Production method of non-loose steel wire rope

A production method and steel wire rope technology, applied in the field of non-loose steel wire rope production, can solve the problems of steel wire rope wear resistance and fatigue strength reduction, steel wire rope twist direction limitation, high temperature furnace temperature instability, etc., to improve tensile strength and other mechanical properties performance, eliminate work hardening and brittleness, and eliminate the effect of internal residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

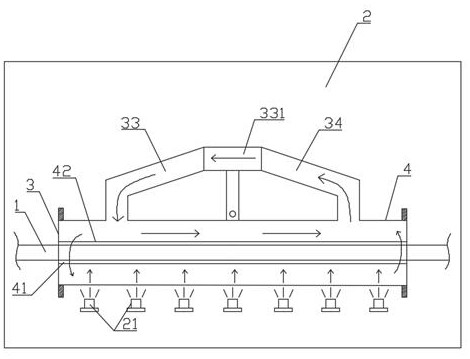

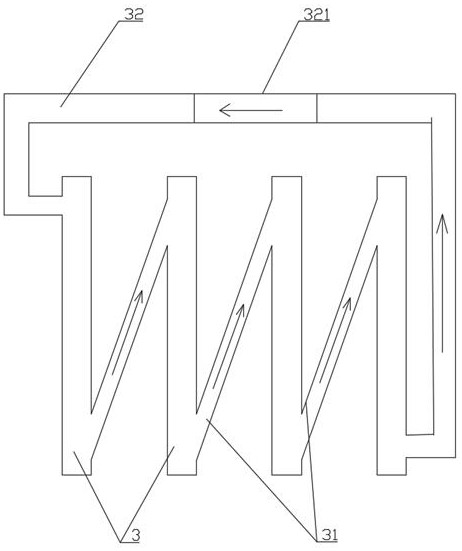

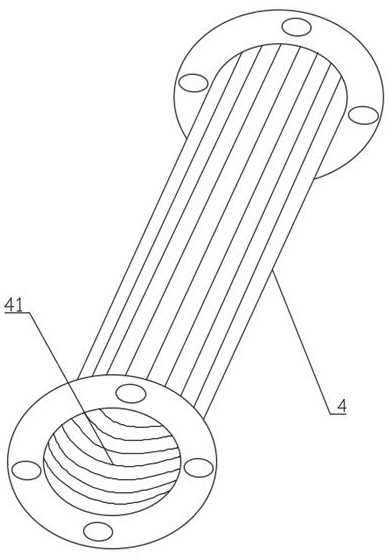

[0035] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, it is figure 1 , figure 2 and image 3 Examples are described in detail as follows.

[0036] The invention provides a method for producing a non-loose steel wire rope, which includes the step of wire rod, selecting a 304 stainless steel wire with a diameter of 5.5 mm; in the step of surface treatment, the wire is immersed in dilute hydrochloric acid to remove the oxide film on the surface of the wire, and the concentration of hydrochloric acid is 5 ~20%, the temperature is 40°C at room temperature; then washed and neutralized, and then soaked in special surface treatment chemicals for coating treatment, and finally the wire rods are dried in the drying box with hot air at 150~250°C Dry for 2~15min; pickling can prevent the iron oxide scale from damaging the surface of the die and steel wire during drawing, prepare good surface conditions for subsequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com