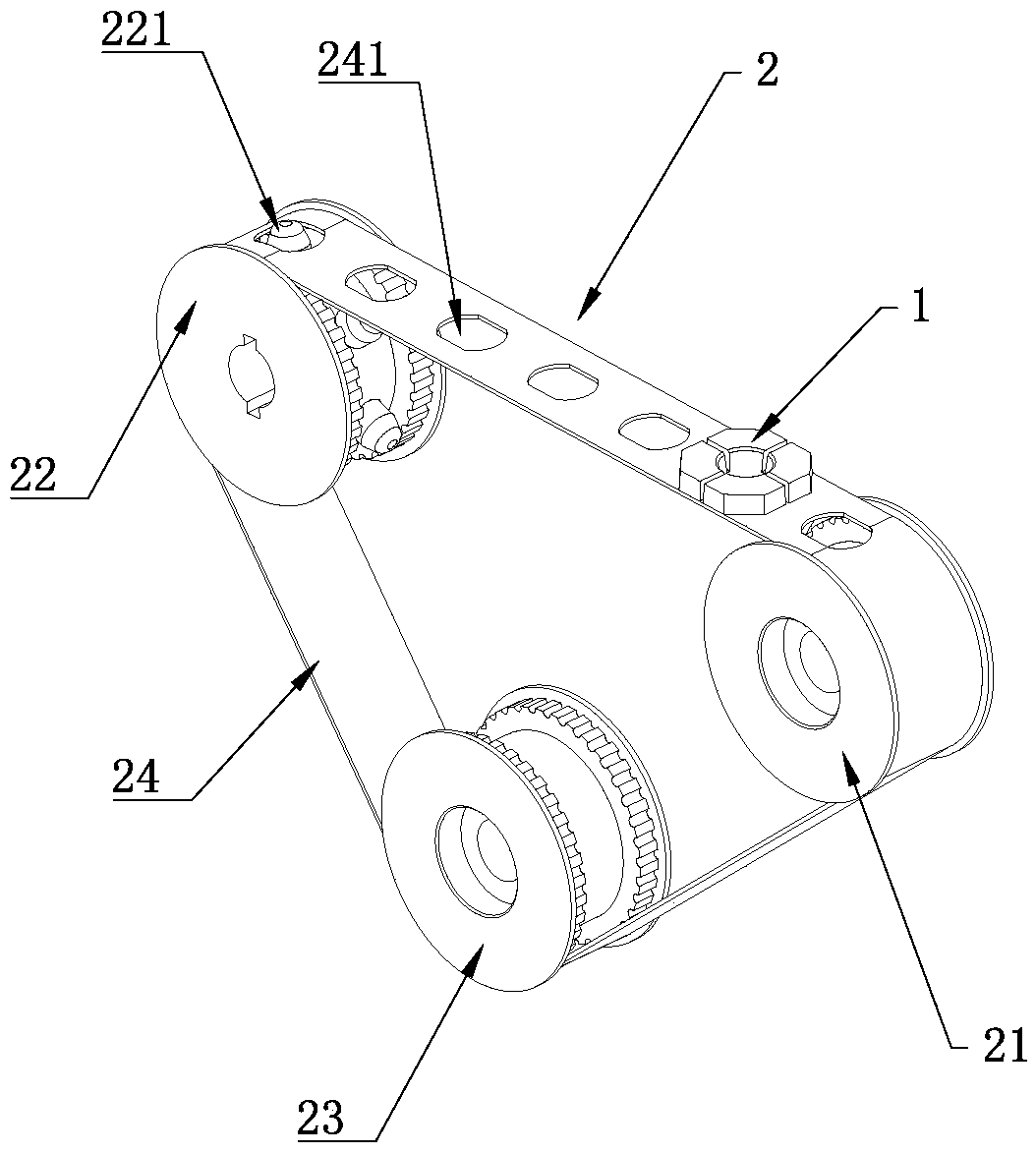

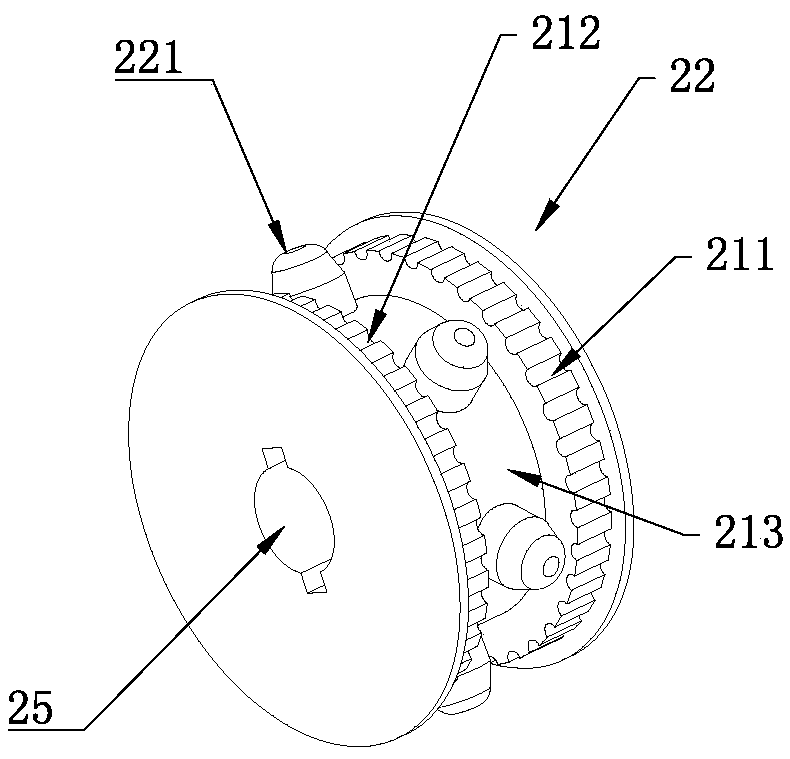

[0029] The present application will be described in detail below in conjunction with specific embodiments and accompanying drawings.

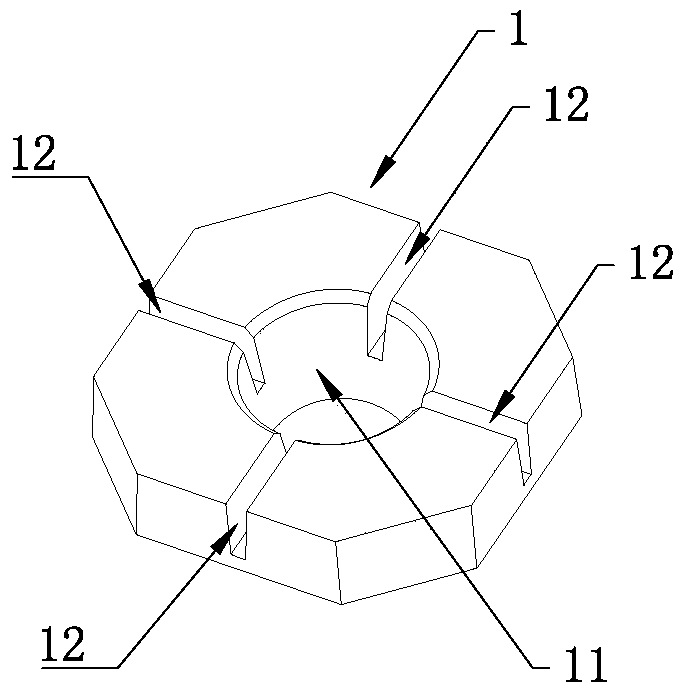

[0030] A special feeding mechanism for soft fixtures in this embodiment, wherein: figure 1 As shown, the soft fixture 1 includes a fixture body made of soft materials. In this embodiment, the soft material is silica gel, because silica gel has the advantages of good thermal stability, corrosion resistance, and high mechanical strength. In addition to silica gel, other elastic soft materials can also be used. The fixture body is integrally formed by injection molding, which is easy to process and easy to control the overall elastic force.

[0031] The middle part of the clamp body is formed with a through hole 11 for clamping objects, and the through hole 11 can be set in a cylindrical shape, a truncated cone or other geometric shapes, so as to be suitable for clamping fruits of various shapes.

[0032] In this embodiment, four slit holes 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com