Q500qE bridge steel plate and production method thereof

A production method and steel plate technology, applied in the field of bridge steel plate smelting, can solve the problems of high production difficulty, low yield strength ratio, unsuccessful production, etc., and achieve the effects of low production cost, low yield strength ratio and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

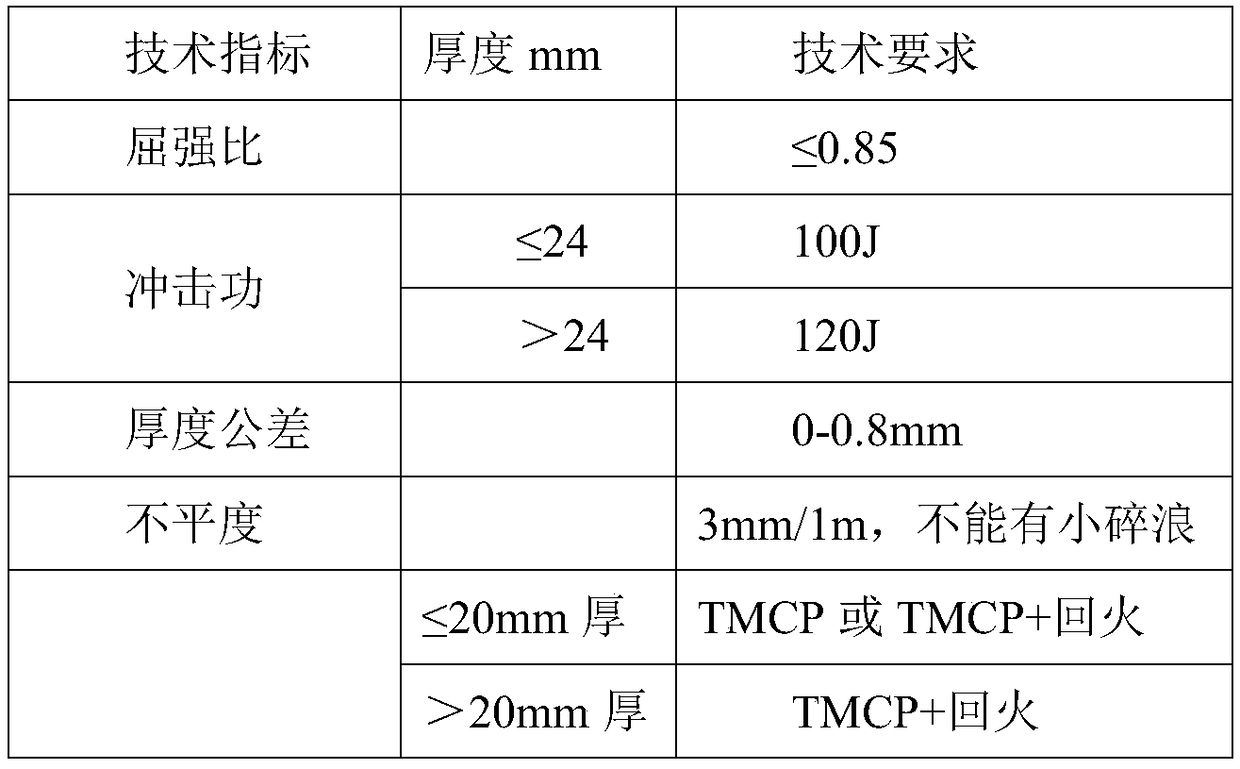

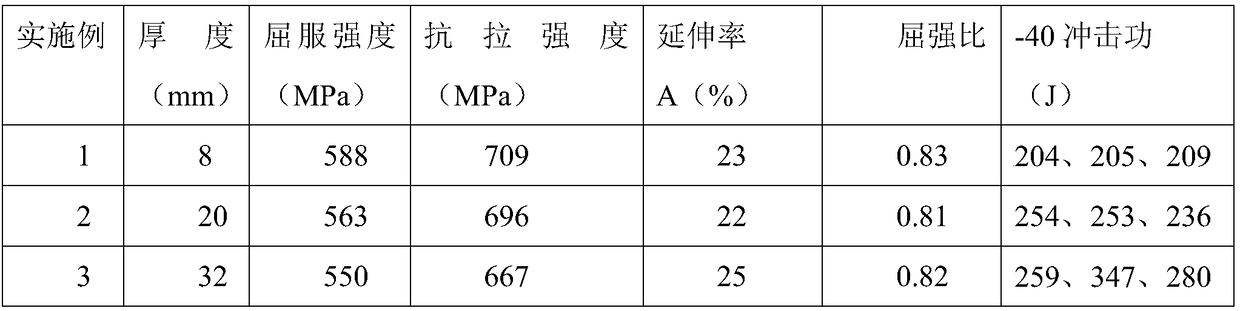

[0052] Smelted according to the chemical composition shown in Table 1, and cast into billets, the heating temperature is 1220 ° C, the total time in the furnace is 255 minutes, the first stage of rolling is rolling in the austenite recrystallization zone, the rolling temperature is 1105 ° C, except Except for the cross rolling pass, the reduction of each pass should be controlled above 15% as far as possible, and the reduction rate of at least 1-2 passes should be controlled above 20%. When the thickness of the rolled piece is 24mm, wait for the temperature on the roller table to 950°C, and then carry out the second stage of rolling, the rolling temperature is 950°C, the first and second passes must ensure that the reduction rate is ≥ 20%, and the final rolling temperature is 838°C, the thickness of the finished steel plate is 8mm. After rolling, the steel plate "relaxes" on the roller table after rolling for 15s and enters laminar flow cooling. Set the cooling control paramet...

Embodiment 2

[0054] The implementation is the same as in Example 1, wherein the heating temperature is 1225°C, the total time in the furnace is 259 minutes, the first stage rolling is rolling in the austenite recrystallization zone, and the rolling start temperature is 1108°C, except for the cross rolling pass , The reduction of each pass should be controlled above 15% as far as possible, and the reduction rate of at least 1 to 2 passes should be controlled above 20%. When the thickness of the rolled piece is 50mm, wait for the temperature on the roller table to 920°C, and then carry out the second stage of rolling, the rolling temperature is 917°C, the first and second passes must ensure that the reduction ratio is ≥ 20%, and the final rolling temperature is 819°C, the thickness of the finished steel plate is 20mm. After rolling, the steel plate "relaxes" for 58s and enters laminar flow cooling. Set the controlled cooling parameters according to Table 2, and cool the steel plate to 420°C....

Embodiment 3

[0056] The implementation is the same as in Example 1, wherein the heating temperature is 1225°C, the total time in the furnace is 251 minutes, the first stage of rolling is rolling in the austenite recrystallization zone, and the rolling start temperature is 1095°C, except for the cross rolling pass , The reduction of each pass should be controlled above 15% as far as possible, and the reduction rate of at least 1 to 2 passes should be controlled above 20%. When the thickness of the rolled piece is 80mm, wait for the temperature on the roller table to 820°C, and then carry out the second stage of rolling, the rolling temperature is 819°C, the first and second passes must ensure that the reduction rate is ≥ 20%, and the final rolling temperature is 791°C, the thickness of the finished steel plate is 32mm. After rolling, the steel plate "relaxes" for 135s and enters laminar flow cooling. Set the controlled cooling parameters according to Table 2, and cool the steel plate to 350...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com