Induction brazing welding method for metal part

A technology of induction brazing and welding methods, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as weld corrosion, reduce weld strength and conductivity, absorb moisture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

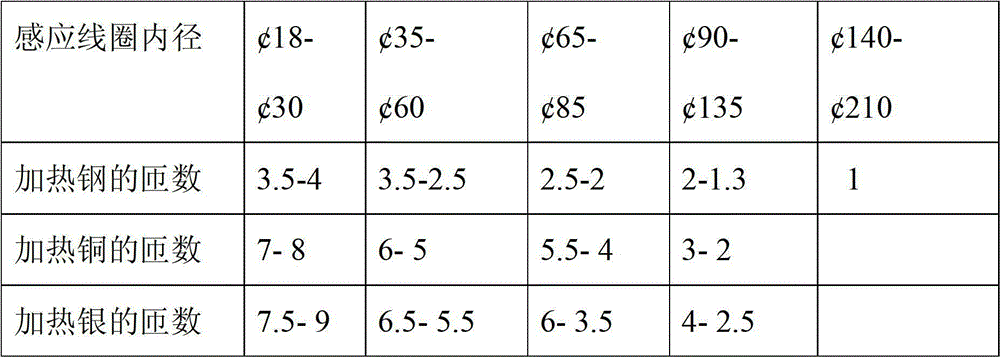

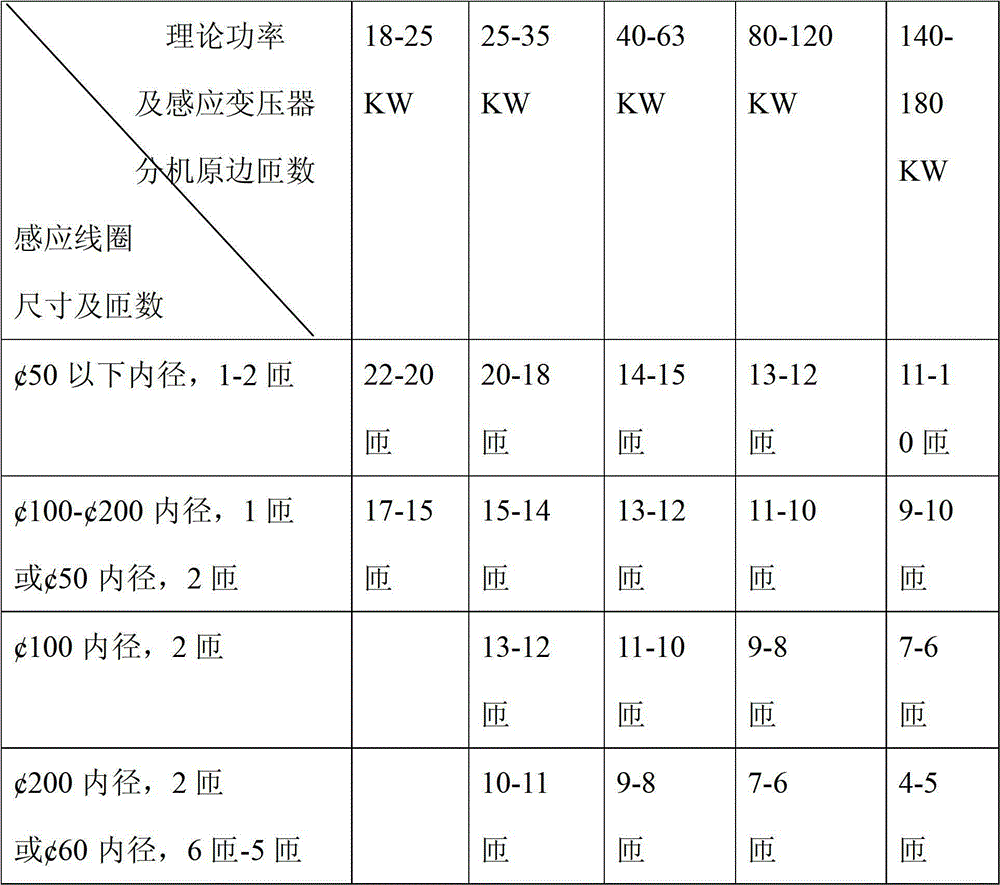

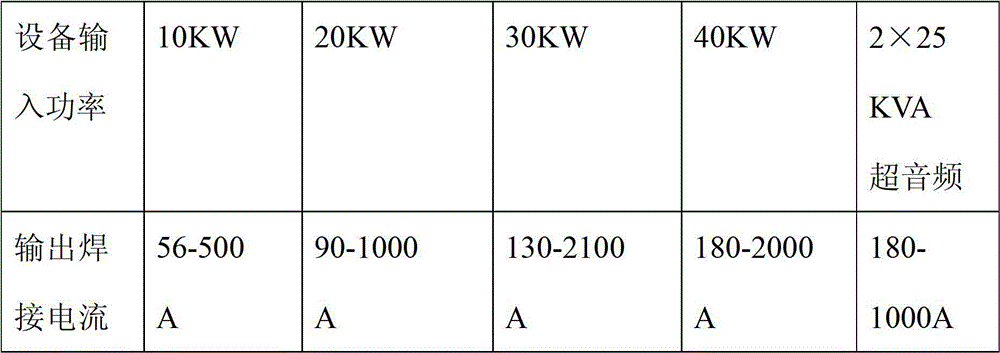

[0168] The following are contact bridge products composed of brass tubes and copper plates, hard copper contact plates on AC contactors and silver cadmium oxide electrical contacts. The induction brazing method of the present invention is used to weld the base metal (copper tube end face, silver oxide The surface of cadmium electrical contact) is plated with 0.2mm-0.3mm silver on the welding surface, calculate the theoretical and actual welding required power according to the weight of the weldment, select the power of the welding equipment, and select the corresponding induction sensor according to the diameter of the weldment and the power of the equipment Coil and induction frequency, the welding current penetration depth △L is selected according to the induction frequency and welding temperature. The heat penetration depth is the difference between the maximum range D2 of the weldment and the current penetration depth △L. Table 10 shows the typical metal weldments Welding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com