Patents

Literature

96results about How to "Eliminate bad" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

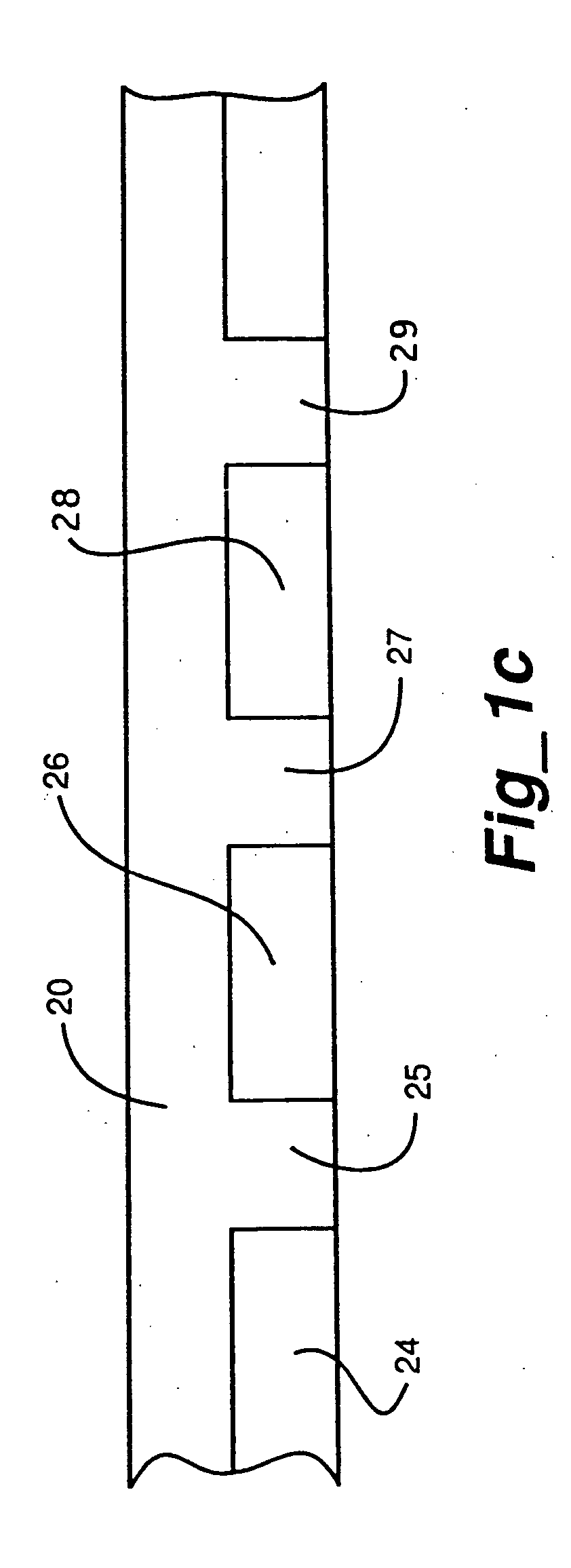

Methods for maskless lithography

InactiveUS20050130351A1Reduce processing costsLow processingSemiconductor/solid-state device detailsSolid-state devicesFlat panel displayPhysics

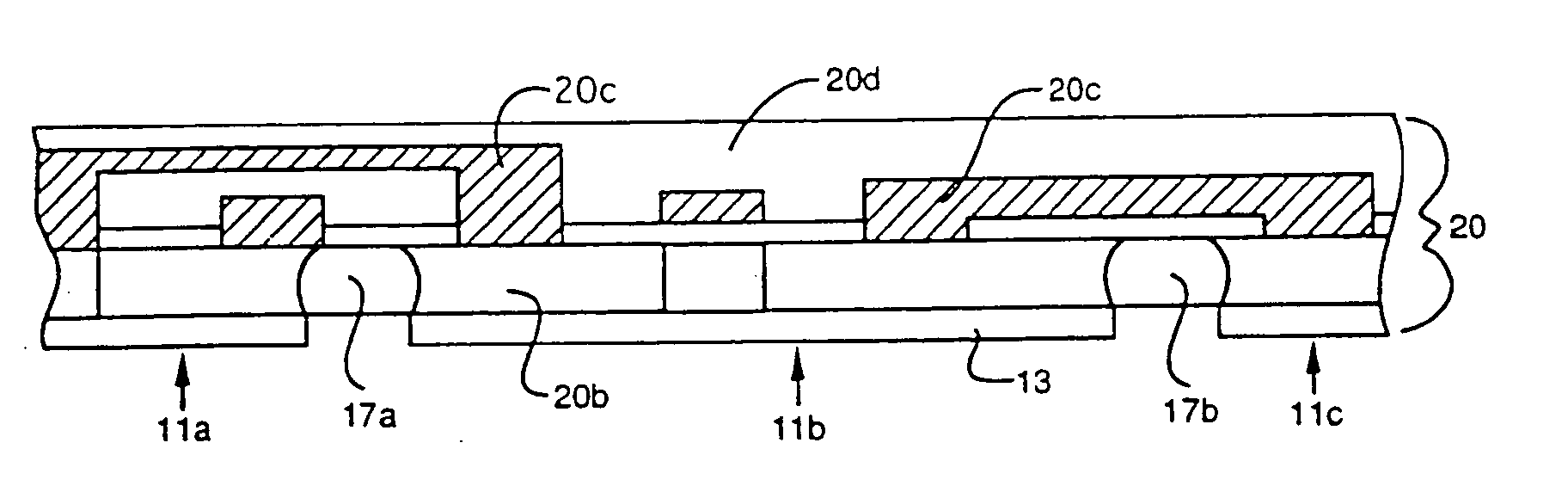

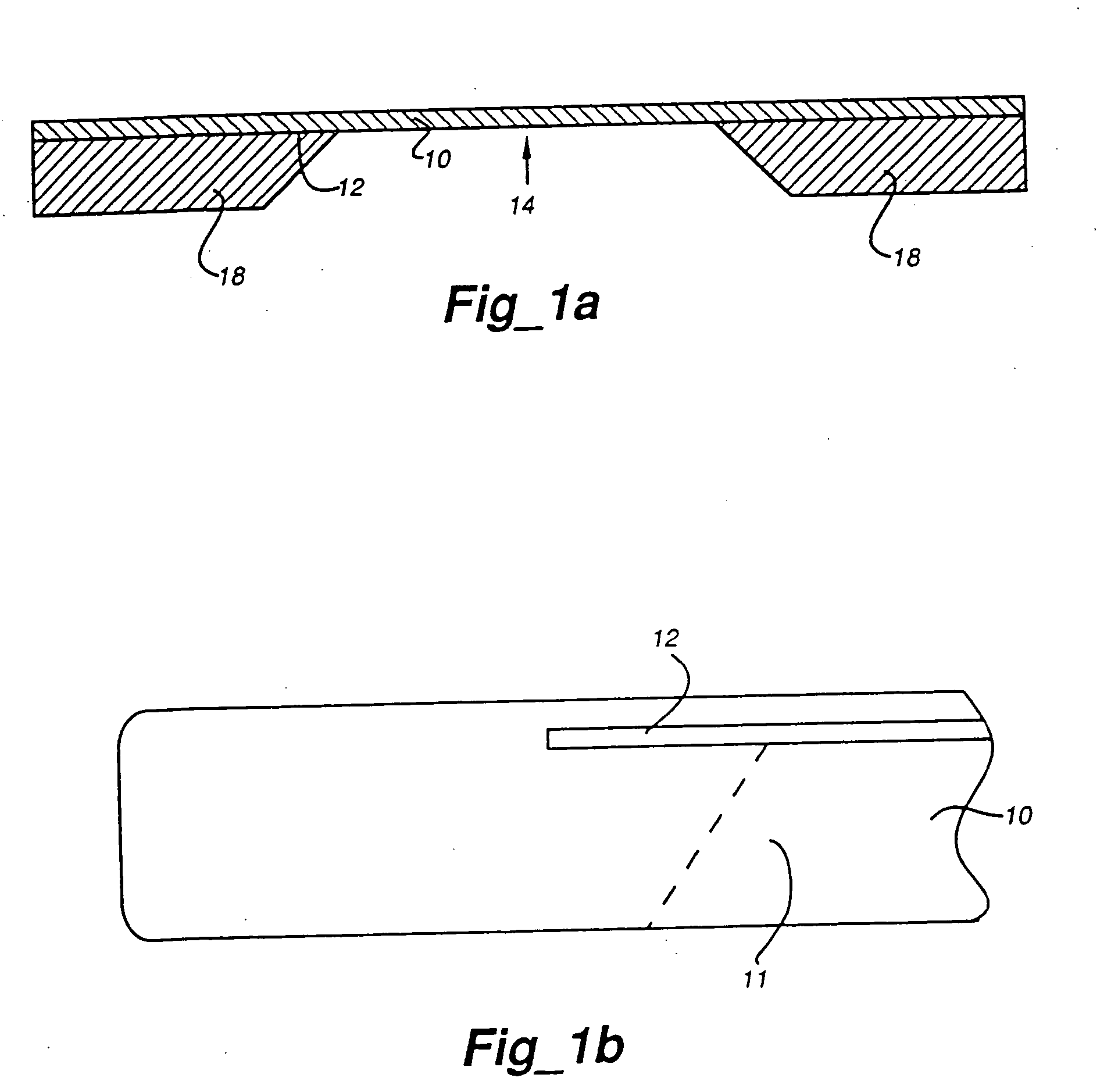

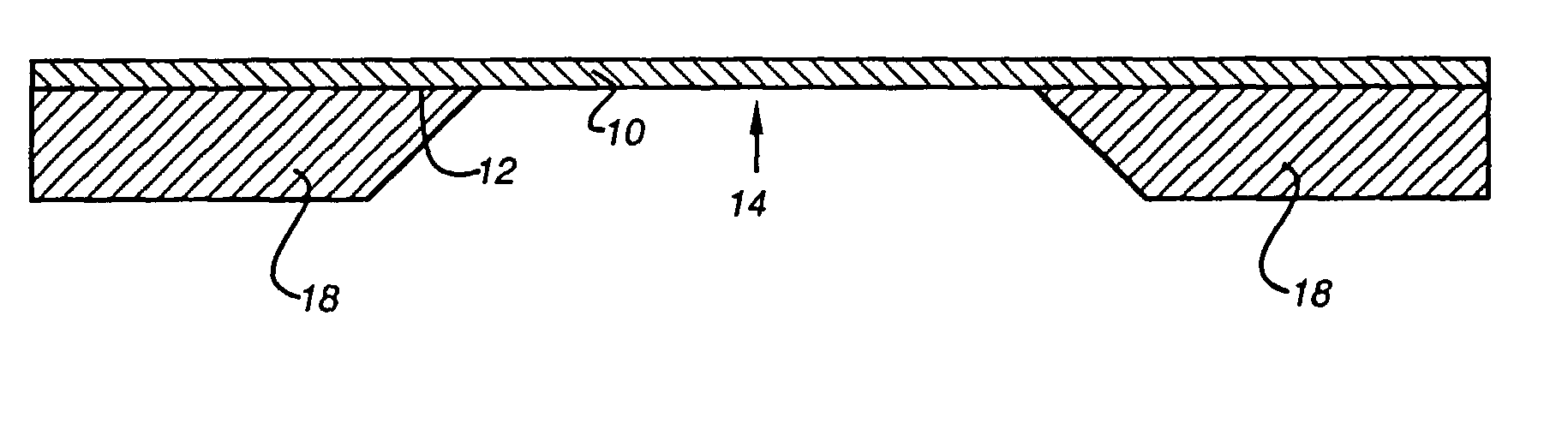

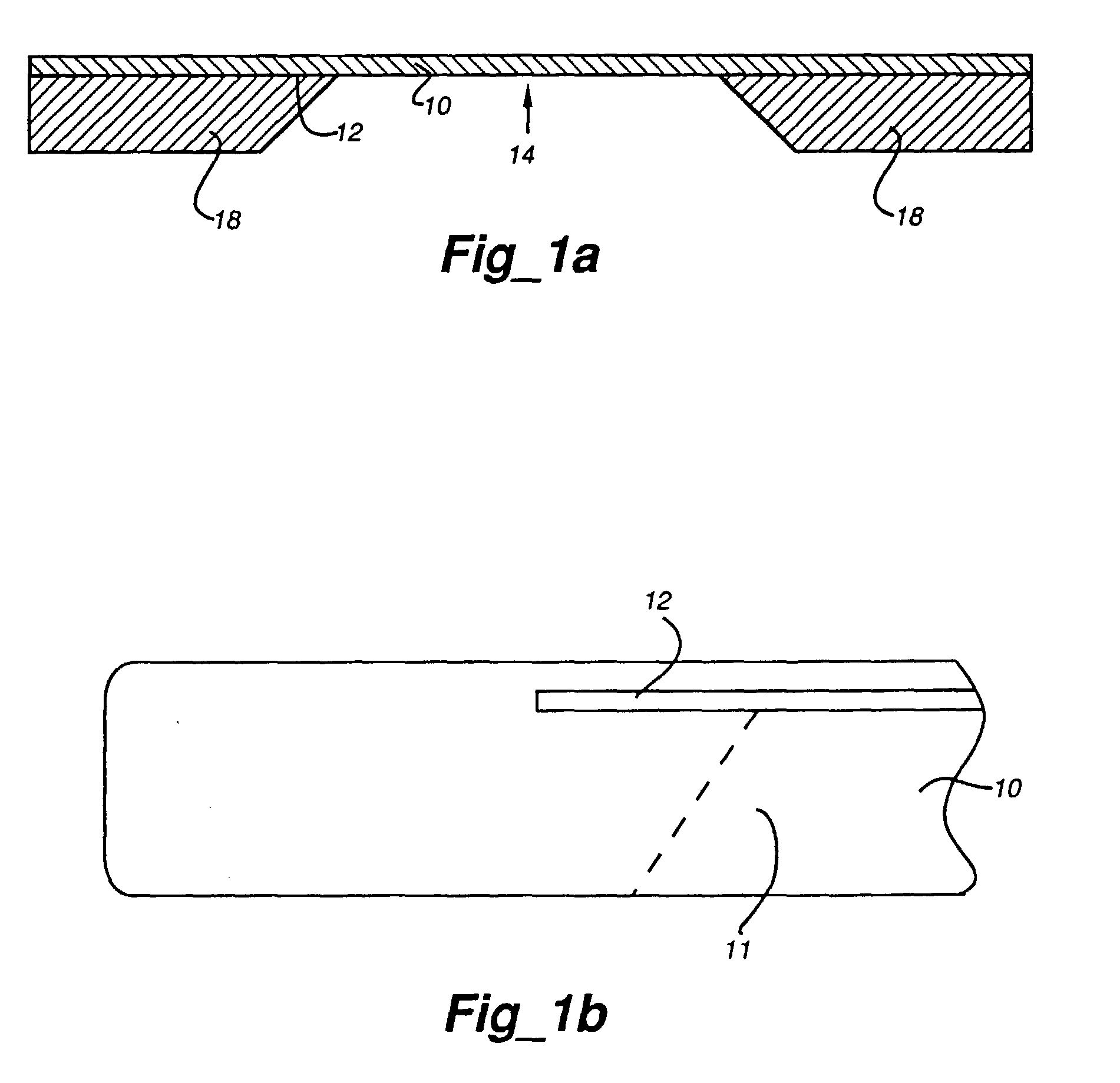

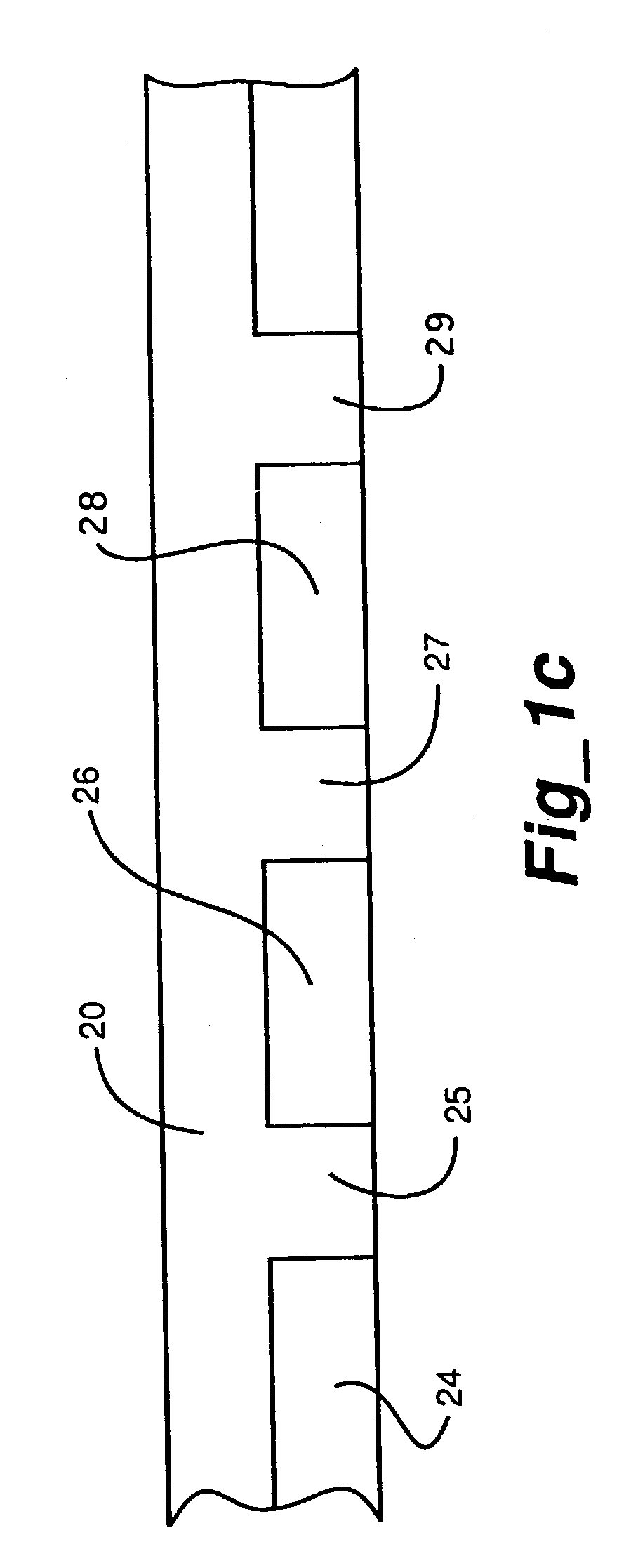

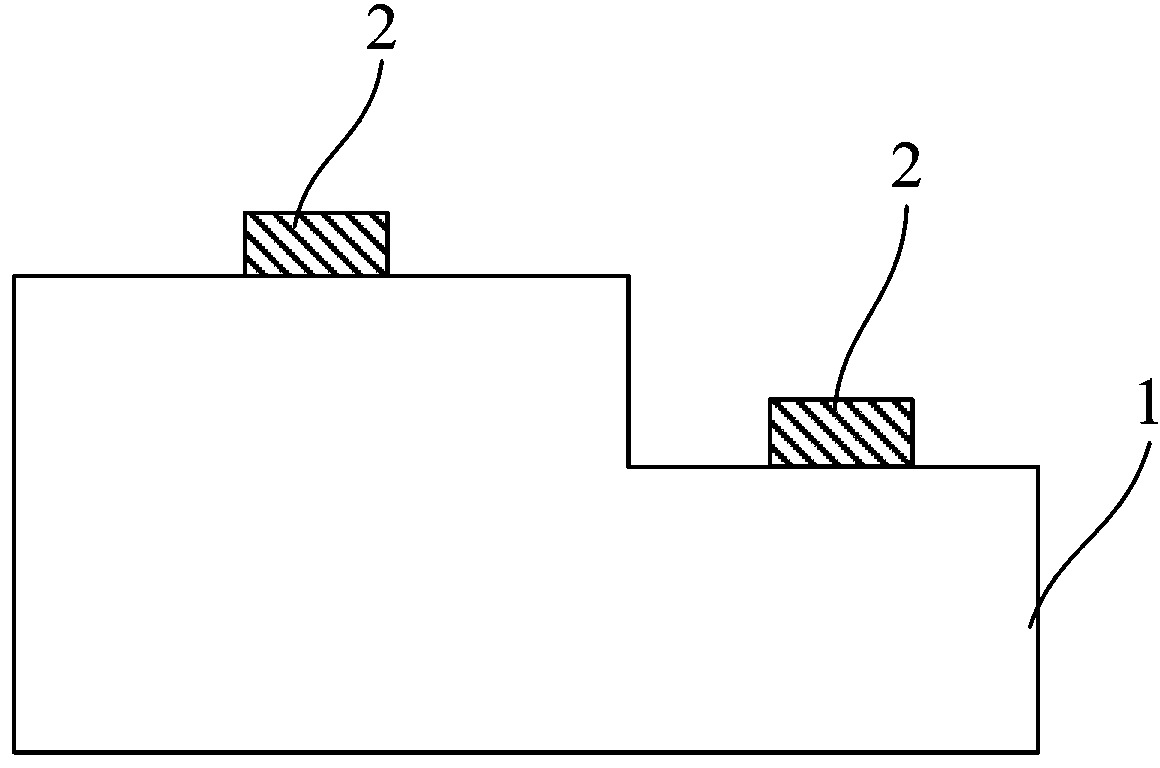

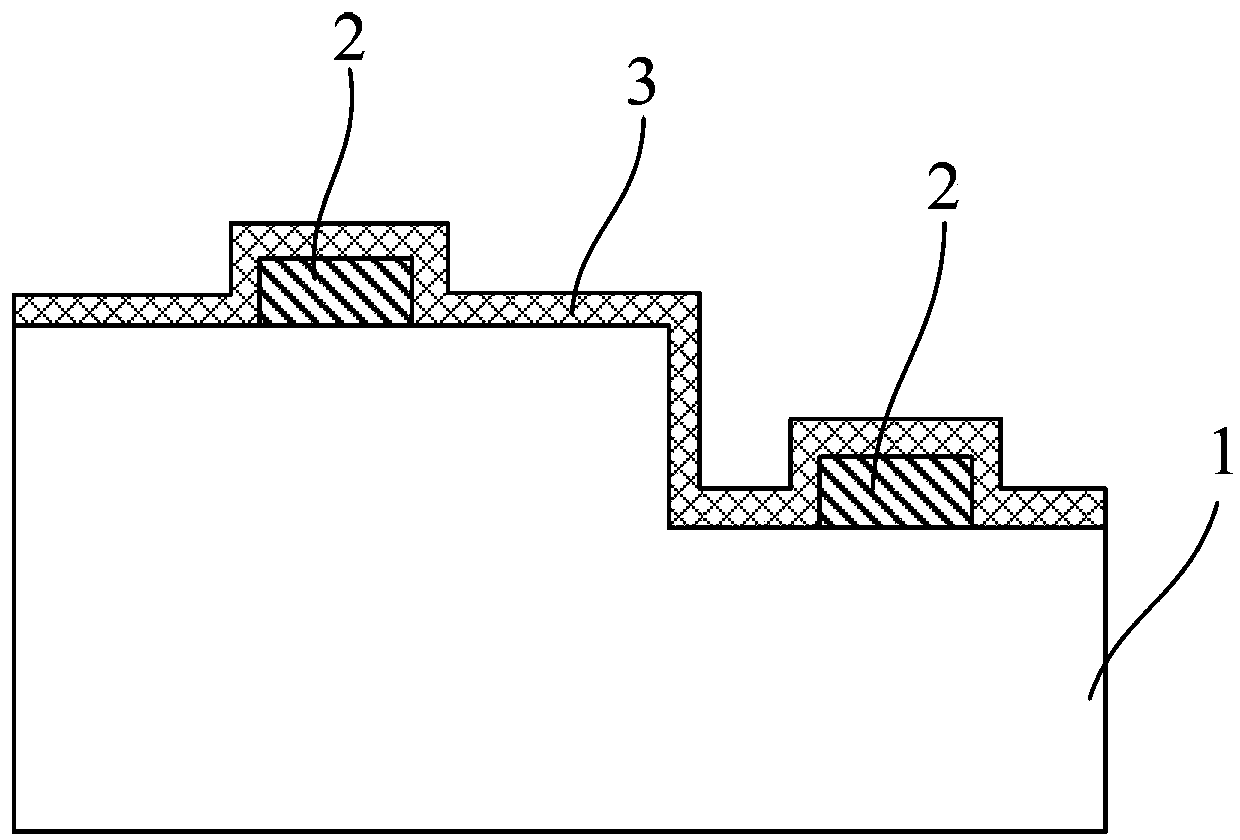

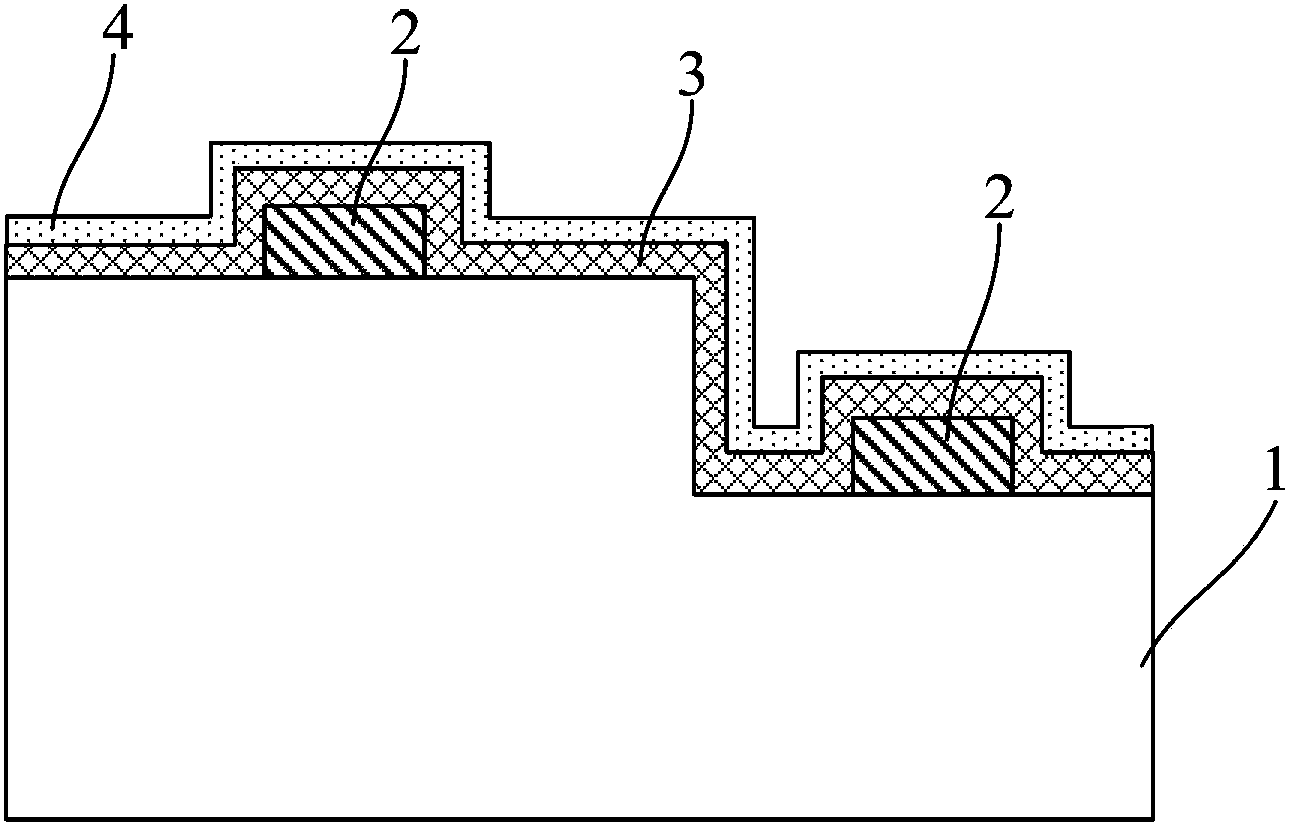

General purpose methods for the fabrication of integrated circuits from flexible membranes formed of very thin low stress dielectric materials, such as silicon dioxide or silicon nitride, and semiconductor layers. Semiconductor devices are formed in a semiconductor layer of the membrane. The semiconductor membrane layer is initially formed from a substrate of standard thickness, and all but a thin surface layer of the substrate is then etched or polished away. In another version, the flexible membrane is used as support and electrical interconnect for conventional integrated circuit die bonded thereto, with the interconnect formed in multiple layers in the membrane. Multiple die can be connected to one such membrane, which is then packaged as a multi-chip module. Other applications are based on (circuit) membrane processing for bipolar and MOSFET transistor fabrication, low impedance conductor interconnecting fabrication, flat panel displays, maskless (direct write) lithography, and 3D IC fabrication.

Owner:TAIWAN SEMICON MFG CO LTD

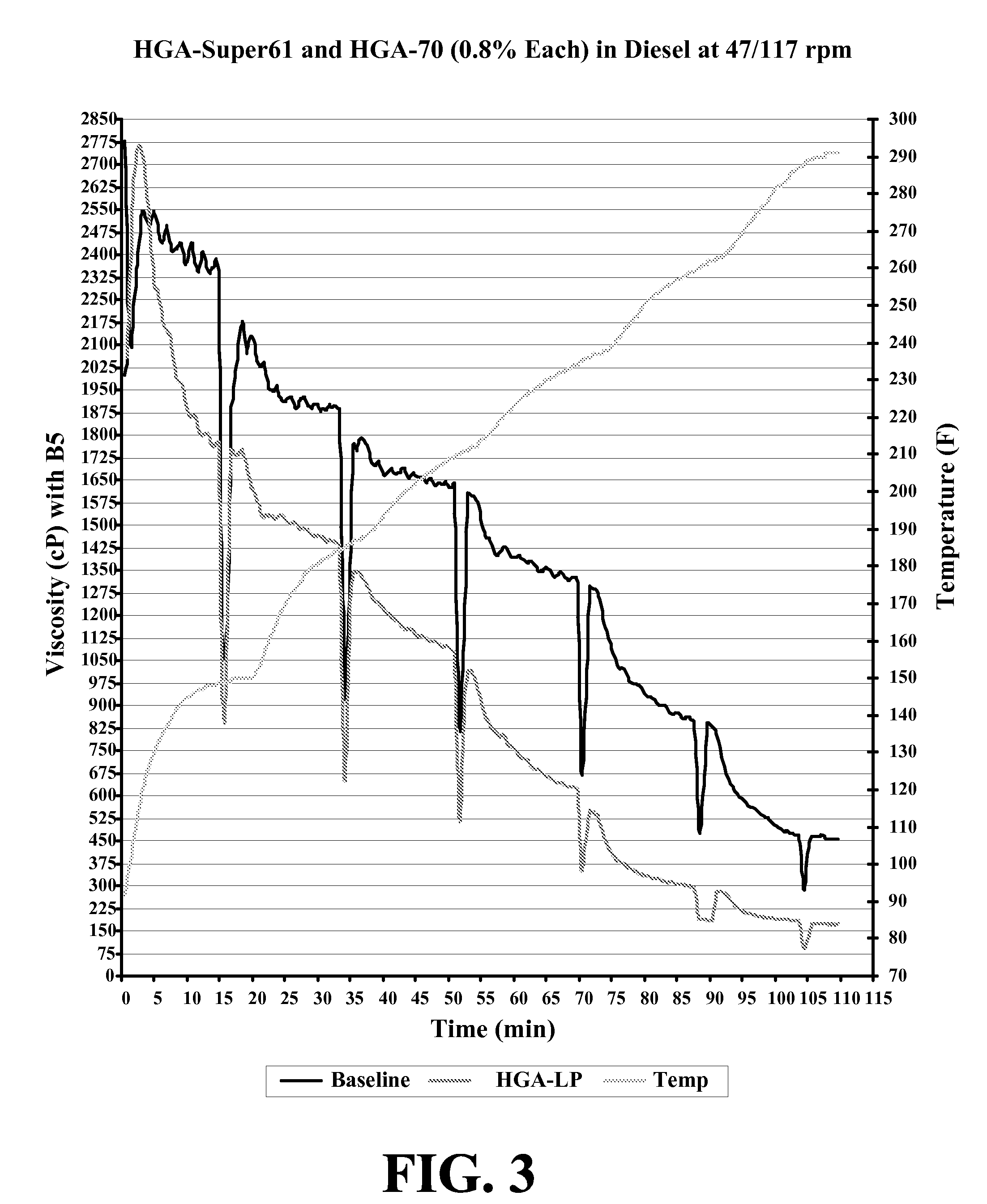

Non-volatile phosphorus hydrocarbon gelling agent

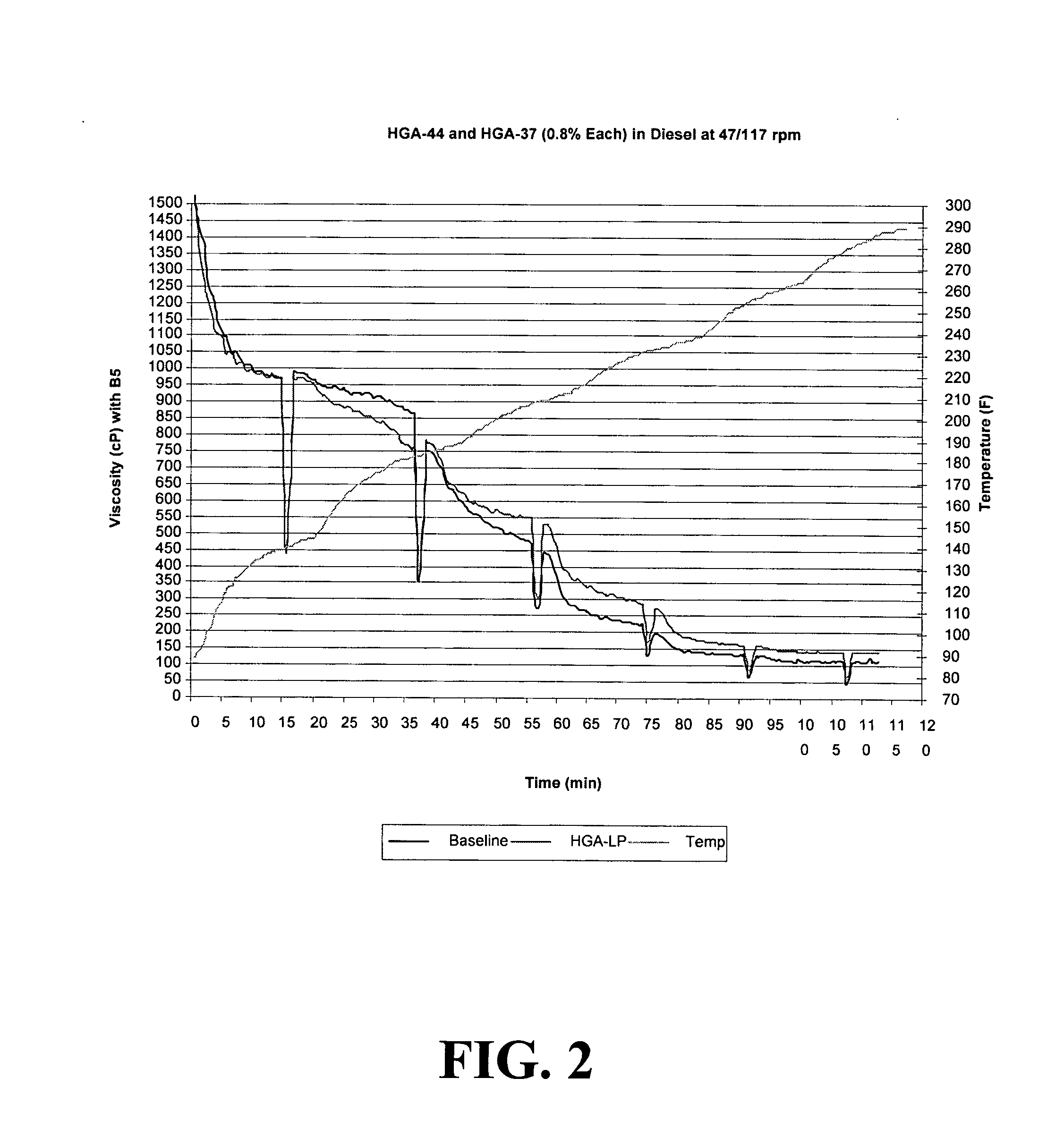

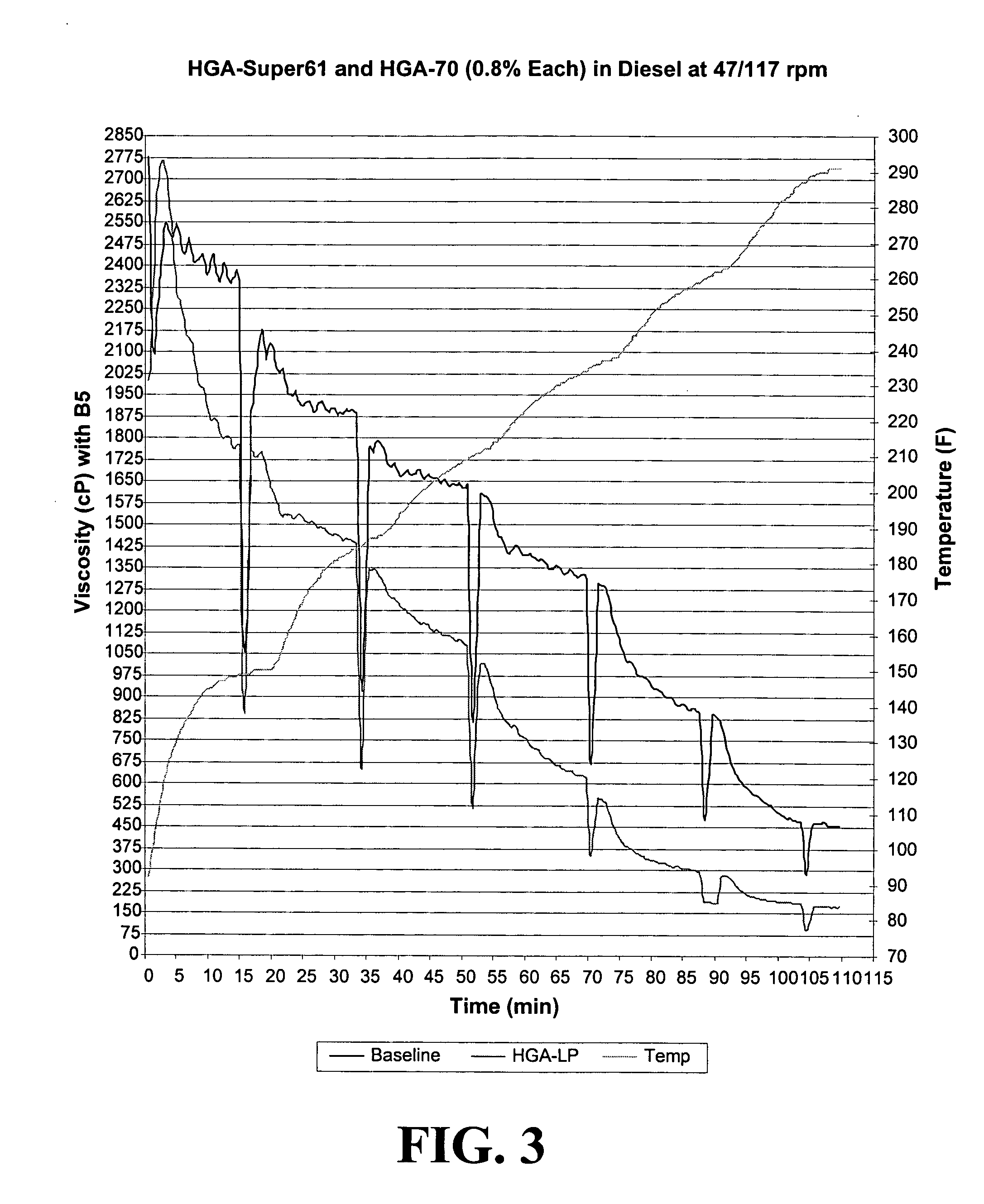

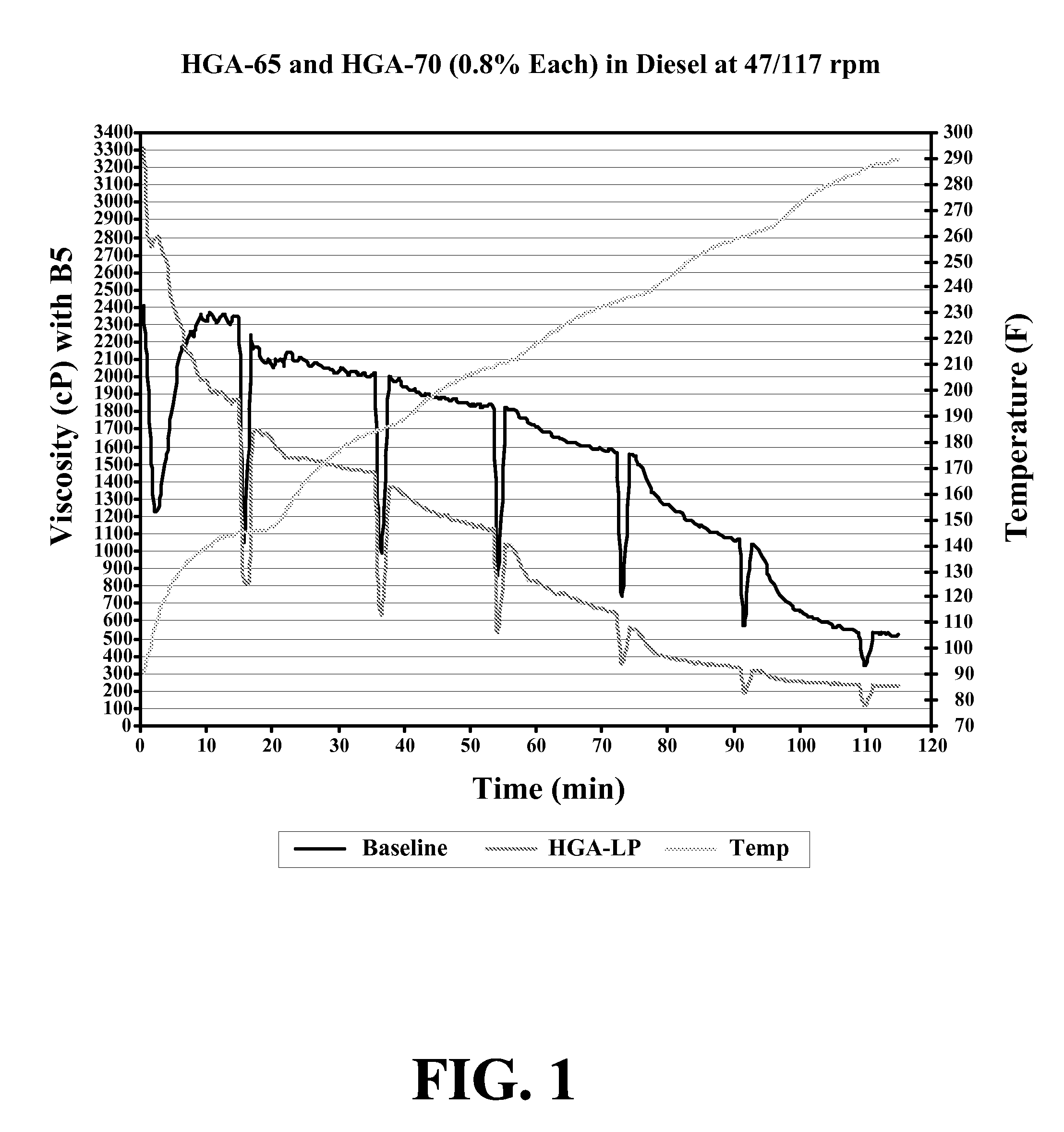

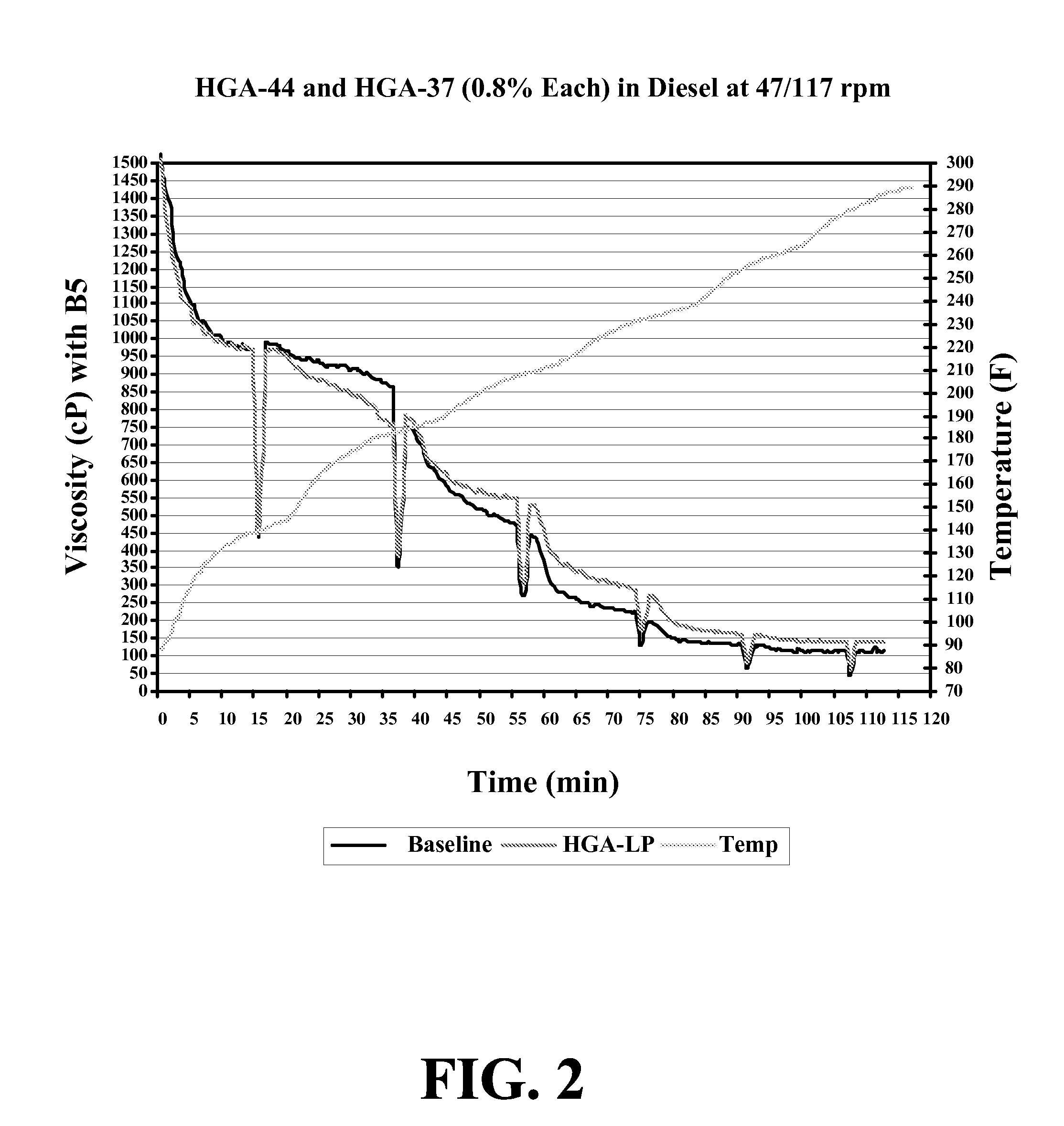

ActiveUS20070173413A1Reduce volatilityEliminate badOther chemical processesGroup 5/15 element organic compoundsCompound (substance)Fracturing fluid

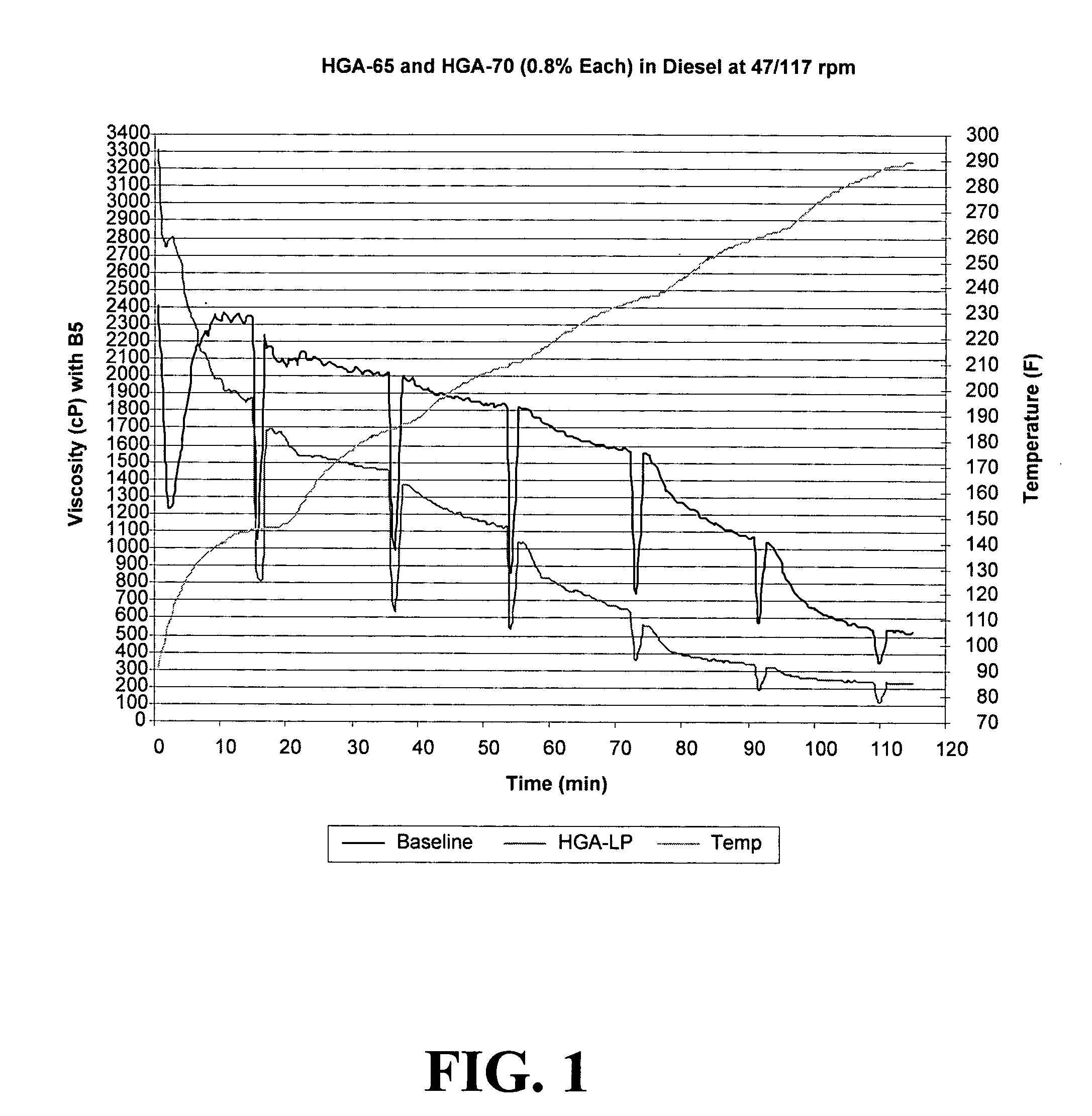

New fluids are disclosed for use in servicing subterranean formations containing oil and gas. In particular, an improved chemical gelling additive for hydrocarbon based fracturing fluids is disclosed having reduce, negligible or no volatile phosphorus at temperatures below about 250° C.

Owner:THE LUBRIZOL CORP

Non-volatile phosphorus hydrocarbon gelling agent

ActiveUS8084401B2Eliminate badReduce foulingOther chemical processesGroup 5/15 element organic compoundsFracturing fluidOil and natural gas

New fluids are disclosed for use in servicing subterranean formations containing oil and gas. In particular, an improved chemical gelling additive for hydrocarbon based fracturing fluids is disclosed having reduce, negligible or no volatile phosphorus at temperatures below about 250° C.

Owner:THE LUBRIZOL CORP

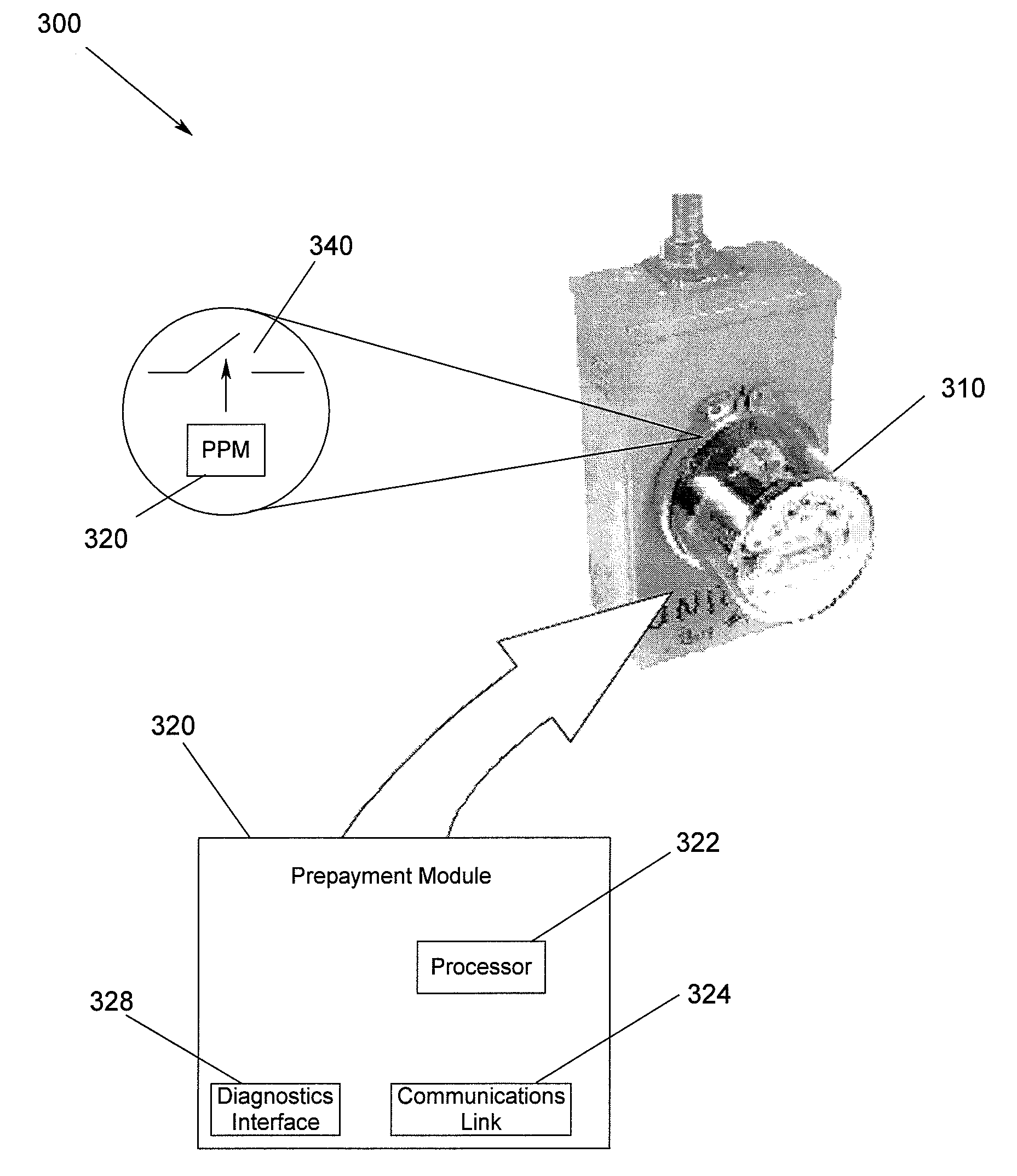

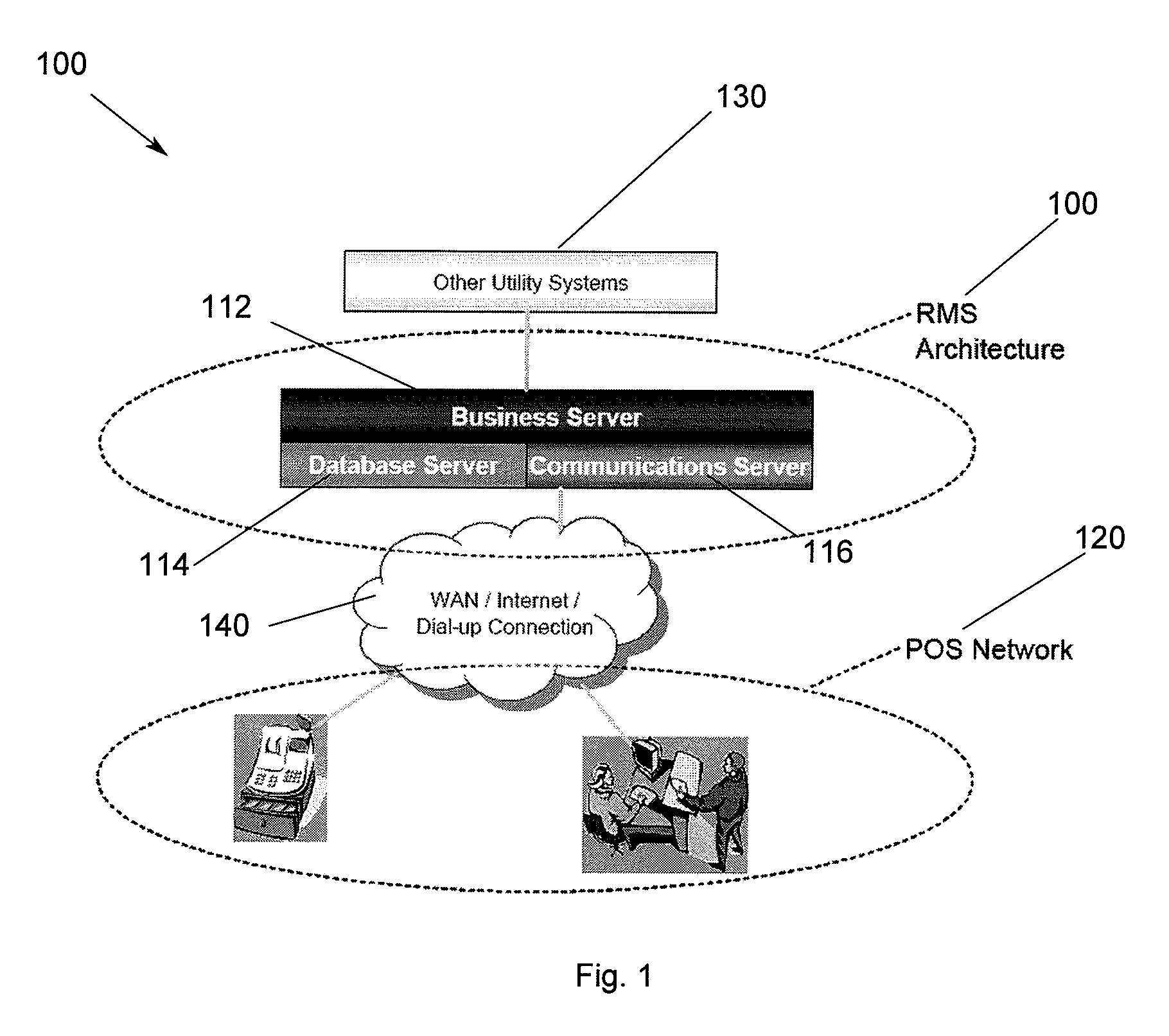

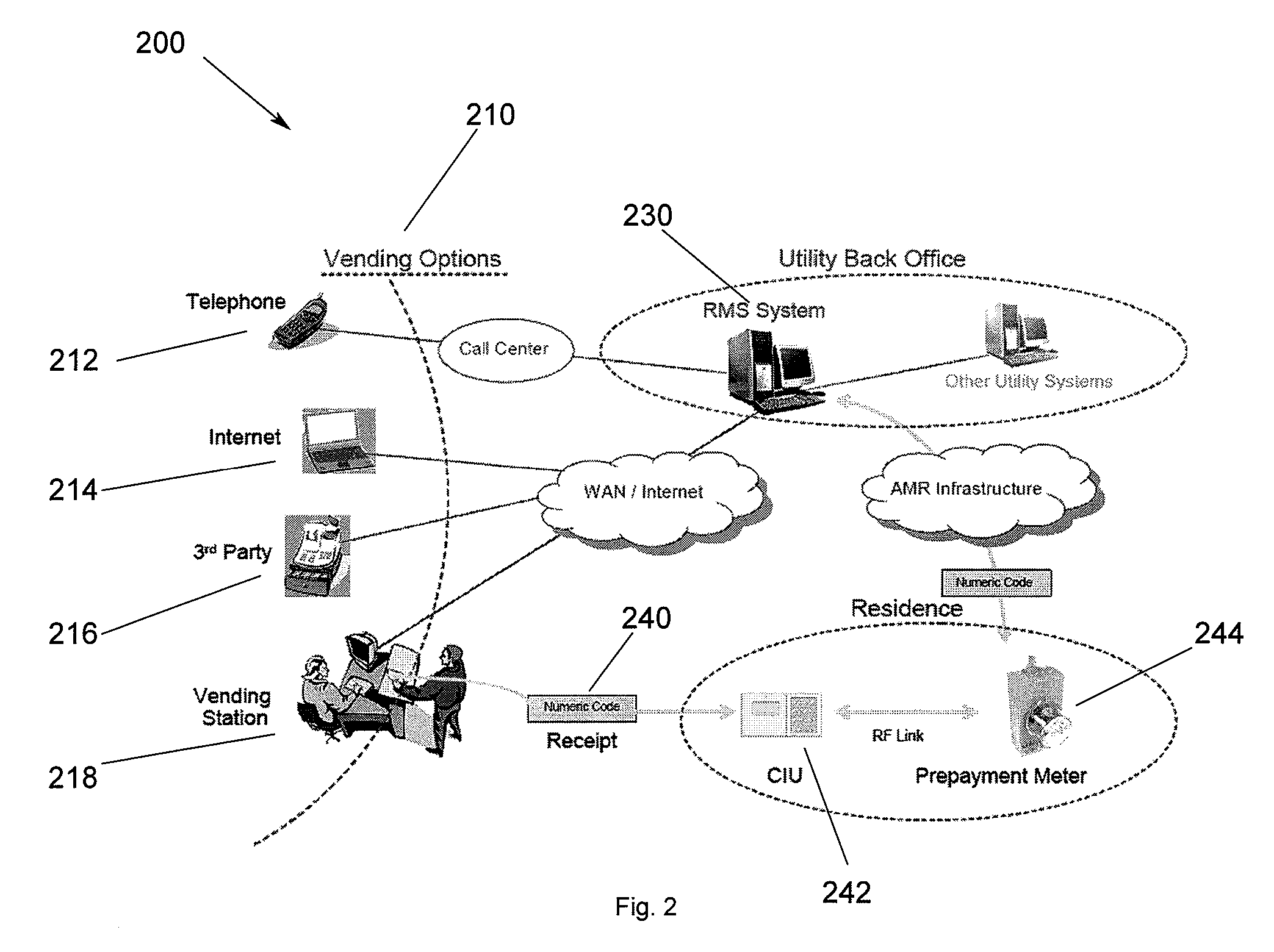

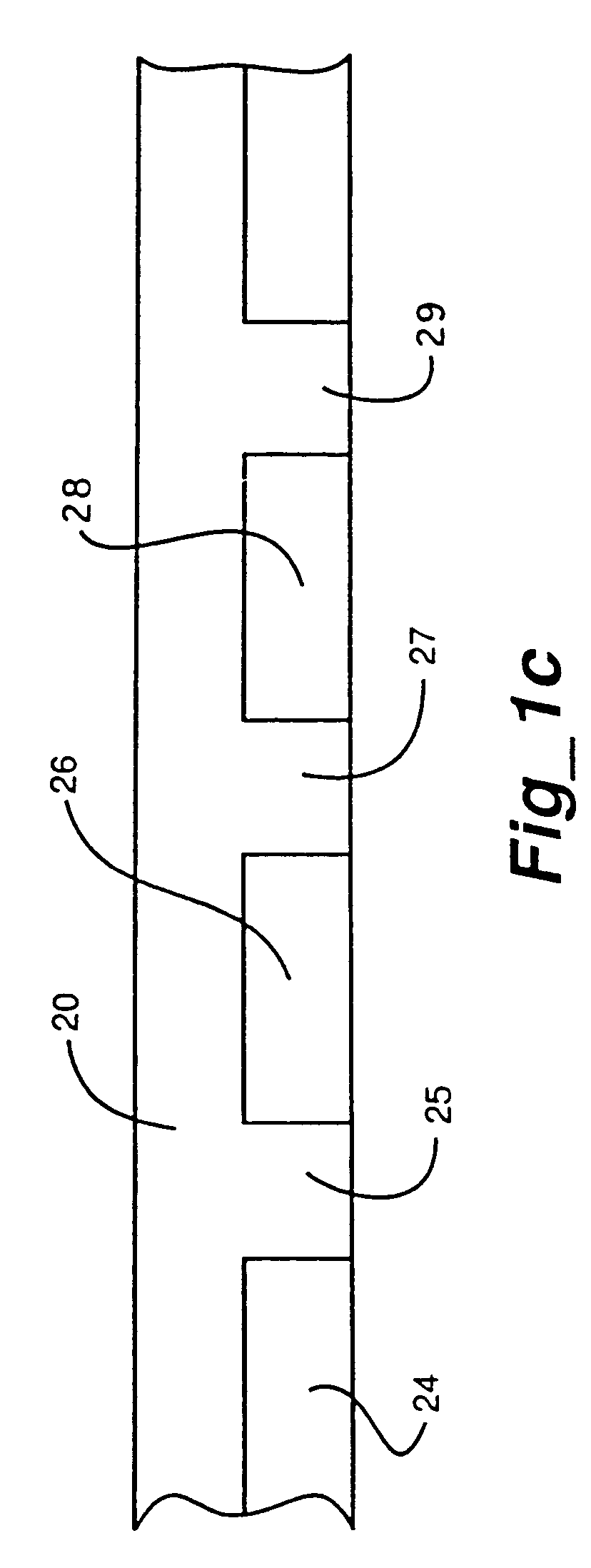

Method, apparatus and program storage device for providing a prepaid metering system

InactiveUS20070083479A1Cost effectiveEliminate badElectric devicesSpecial tariff metersEmbedded systemManagement system

A method, apparatus and program storage device for providing a prepaid metering system an electric utility meter interface. The prepaid metering system includes a meter interface a customer interface unit and a revenue management system.

Owner:SWARTZ STEPHEN BRANT +2

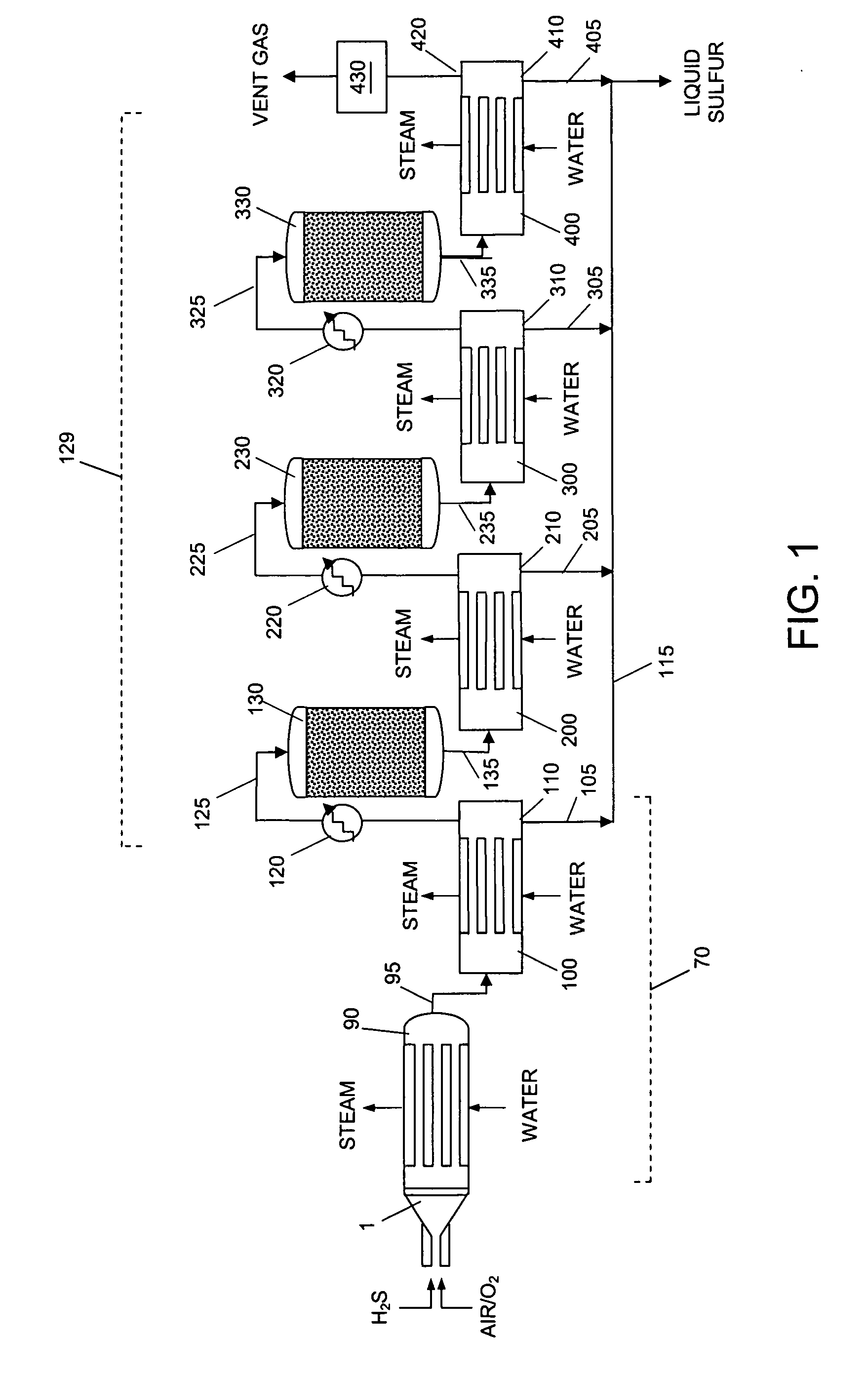

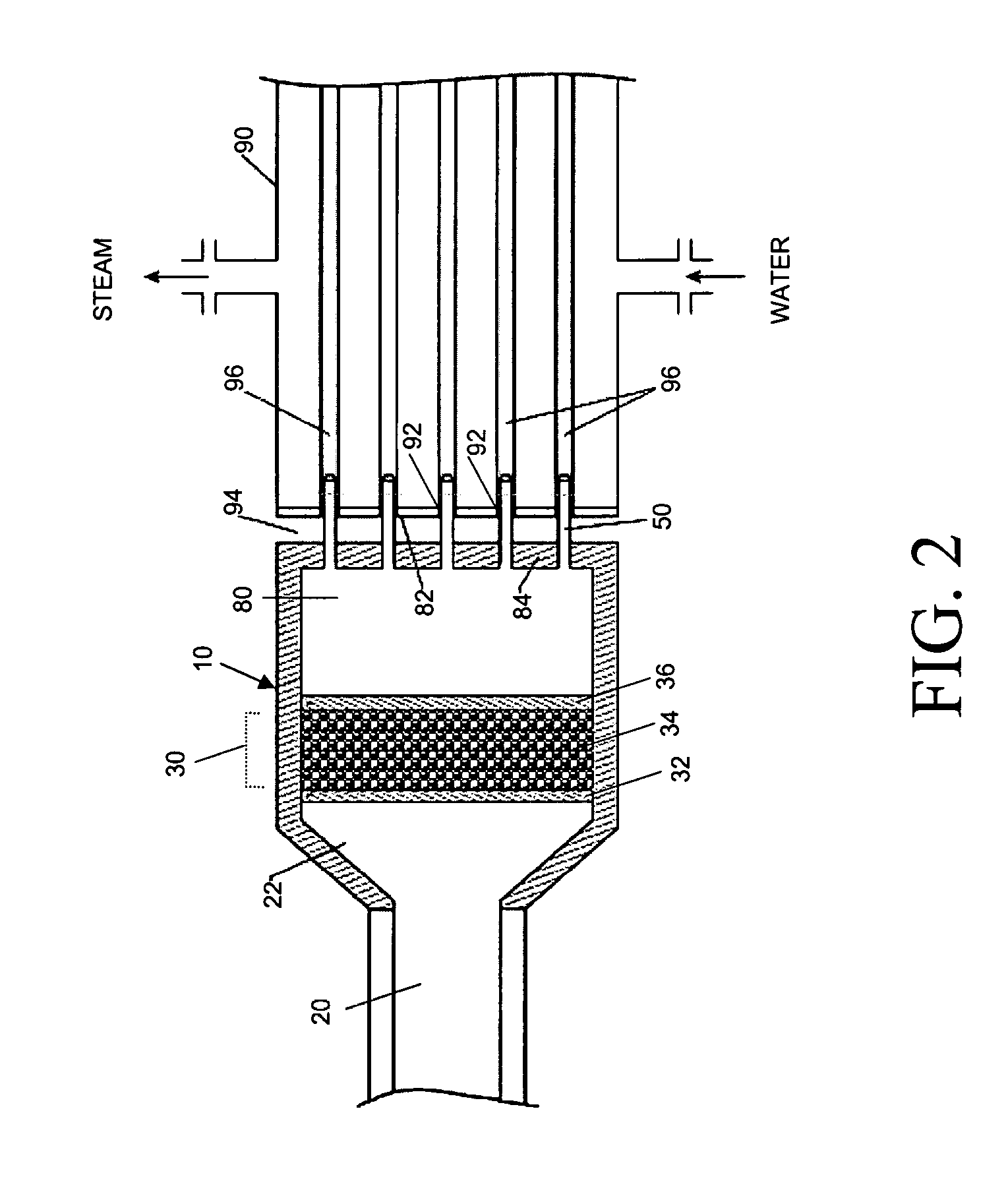

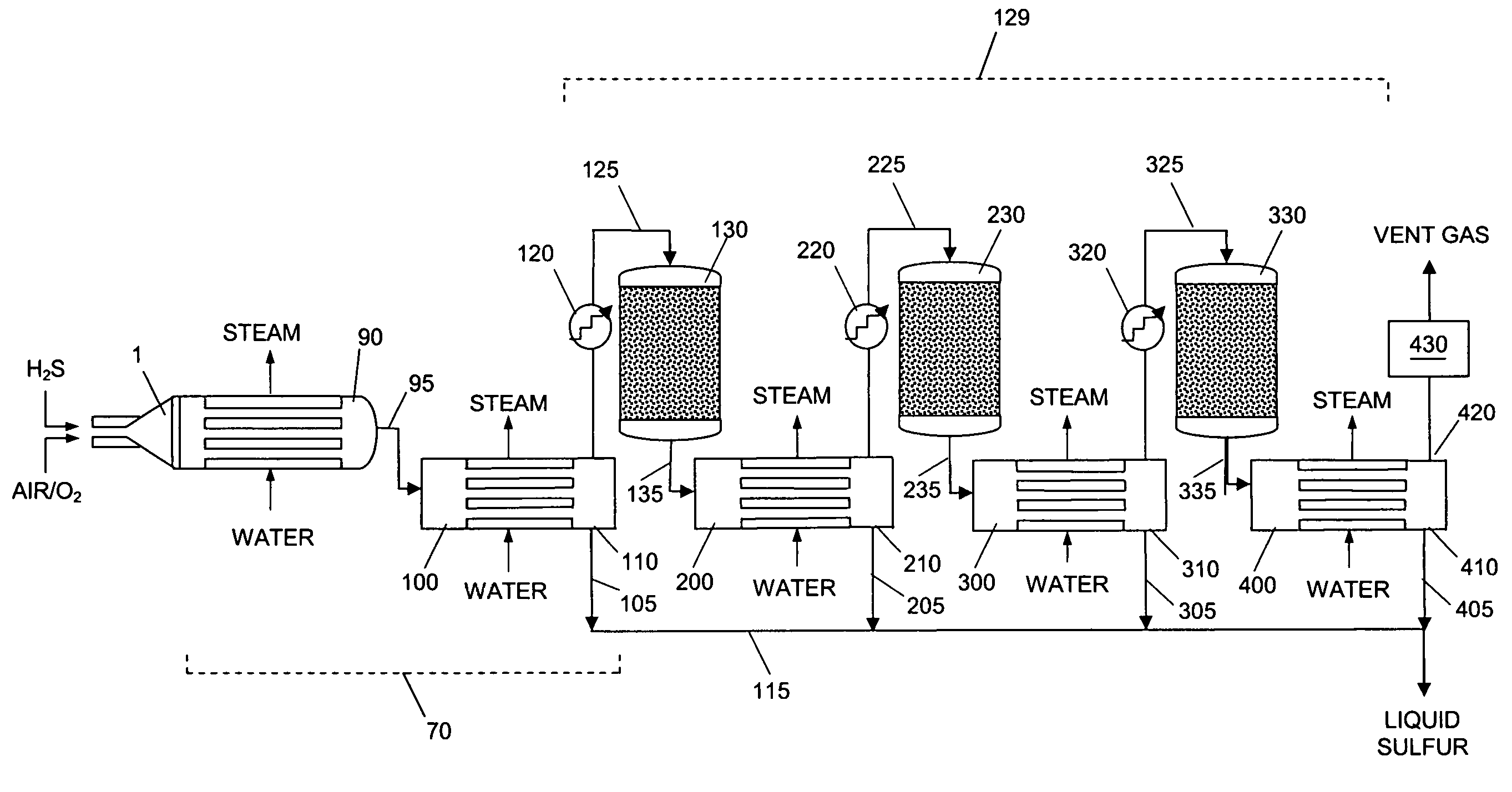

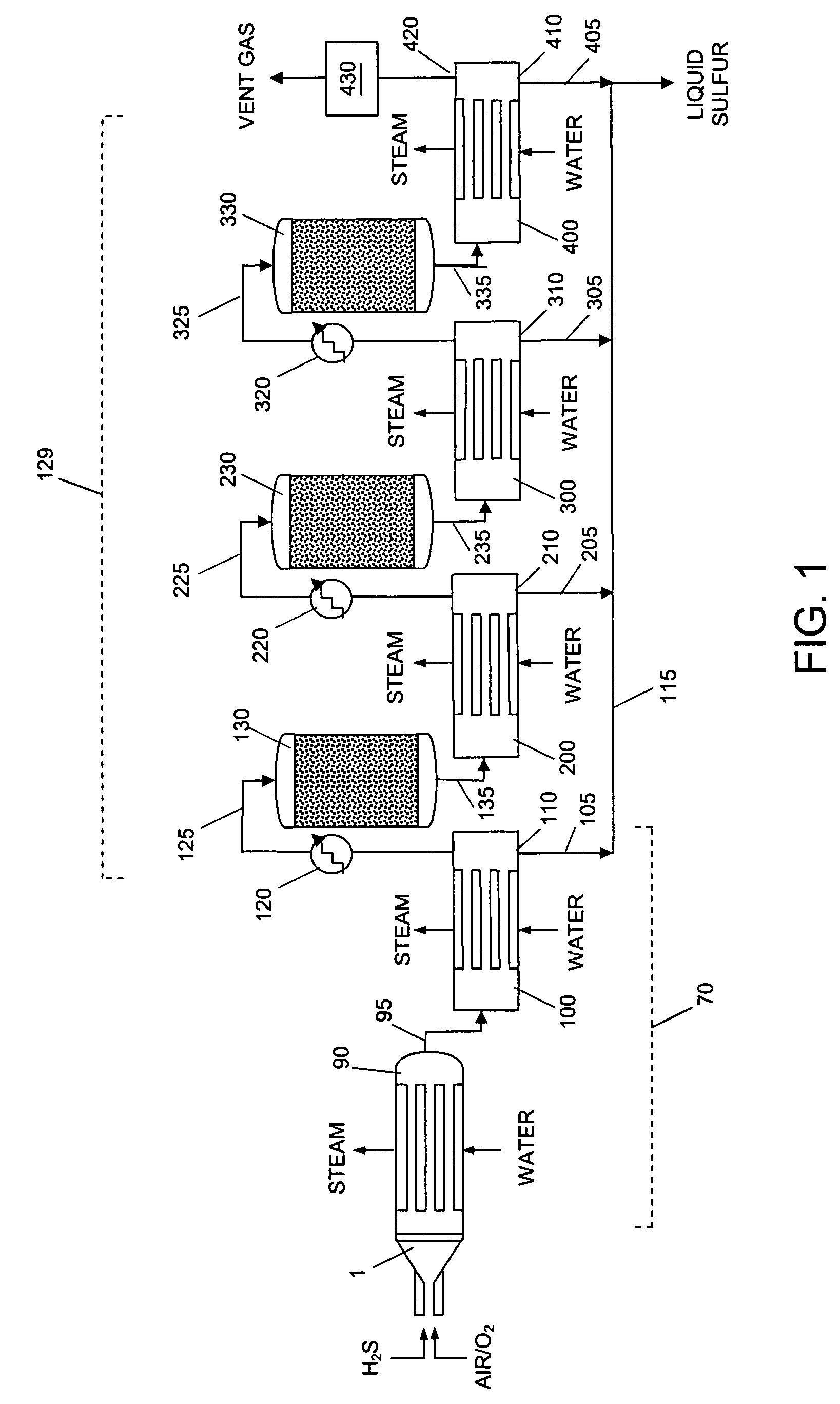

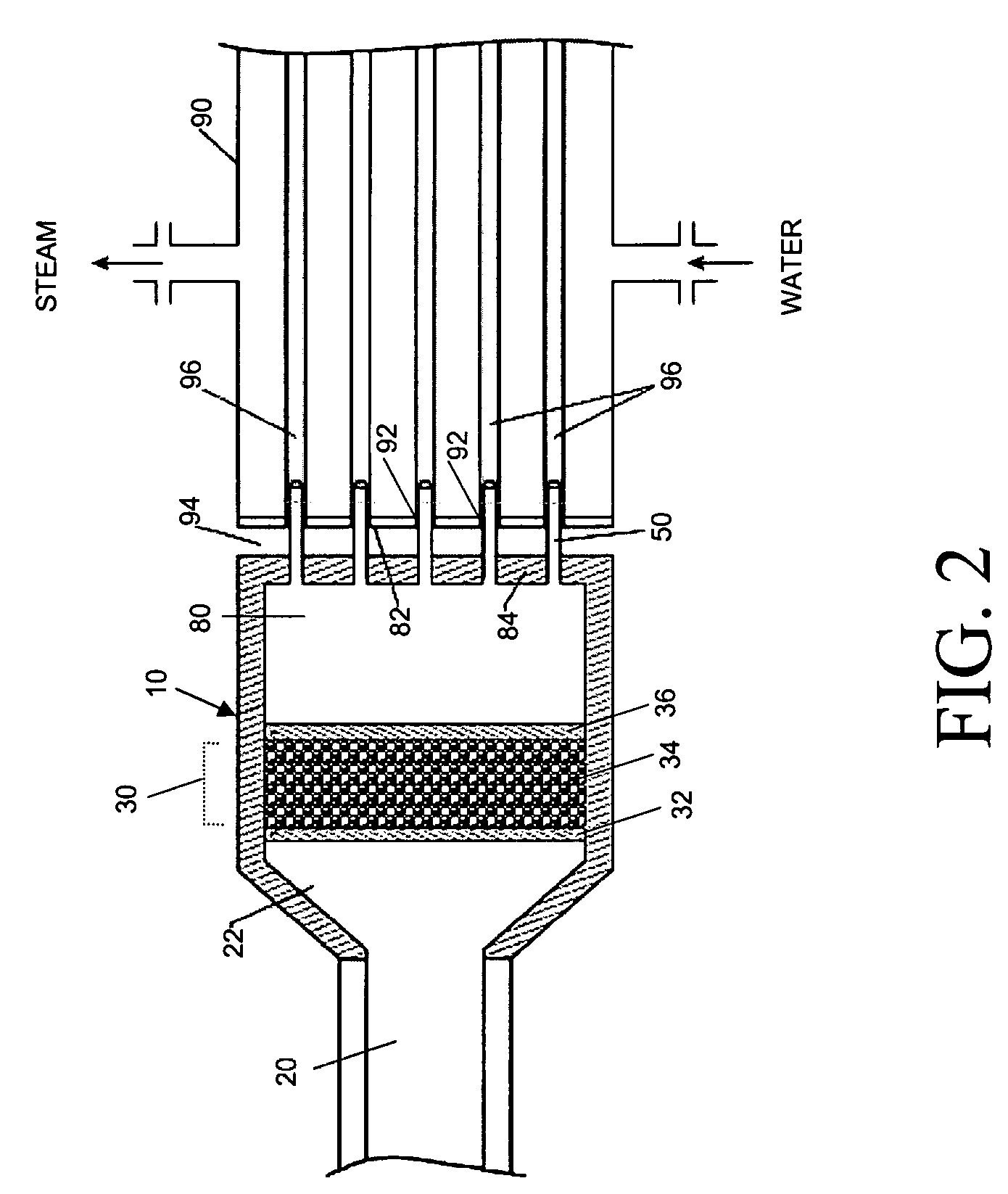

Apparatus and catalytic partial oxidation process for recovering sulfur from an H2S-containing gas stream

InactiveUS20050201924A1Eliminate the problemReduce contact timeCombination devicesExhaust apparatusCombustorPartial oxidation

The disclosed sulfur recovery system and process avoid some of the operational problems of conventional Claus plants and processes by replacing the reaction burner and furnace tube of a conventional Claus plant with a more efficient short contact time catalytic reactor assembly containing a SPOC™ catalyst that operates efficiently at elevated temperatures. Such Claus plant modification also reduces or avoids the negative effects of hydrocarbons, CO2 and ammonia in Claus sulfur plant feeds, and permits efficient processing of dilute to concentrated H2S feeds. The disclosed modification makes possible the expansion of Claus plant capacity at lower cost.

Owner:PHILLIPS 66 CO

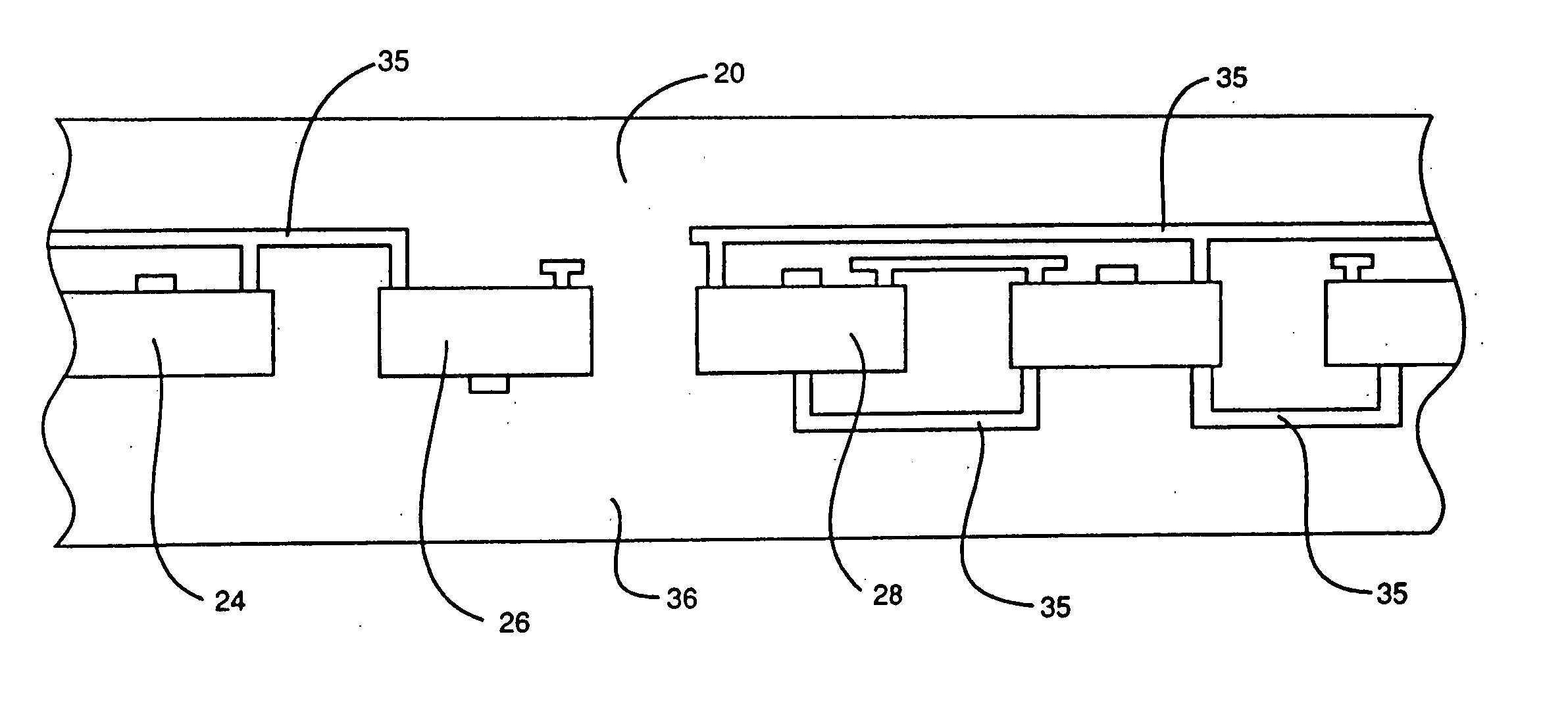

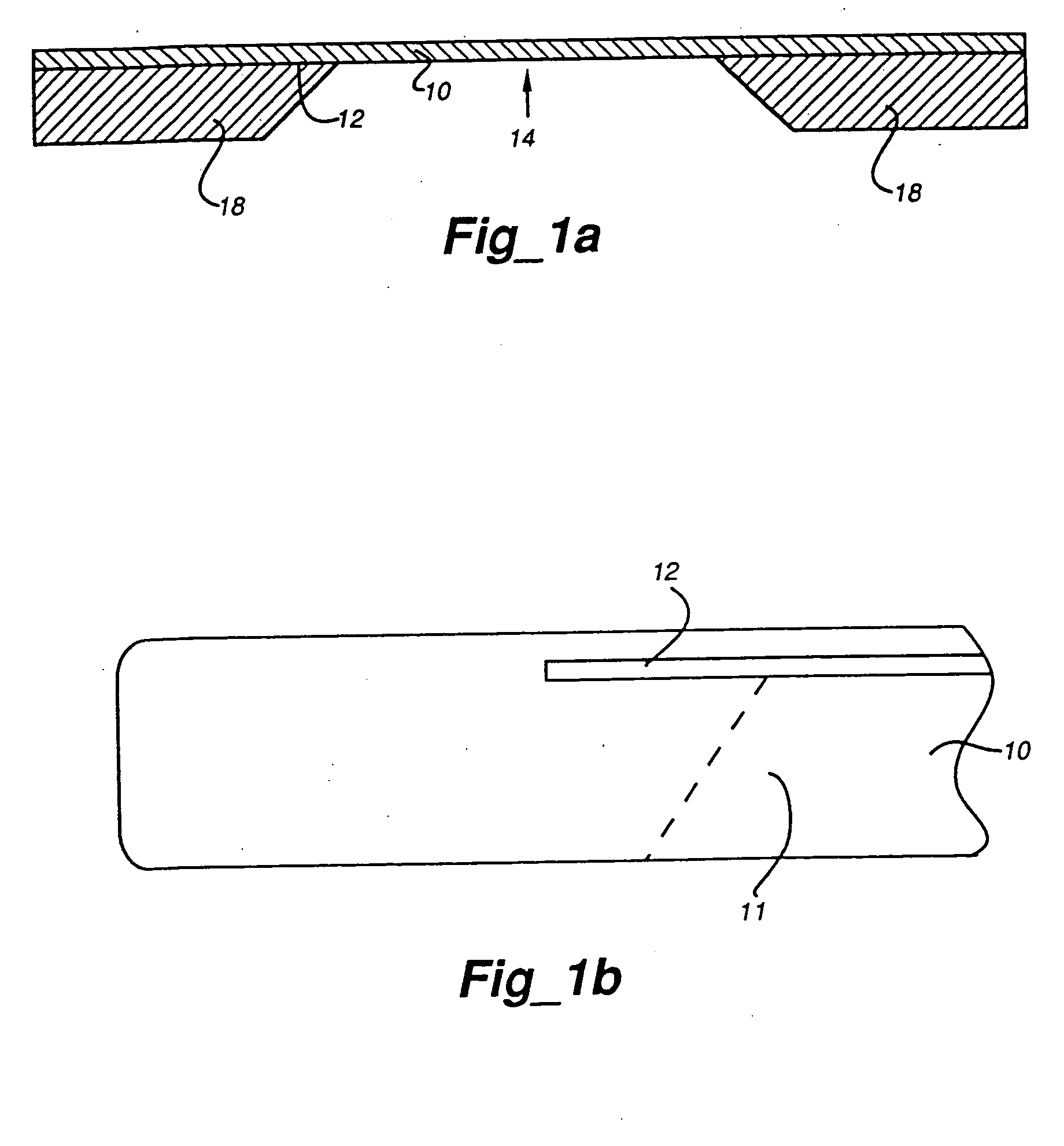

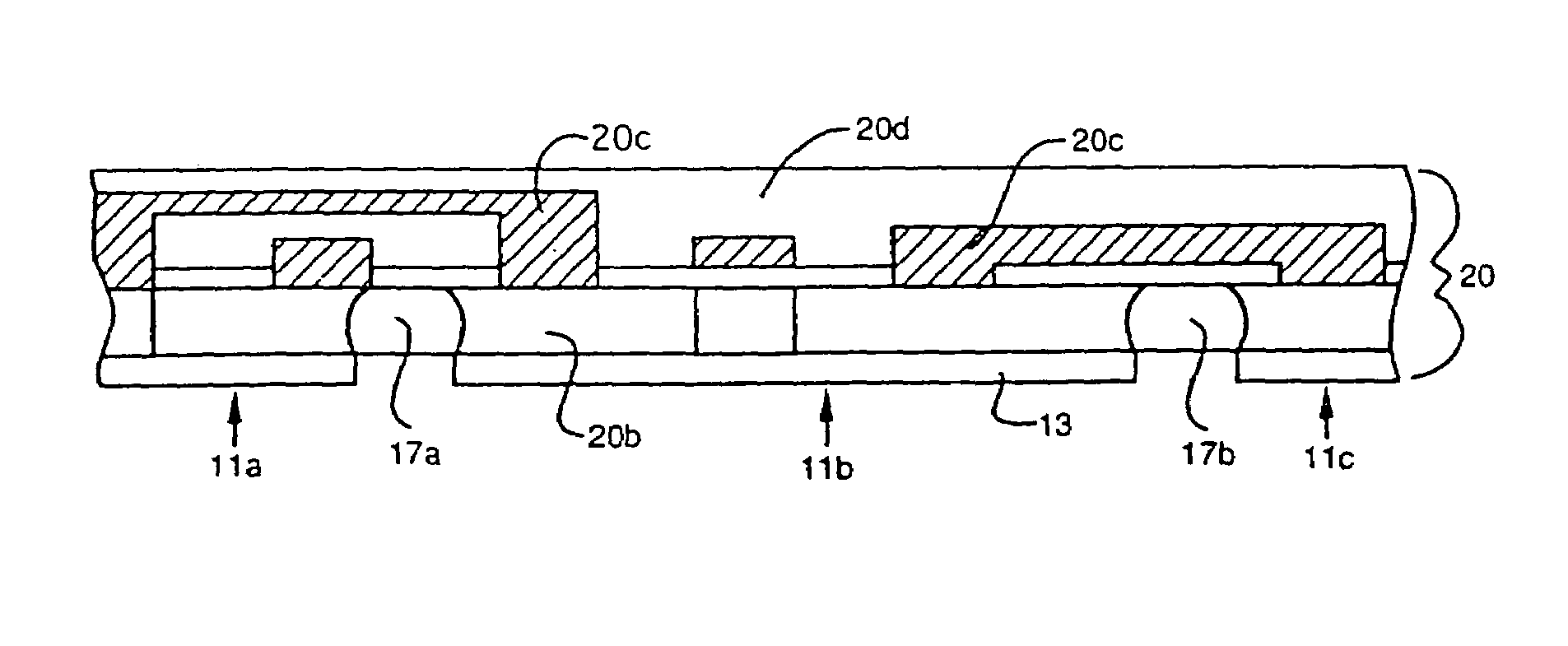

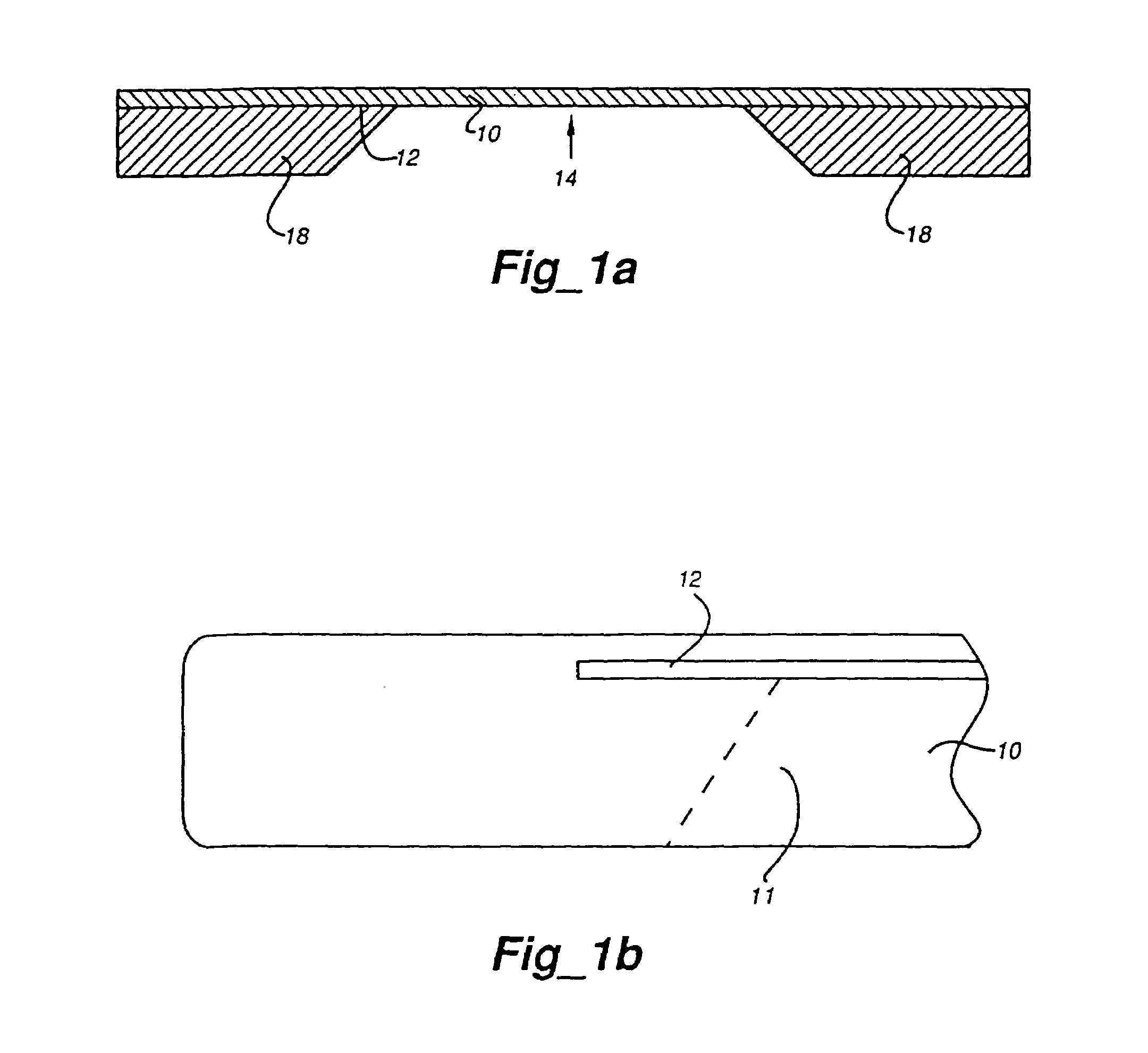

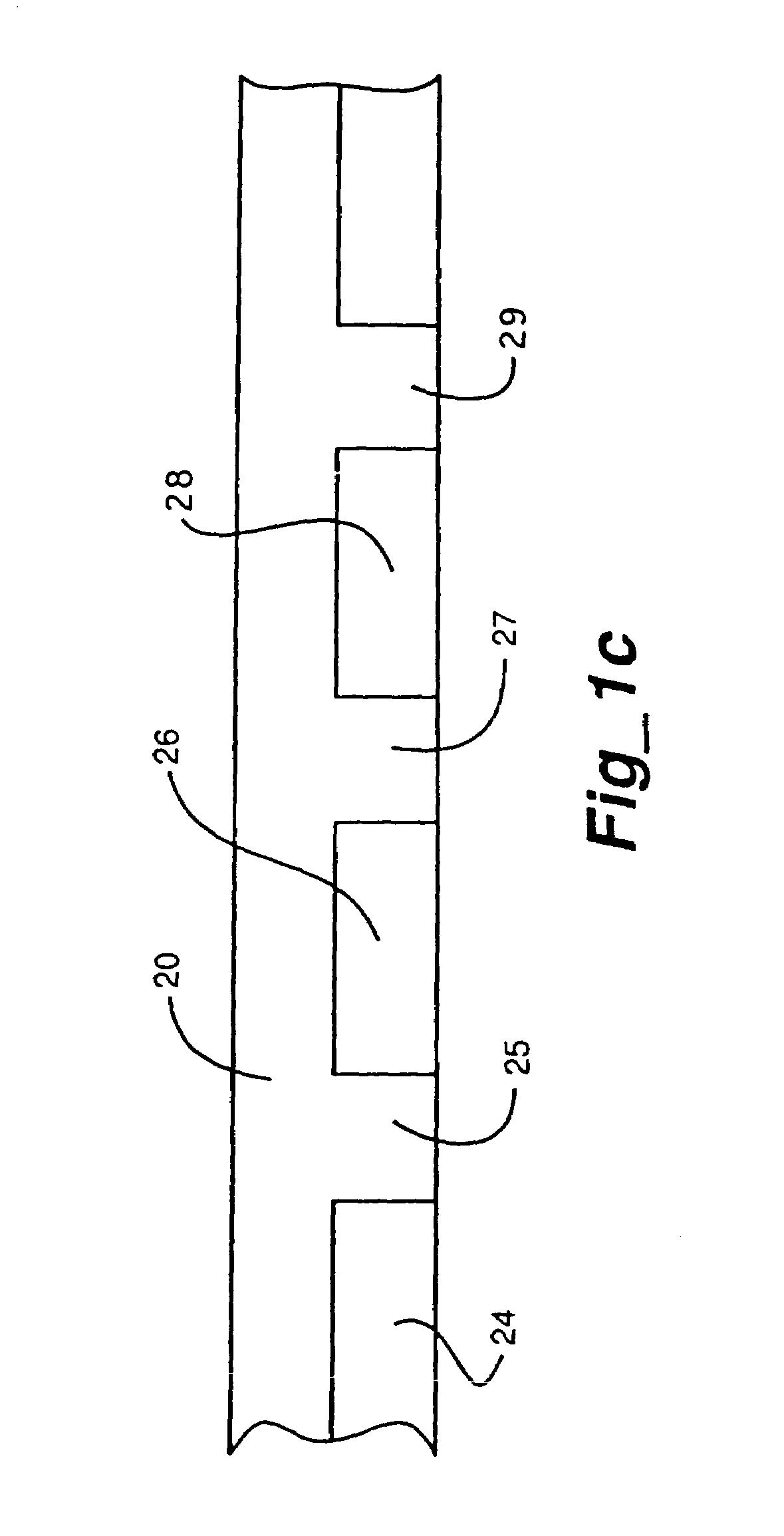

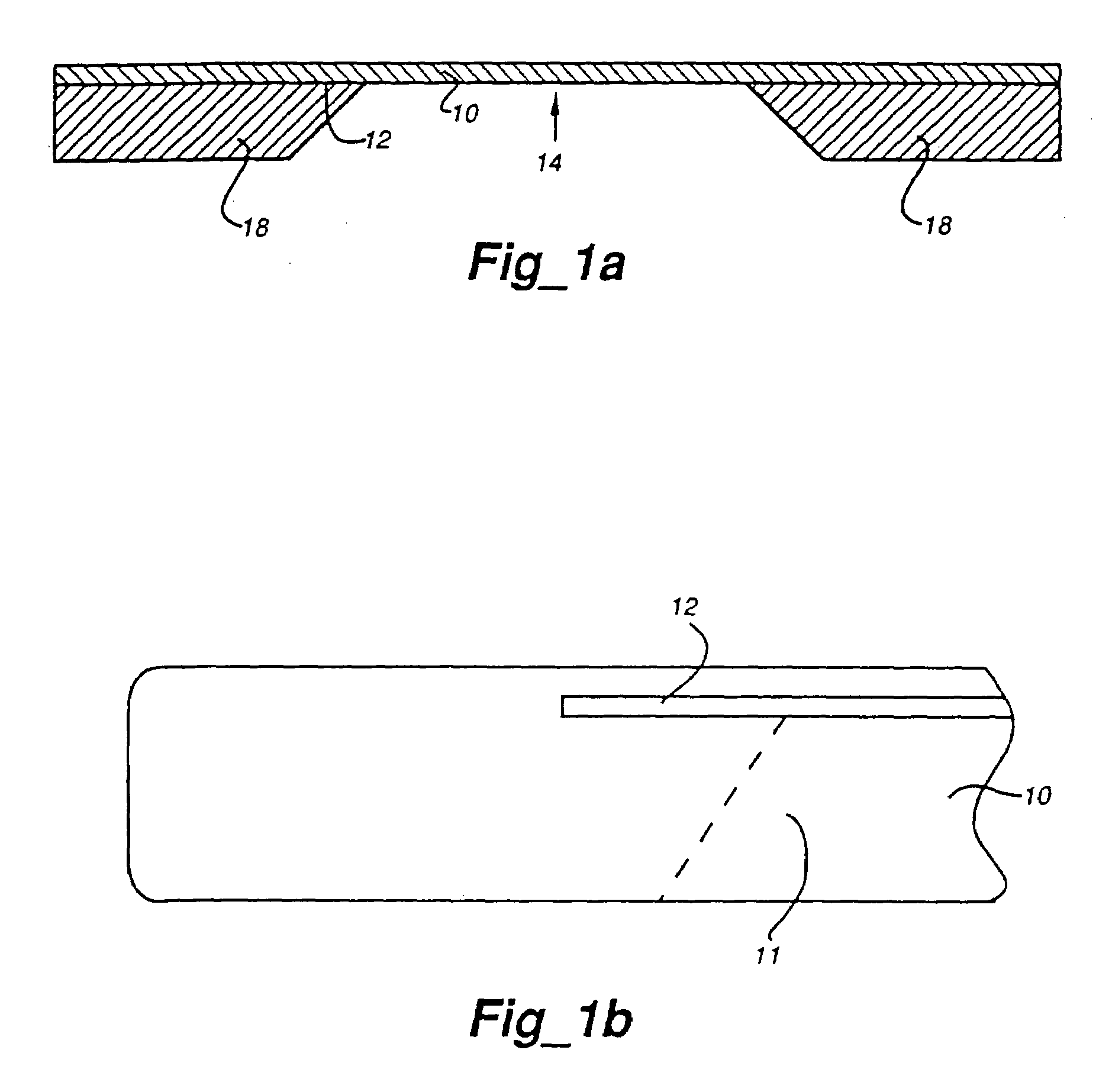

Flexible and elastic dielectric integrated circuit

InactiveUS20050082641A1Cost effectiveImprove performanceSemiconductor/solid-state device detailsFluid pressure measurement by electric/magnetic elementsMOSFETDevice material

General purpose methods for the fabrication of integrated circuits from flexible membranes formed of very thin low stress dielectric materials, such as silicon dioxide or silicon nitride, and semiconductor layers. Semiconductor devices are formed in a semiconductor layer of the membrane. The semiconductor membrane layer is initially formed from a substrate of standard thickness, and all but a thin surface layer of the substrate is then etched or polished away. In another version, the flexible membrane is used as support and electrical interconnect for conventional integrated circuit die bonded thereto, with the interconnect formed in multiple layers in the membrane. Multiple die can be connected to one such membrane, which is then packaged as a multi-chip module. Other applications are based on (circuit) membrane processing for bipolar and MOSFET transistor fabrication, low impedance conductor interconnecting fabrication, flat panel displays, maskless (direct write) lithography, and 3D IC fabrication.

Owner:TAIWAN SEMICON MFG CO LTD

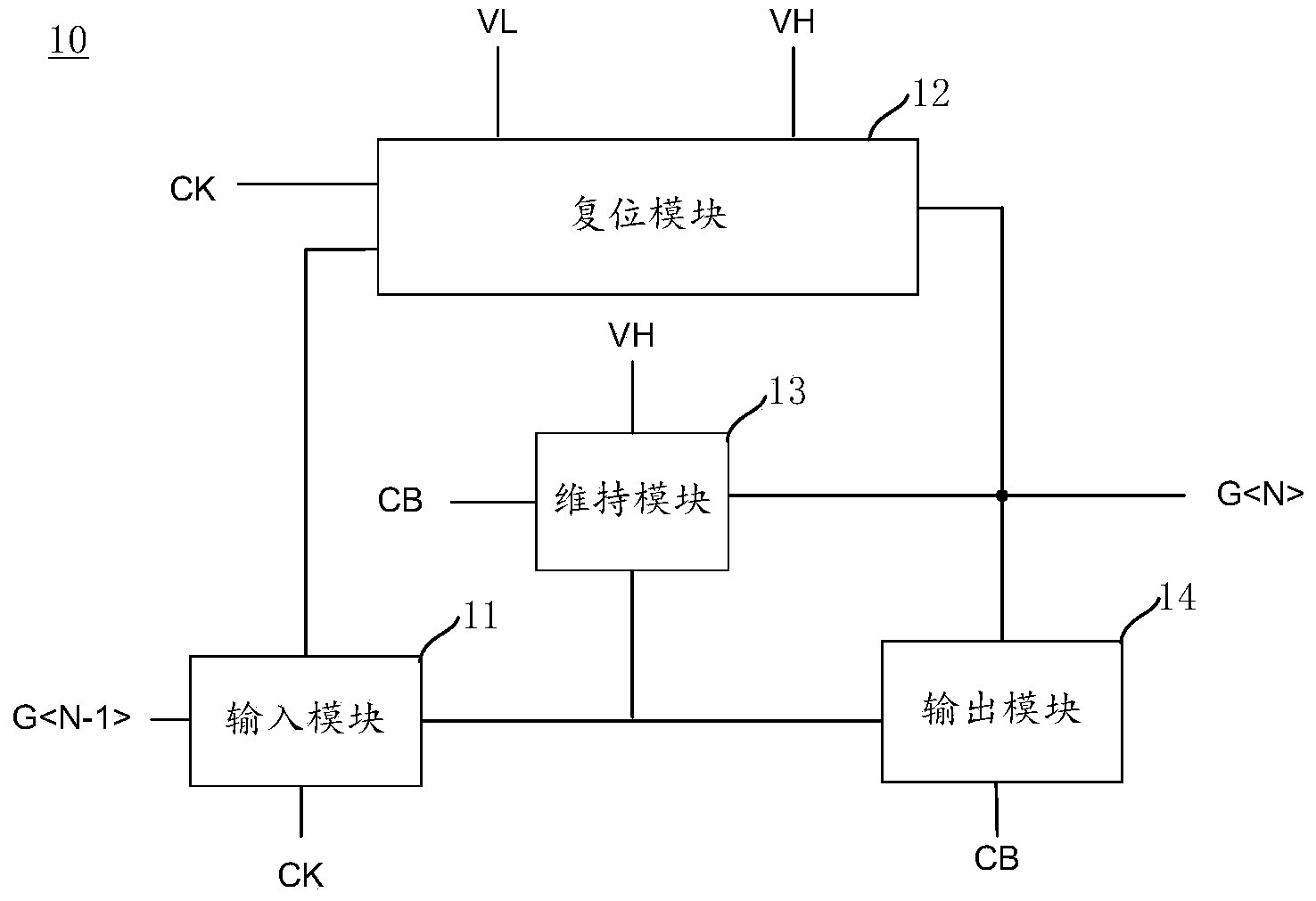

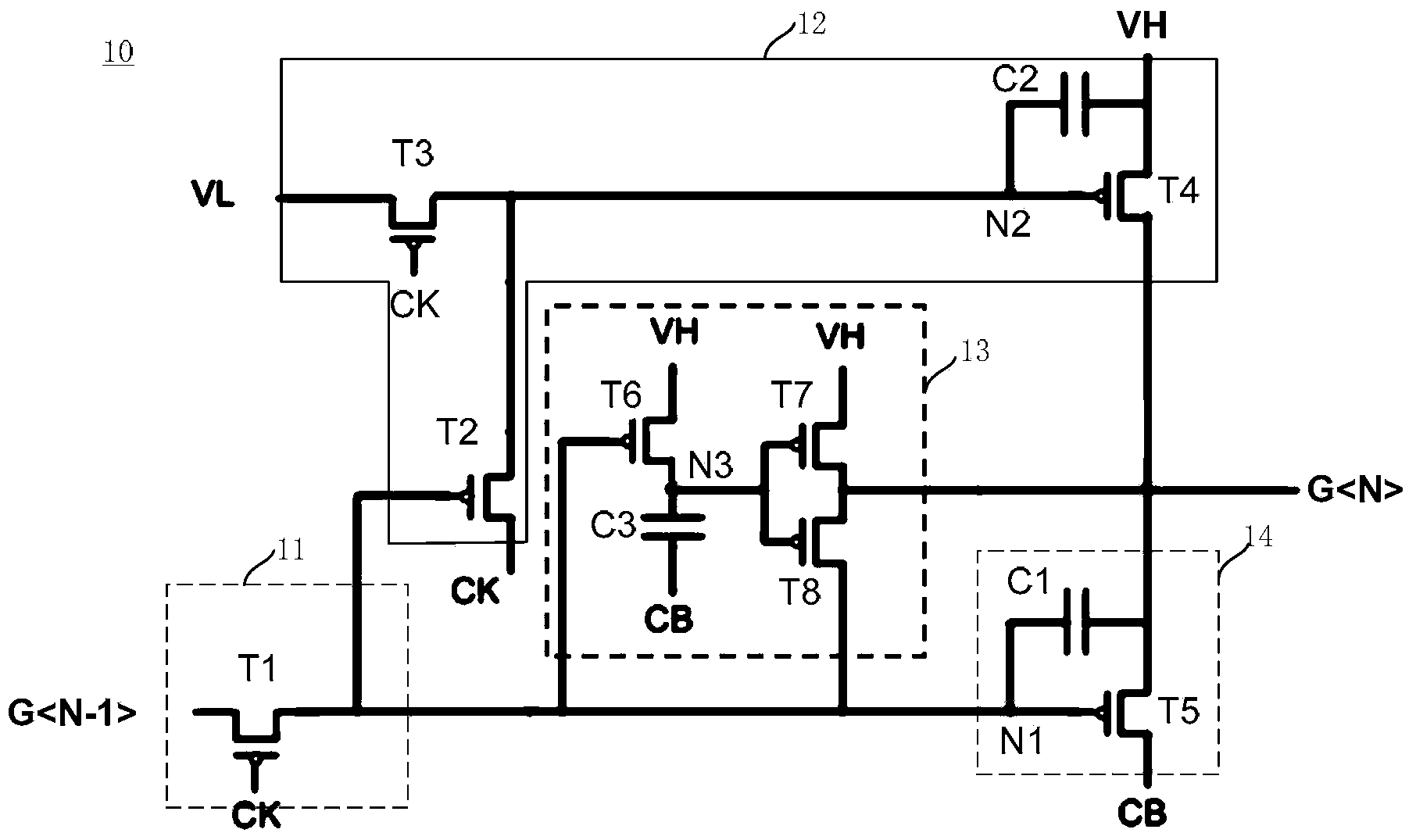

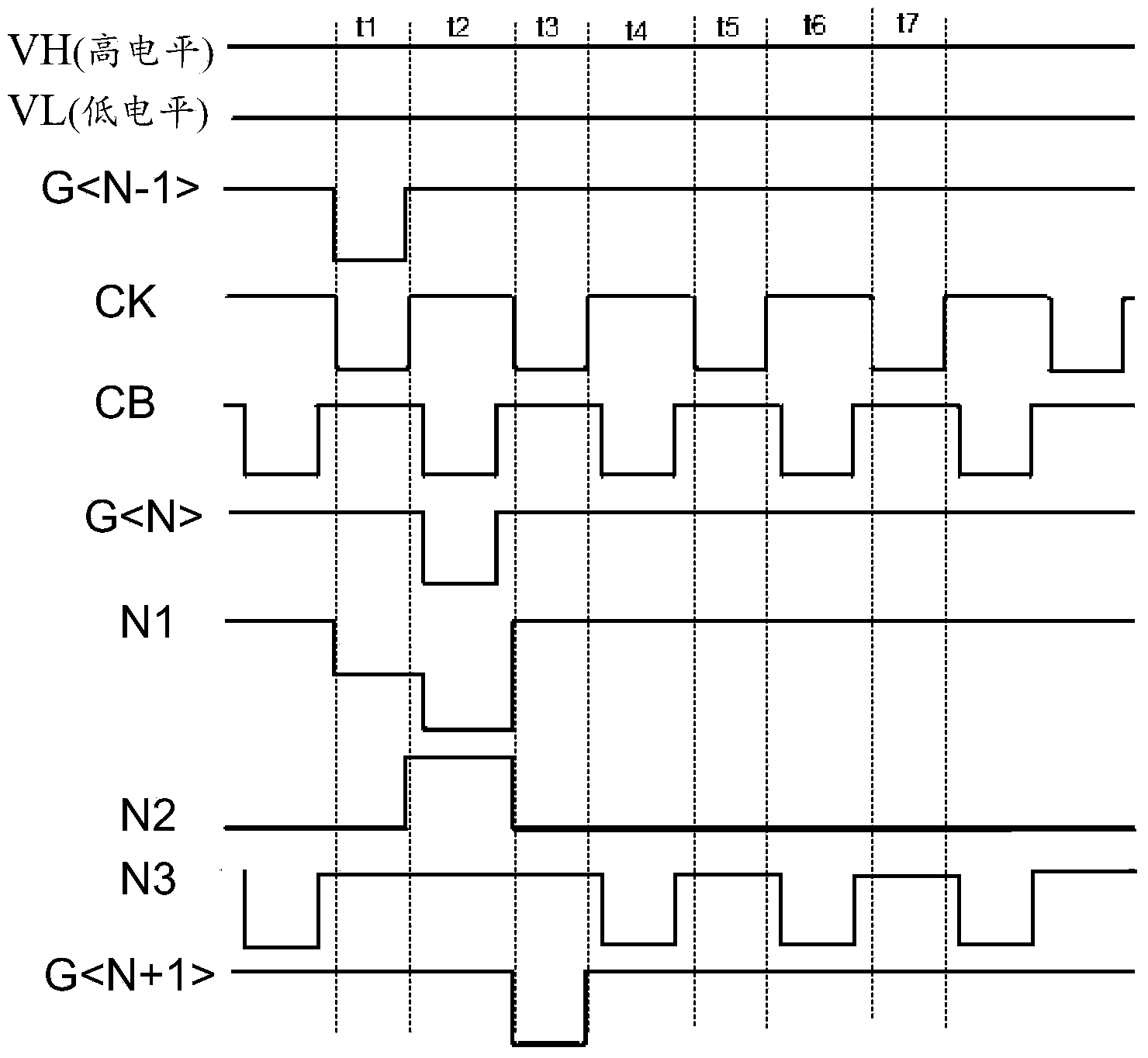

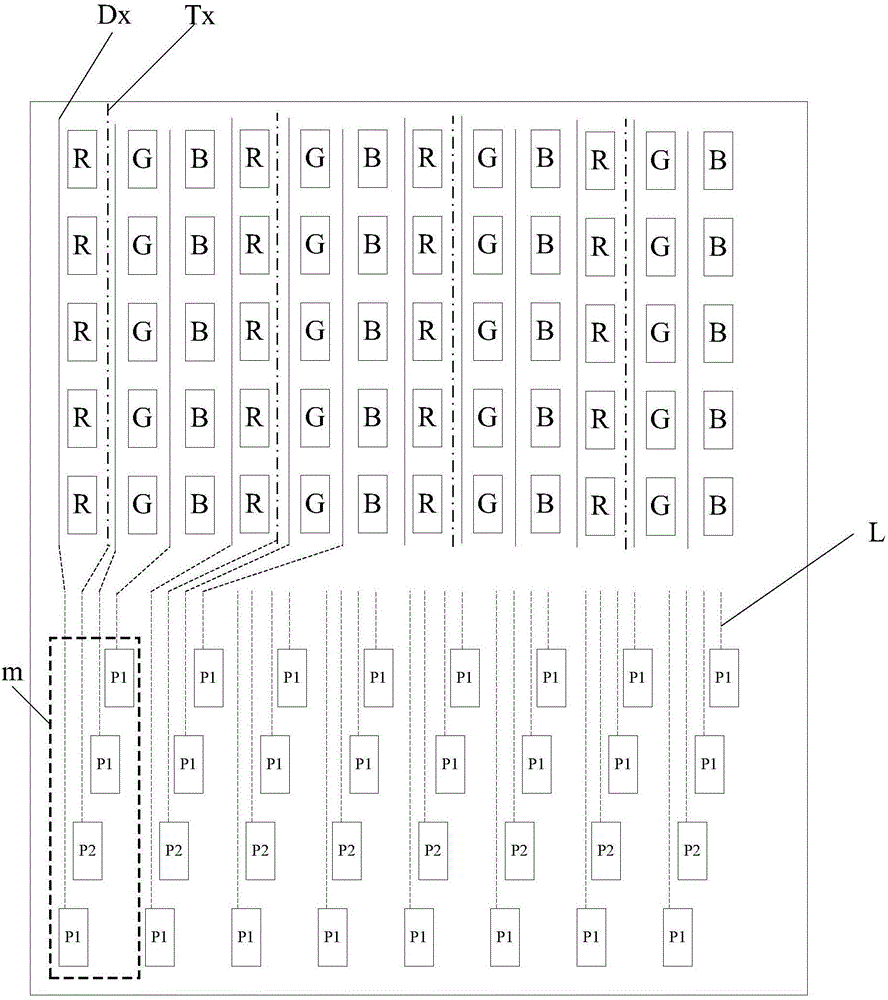

Shifting register and driving method thereof as well as grid electrode driving circuit and display device

ActiveCN104299652AInput stableRealize the shift functionStatic indicating devicesDigital storageDriver circuitShift register

The invention discloses a shifting register and a driving method thereof as well as a grid electrode driving circuit and a display device, relating to the field of display. A needed electrical level can be stably output and bad phenomena caused by the fact that the output is not stable when a clock signal is converted and an output signal is interfered are eliminated, so that the display quality is guaranteed. According to the shifting register, an input module is used for sending an input signal to an output module, a resetting module and a maintaining module according to an input signal and a first clock signal; the resetting module is connected with the input module and a signal output end and is used for resetting a signal output end according to the first clock signal, first and second electrical level signals and the input signal; the maintaining module is connected with the input module and the output module and is used for sending a maintaining signal to the output module according to the input signal, the second clock signal and the second electrical level signal; and the output module is connected with the input module, the maintaining module and the signal output end and is used for sending the output signal to the signal output end according to the input signal, the maintaining signal and the second clock signal.

Owner:BOE TECH GRP CO LTD +1

Stress-controlled dielectric integrated circuit

InactiveUS20050051841A1Reduce processing costsFew device isolation processing stepTransistorSemiconductor/solid-state device detailsDielectricDisplay device

General purpose methods for the fabrication of integrated circuits from flexible membranes formed of very thin low stress dielectric materials, such as silicon dioxide or silicon nitride, and semiconductor layers. Semiconductor devices are formed in a semiconductor layer of the membrane. The semiconductor membrane layer is initially formed from a substrate of standard thickness, and all but a thin surface layer of the substrate is then etched or polished away. In another version, the flexible membrane is used as support and electrical interconnect for conventional integrated circuit die bonded thereto, with the interconnect formed in multiple layers in the membrane. Multiple die can be connected to one such membrane, which is then packaged as a multi-chip module. Other applications are based on (circuit) membrane processing for bipolar and MOSFET transistor fabrication, low impedance conductor interconnecting fabrication, flat panel displays, maskless (direct write) lithography, and 3D IC fabrication.

Owner:TAIWAN SEMICON MFG CO LTD

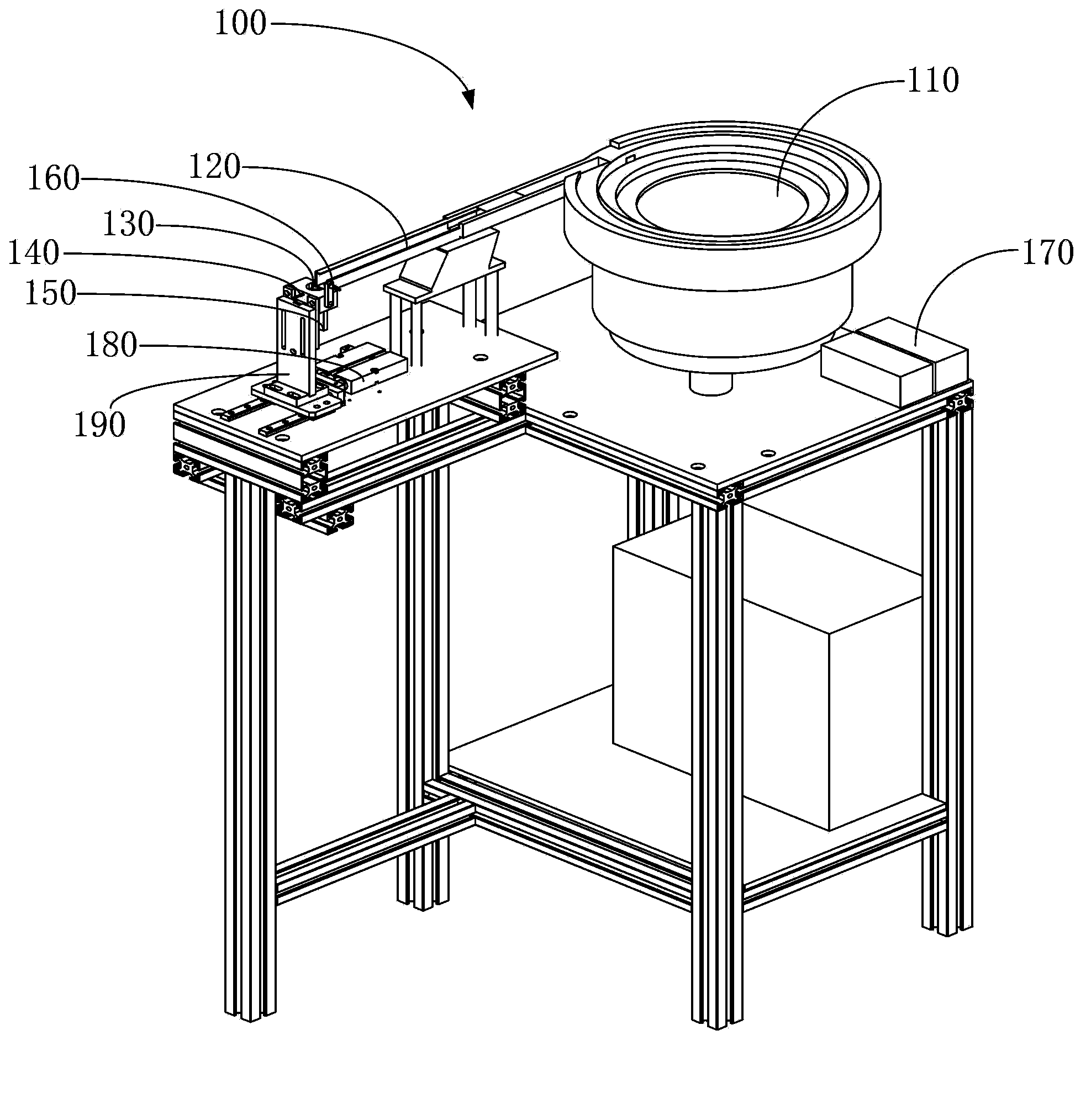

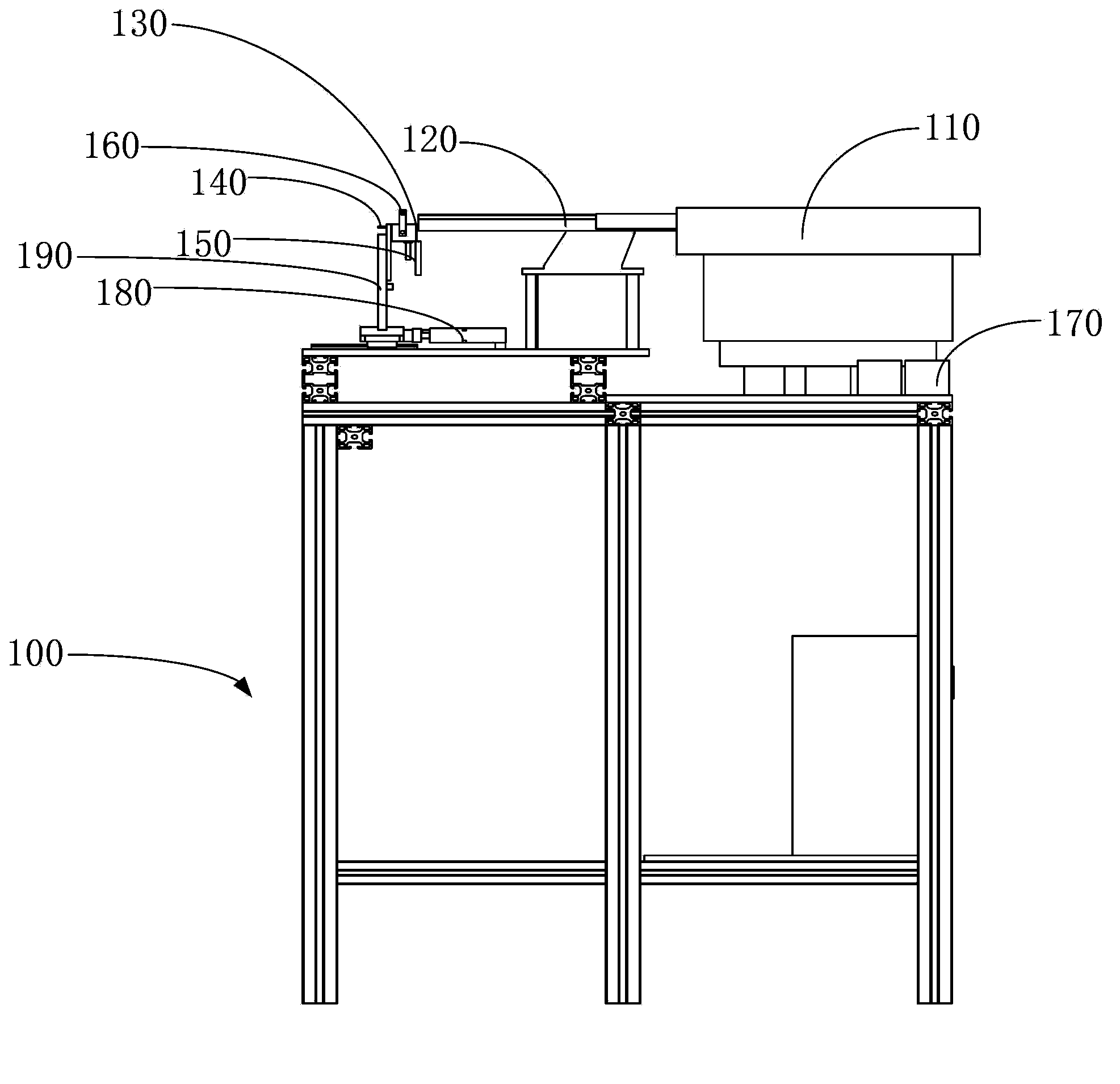

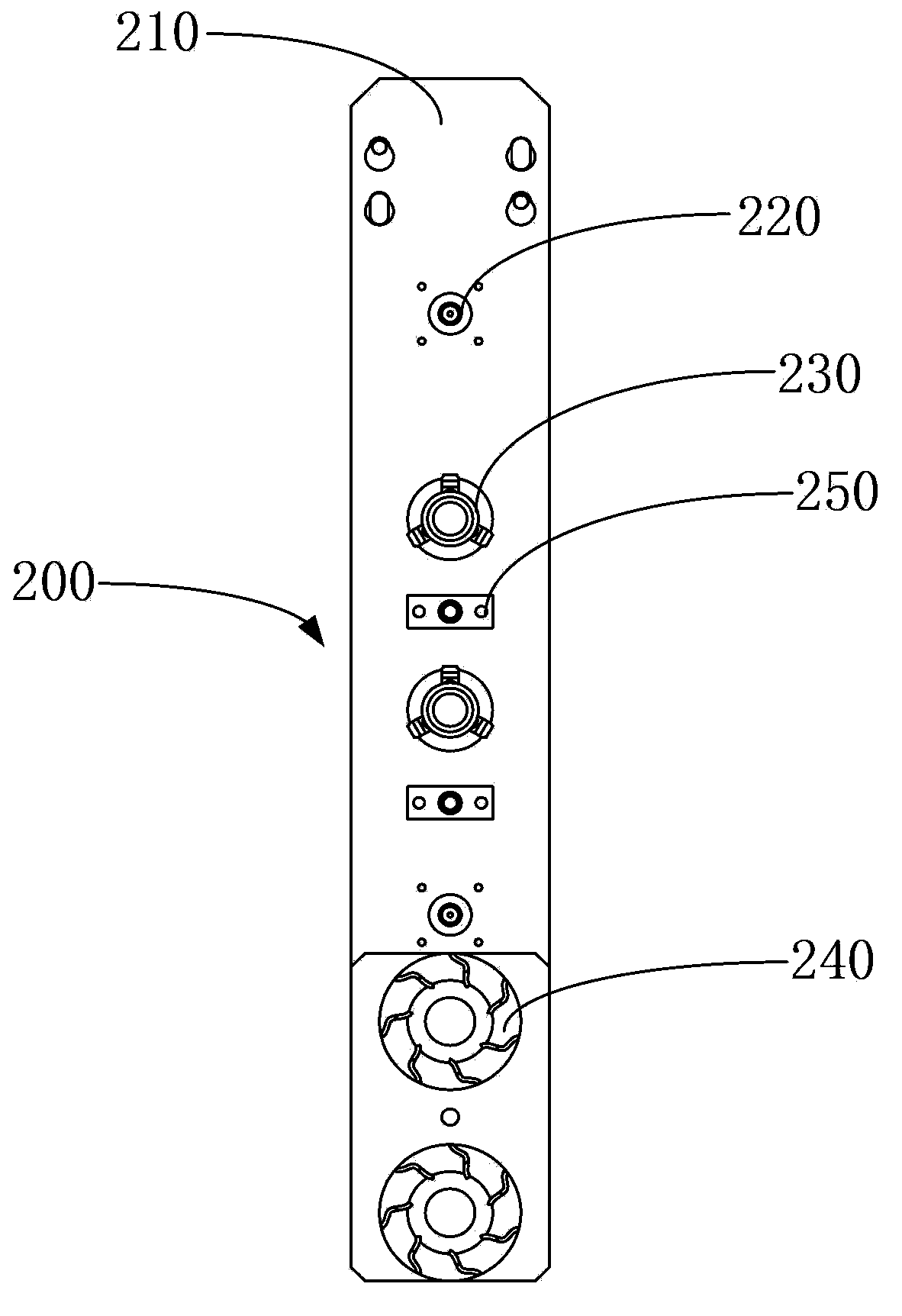

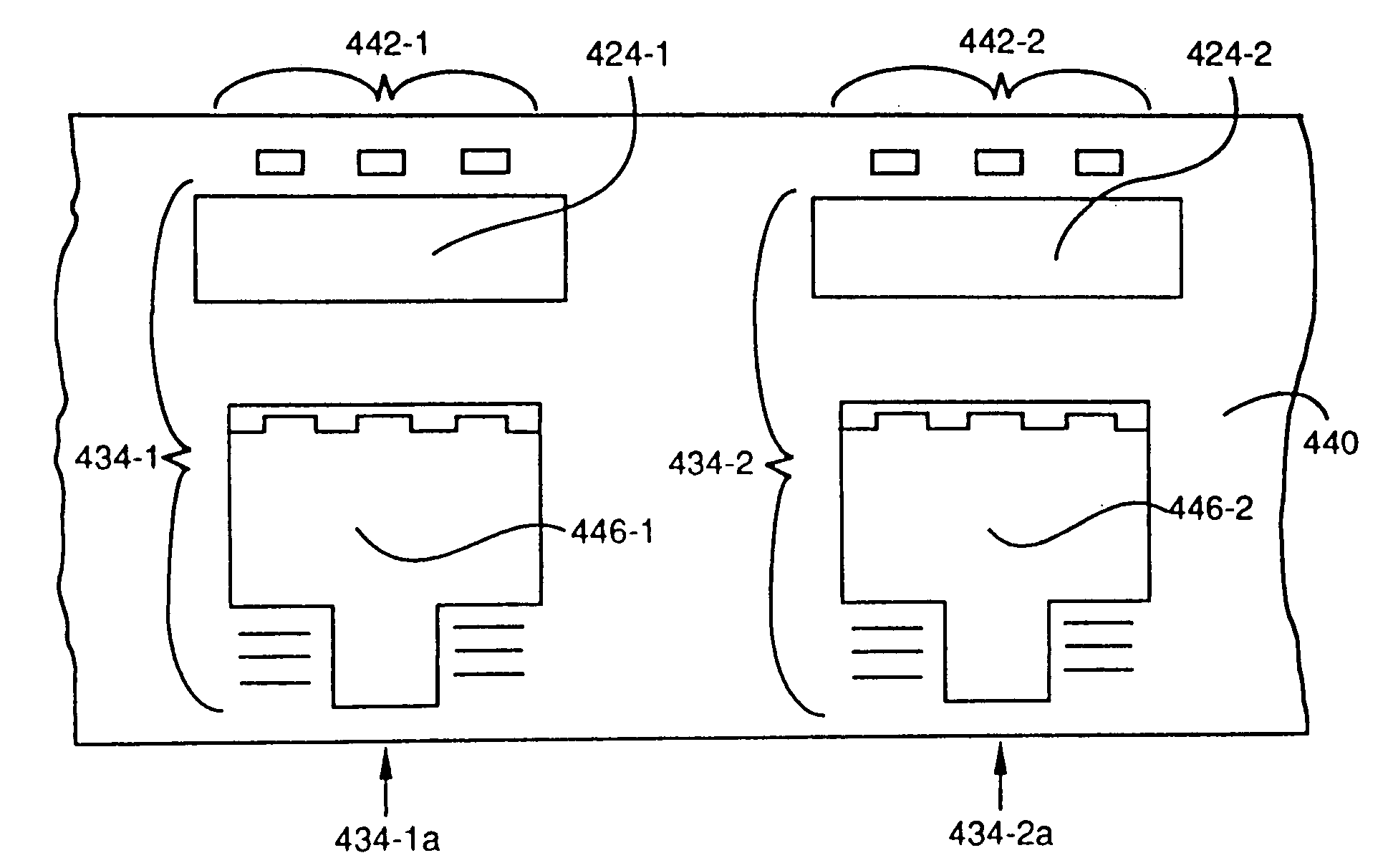

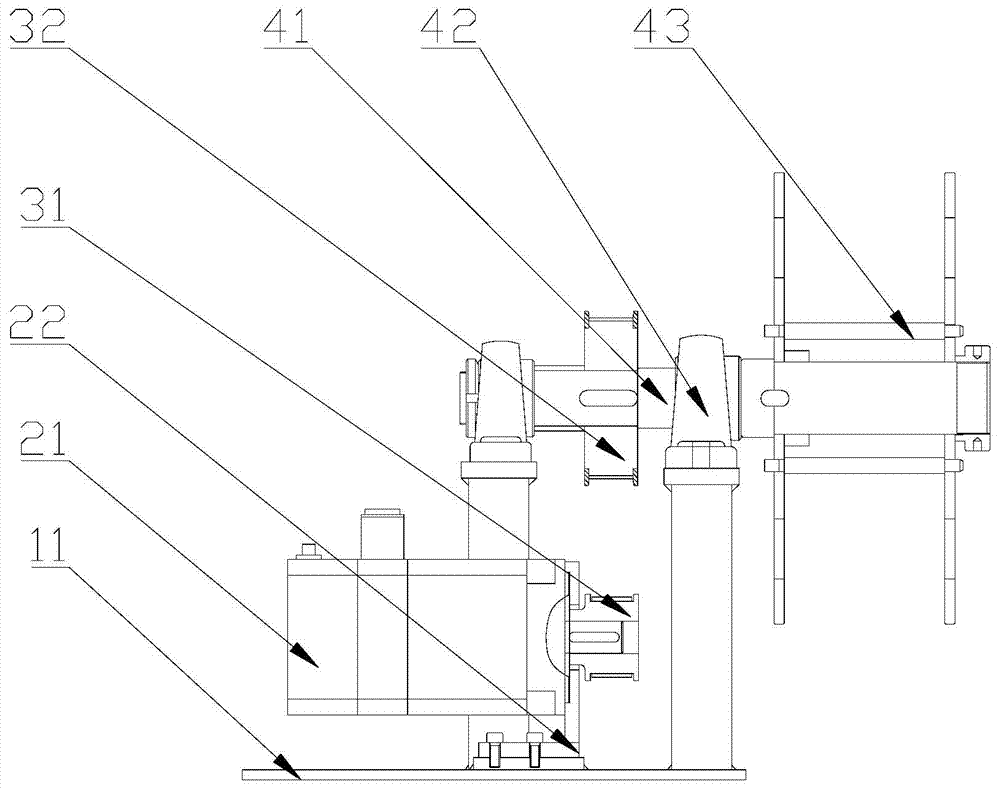

Insert feeding device and method

InactiveCN103660079AThe positive and negative directions are correctEliminate the disadvantages of manual workElectrical and Electronics engineeringOptical fiber

The invention relates to an insert feeding device and method. The device comprises a discharge unit and a feeding unit, wherein the discharge unit comprises a vibration plate, a linear vibrator, a material wait hole, a first detection optical fiber, a first cylinder and a second detection optical fiber; one end of the linear vibrator is fixedly connected with a discharge hole of the vibration plate, and the other end of the linear vibrator is connected with the material wait hole; the vibration plate is provided with a distribution strip for preventing an insert from being reversely arranged; the first detection optical fiber is arranged at the material wait hole and is used for detecting whether the insert exists or not; the first cylinder is arranged under the material wait hole; the second detection optical fiber is arranged at the upper side of the material wait hole and is used for detecting whether the insert is lifted or not; the feeding unit comprises a fixed plate, and two guide locating ejector pins, two grabbing mechanisms and two suction cups which are arranged on the fixed plate; the guide locating ejector pins can be inserted into locating holes of a mould and are used for guiding and locating the fixed plate; the grabbing mechanisms are used for grabbing the insert from the material wait hole; the suction cups are used for absorbing a product in which the insert is installed. After the device and the method are adopted, the insert can be automatically fed and is prevented from being reversely installed.

Owner:STARYY RESIN PROD KUSN

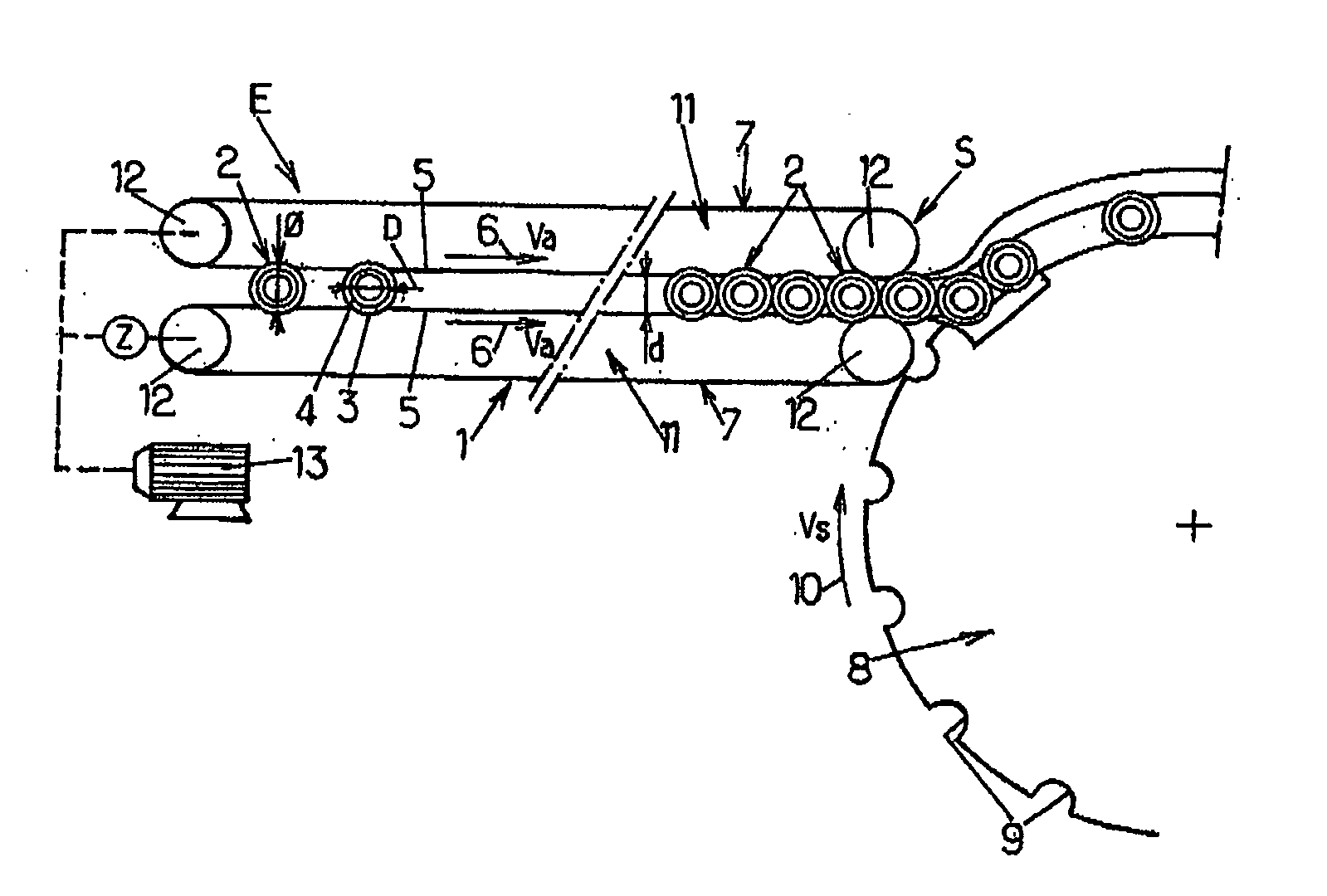

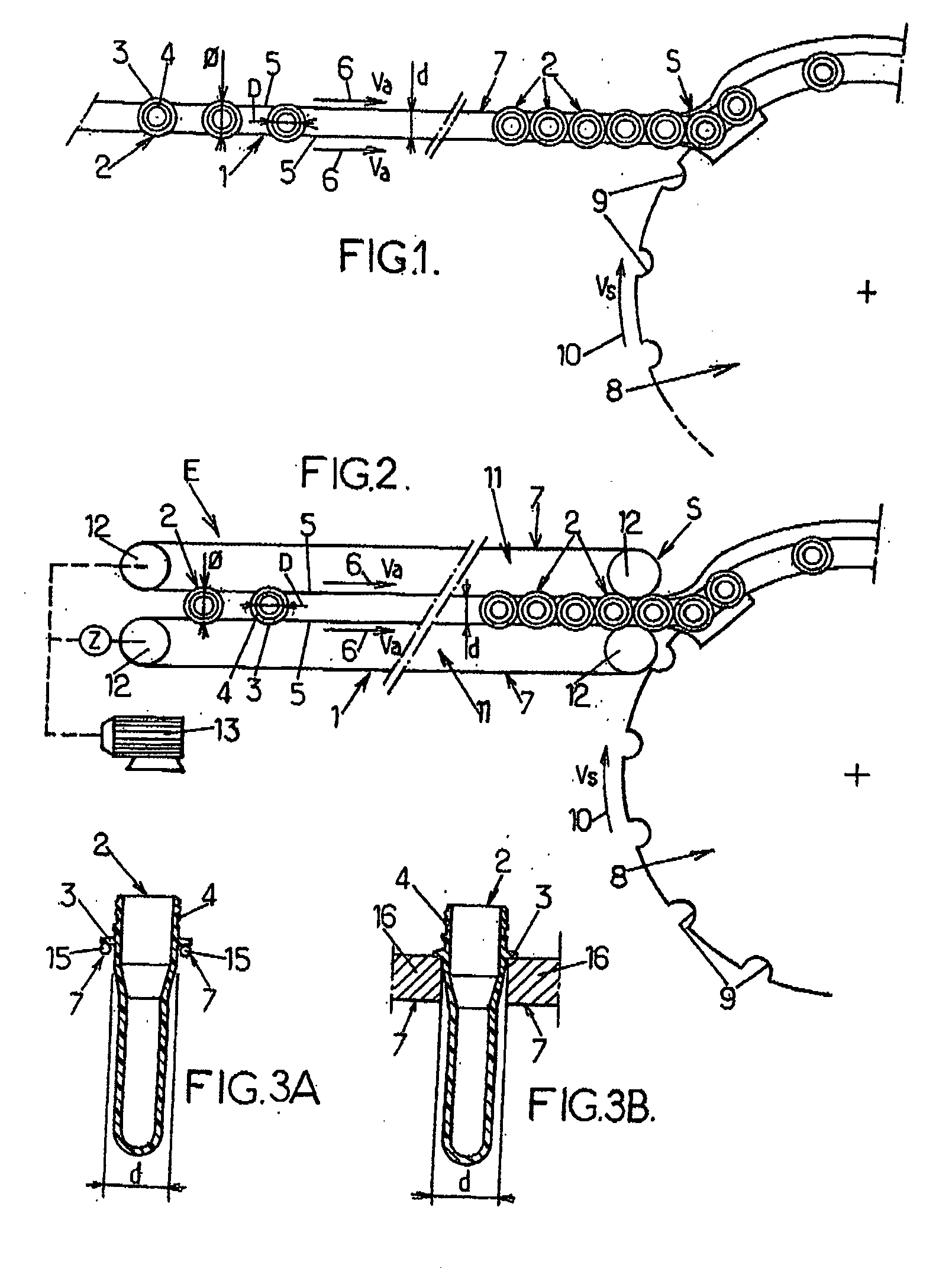

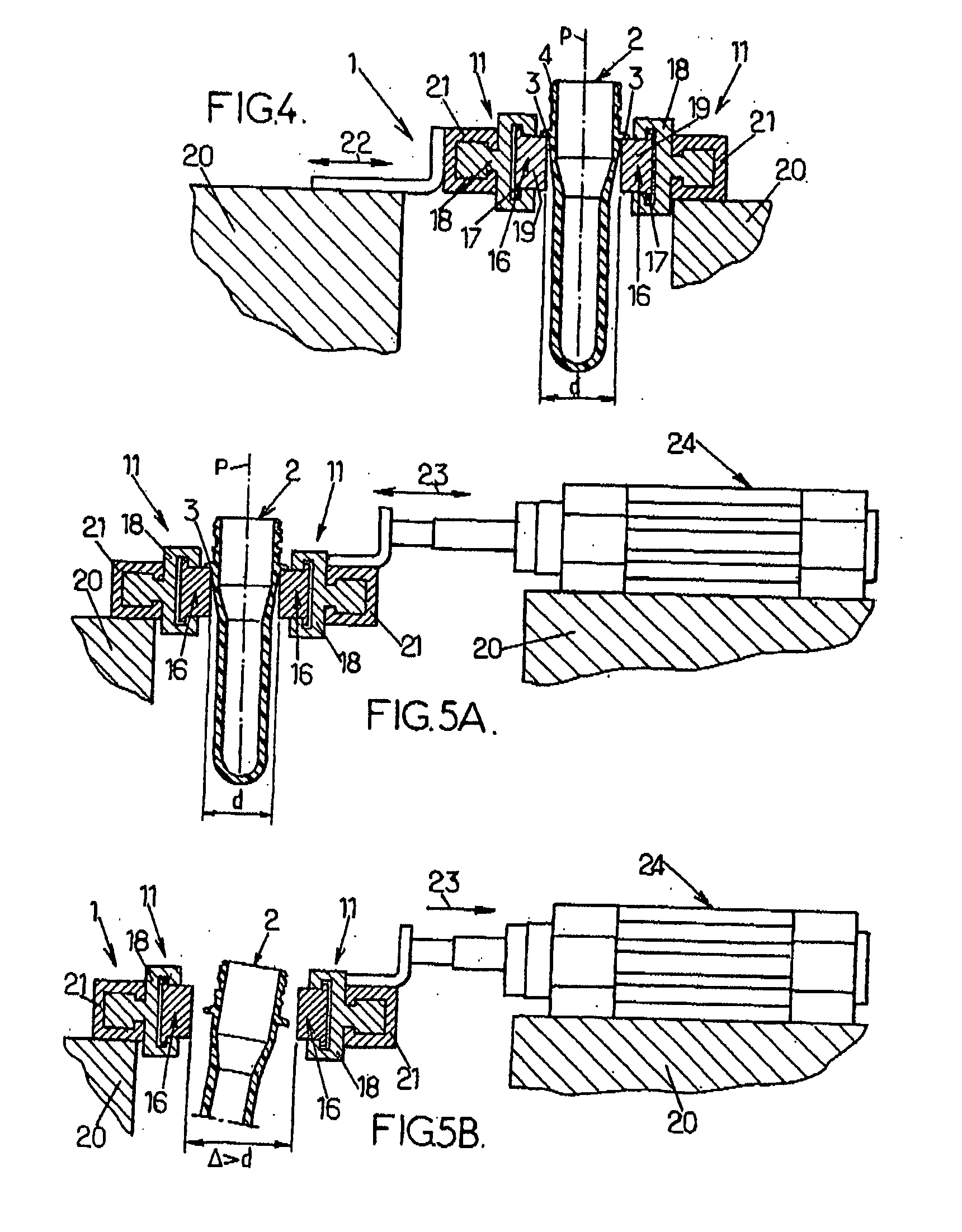

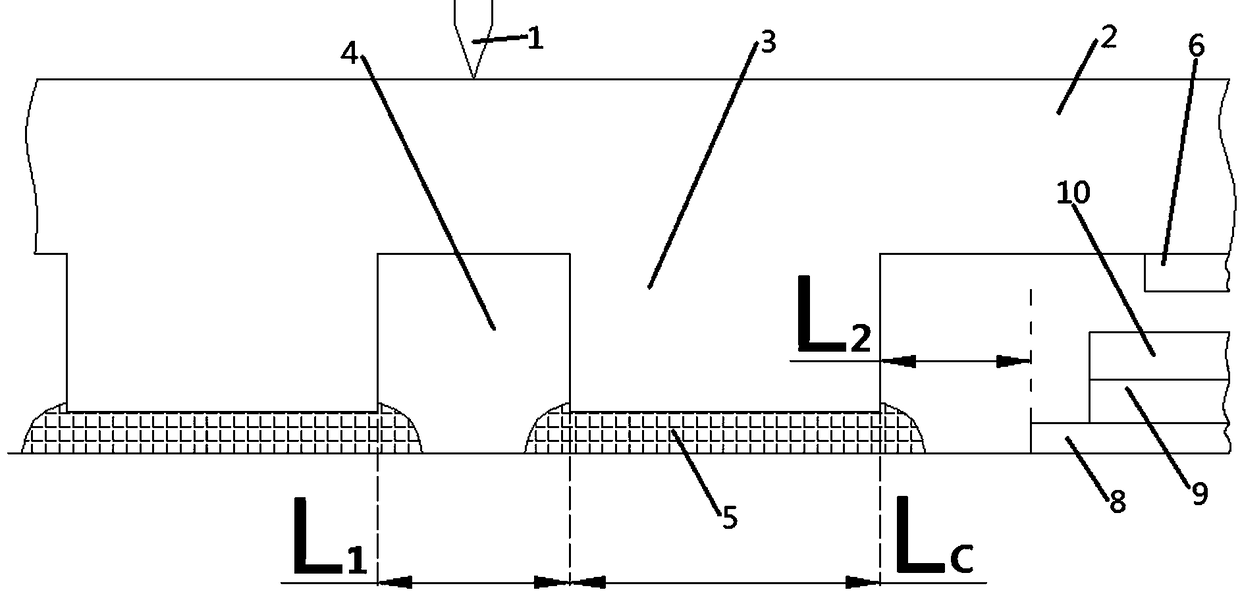

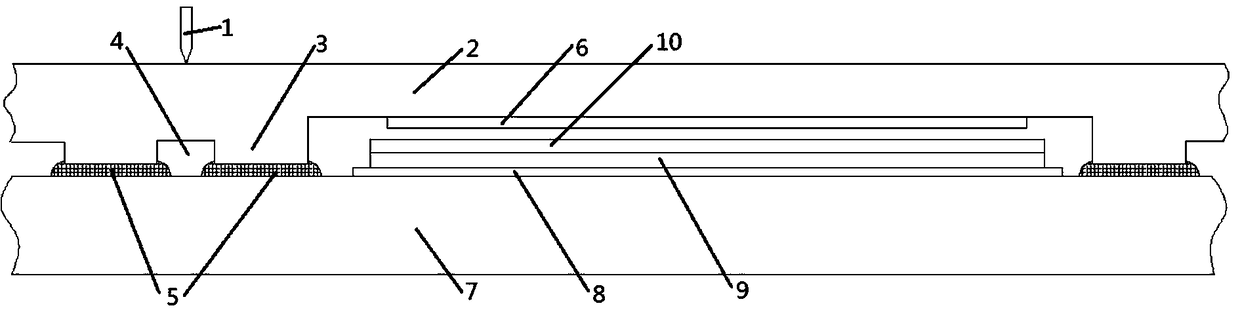

Conveyor Device for Containers Such as Preforms

InactiveUS20080142339A1Avoid disadvantagesEliminate badConveyor partsMechanical conveyorsEngineeringShaft collar

A linear, horizontal conveyor device for containers which are equipped with a collar at the base of the neck thereof. The invention includes two conveyors including endless links, which are each equipped with two parallel, mobile lines which face one another and which are driven in the same direction and at the same speed. The aforementioned lines are separated from one another by a distance that is greater than the diameter of the body of the containers and less than the diameter of the collars thereof. At least one conveyor includes a short segment that can be moved transversely outwards, such that the space between the two facing lines becomes greater than the diameter of the collar and the container falls.

Owner:SIDEL PARTICIPATIONS SAS

Methods for maskless lithography

InactiveUS7223696B2Cost effectiveImprove performanceSemiconductor/solid-state device detailsSolid-state devicesMOSFETDevice material

Owner:TAIWAN SEMICON MFG CO LTD

High surface area adsorbents and methods of preparation

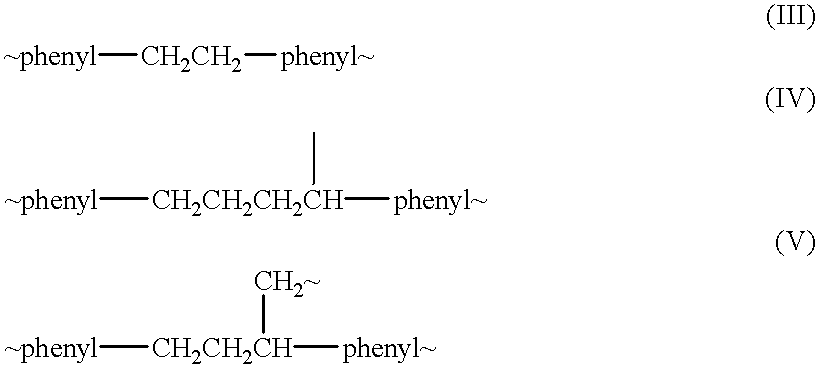

InactiveUS6147127AImprove physical stabilityLittle or no swelling in organic solventsCation exchanger materialsOther chemical processesPorosityOrganic sulfonic acid

A process for the preparation of high surface area, low-swelling macroporous polymeric adsorbents is disclosed. The use of organic sulfonic acids to provide postcrosslinking of macroporous copolymers eliminates the need for traditional organic swelling solvents and Lewis-acid catalysts used to provide conventional macronetted polymers. In particular, methanesulfonic acid provides macroporous polymeric adsorbents having high surface area and porosity, low levels of residual vinyl groups, and free of residual contaminants from conventional Lewis-acid / Friedel-Crafts reactions.

Owner:ROHM & HAAS CO

Apparatus and methods for maskless pattern generation

InactiveUS7176545B2Cost effectiveImprove performanceSemiconductor/solid-state device detailsSolid-state devicesMOSFETSilicon dioxide

General purpose methods for the fabrication of integrated circuits from flexible membranes formed of very thin low stress dielectric materials, such as silicon dioxide or silicon nitride, and semiconductor layers. Semiconductor devices are formed in a semiconductor layer of the membrane. The semiconductor membrane layer is initially formed from a substrate of standard thickness, and all but a thin surface layer of the substrate is then etched or polished away. In another version, the flexible membrane is used as support and electrical interconnect for conventional integrated circuit die bonded thereto, with the interconnect formed in multiple layers in the membrane. Multiple die can be connected to one such membrane, which is then packaged as a multi-chip module. Other applications are based on (circuit) membrane processing for bipolar and MOSFET transistor fabrication, low impedance conductor interconnecting fabrication, flat panel displays, maskless (direct write) lithography, and 3D IC fabrication.

Owner:TAIWAN SEMICON MFG CO LTD

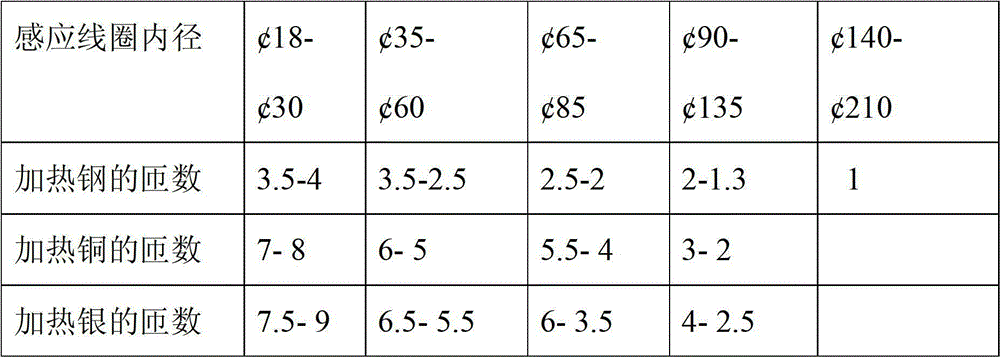

Induction brazing welding method for metal part

The invention discloses an induction brazing welding method for a metal part. The method utilizes induction brazing welding equipment and then is implemented according to the following steps of: a step 1 of selecting the induction brazing welding equipment and determining related parameters; a step 2 of carrying out weldment surface processing, i.e. roughening the welding surface of a weldment, processing the metal-plated surface of the weldment, carrying out matched selection between the weldment and a soldering flux, a brazing filler metal, a welding temperature and a brazing clearance and selecting each process parameter of induction brazing; a step 3 of assembling and fixing the weldment; and a step 4 of implementing welding. According to the induction brazing welding method disclosed by the invention, the induction welding and the induction brazing welding of structures of different materials, pipe fittings, sheets, tube plates and the like are implemented, the sealing performance of a weld joint is improved, the intensity of the weld joint is reduced, the electrical conductivity is obviously improved, and the weld joint has a reliable quality.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

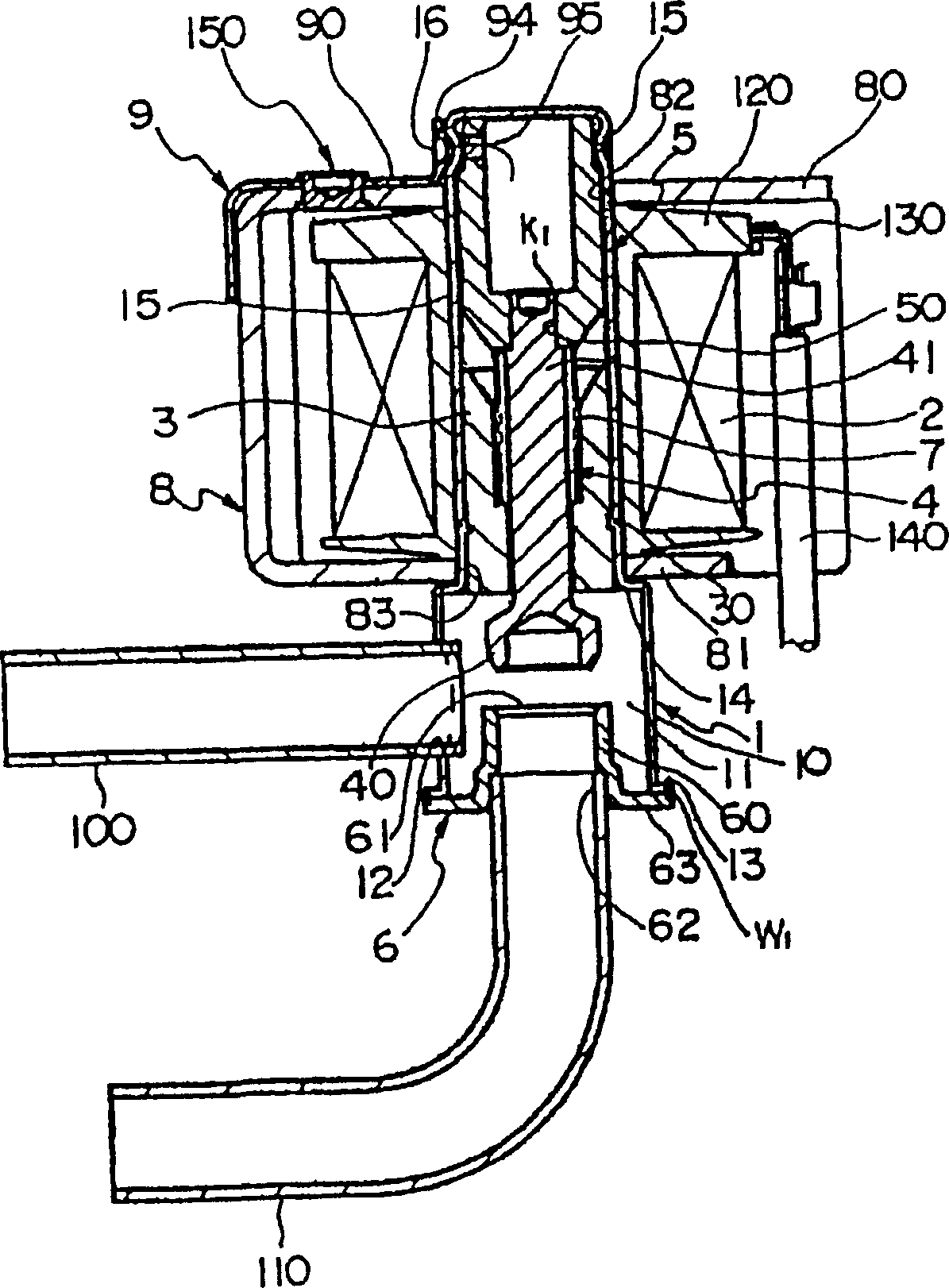

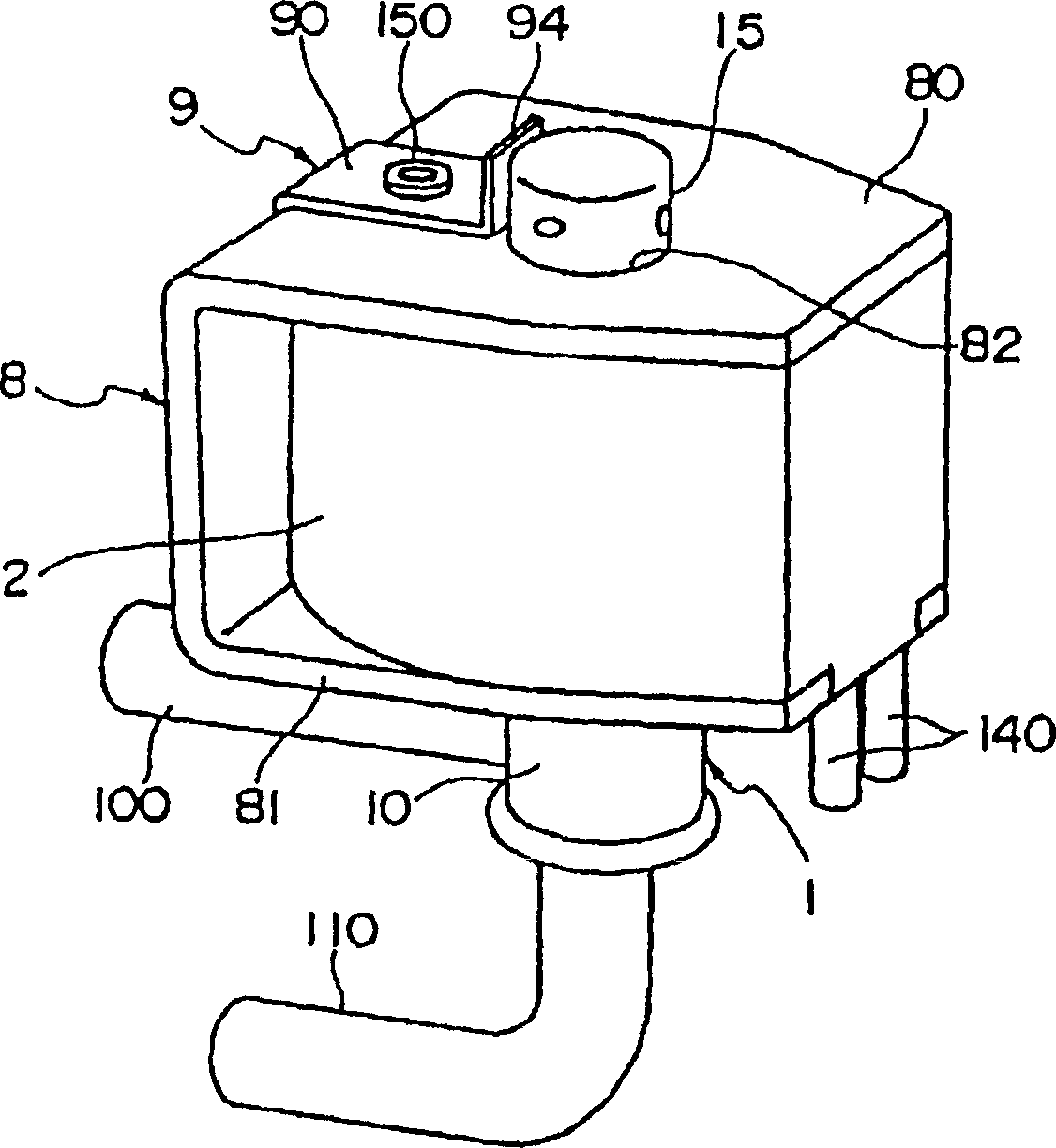

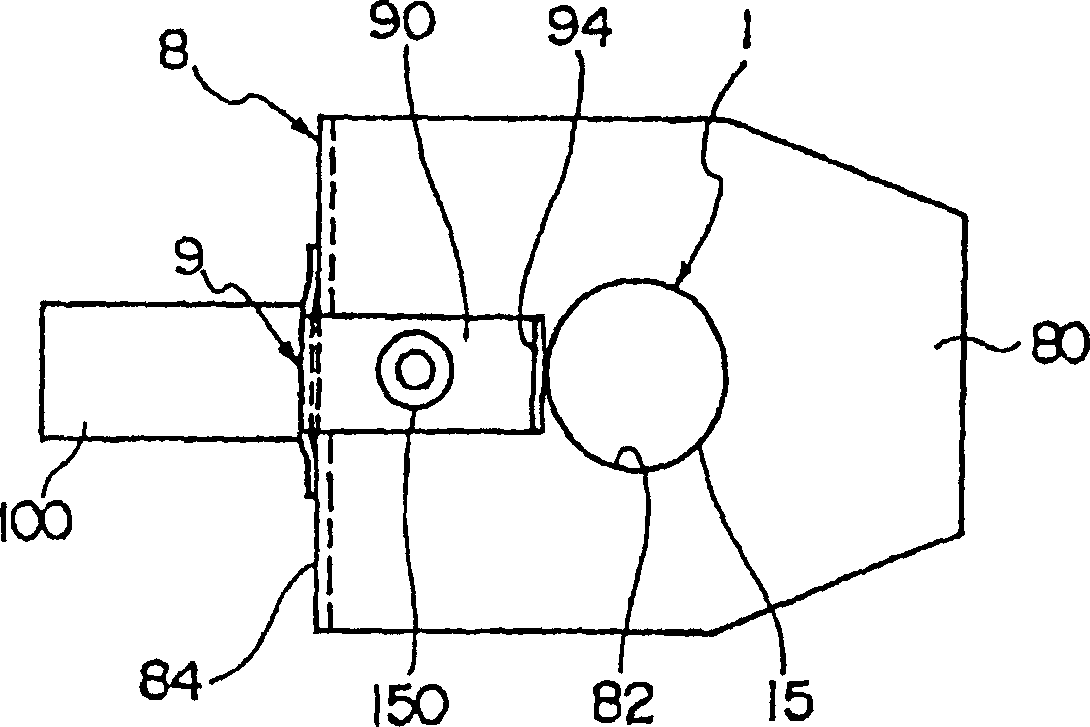

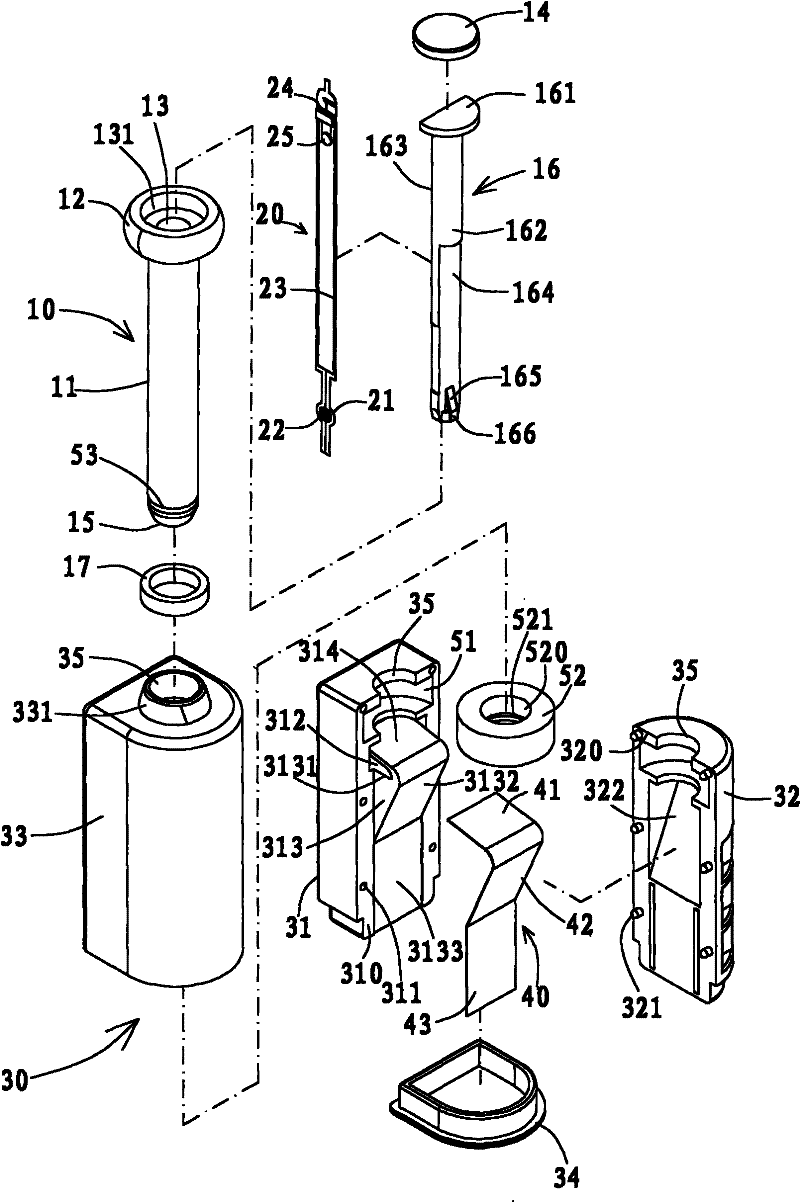

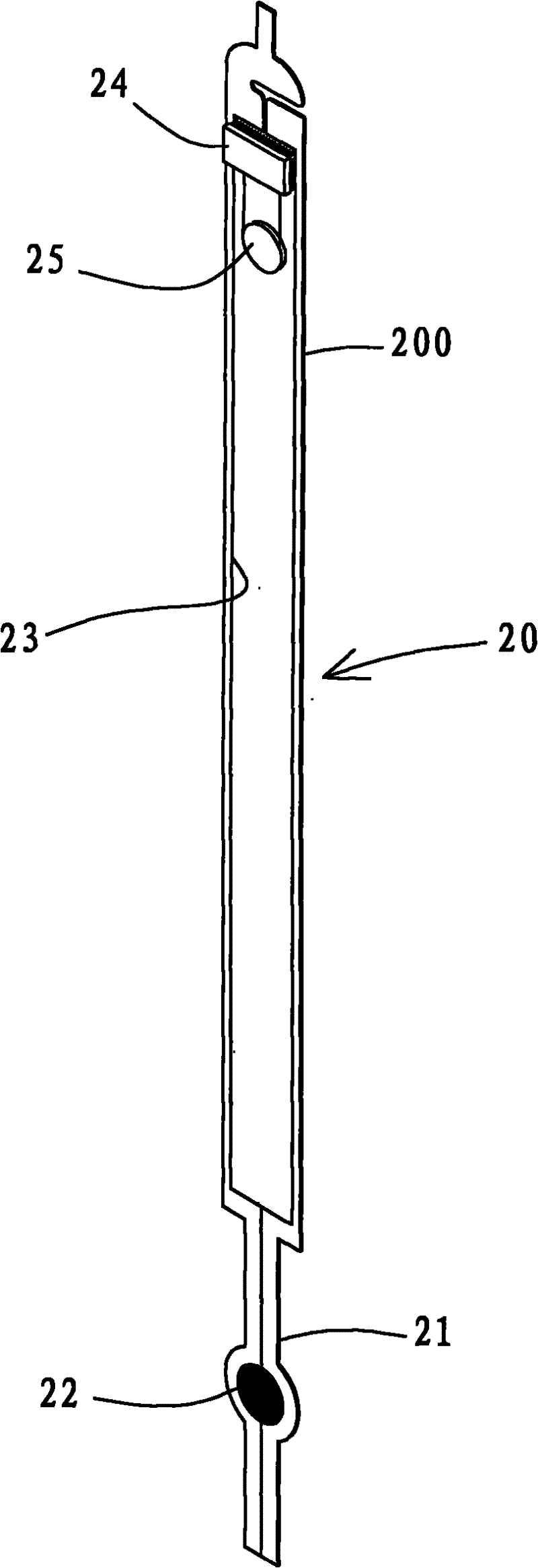

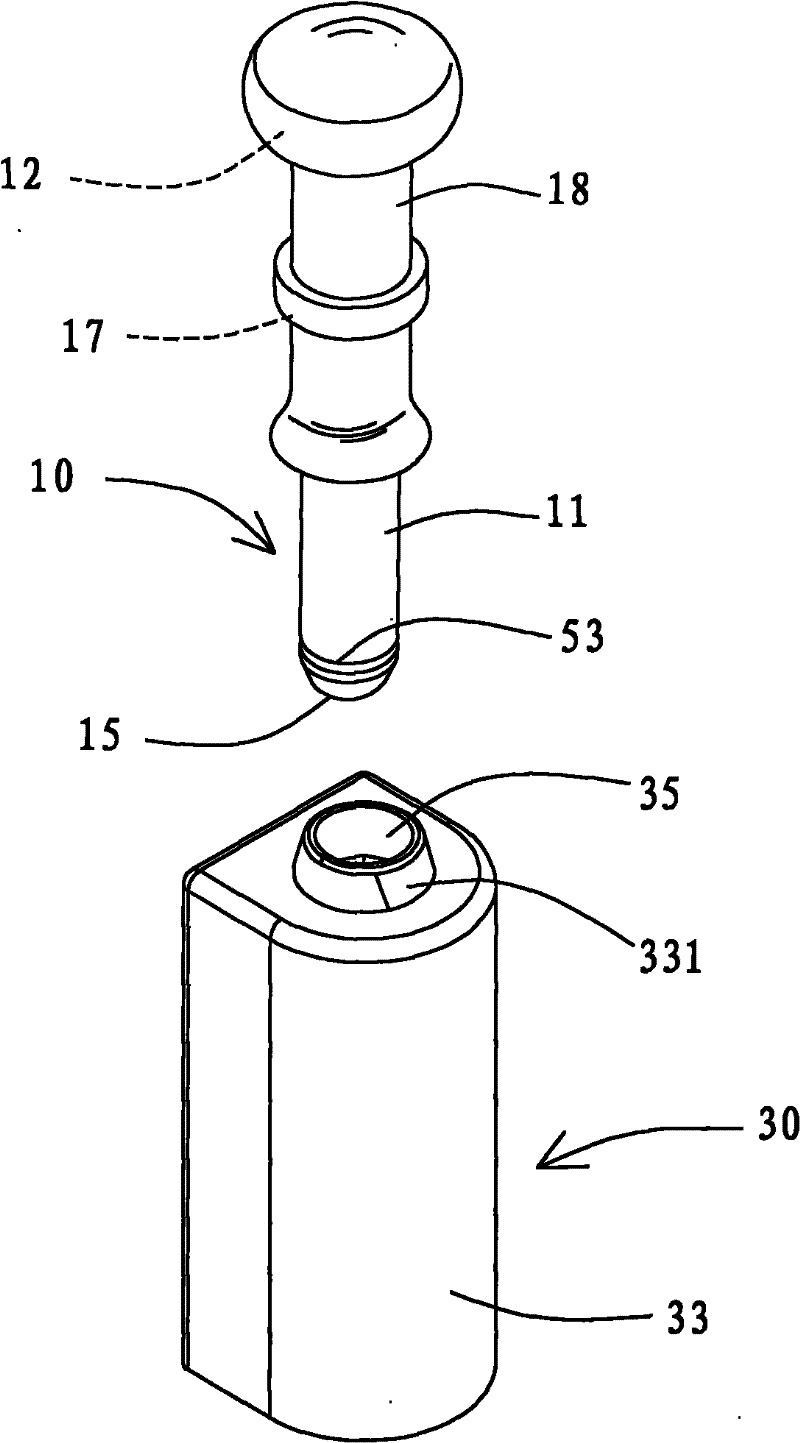

Solenoid valve

InactiveCN1432746AEasy to assembleImprove liquidityOperating means/releasing devices for valvesLift valveElectricitySolenoid valve

The present invention can facilitate mobility of fluid in a solenoid valve when opening and shutting the valve by separating and connecting a valve body with respect to a valve seat with magnetic force of a solenoid coil. The solenoid valve is provided with a valve main part 1, the solenoid coil 2, a suctioner 3, the valve body 4, a plunger 5 connecting with the valve body 4, a valve-seat sheet member 6 forming the valve seat 61, and a coil spring 7 arranged between the suctioner 3 and the plunger 5. When electricity is applied to the solenoid coil 2, a magnetic force caused by electric conduction of the solenoid coil 2 is generated on the suctioner 3, and the plunger 5 moves toward the suctioner 3 while resisting to urging force of the coil spring 7. The valve body 4 moves toward the valve seat 61 of the valve-seat sheet member 6 together with the plunger 5, the valve body 4 is firmly touched with the valve seat 61 of the valve-seat sheet member 6, and the solenoid valve performs a closing-valve operation. A clearance 17 is formed between a pipe portion 15 and the suctioner 3, and caulked portions 20 are provided in a plurality of places by caulking so as to maintain the clearance.

Owner:FUJIKOKI MFG CO LTD

High surface area adsorbents and method of preparation

InactiveUS6235802B1Improve physical stabilityLittle or no swelling in organic solventsCation exchanger materialsOther chemical processesPorosityOrganic sulfonic acid

A process for the preparation of high surface area, low-swelling macroporous polymeric adsorbents is disclosed. The use of organic sulfonic acids to provide postcrosslinking of macroporous copolymers eliminates the need for traditional organic swelling solvents and Lewis-acid catalysts used to provide conventional macronetted polymers. In particular, methanesulfonic acid provides macroporous polymeric adsorbents having high surface area and porosity, low levels of residual vinyl groups, and free of residual contaminants from conventional Lewis-acid / Friedel-Crafts reactions.

Owner:ROHM & HAAS CO

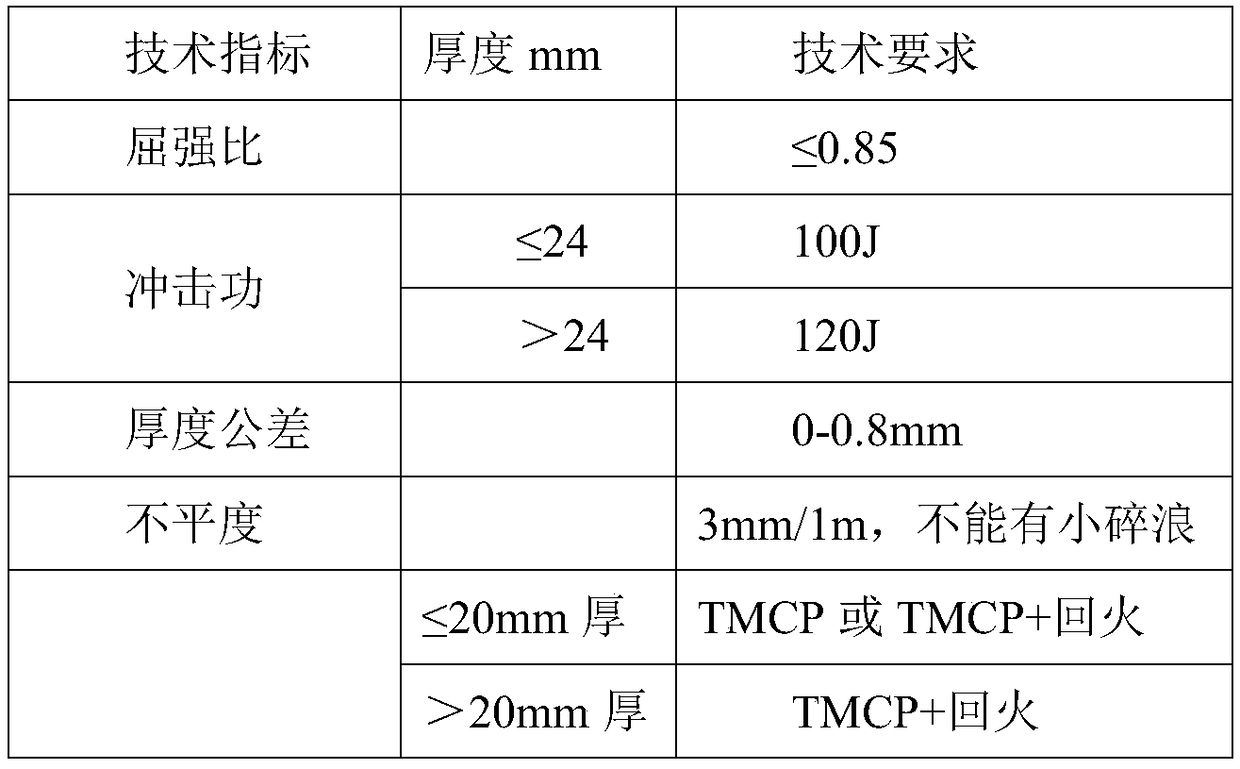

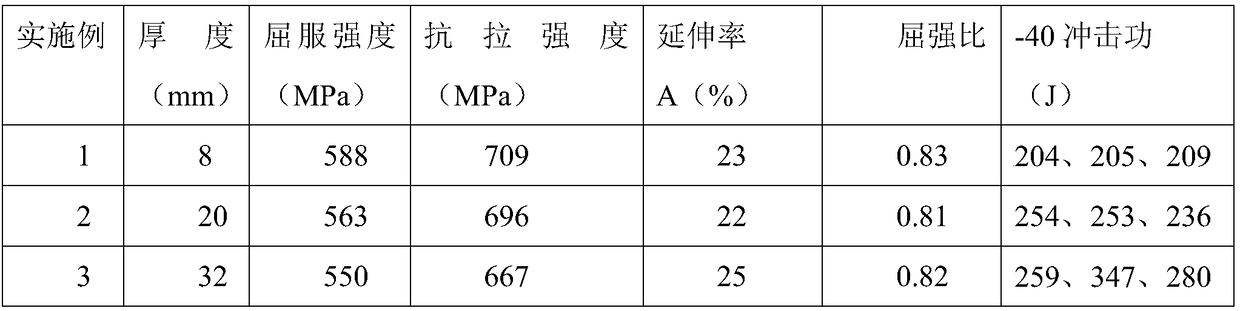

Q500qE bridge steel plate and production method thereof

ActiveCN108624744APrecise control of water temperaturePrecisely control the red temperatureSheet steelYield ratio

The invention relates to the technical field of bridge steel plate smelting, in particular to a Q500qE bridge steel plate and a production method thereof. After rolling control is finished, the steelplate is relaxed for 10-160 seconds after rolling is finished, and then enters a laminar flow cooling area to be cooled to 300-650 DEG C with the cooling rate of 20 DEG C / s; and the relaxation time and the finished cooling temperature of steel plates of different thicknesses are different. After the steel plate is subjected to controlled cooling, the steel plate is straightened for more than two passes through a heat straightening machine, the poor external plate shape caused by online quenching is eliminated, then the steel plate is cooled to below 400 DEG C on a cooling bed and then is straightened by a cold straightening machine, the finished straightening temperature is controlled to be 200-400 DEG C, and the poor plate shape caused by transformation stress is eliminated. The Q500qE bridge steel plate and the production method thereof have the advantages that the yield ratio is low, the welding performance is good, the plate shape is good, the production process is simple in procedure, the production period is short, and the production cost is low.

Owner:ANGANG STEEL CO LTD

Apparatus and catalytic partial oxidation process for recovering sulfur from an H2S-containing gas stream

InactiveUS7357908B2Efficient processingReduce contact timeCombination devicesExhaust apparatusCombustorPartial oxidation

Owner:PHILLIPS 66 CO

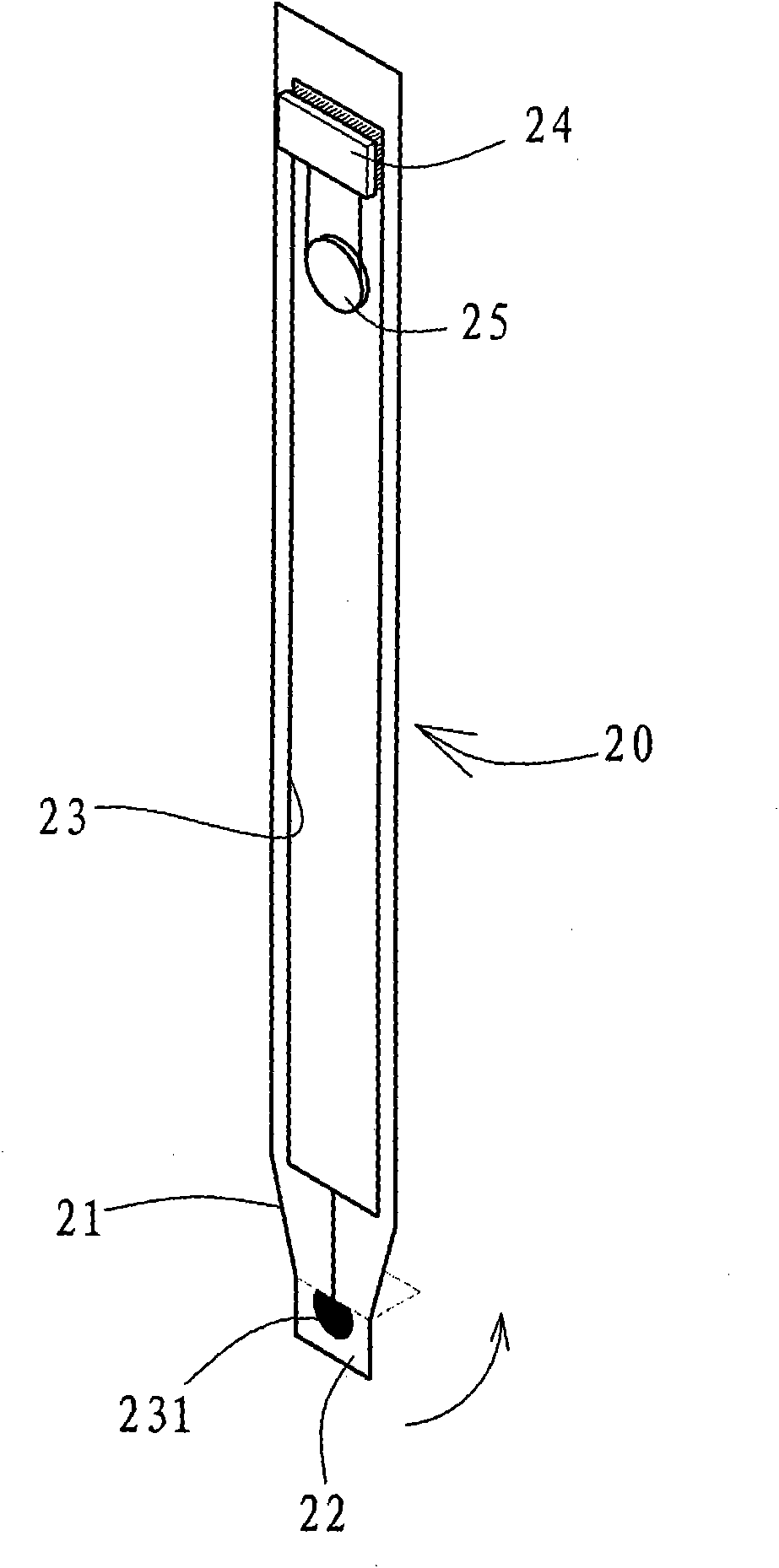

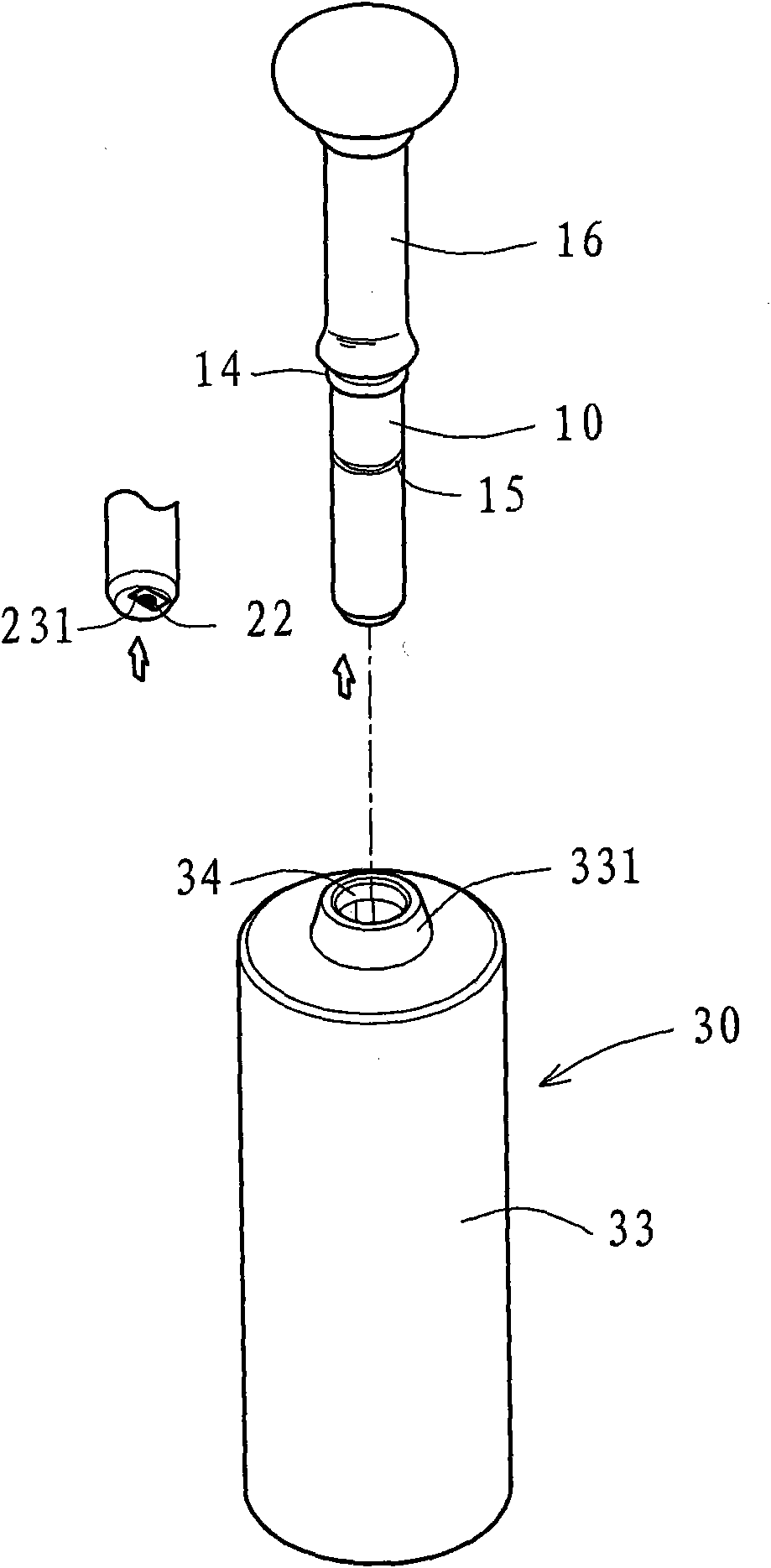

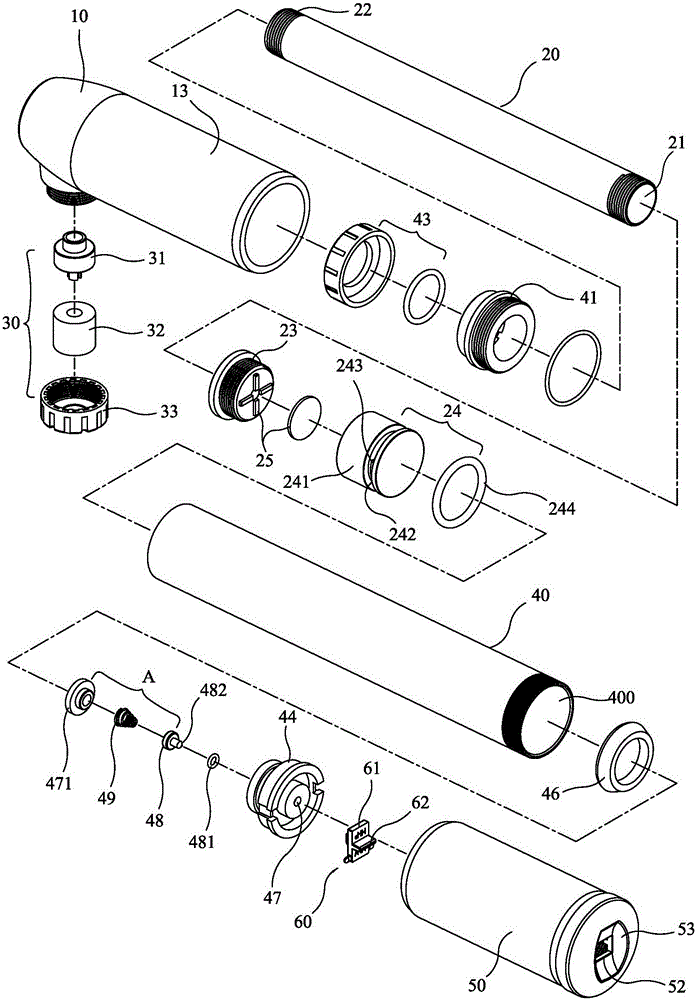

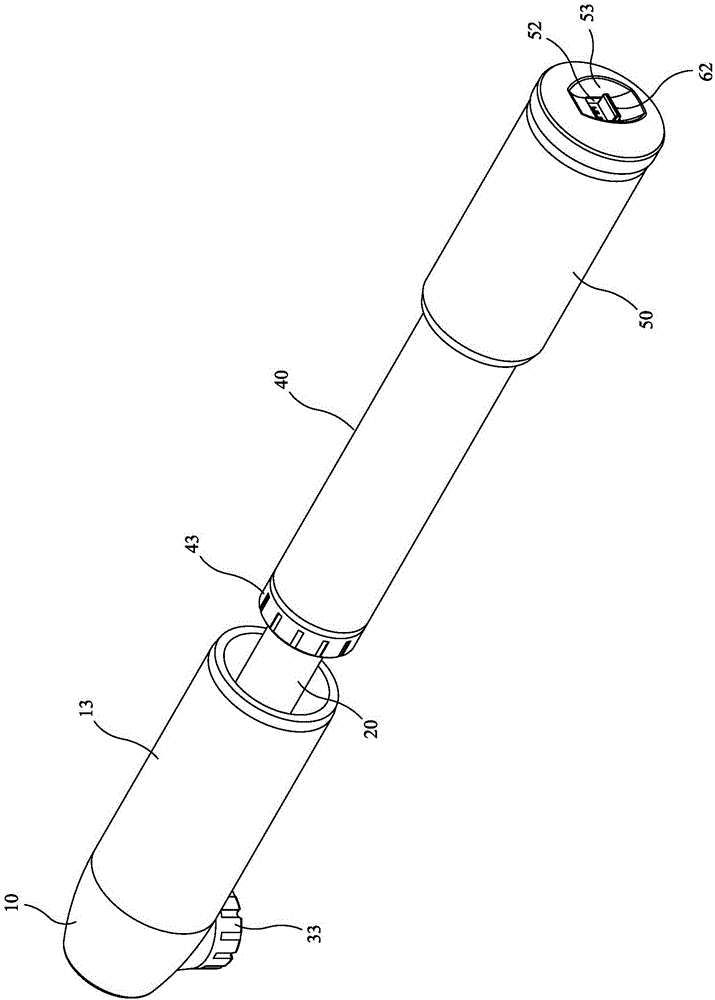

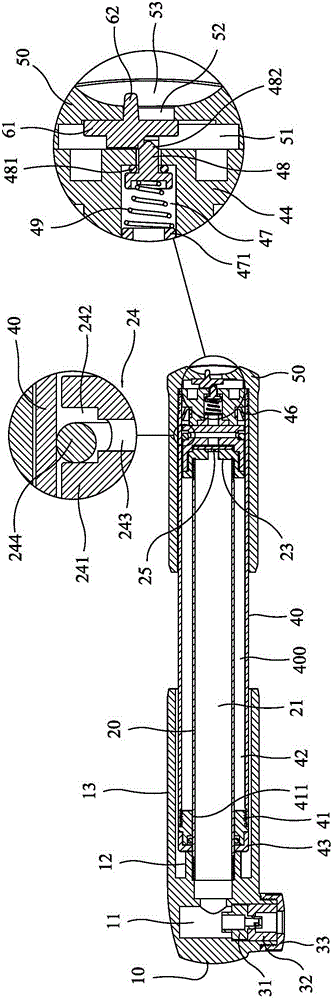

Electronic seal

ActiveCN102542316AImprove assembly efficiencyEliminate badRecord carriers used with machinesEngineeringElectrical bonding

Owner:陈志权

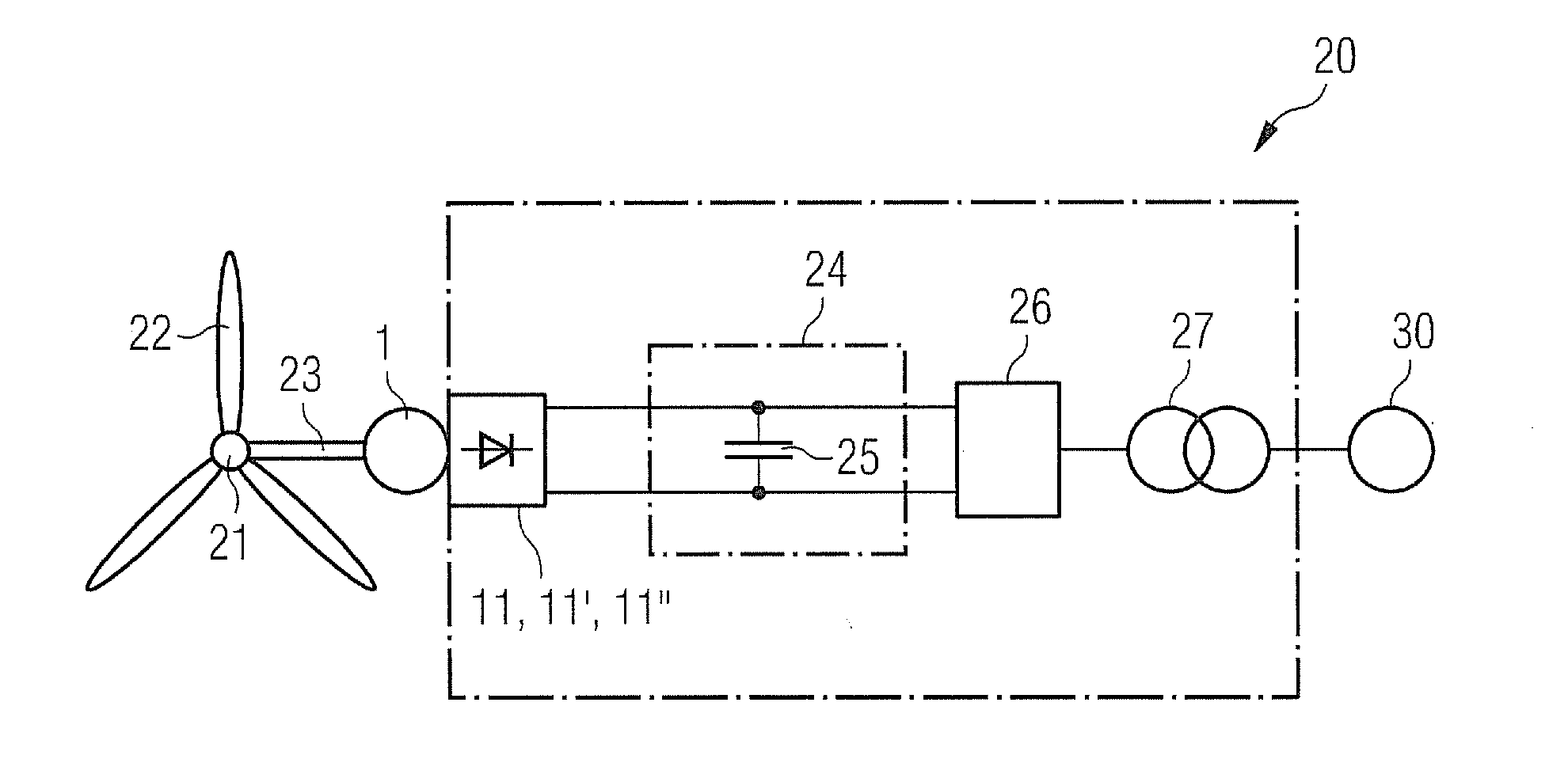

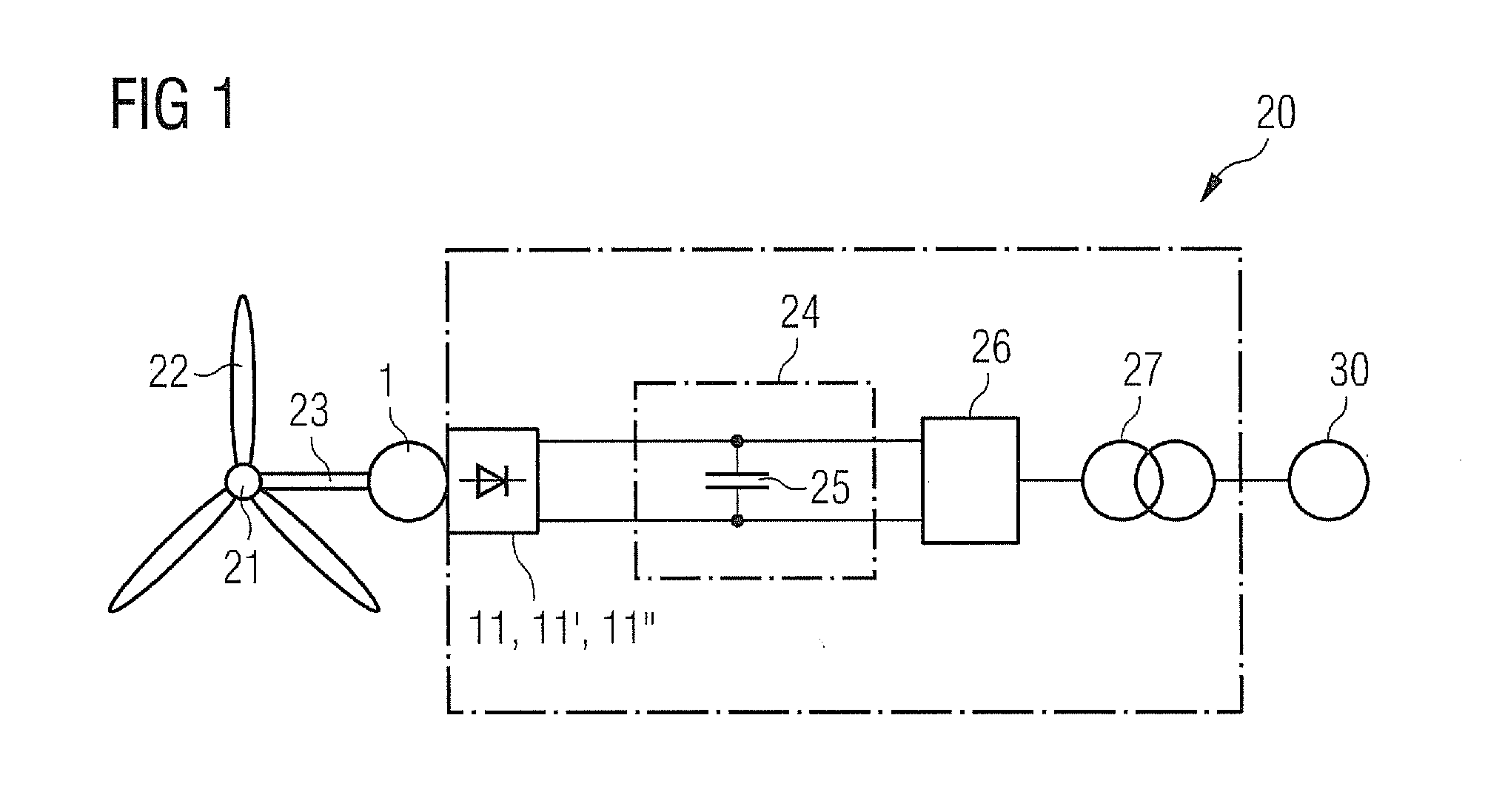

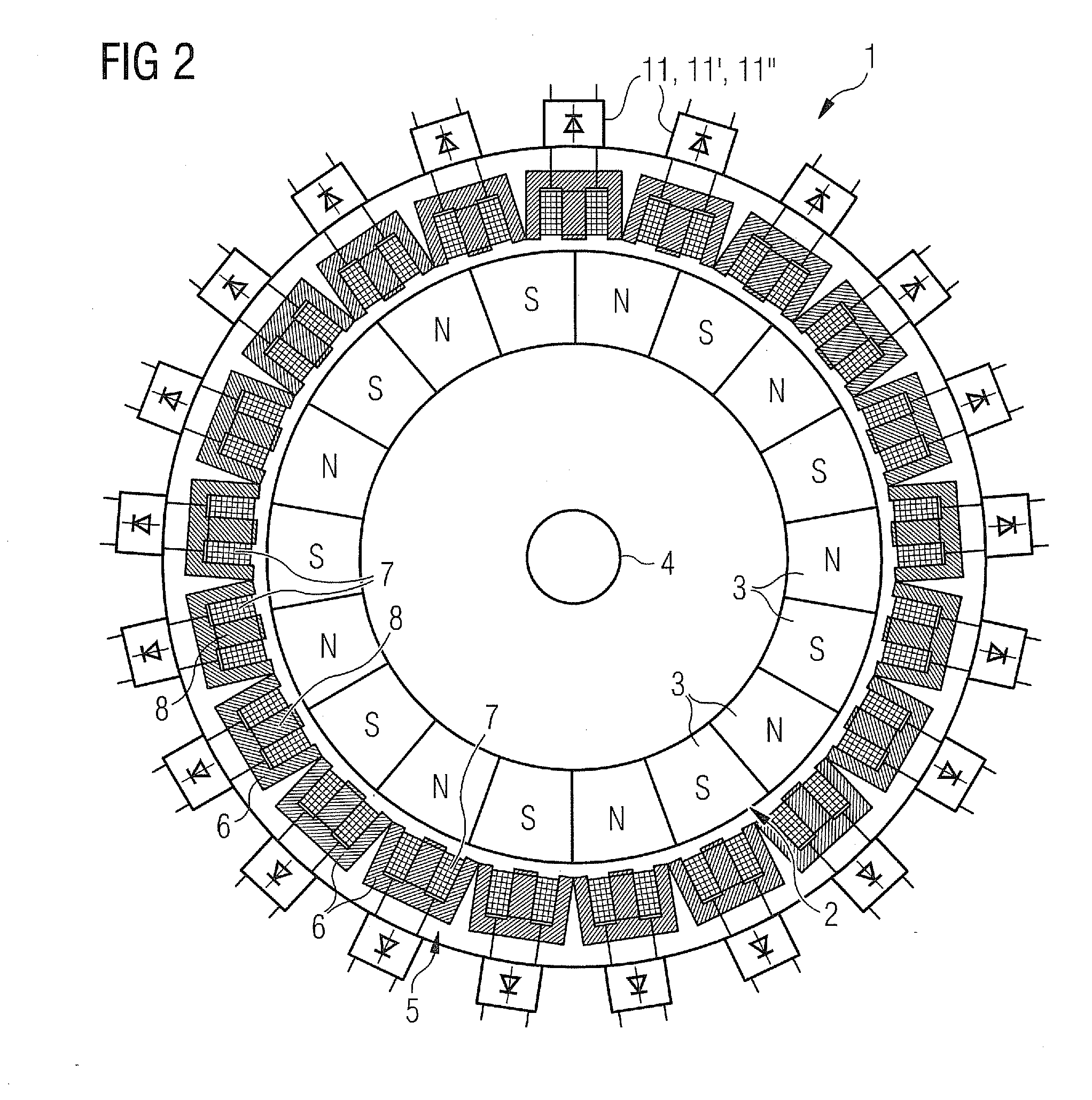

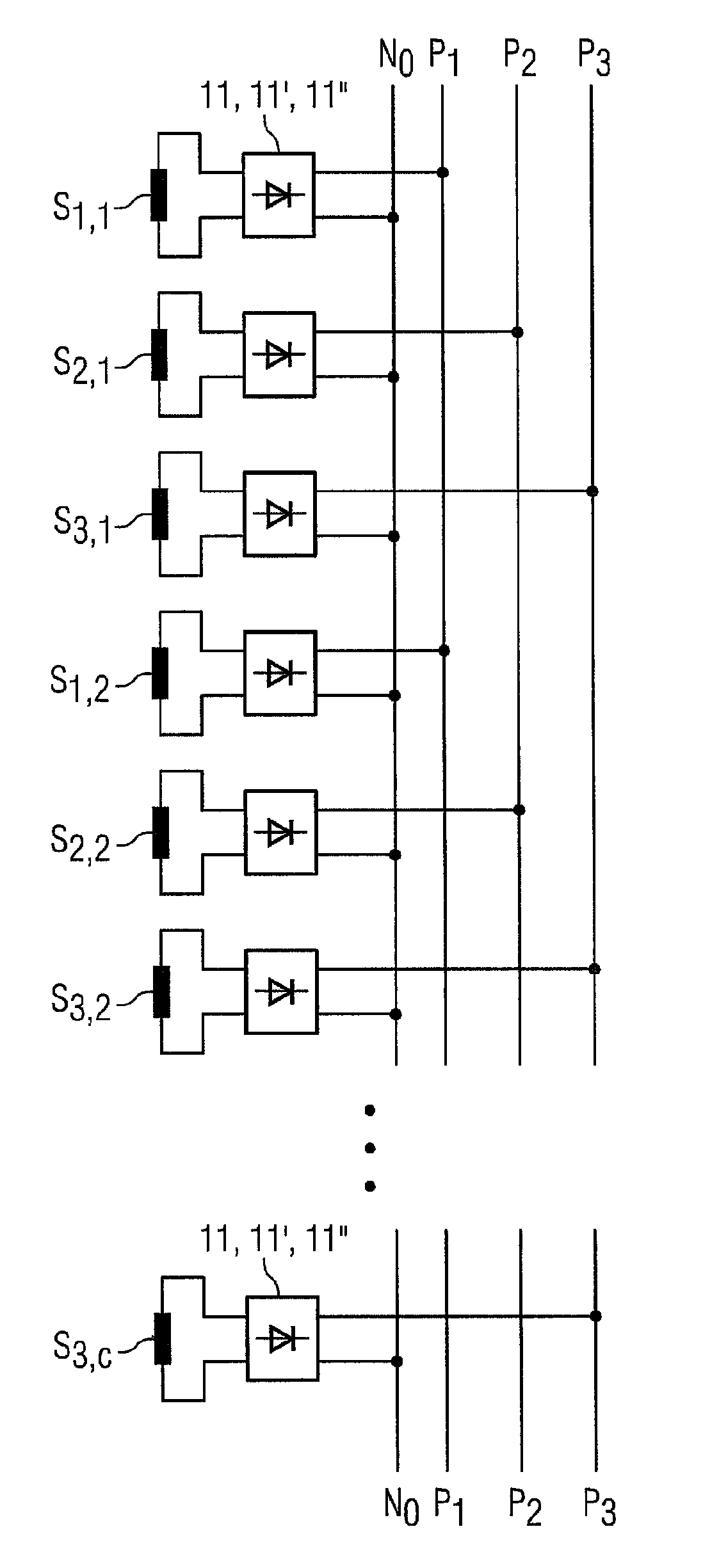

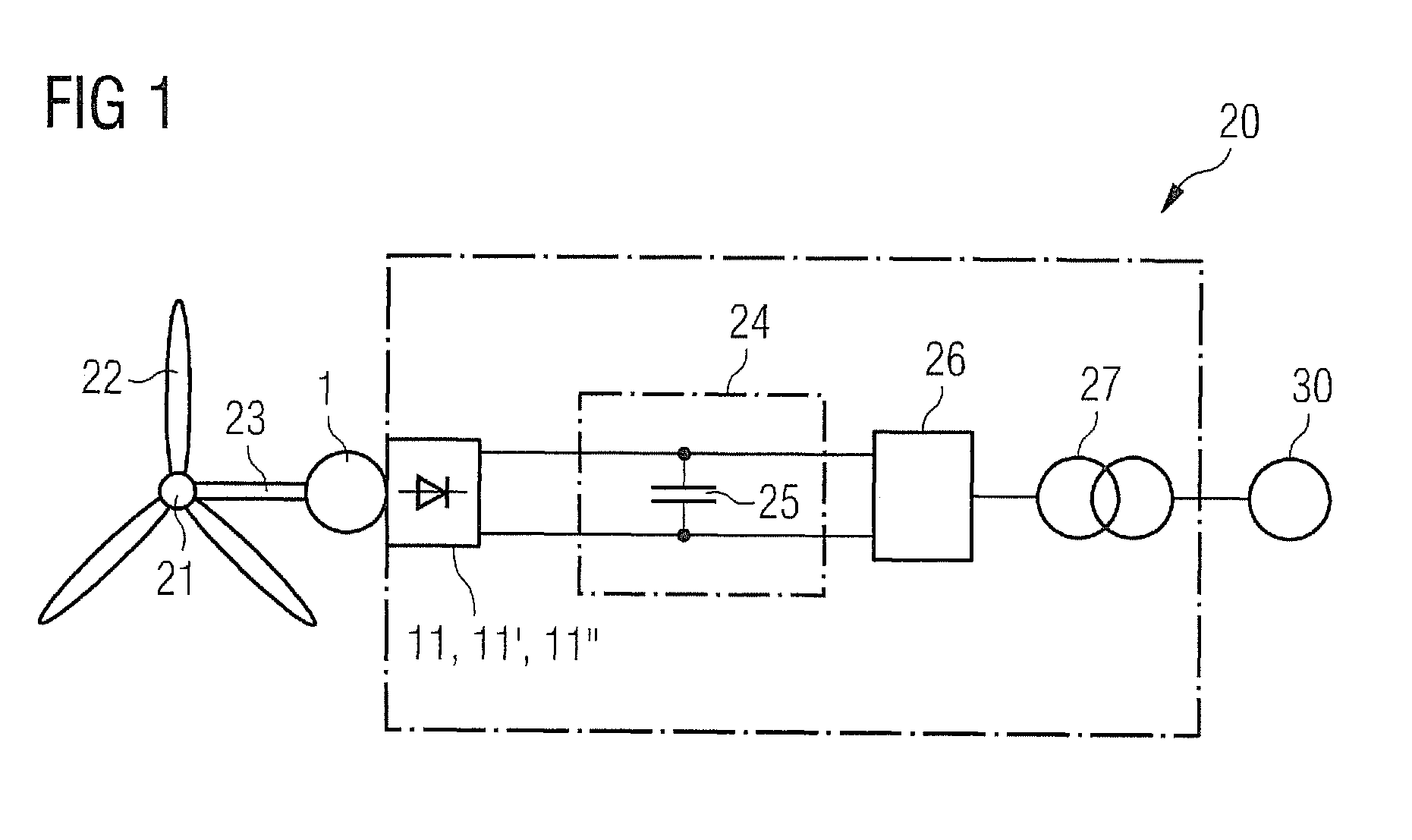

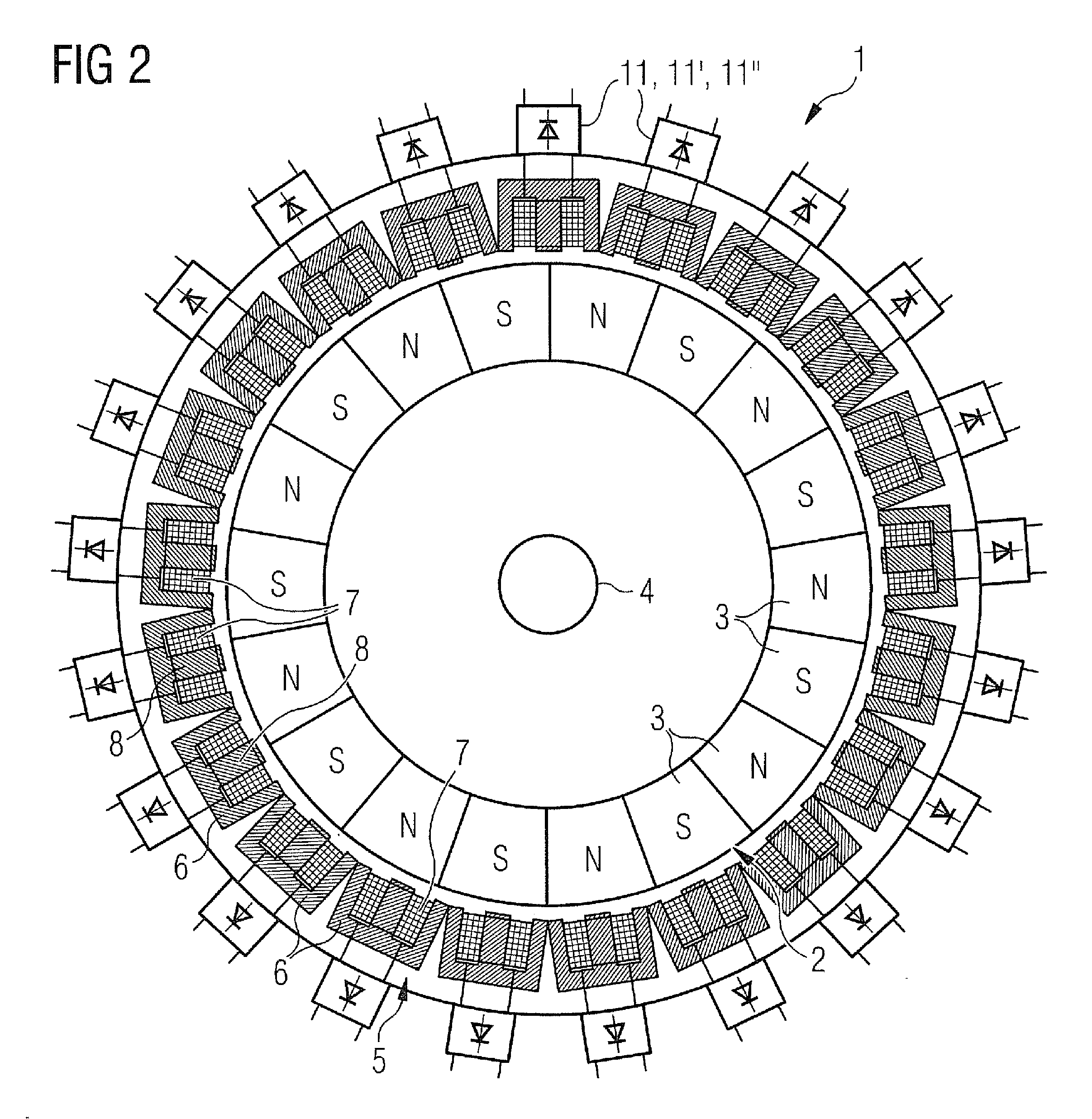

Generator, wind turbine, method of assembling a generator and use of a generator in a wind turbine

InactiveUS20110316287A1Simple configurationSmall sizeSynchronous generatorsMachines/enginesStator coilEngineering

A generator is provided comprising a rotor with a number of magnetic rotor pole shoes, a stator with a number of stator coils wound on the stator, and a generator-utility grid interface comprising a plurality of diode rectifiers, each diode rectifier is connected to a stator coil and the number of stator coils is greater than the number of rotor pole shoes, or the number M of rotor pole shoes is greater than, but not an integer multiple of, the number of stator coils. A wind turbine utilizing the generator of the present invention and a method of assembling such a generator are provided

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

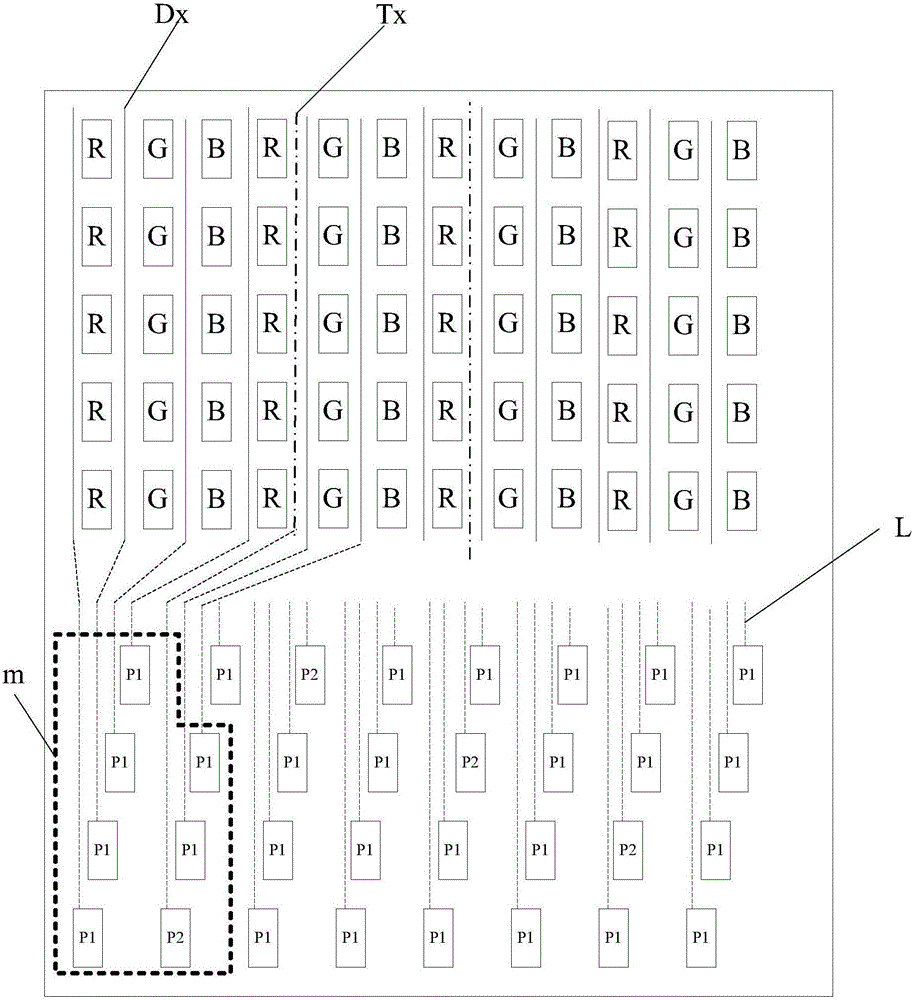

Touch display panel and display apparatus

InactiveCN106598346AReduce manufacturing costEliminate badNon-linear opticsInput/output processes for data processingComputer scienceSignal lines

The invention discloses a touch display panel and a display apparatus. Lead terminals corresponding to pins of a touch driving chip in the touch display panel are arranged in a matrix, and at least one second terminal corresponding to a touch signal line is arranged in each row or column of the lead terminals, so that first terminals corresponding to data lines and the second terminals corresponding to the touch signal lines are arranged in a mixed way, and leads corresponding to the data signal lines and leads corresponding to the touch signal lines are arranged on a same layer. Compared with the prior art, a layer of metal and a corresponding fabrication process do not need to be additionally added for fabricating the leads corresponding to the touch signal lines separately, so that the fabrication cost can be reduced; and meanwhile, the problems of various bad phenomena and relatively large occupied space of wiring caused by additional metal routing can be solved, so that the product yield is increased.

Owner:BOE TECH GRP CO LTD +1

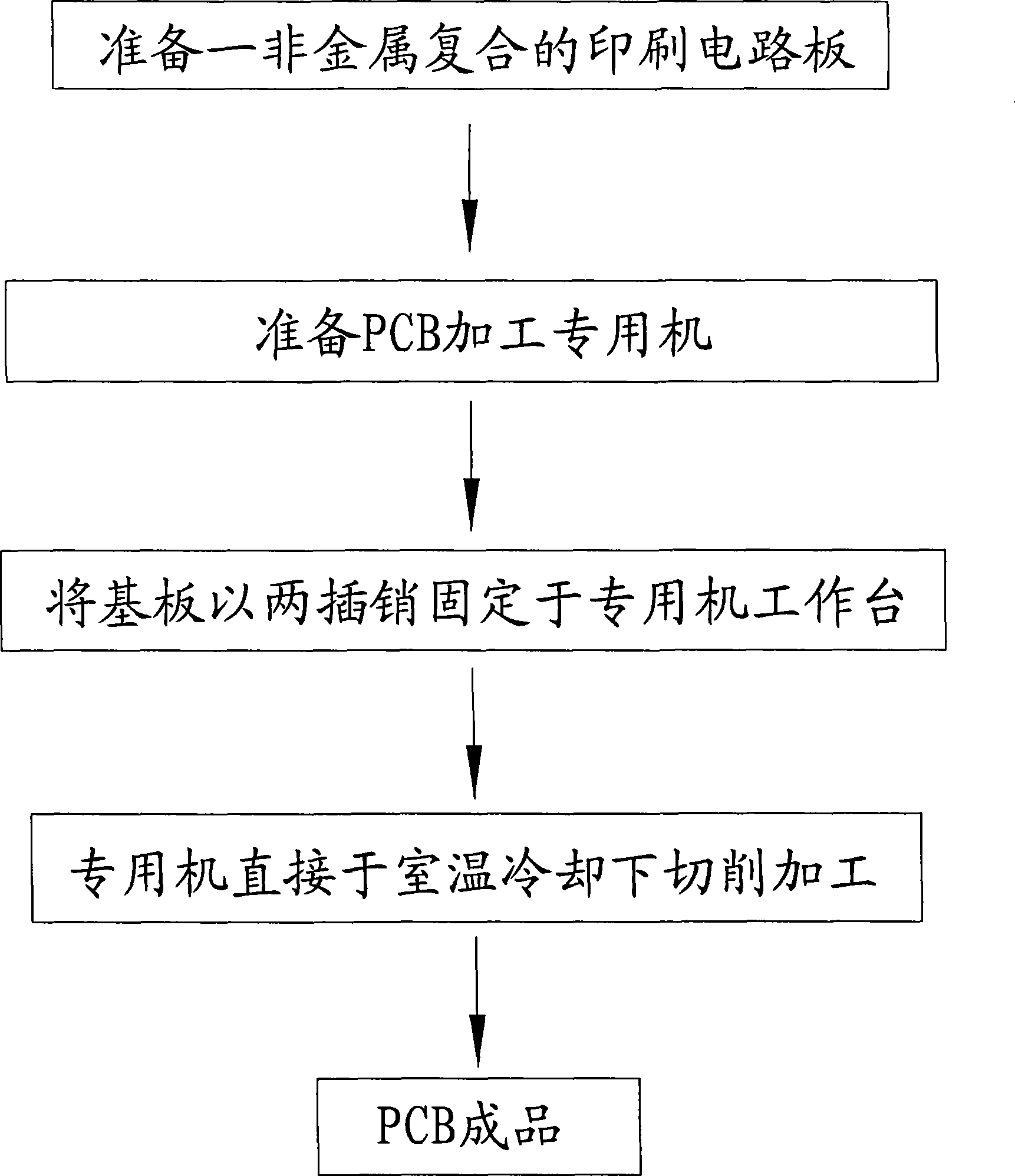

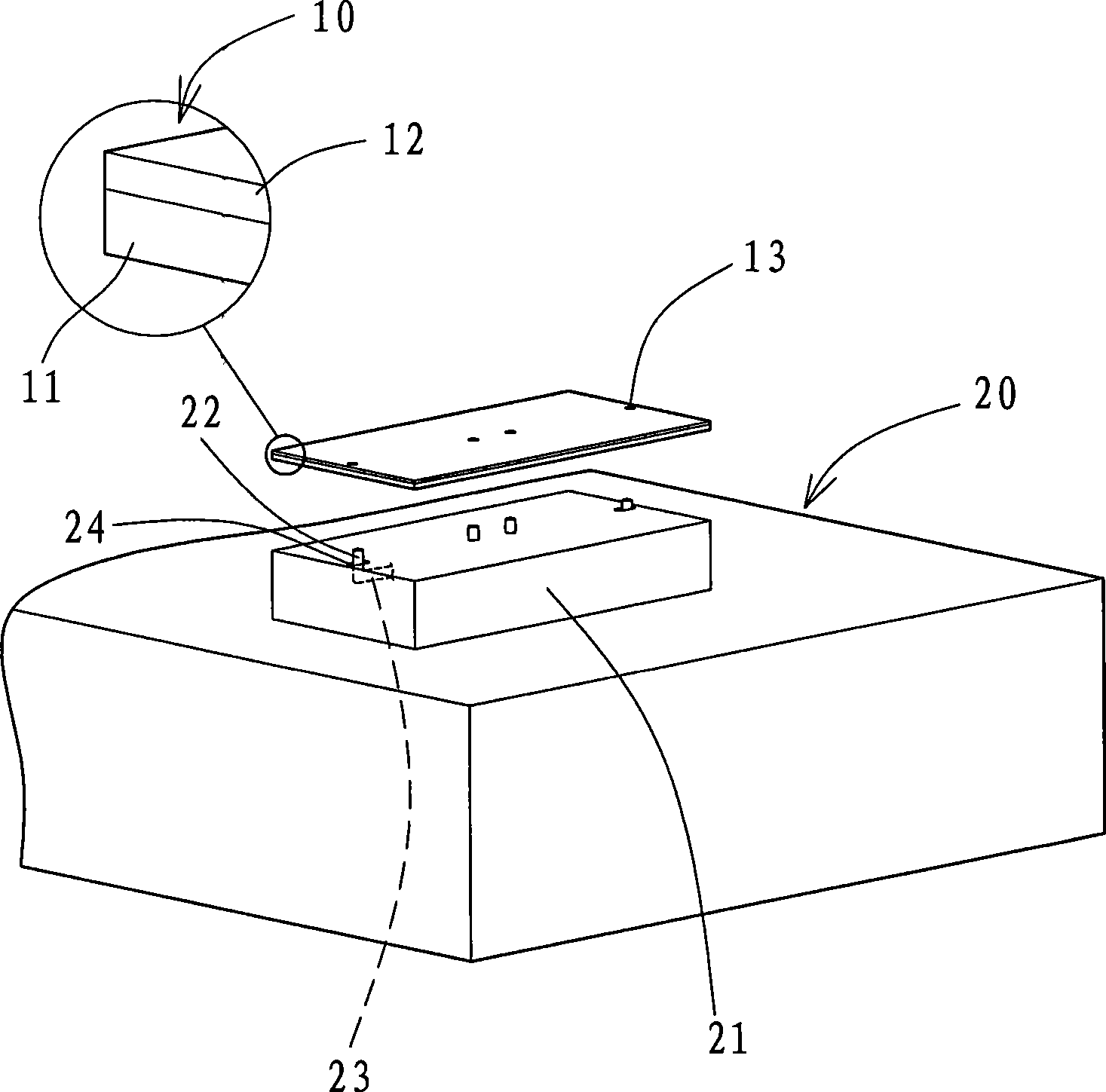

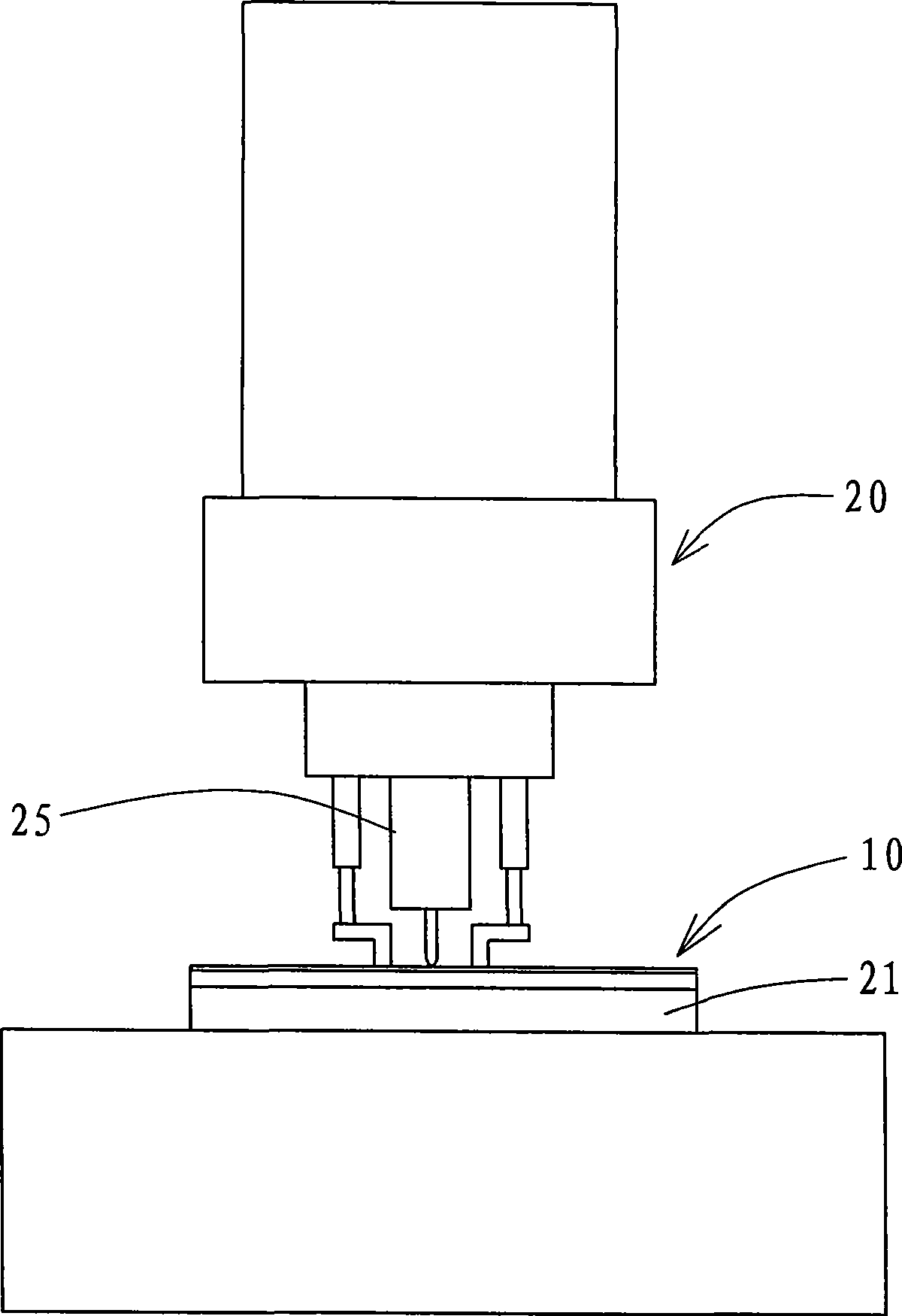

Production method for printed circuit heat radiation board

InactiveCN101489352ANot afraid of the problem of high loss rateEasy chip removalPrinted circuit manufactureMilling equipment detailsEngineeringCopper

The present invention provides a method for preparing cooling plate of printed circuit. Firstly a double layer metal cooling plate compounding aluminum and copper is firstly prepared, wherein the cooling plate is etched with a wiring circuit pattern on the surface of copper layer. Then the cooling plate is fixed on a platform with a vacuum absorption mode. The platform is installed on a processor and is provided with a positioning structure for locating the cooling plate. The limiting of main shaft of processor has high cutting torsion and strong structural property compared with the known PCB processing special machine. The main shaft can execute cutting to the cooling plate on the platform after assembling the cutter. Simultaneously the cutting position can be executed with temperature dropping and chip removal with a mode of forced cooling for quickly completing the procession of a high-quality cooling plate.

Owner:SHENQ FANG YUAN TECH

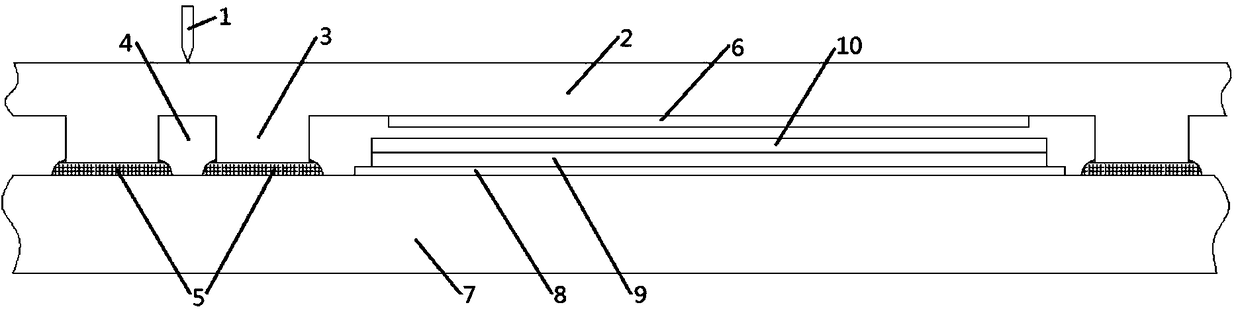

Method for photoetching of LED wafer without mask plate

ActiveCN103515492AInhibit sheddingLow costPhotomechanical apparatusSemiconductor devicesEngineeringMetal electrodes

The invention provides a method for photoetching of an LED wafer without a mask plate. The method makes good use of the light-proof characteristics of metal electrodes, carries out exposure on negative photoresist from the back face of the substrate of the LED wafer, achieves accurate self-aligned photoetching, and overcomes the defects that SiO2 above the electrodes cannot be etched off completely due to the fact that the alignment accuracy of a photoetching machine is insufficient in a traditional SiO2 layer trepanning technology, a SiO2 layer is made to be tightly connected with the electrodes, the SiO2 on the electrodes is completely eradicated from falling off, and therefore the problem that wires cannot be bonded in follow-up wire bonding is solved. In addition, according to the method, only a simple photoetching machine is needed, no photoetching plate is needed, the expensive cost of photoetching machine devices and photoetching plates is saved, poor products caused by alignment errors are eliminated, working efficiency is improved, and the SiO2 trepanning manufacturing cost in the manufacturing process of LED chips is reduced greatly.

Owner:EPILIGHT TECH

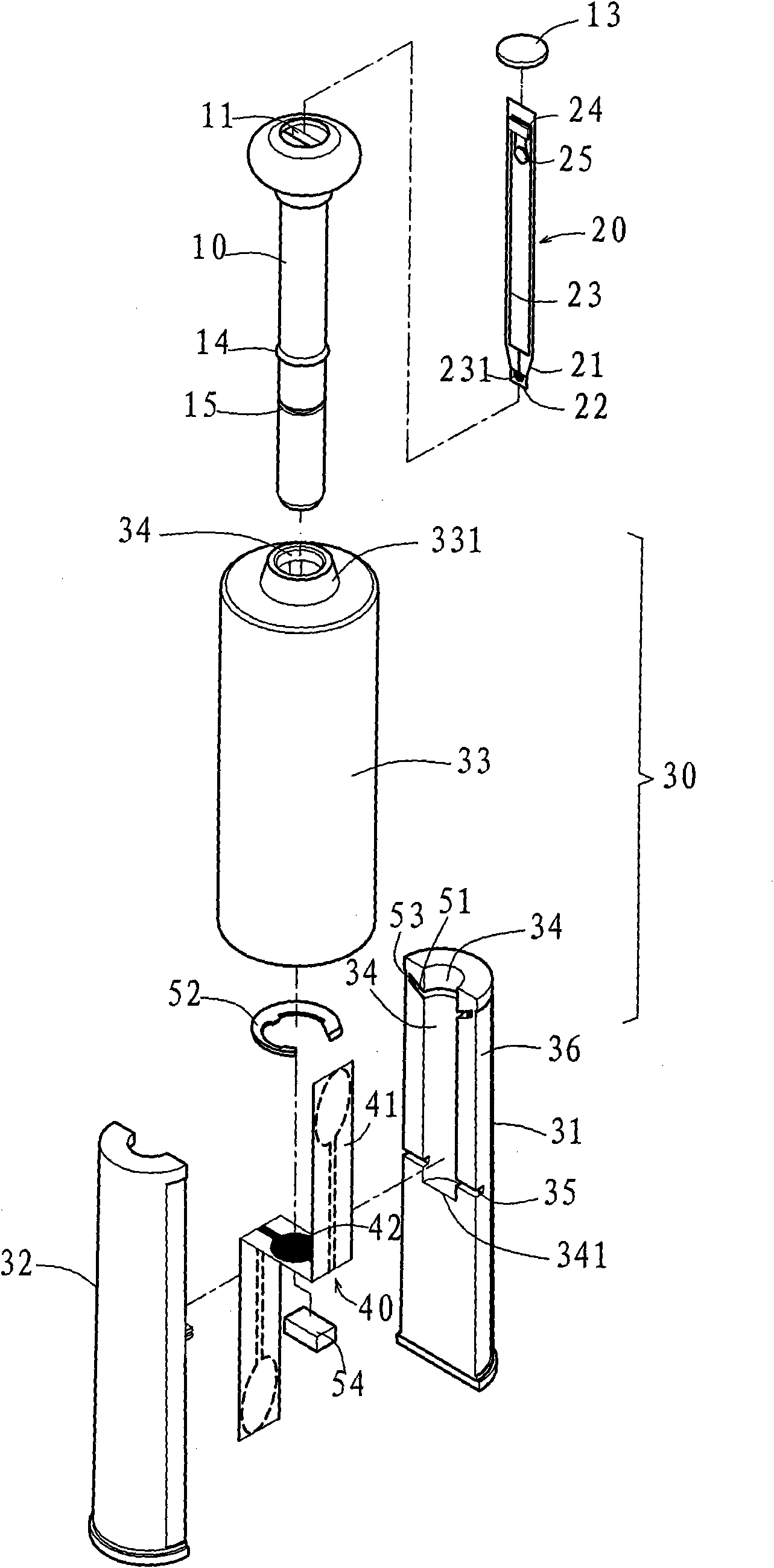

Electronic sealing strip

The invention discloses an electronic sealing strip. The electronic sealing strip comprises a lock rod, a circuit board, a lock head into which the lock rod can be inserted, and an antenna which can be matched with a radio frequency identification (RFID) chip, wherein the lock rod is provided with an accommodating chamber which passes through a bottom surface; the circuit board is fixedly arranged in the accommodating chamber and is provided with a printed circuit and the RFID chip arranged in the printed circuit; the lock head is provided with a buckling device which ensures that the lock rod cannot retreat; the antenna is arranged in the lock head; when the lock rod is inserted into the lock head, the antenna, the printed circuit and the RFID chip are in electric connection directly; and when the lock rod is cut off, the electric connection is interrupted, so that an identification host arranged in customs can have the function of quickly identifying and managing containers. The electronic sealing strip with the structure has economic benefits and can effectively overcome the defects that the cost is soaring and the quality cannot be improved in the conventional electronic sealing strip.

Owner:陈志权

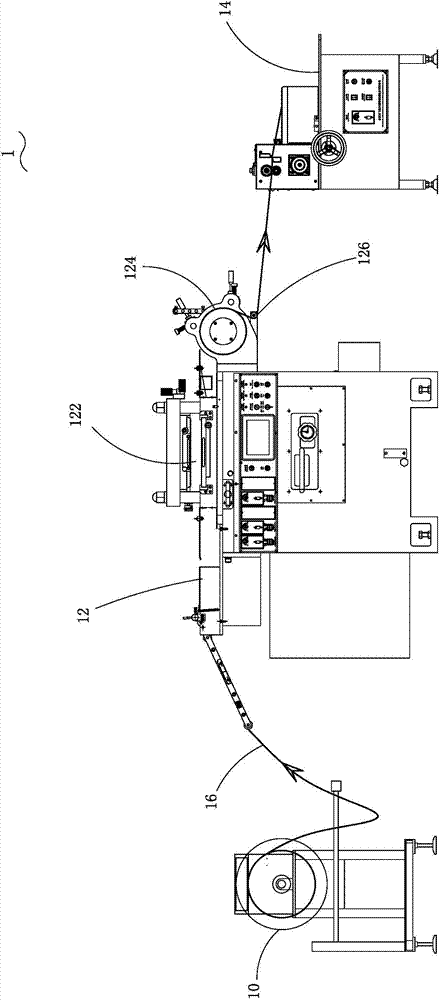

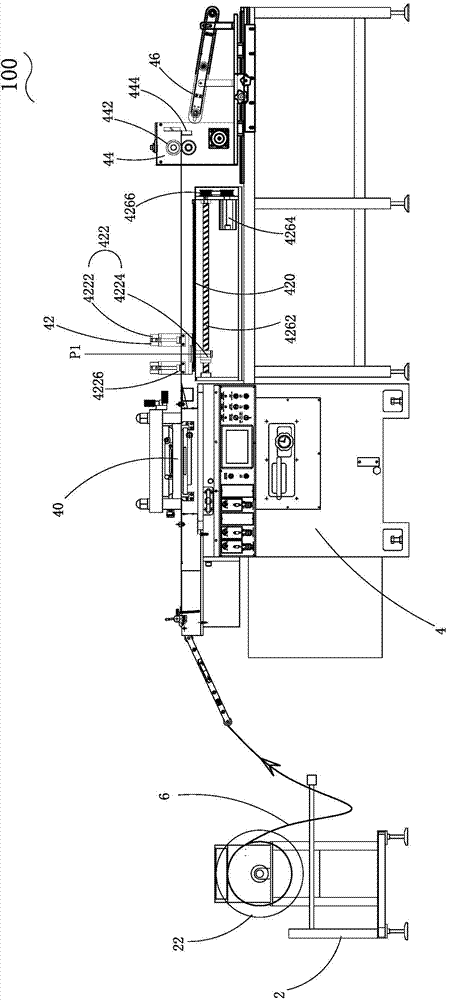

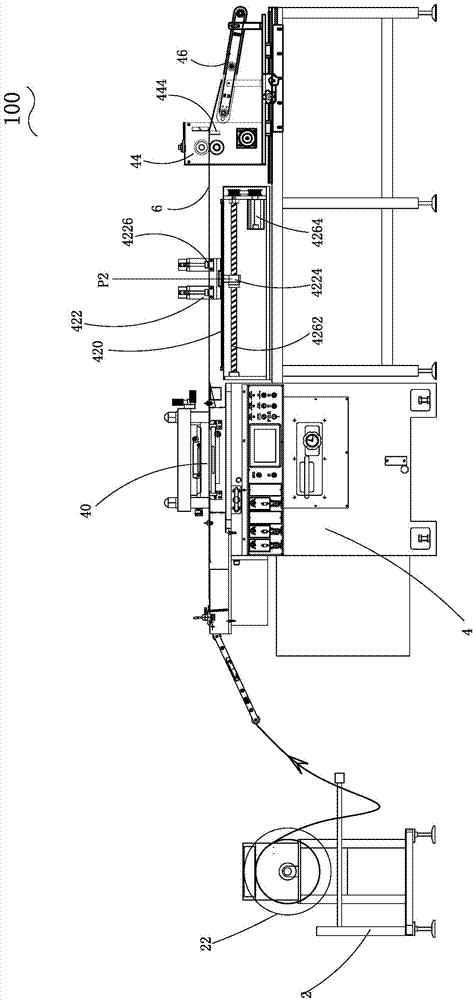

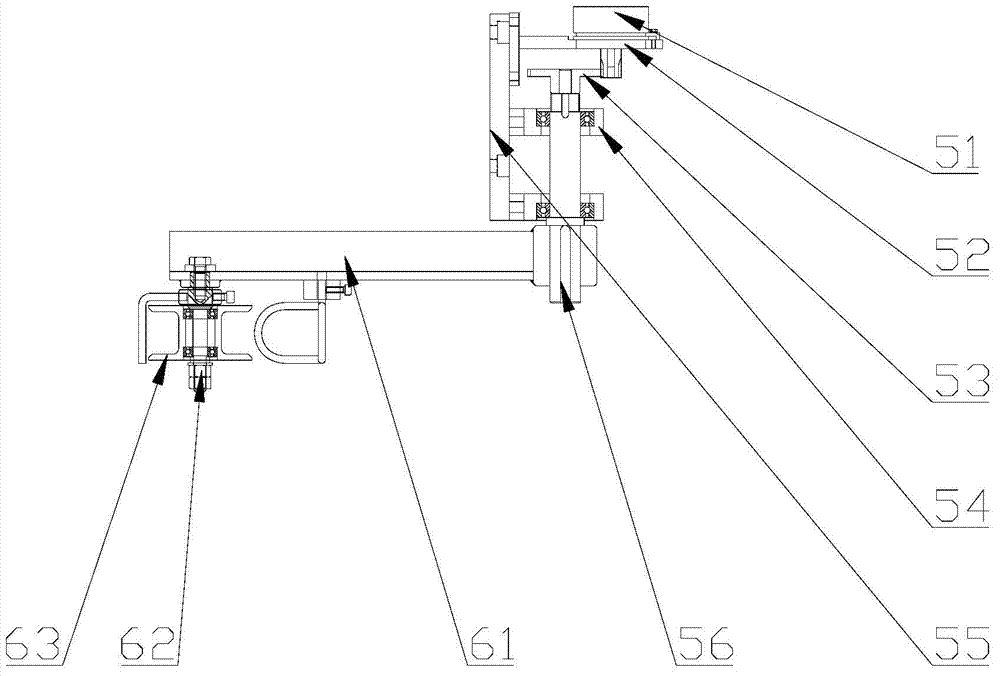

Die cutting machining device and method

The invention relates to a die cutting machining device and method. The die cutting machining device comprises a feeding machine and a die cutting machine. The feeding machine is used for feeding raw materials to the die cutting machine. The die cutting machine comprises a die base, a material pressing device and a slicing device. The die base is used for conducting half-cutting machining on the fed raw materials. The material pressing device comprises a guide rail, a material pressing component capable of conducting back-and-forth linear movement on the guide rail and a drive component for driving the material pressing component to move on the guide rail. The material pressing component can tightly press and fix the raw material obtained after half-cutting machining is conducted to the material pressing device and then drive the raw materials to conduct linear movement synchronously so as to feed the raw materials into the slicing device to be sliced. By means of the die cutting machining device and method, the raw materials can be fed into the slicing device in a linear mode, and the percent of pass of products is improved beneficially.

Owner:GUANGDONG FXD INTELLIGENT EQUIP CO LTD

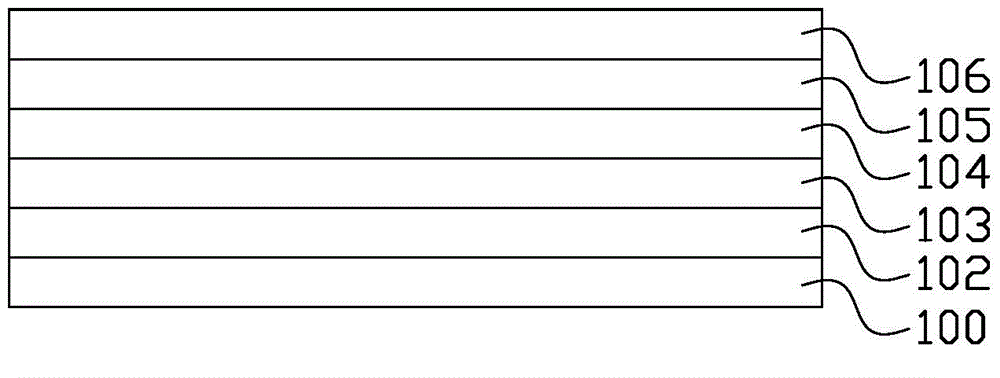

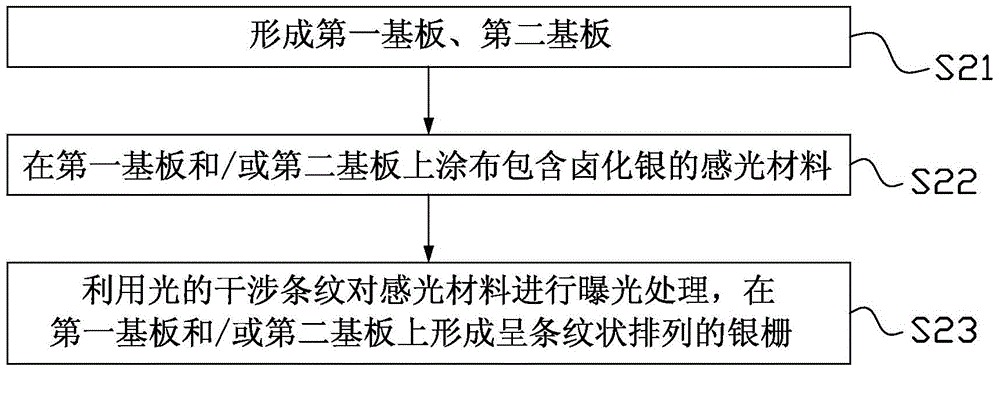

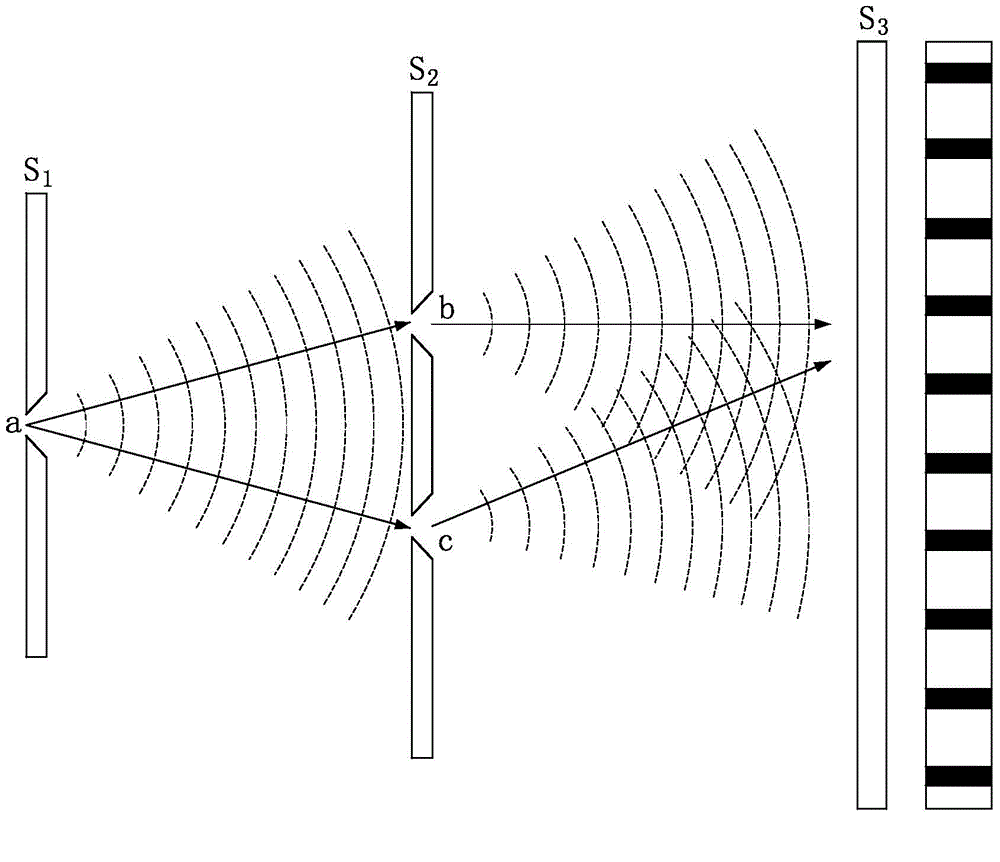

Liquid crystal display panel and production method thereof

The invention provides a liquid crystal display panel and a production method thereof. The liquid crystal display panel includes a first substrate, a second substrate and a liquid crystal layer clamped between the first substrate and the second substrate. The first substrate is a thin film transistor array substrate, and the second substrate is a colored optical filter substrate. Photosensitive materials containing silver halides are coated on the first substrate and the second substrate, and are subject to exposure processing through light interference fringes, and silver grates in stripe arrays are formed on the first substrate and the second substrate. The liquid crystal display panel includes the first substrate and the second substrate which are provided with polarization structures, the photosensitive materials are subject to exposure processing by aid of the light interference fringes through the polarization structures, and accordingly the silver grates in stripe arrays are formed on the first substrate and the second substrate. The liquid crystal display panel omits polaroids so the adverse effects caused by attachment of polaroids can be avoided. Meanwhile, the process is simplified and cost is reduced by omitting the procedure of attaching polaroids.

Owner:KUSN INFOVISION OPTOELECTRONICS

Pressure-changeable inflator capable of being fast switched

ActiveCN106337792ASimplify complexityEliminate badPositive displacement pump componentsPump controlEngineeringPressure release

The invention discloses a pressure-changeable inflator capable of being fast switched. According to the inflator, a movable air cylinder with a cylinder hole is provided with a rear end cover for forming a rear air chamber between the cylinder hole and the rear end cover, the rear end cover is provided with a pressure release hole communicating with the interior and the exterior of the rear air chamber, a switch valve capable of opening and closing the pressure release hole is arranged, and therefore when the pressure release hole is opened, second-section pressurization air supply of the rear air chamber can be eliminated, and the inflator can be applied in a common low-pressure inflation mode. The problems that the structure is complex, assembly consumes a lot of time and control is difficult can be solved.

Owner:昆山十全塑胶五金产品有限公司

Sealing-glue-spreading controlling method for display-panel mother board

InactiveCN108957866AAvoid breakingAvoid contactSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention provides a sealing-glue-spreading controlling method for a display-panel mother board. As etching grooves and / or an etching groove are / is formed in the outer sides and / or the outer sideof annular frame glue areas and / or an annular frame glue area of a mother cover board and / or a mother substrate, excessive spreading of sealing glue towards a cutting area in the laminating process can be effectively controlled, glue adhering between single-particle display screens after particle cutting is avoided accordingly, the production efficiency is improved, breakage, caused in the adhesive separating process, of the display screens is solved, the yield of products is increased, and the production cost is reduced; as etching grooves and / or an etching groove are / is formed in the inner sides and / or the inner side of the annular frame glue areas and / or the annular frame glue area of the mother cover board and / or the mother substrate, it can be effectively avoided that the sealing glueis in contact with display devices after laminated spreading, and it is avoided that as the sealing glue is excessively spread, the display devices are corroded; the yield of the products is increased, and the cost is reduced; in addition, due to etching grooves in cutting baths, the cutting thickness in the cutting process is thinned, the cutting efficiency is improved, the productivity of the products is increased, and the product cost is reduced.

Owner:TRULY SEMICON

Generator, wind turbine, method of assembling a generator and use of a generator in a wind turbine

InactiveUS8610321B2Simple configurationSmall sizeSynchronous generatorsWind motor combinationsStator coilTurbine

A generator is provided comprising a rotor with a number of magnetic rotor pole shoes, a stator with a number of stator coils wound on the stator, and a generator-utility grid interface comprising a plurality of diode rectifiers, each diode rectifier is connected to a stator coil and the number of stator coils is greater than the number of rotor pole shoes, or the number M of rotor pole shoes is greater than, but not an integer multiple of, the number of stator coils. A wind turbine utilizing the generator of the present invention and a method of assembling such a generator are provided.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

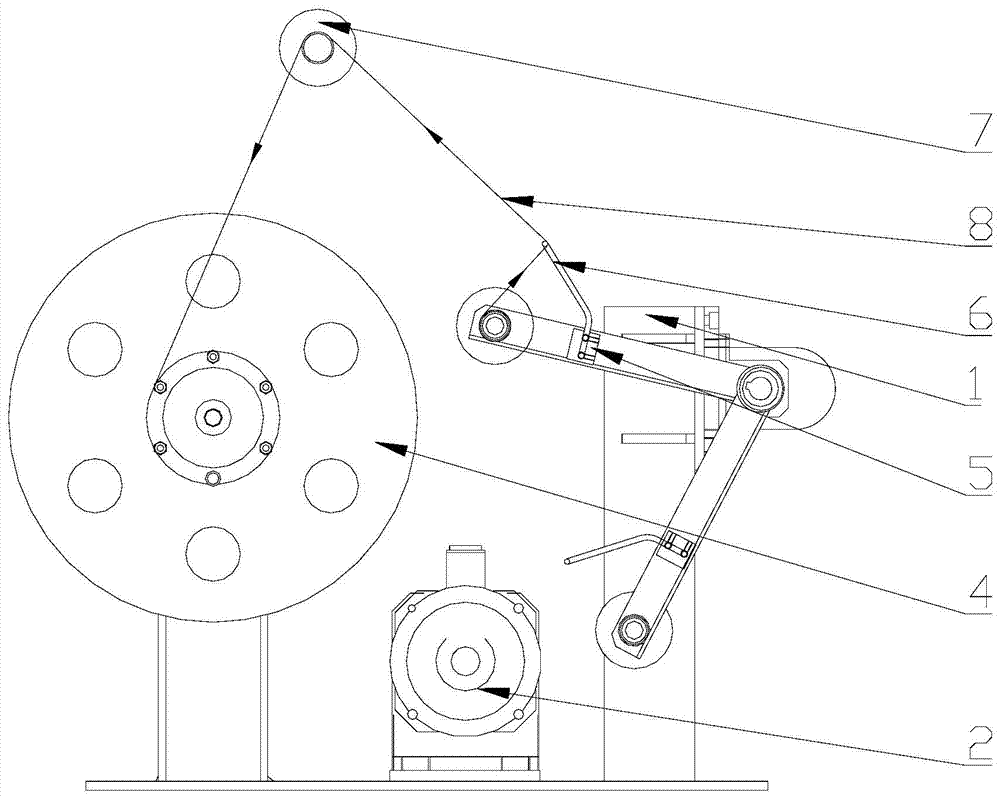

Synchronous precise rolling device of rolled slitter edge of metal plate

The invention relates to the technical field of production equipment, and particularly discloses a synchronous precise rolling device of a rolled slitter edge of a metal plate. The synchronous precise rolling device comprises a rack, a power plant, a driving device, a rolling device, a position detection device and a steering roller, wherein the power plant, the rolling device and the driving device are respectively installed on the rack; the position detection device is composed of a position detection head and a swinging bracket; the position detection head is composed of a precision potentiometer, a driving gear, a rotating shaft and a bearing seat of the rotating shaft, the rotating shaft and the bearing seat of the rotating shaft are fixed together with the rack through seat plates, the position detection head is connected with the swinging bracket through the rotating shaft, a pulley is installed on the end of the swinging bracket, the rolled slitter edge enters the rolling device through a pulley groove and the steering roller, so as to be rolled, and the rolling device is driven to rotate by the driving device. When the slitter edge rolling speed of the device changes, a motor is regulated by the device according to an output signal of the precision potentiometer, so as to change the slitter edge speed to adapt to the whole line speed, and the condition that the whole line is shut down due to breaking or accumulation of the slitter edge is avoided.

Owner:苏州茂腾剪切机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com