High-plasticity-toughness low-alloy ultrahigh-strength steel and preparation method

A technology of ultra-high strength steel and high plastic toughness, which is applied in the field of high plastic toughness and low alloy ultra-high strength steel and its preparation, can solve the problem of low hardenability of steel materials, low value of impact toughness parameters of section shrinkage, and high hardenability. Low yield ratio and other problems, to achieve the effect of good hardenability and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

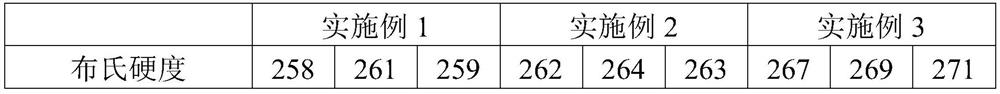

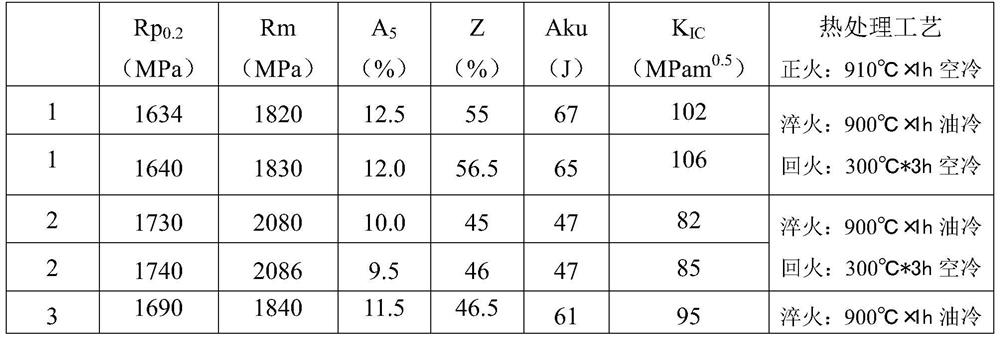

Embodiment 1

[0033] Smelting and casting: smelting and casting ∮290mm electrodes in a vacuum induction furnace. When smelting and pouring in the vacuum induction furnace, vacuum the vacuum induction furnace. When the vacuum degree is less than 2.7Pa, load the material and supply electricity. When the vacuum degree reaches 2.7Pa, add iron and alloy raw materials in batches and melt them. Raise the temperature to 1580-1600°C, keep the refining time for more than 30 minutes, adjust the composition slightly, after refining, fill with argon until the pressure is greater than or equal to 3000pa, then add manganese to adjust the carbon, after the complete melting, take samples and tap the steel, and form a ∮290mm electrode by electrified casting. After the electrode is cooled for 1.5 hours, it is annealed by heat. The annealing process is to keep the temperature at 670-700 ° C for more than 6 hours, cool it in the furnace to 500 ° C, and then air cool it in the air cooler.

[0034] Remelting: The...

Embodiment 2

[0038] Smelting and casting: smelting and casting ∮290mm electrodes in a vacuum induction furnace. When smelting and pouring in the vacuum induction furnace, vacuum the vacuum induction furnace. When the vacuum degree is less than 2.7Pa, load the material and supply electricity. When the vacuum degree reaches 2.7Pa, add iron and alloy raw materials in batches and melt them. Raise the temperature to 1580-1600°C, keep the refining time for more than 30 minutes, adjust the composition slightly, after refining, fill with argon until the pressure is greater than or equal to 3000pa, then add manganese to adjust the carbon, after the complete melting, take samples and tap the steel, and form a ∮290mm electrode by electrified casting. After the electrode is cooled for 1.5 hours, it is annealed by heat. The annealing process is to keep the temperature at 670-700 ° C for more than 6 hours, cool it in the furnace to 500 ° C, and then air cool it in the air cooler.

[0039] Remelting: The...

Embodiment 3

[0043] Smelting and pouring: When smelting and pouring is carried out in the electric arc furnace + ladle refining furnace + vacuum degassing furnace, the material is loaded, and the ladle is baked in the electric arc furnace. The ladle uses low-sulfur phosphorus raw materials to control residual elements. Afterwards, give electric blowing oxygen to boost the melting, control the element content, control the end point in the electric arc furnace so that the chemical composition P is less than or equal to 0.005%, the temperature is greater than or equal to 1640°C, the steel slag is 100%, and the ladle is filled with lime; after that, the ladle Enter the ladle refining furnace and heat it with electricity, add lime and si-c powder in batches for deoxidation and reduction, and make white slag. The white slag time is ≥40min. t, sample analysis, adjust the composition according to the analysis results, and heat up to 1590-1620°C with electricity; after that, the ladle enters the vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com