Low-power heat dissipation performance test inlet oil and water temperature stabilizing device

A stable device, low-power technology, applied in the field of vehicle engineering, can solve the problems of oil temperature fluctuation at the radiator inlet, reduce the test accuracy, increase the difficulty of test operation, etc., to achieve the effect of precise control, improve accuracy, and shorten preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

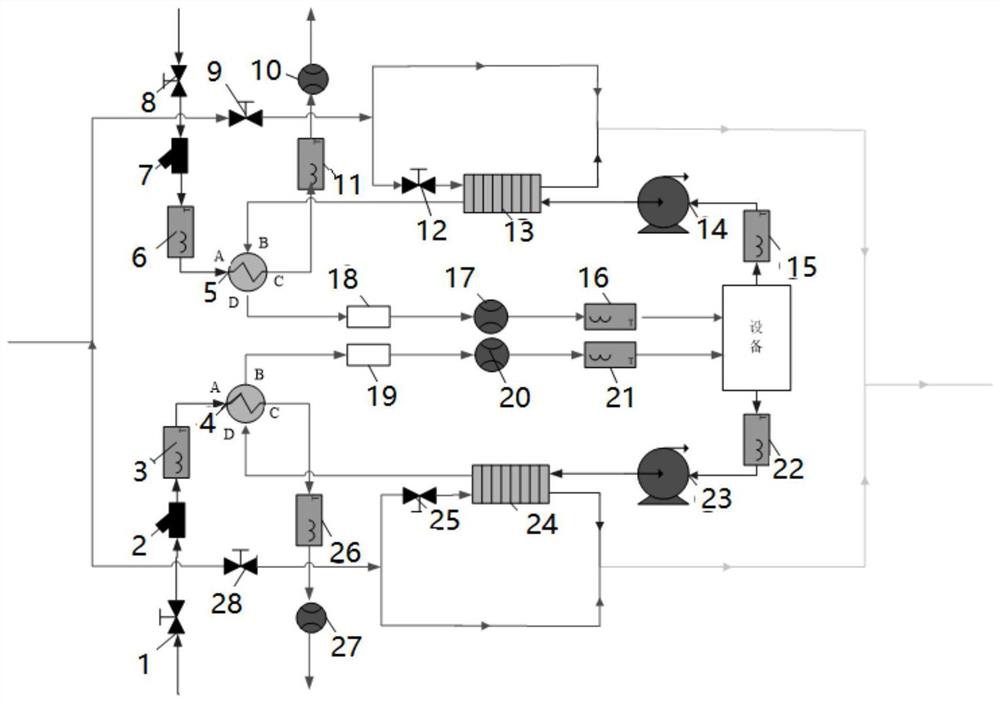

[0061] The inlet oil temperature and water temperature stabilizing device for the low-power heat dissipation test provided in this embodiment is based on the original temperature control device by adding an equipment inlet water temperature stabilizer and an equipment oil inlet temperature stabilizer.

[0062] (1) Improve the stability of the inlet water temperature and oil temperature of the equipment:

[0063] The equipment inlet temperature stabilizing device includes an equipment inlet water temperature cooling device and an equipment inlet water temperature heating device; the equipment oil inlet temperature stabilizing device includes an equipment oil inlet temperature cooling device and an equipment oil inlet temperature heating device;

[0064] The equipment inlet water temperature cooling device includes: a water-water heat exchanger 5, a second temperature sensor 6, a third temperature sensor 11, a second water filter 7, a second proportional valve 8, and a first flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com