Solenoid valve

A technology of solenoid valves and solenoid coils, applied in the field of solenoid valves, can solve problems such as defects, corrosion, and difficult handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

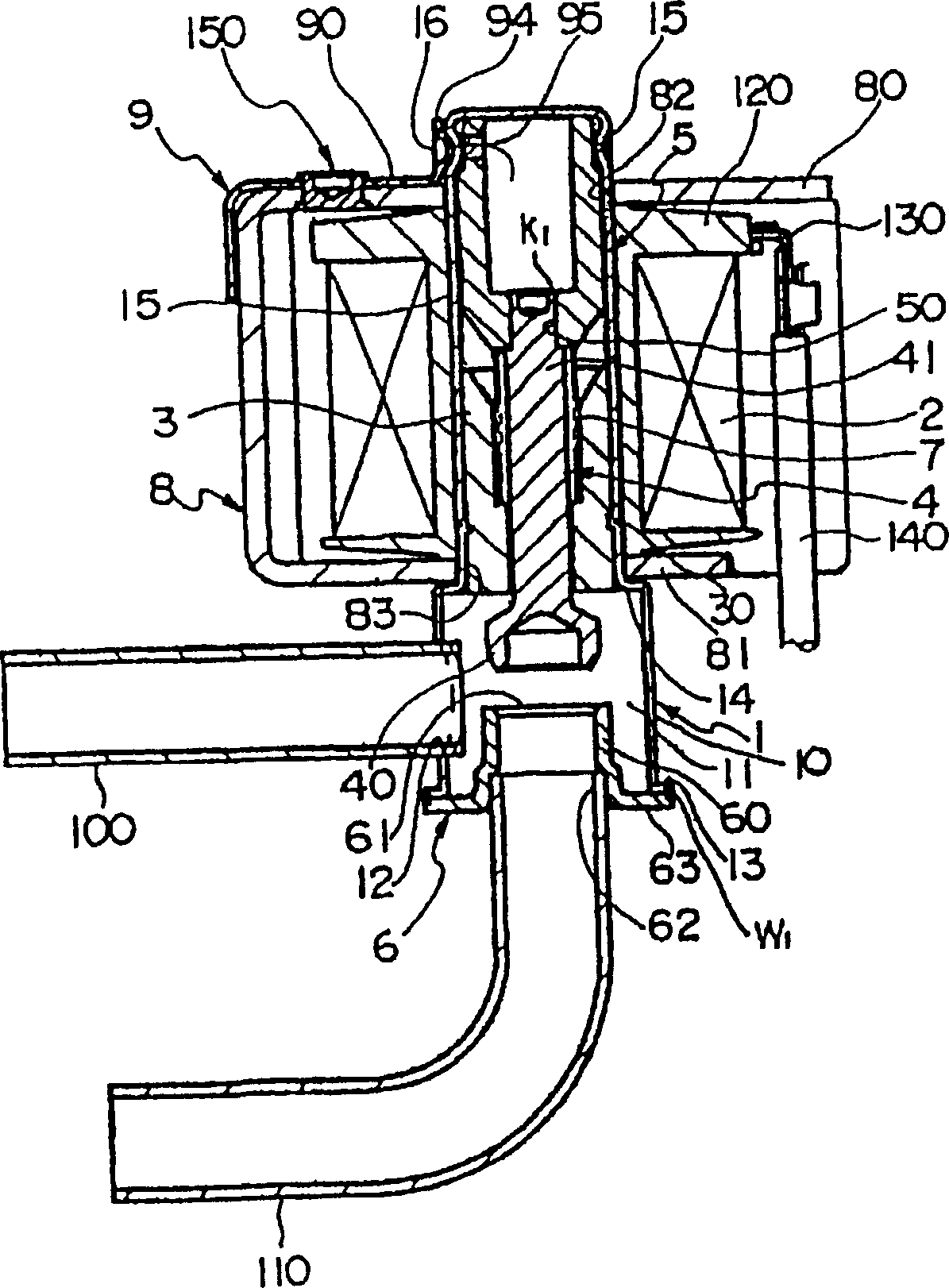

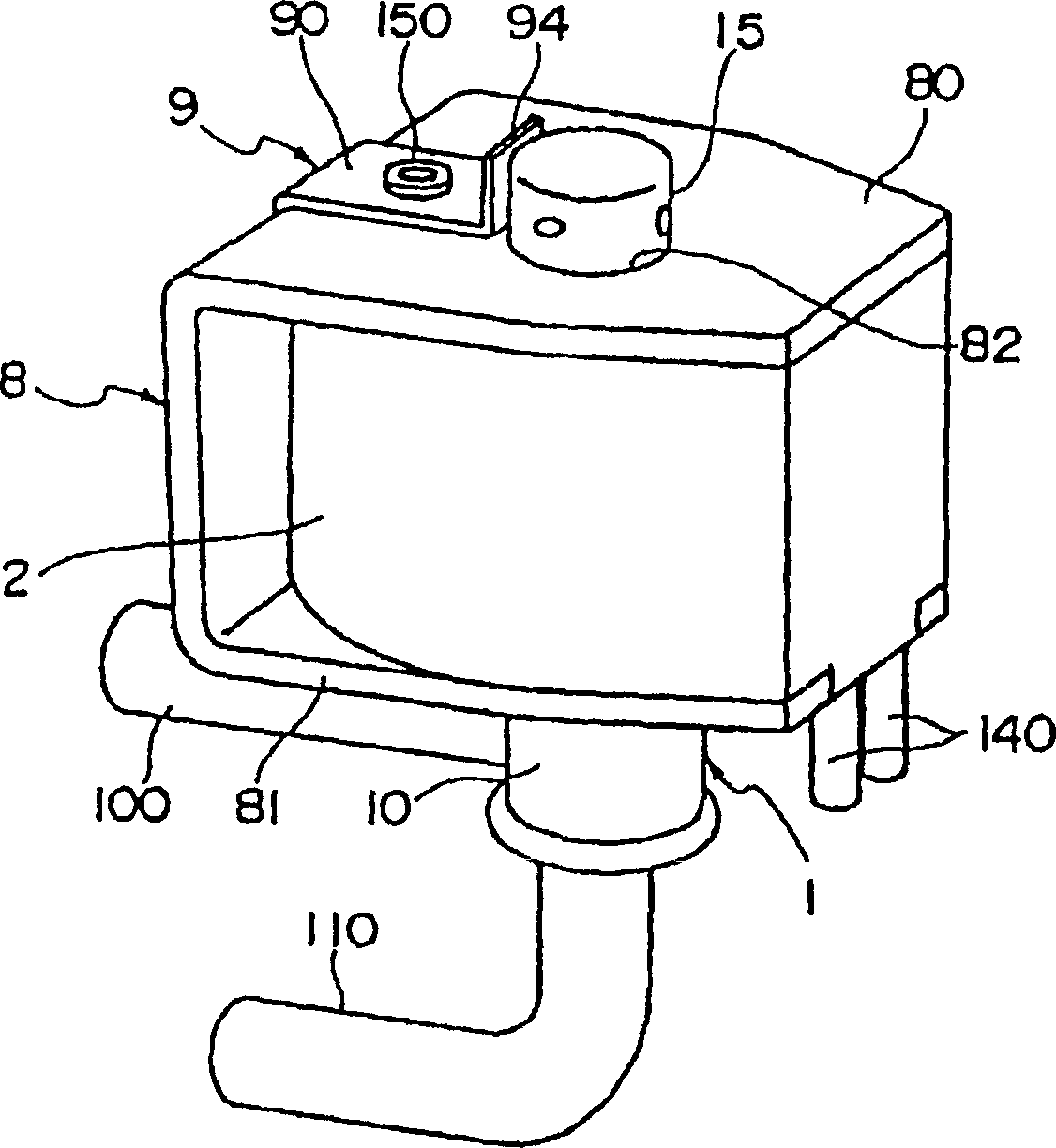

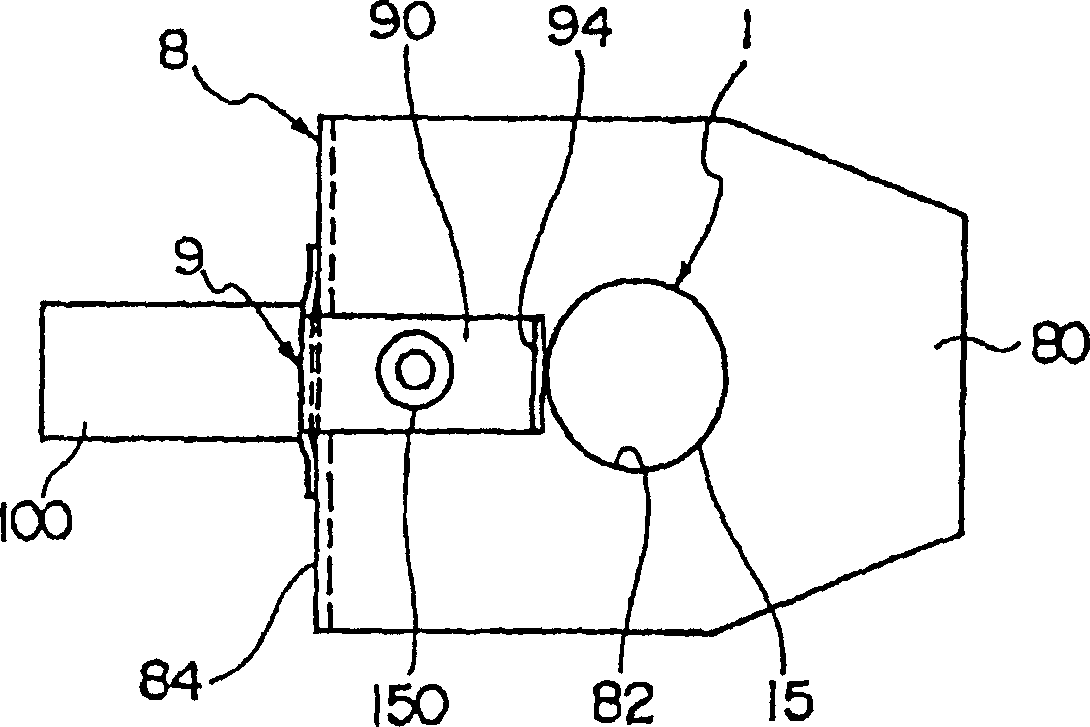

[0033] figure 1 is a longitudinal sectional view showing the solenoid valve in the first embodiment of the present invention, figure 2 is a perspective view showing the solenoid valve in the first embodiment of the present invention, image 3 yes figure 2 floor plan; Figure 4 yes figure 1 Enlarged view of the main part.

[0034] Such as figure 1 As shown, the solenoid valve of the first embodiment has not only the valve chamber 11 but also: a valve body 1 with a pipe portion that blocks one end of the pipe portion 15, an electromagnetic coil 2 disposed on the outer periphery of the pipe portion 15 of the valve body 1, The suction body 3 fixed inside the pipe portion 15 of the valve body 1, the rod-shaped valve body 4 that is arranged on the suction body 3 and can slide freely in the longitudinal direction of the pipe portion 15 of the valve body 1, the plunger 5 connected to the valve body 4, and the The valve seat part 6 with the opening of the main body 1, and the v...

Embodiment 2

[0058] Below, use Figure 5 and Figure 6 A second embodiment of the present invention will be described. The second embodiment involves pair-on-pair Figure 4 The illustrated manner in which the solenoid valve copper tube 100 is bent. Figure 5 It is a longitudinal sectional view of the solenoid valve 163 before processing, Figure 6 It is a longitudinal section view after processing. in addition, Figure 5 and Figure 6 left and right with Figure 4 Left and right are shown in reverse.

[0059] For example, the solenoid valve 163 is configured in the cooling cycle of the air conditioner, such as Figure 6 As shown, opposite to the copper pipe 110 on one side, use the copper pipe 100 on the other side from Figure 5 The straight line shown is often bent (in addition, in figure 1 and figure 2 In the case shown, the copper tube 110 is bent).

[0060] In addition, when the copper pipe 100 is to be bent, in order to save space in the air conditioner, when the copper ...

Embodiment 3

[0074] Refer below Figure 7 to Figure 10 A third embodiment will be described. The third embodiment is with figure 2 and image 3 Different embodiments of the coil housing 8 are shown.

[0075] Figure 7 It is a plan view showing the state that the solenoid valve 163 is installed on the air conditioner indoor unit 161 in the third embodiment of the present invention; Figure 8 It is a function explanatory diagram, (A) shows figure 2 and image 3 The situation of the shown coil housing 8, (B) represents the situation of the solenoid valve 163 in the third embodiment; Figure 9 is a perspective view of the solenoid valve 163 of the third embodiment of the present invention; Figure 10 yes Figure 9 A plan view of solenoid valve 163 is shown. In addition, in Figure 9 to Figure 10 in, with figure 2 and image 3 The same symbols are used for structures having the same constituent parts shown, and their descriptions are omitted.

[0076] Such as Figure 7As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com