Low-temperature stress relieving and tension straightening process of copper alloy plate and strip foils

A copper alloy plate, stress relief technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., to eliminate residual internal stress, eliminate poor plate shape, and improve electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

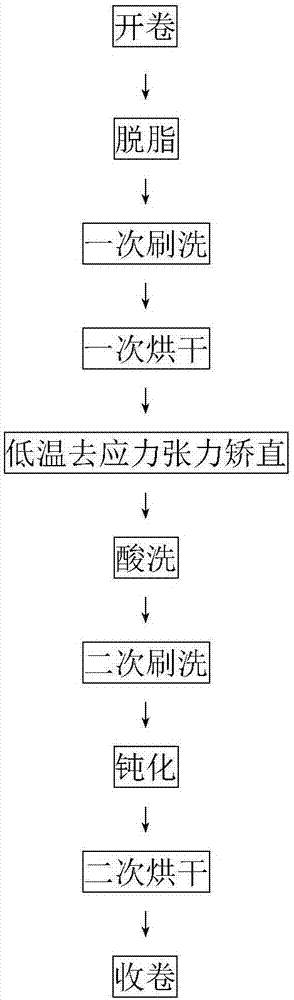

Image

Examples

Embodiment 1

[0025] It is used for the copper alloy frame material that not only requires the material to reach the set hardness, but also meets the subsequent half-etching requirements. The technical requirements are:

[0026] Grade: C19400

[0027] Copper strip specification: 0.3×176mm

[0028] Status: hard status

[0029] Performance requirements: hardness HV125-145, the copper plate is flat after half-etching, without warping or twisting;

[0030] The first step, uncoiling: Uncoil the copper strip with a thickness of 0.05-2mm and a width of 400-1100mm, and the uncoiling tension is: 5-30N / mm 2 ;

[0031] The second step, degreasing: use a degreasing agent on the uncoiled copper strip to clean the residual rolling oil on the surface of the copper strip;

[0032] The third step, a scrubbing: scrubbing with cold and hot water, and scrubbing the residual degreasing liquid on the surface of the copper strip;

[0033] The fourth step, one-time drying: at a temperature of 60-90°C, dry the...

Embodiment 2

[0044] It is used for the copper alloy frame material that not only requires the material to reach the set hardness, but also meets the subsequent half-etching requirements. The technical requirements are:

[0045] Grade: C19400

[0046] Copper strip specification: 0.254×60.5mm

[0047] Status: hard status

[0048] Performance requirements: hardness HV125-145, the copper plate is flat after half-etching, without warping or twisting;

[0049] The first step, uncoiling: Uncoil the copper strip with a thickness of 0.05-2mm and a width of 400-1100mm, and the uncoiling tension is: 5-30N / mm 2 ;

[0050] The second step, degreasing: use a degreasing agent on the uncoiled copper strip to clean the residual rolling oil on the surface of the copper strip;

[0051] The third step, a scrubbing: scrubbing with cold and hot water, and scrubbing the residual degreasing liquid on the surface of the copper strip;

[0052] The fourth step, one-time drying: at a temperature of 60-90°C, dry ...

Embodiment 3

[0063] It is used for the copper alloy frame material that not only requires the material to reach the set hardness, but also meets the subsequent half-etching requirements. The technical requirements are:

[0064] Grade: C19400

[0065] Copper strip specification: 0.203×71mm

[0066] Status: hard status

[0067] Performance requirements: hardness HV125-145, the copper plate is flat after half-etching, without warping or twisting;

[0068] The first step, uncoiling: Uncoil the copper strip with a thickness of 0.05-2mm and a width of 400-1100mm, and the uncoiling tension is: 5-30N / mm 2 ;

[0069] The second step, degreasing: use a degreasing agent on the uncoiled copper strip to clean the residual rolling oil on the surface of the copper strip;

[0070] The third step, a scrubbing: scrubbing with cold and hot water, and scrubbing the residual degreasing liquid on the surface of the copper strip;

[0071] The fourth step, one-time drying: at a temperature of 60-90°C, dry the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com