Micro-nano particle reinforced aluminum alloy flux-cored filler wire used for TIG welding of 7075 aluminum alloy

A micro-nano particle, aluminum alloy technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problem of inability to change the alloy composition and particle enhancement, achieve good market application value, good welding forming, forming beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

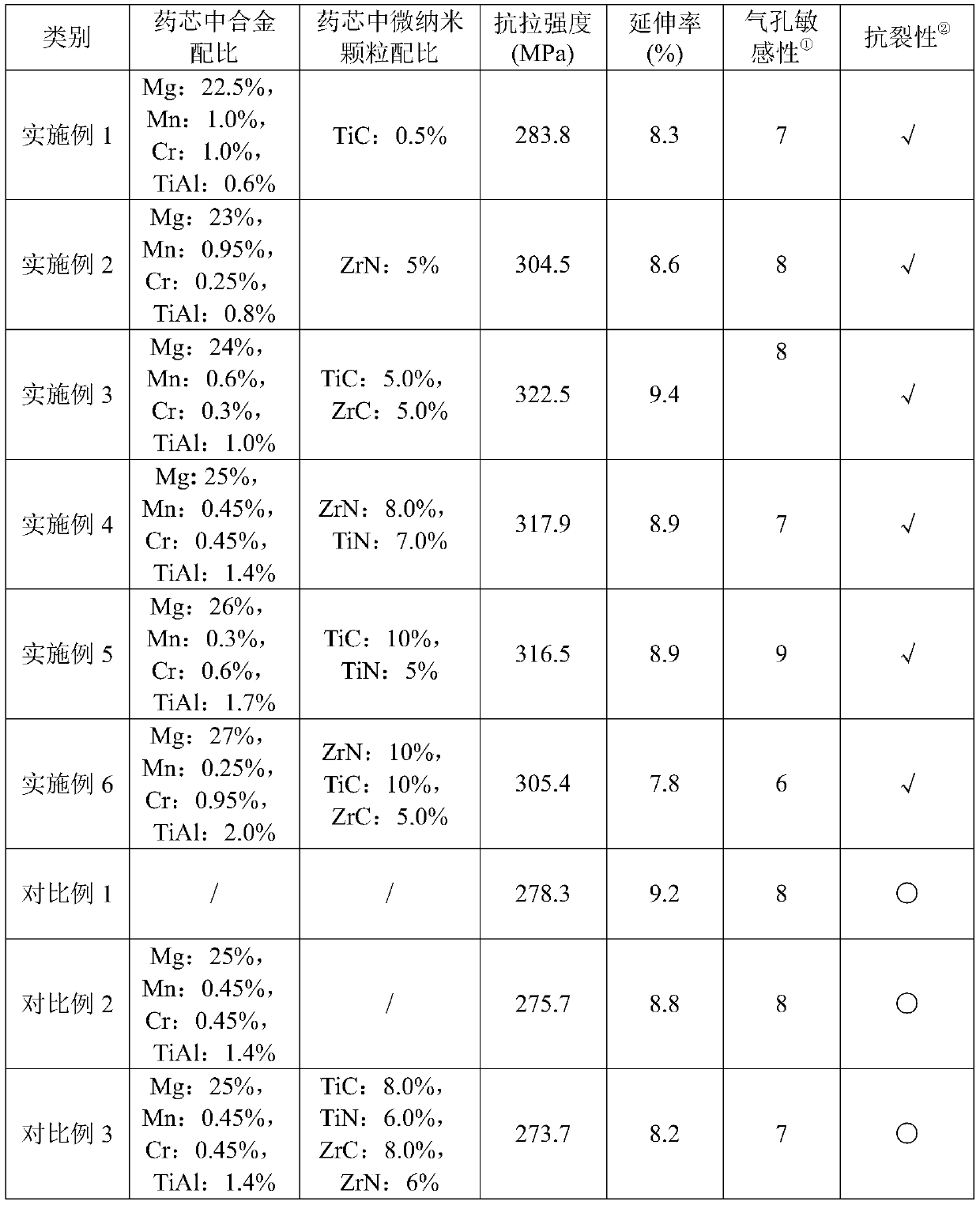

Examples

Embodiment 1

[0029] The micro-nanoparticle-reinforced core filler wire used for 7075 ultra-high-strength aluminum alloy TIG welding adopts 1070 pure aluminum strip sheath 8×0.3mm, the filling rate is 20%, and the diameter of the filler wire after drawing and reducing is 0.8mm; The chemical composition (weight %) of core is metallic Mg powder: 22.5%, metallic manganese powder: 1.0%, metallic chromium powder: 1.0%, titanium-aluminum alloy powder: 0.6%, composite micro-nano ceramic powder is TiC: 0.5%, surplus The amount is pure aluminum powder. 99.99% pure argon is used as the shielding gas, the gas flow rate is 6L / min, and the welding current is 80A.

Embodiment 2

[0031] The micro-nanoparticle-reinforced flux core filler wire used for 7075 ultra-high-strength aluminum alloy TIG welding adopts 1070 pure aluminum strip sheath 8×0.4mm, the filling rate is 22%, and the diameter of the filler wire is 1.0mm after drawing and diameter reduction; The chemical composition (weight %) of core is metallic Mg powder: 23%, metallic manganese powder: 0.95%, metallic chromium powder: 0.25%, titanium-aluminum alloy powder: 0.8%, composite micro-nano ceramic powder is ZrN: 5%, surplus The amount is pure aluminum powder. 99.99% pure argon is used as the shielding gas, the gas flow rate is 7L / min, and the welding current is 110A.

Embodiment 3

[0033] The micro-nanoparticle-reinforced core filler wire used for TIG welding of 7075 ultra-high-strength aluminum alloy adopts 1070 pure aluminum strip sheath 12×0.4mm, the filling rate is 24%, and the diameter of the filler wire after drawing and reducing is 1.6mm; The chemical composition (% by weight) of the core is metal Mg powder: 24%, metal manganese powder: 0.60%, metal chromium powder: 0.30%, titanium aluminum alloy powder: 1.0%, composite micro-nano ceramic powder is TiC: 5%, ZrC : 5%, the balance is pure aluminum powder. 99.99% pure argon is used as the shielding gas, the gas flow rate is 8L / min, and the welding current is 140A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com