Die cutting machining device and method

A technology of processing equipment and processing methods, which is applied in metal processing and other directions, can solve problems such as the increase of defective products, falling off, air bubbles, etc., and achieve the effects of eliminating defects, reducing losses, and improving product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be noted that, in the case of no conflict, the embodiments in the present application and the technical features in the embodiments can be combined with each other. The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

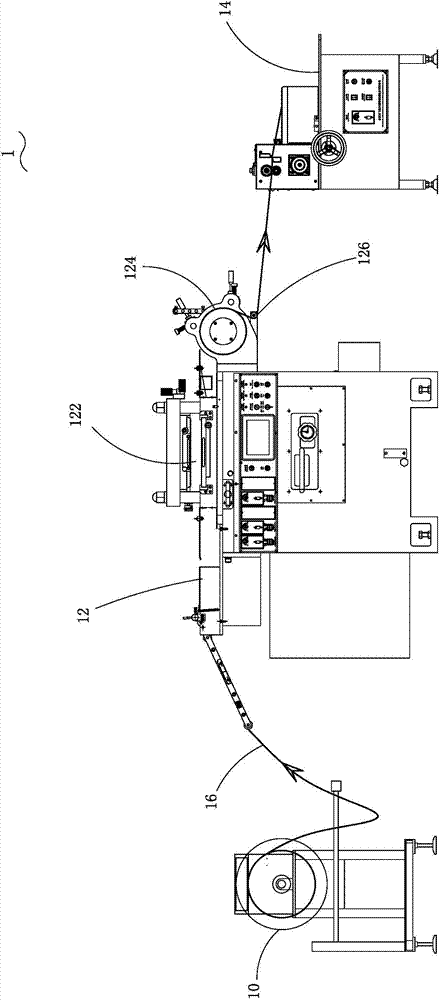

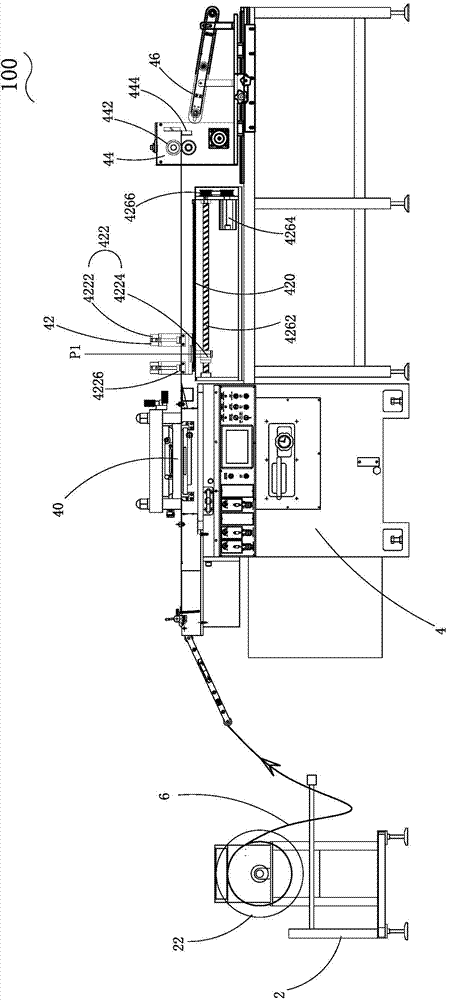

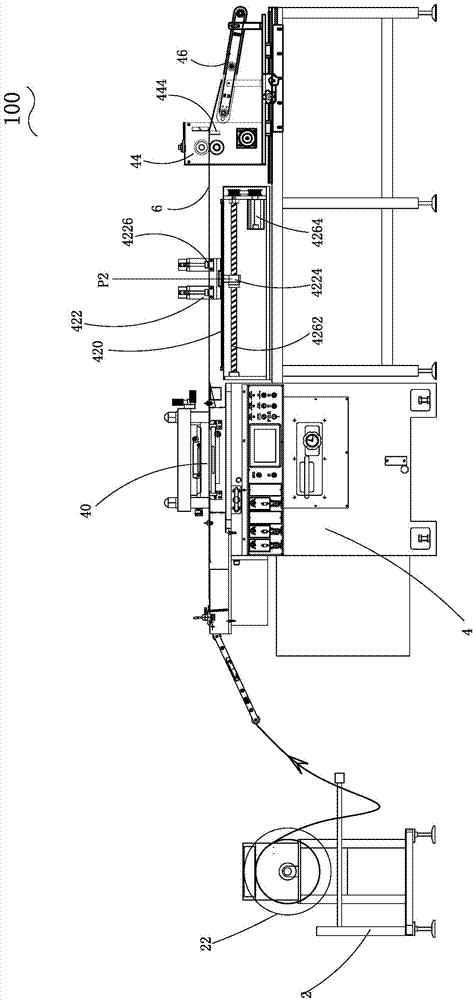

[0023] Such as Figure 2 to Figure 4 As shown, the present invention provides a die-cutting processing equipment 100 , which includes a feeder 2 and a die-cutting machine 4 . The feeder 2 preferably has a freely rotatable roller 22, and the outer periphery of the roller 22 is wound with the raw material 6 rolled into a roll. The raw material 6 is preferably a sheet made of non-metallic materials, self-adhesive, EVA, double-sided adhesive, copper foil and other materials.

[0024] The die cutting machine 4 preferably includes a die base 40 , a pressing device 42 , a slicing device 44 and a conveying device 46 . The die-cutting machine 4 is provided with a mold base 40 on a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com