Method for eliminating rapid tensile strain marks of cold-rolled sheet for stamping

A technology of tensile strain and cold-rolled sheet, which is applied in the production field of continuous annealed ultra-low carbon stamping steel cold-rolled sheet, which can solve problems such as tensile strain marks, grain growth, and large quality problems, and achieve good stamping processing Excellent performance, simple operation process, and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

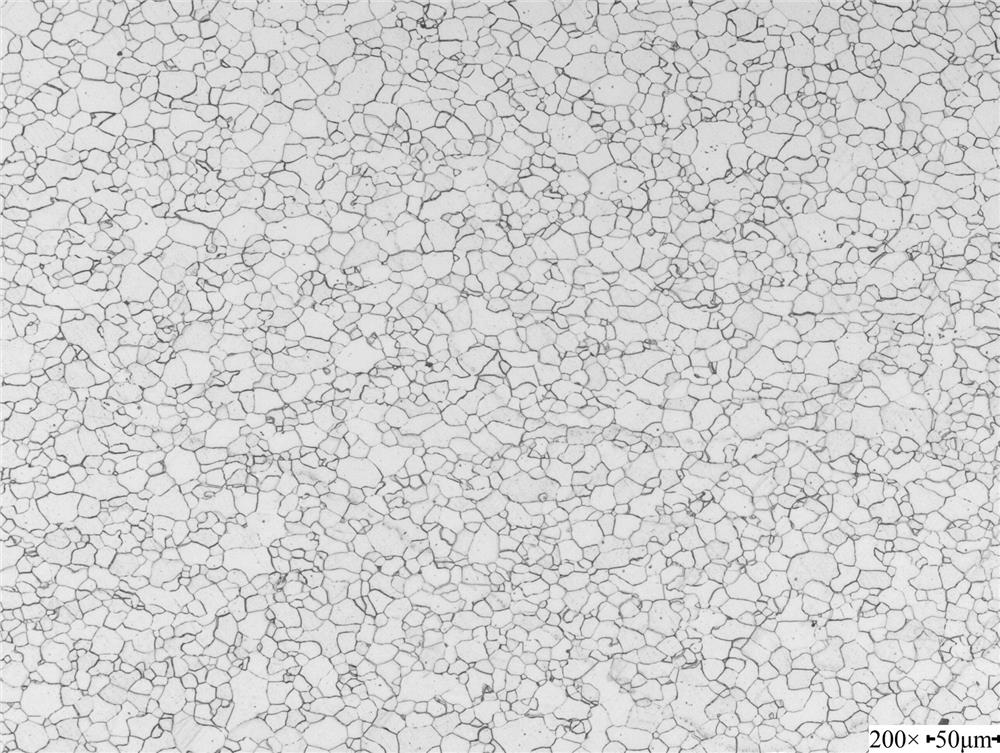

Embodiment 1

[0024] The cold-rolled sheet DC03 for stamping adopts ultra-low carbon steel composition system: C 0.001%~0.004%, Si≤0.03%, Mn0.13%~0.2%, P≤0.015%, S≤0.020%, Al 0.03%~0.06 %, N≤0.004%, the rest is Fe and unavoidable impurities.

[0025] When producing 0.8mm stamping cold-rolled sheet DC03, the specific requirements for each process are as follows:

[0026] 1) Steelmaking, using a 150t oxygen top-bottom double-blown converter to smelt molten steel, using high-grade metallurgical lime and low-sulfur dolomite, and the lime composition is: SiO 2 1.01%, CaO 94.6%, MgO 1.7%, P 0.002%, S 0.025%, activity 378; dolomite composition: SiO 2 1.06%, CaO 54.5%, MgO 37.1%, P 0.01%, S 0.082%. During the blowing process, the slag is melted early and the slag is melted in the whole process. RH refining process: RH vacuum treatment time is 28 minutes, of which the net cycle time is 9 minutes; a sufficient amount of carbon-free covering agent is added after refining. The specific smelting co...

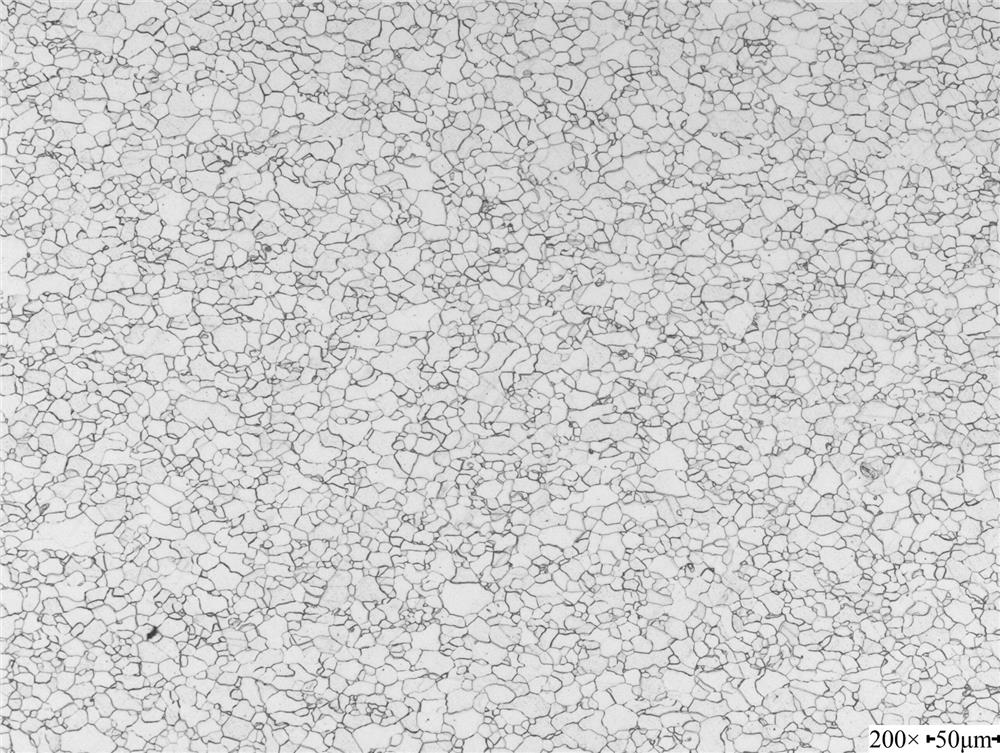

Embodiment 2

[0033] The cold-rolled sheet DC03 for stamping adopts ultra-low carbon steel composition system: C 0.001%~0.004%, Si≤0.03%, Mn0.13%~0.2%, P≤0.015%, S≤0.020%, Al 0.03%~0.06 %, N≤0.004%, the rest is Fe and unavoidable impurities.

[0034] When producing 1.2mm stamping cold-rolled sheet DC03, the specific requirements for each process are as follows:

[0035] 1) Steelmaking, using a 150t oxygen top-bottom double-blown converter to smelt molten steel, using high-grade metallurgical lime and low-sulfur dolomite, and the lime composition is: SiO 2 0.93%, CaO 93.4%, MgO 1.4%, P 0.002%, S 0.028%, activity 386; dolomite composition: SiO 20.97%, CaO 54.2%, MgO 36.9%, P 0.01%, S 0.079%. During the blowing process, the slag is melted early and the slag is melted in the whole process. RH refining process: RH vacuum treatment time is 29 minutes, of which the net cycle time is 8 minutes; a sufficient amount of carbon-free covering agent is added after refining. The specific smelting com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com