Assembly line equipment and process for cleaning surfaces of insects

An assembly line, insect technology, applied in lighting and heating equipment, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of mechanization, low automation level, and poor cleaning effect in insect cleaning links, and achieve removal of insect surfaces. Dirt and impurities, the effect of reducing manpower requirements, improving efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

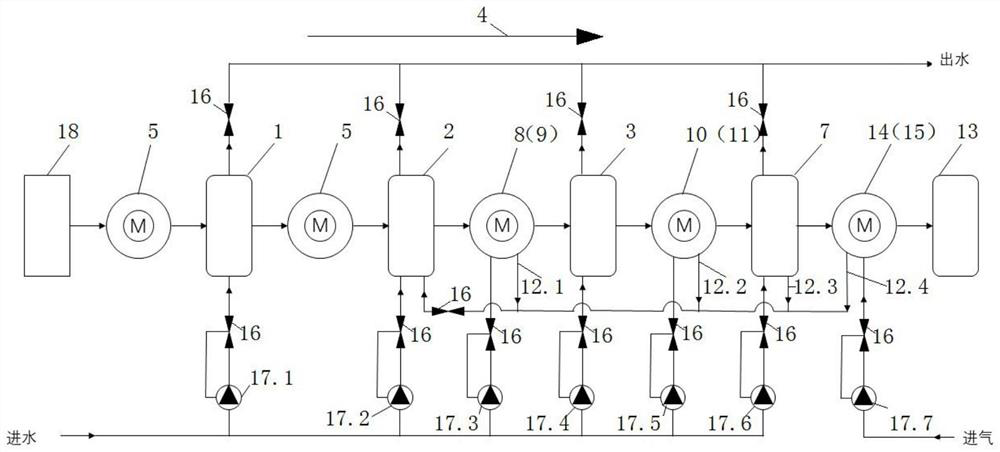

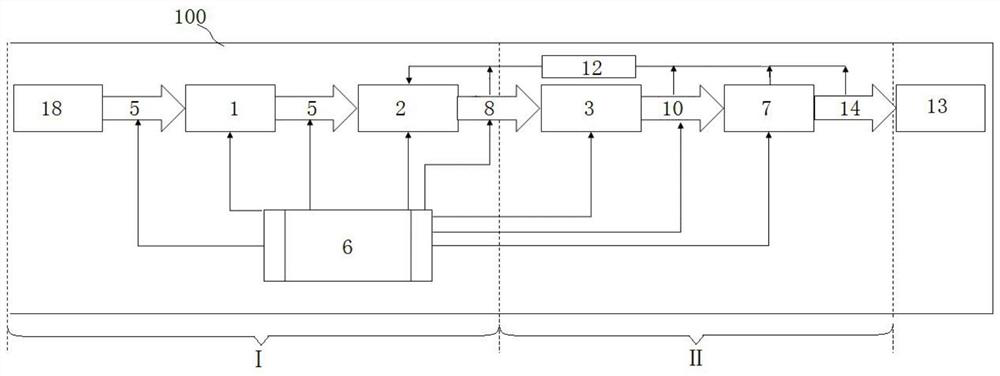

[0051] like figure 1 As shown, this embodiment provides an insect surface cleaning assembly line 100 , which mainly includes a cleaning module, a conveying module and an automatic control system 6 . Wherein, the cleaning module includes a first dipping machine 1, a vortex cleaning machine 2 and an ultrasonic cleaning machine 3 arranged in sequence along the pipeline advancing direction 4; wherein, the first dipping machine 1 is used to soak and soften the surface dirt of insects 18 to be cleaned. The vortex cleaner 2 is used to clean the part of the surface of the insect 18 to be cleaned to soften the dirt, and the ultrasonic cleaner 3 is used to clean the residual dirt on the surface folds of the insect 18 to be cleaned. The inside has also been softened to a certain extent. The transport module includes a conveyor 5 arranged along the advancing direction 4 of the assembly line, and the conveyor 5 is used to transport the insects 18 to be cleaned to the first dipping machine...

Embodiment 2

[0092] In this embodiment, the black soldier fly larvae bioreactor is selected, and kitchen waste is used as an example to transform organic waste, and the insect surface cleaning assembly line equipment and process in the above-mentioned embodiment 1 are described in detail.

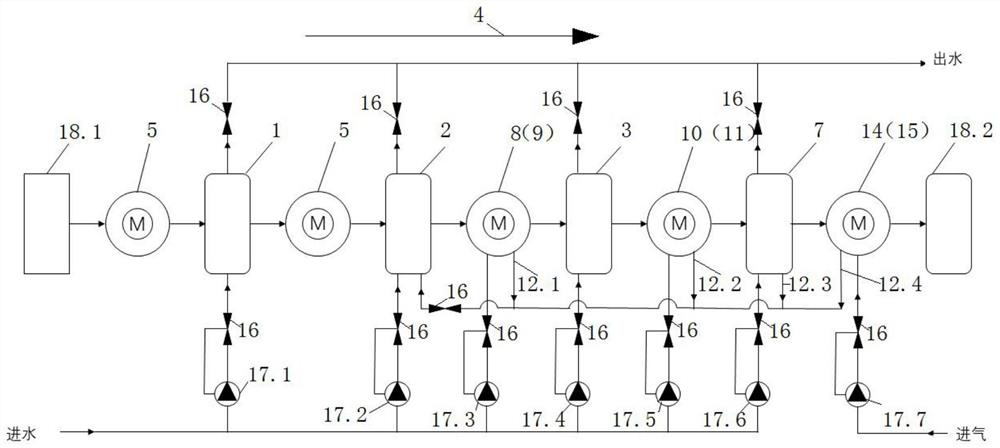

[0093] Such as image 3 As shown, the insect appearance cleaning line equipment 100 of the present embodiment is equipped with a total of four cleaning machines, a first dipping machine 1, a vortex cleaning machine 2, an ultrasonic cleaning machine 3 and a second dipping machine 7, and two high-pressure spray guns. Namely the first high-pressure spray gun 9 and the second high-pressure spray gun 11, one high-pressure air gun 15. The first dipping machine 1 selects an oscillating cleaning machine, the conveyor 5 before the first dipping machine 1 selects an electric-driven scraper conveyor, and each conveyor 5 after the first dipping machine 1 includes the first conveying section 8 , the second conveyin...

Embodiment 3

[0103] In this embodiment, fly maggot bioreactor is selected, and kitchen waste is used as an example to transform organic waste, and the insect surface cleaning assembly line equipment and process in the above-mentioned embodiment 1 are described in detail. The difference from Embodiment 2 is that in this embodiment, the first soaking machine 1 is a non-oscillating type, and the vortex cleaning machine 2 adopts a bubble cleaning machine.

[0104] like Figure 4 As shown, the insect appearance cleaning line equipment 100 of the present embodiment is equipped with a total of four cleaning machines, a first dipping machine 1, a vortex cleaning machine 2, an ultrasonic cleaning machine 3 and a second dipping machine 7, and two high-pressure spray guns. Namely the first high-pressure spray gun 9 and the second high-pressure spray gun 11, one high-pressure air gun 15. The vortex cleaning machine 2 is a bubble cleaning machine, the conveyor 5 before the first dipping machine 1 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com