Method for straightening cross-beam of car and apparatus thereof

An automobile beam and straightening technology is applied in the field of automobile beam straightening and its equipment, which can solve the problems of inability to eliminate internal stress, deviation and rollover, and performance degradation of the beam, so as to eliminate vibration and re-deformation or cracking, and ensure the straight line. Good consistency of degree and verticality and riveting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

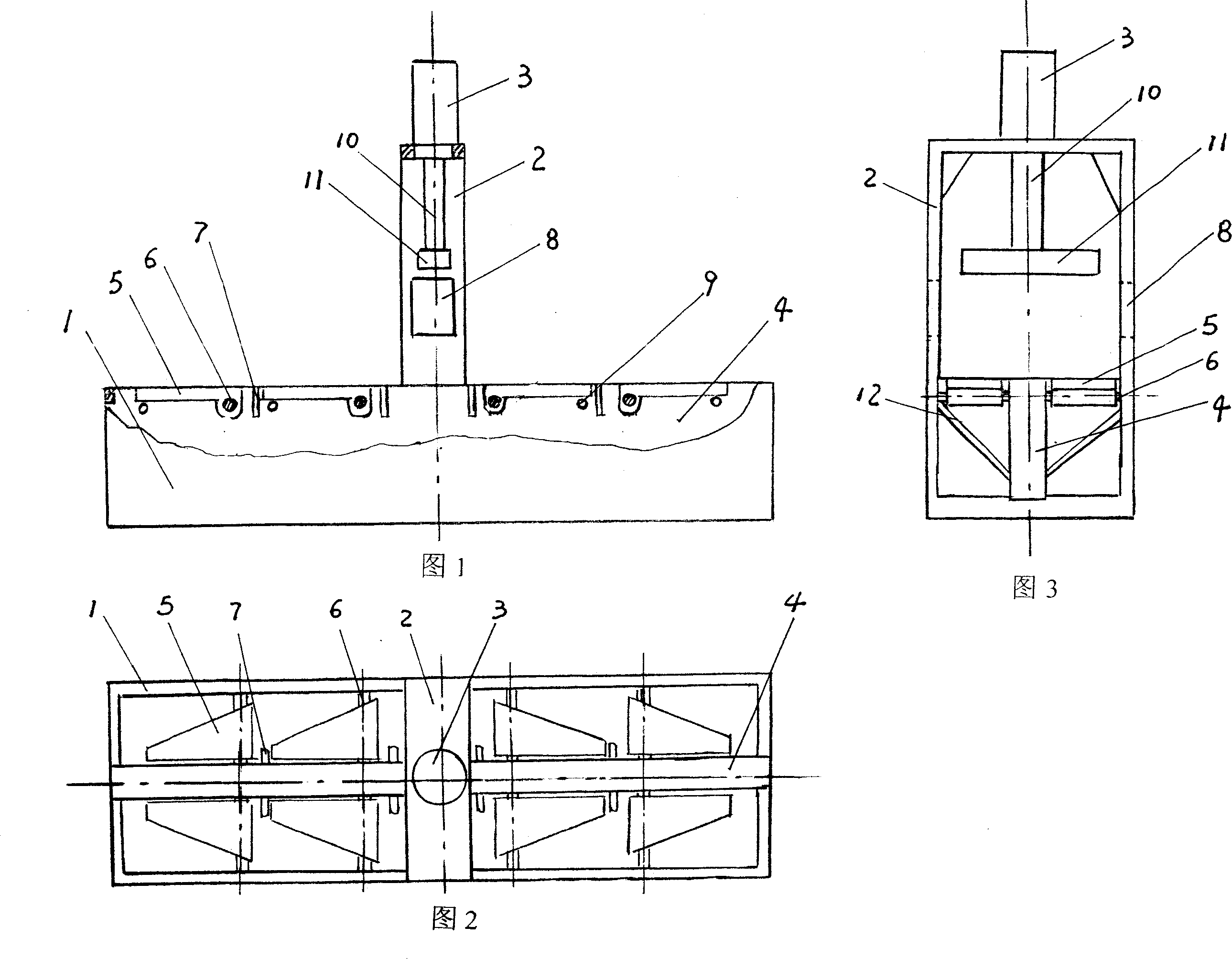

[0020] As shown in Figure 1-3: Automobile girder straightening method and its equipment, the method described is to remove all the rivets connected between the parts of the deformed girder by cold dismantling, and then remove the dismantled main girder and the outer surface of the beam Oil stains, remove the burrs around the rivet holes, and then use the hammering method to check the cracks of each component. For parts with cracks and cracks, use triangular welding to open grooves at the cracks, and use repair welding for all damaged holes on the beam. Drill the hole in situ after plugging by the method, and the size of the drill hole is the same as the original hole before the damage. The disassembled parts are straightened one by one on the straightening equipment by cold straightening method and restored to their original shape. The straight method is to straighten without heating, and reset the deformed parts’ facade and the plane perpendicular to it to restore the original...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com