A production method of a 2507 stainless steel pump casting

A production method and technology for stainless steel pumps, applied in the direction of casting molds, casting mold components, casting molding equipment, etc., can solve the problems of high rejection rate of pump castings and large amount of welding repair, so as to reduce the amount of subsequent repair welding and reduce the repair rate and scrap rate, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

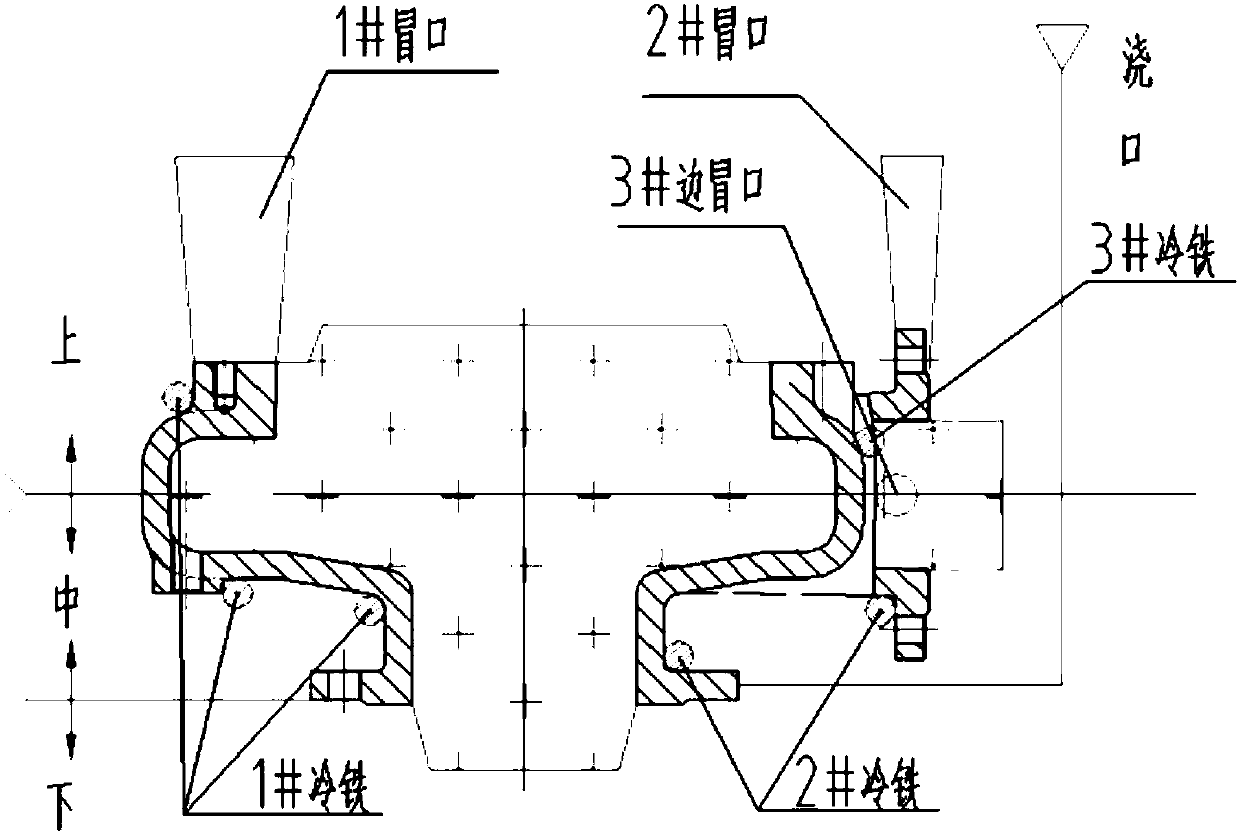

[0143] Such as figure 1 Shown, a kind of production method of 2507 stainless steel pump body, this method comprises the following steps:

[0144] (1) Mold design and production

[0145] Make wooden molds and check and accept them;

[0146] (2) Modeling and core making

[0147] 2.1 Sand mixing

[0148] Dry mix the quartz sand and bentonite for 5 minutes until uniform, then add water glass and sodium hydroxide solution and mix for 8 minutes until uniform, and then produce sand;

[0149] 2.2 Modeling

[0150] Wooden molds are used for manual molding to obtain sand molds, and heavy objects are used for manual compaction and uniformity;

[0151] 2.3 Set stomata

[0152] The cover box of the sand mold adopts the vent needle to insert the air outlet connected with the sand mold cavity as the exhaust channel, and the interval between the air outlets is set at 50mm, and the bottom box of the sand mold is 10mm away from the wooden mold, and multiple exhaust channels are also opene...

specific Embodiment 2

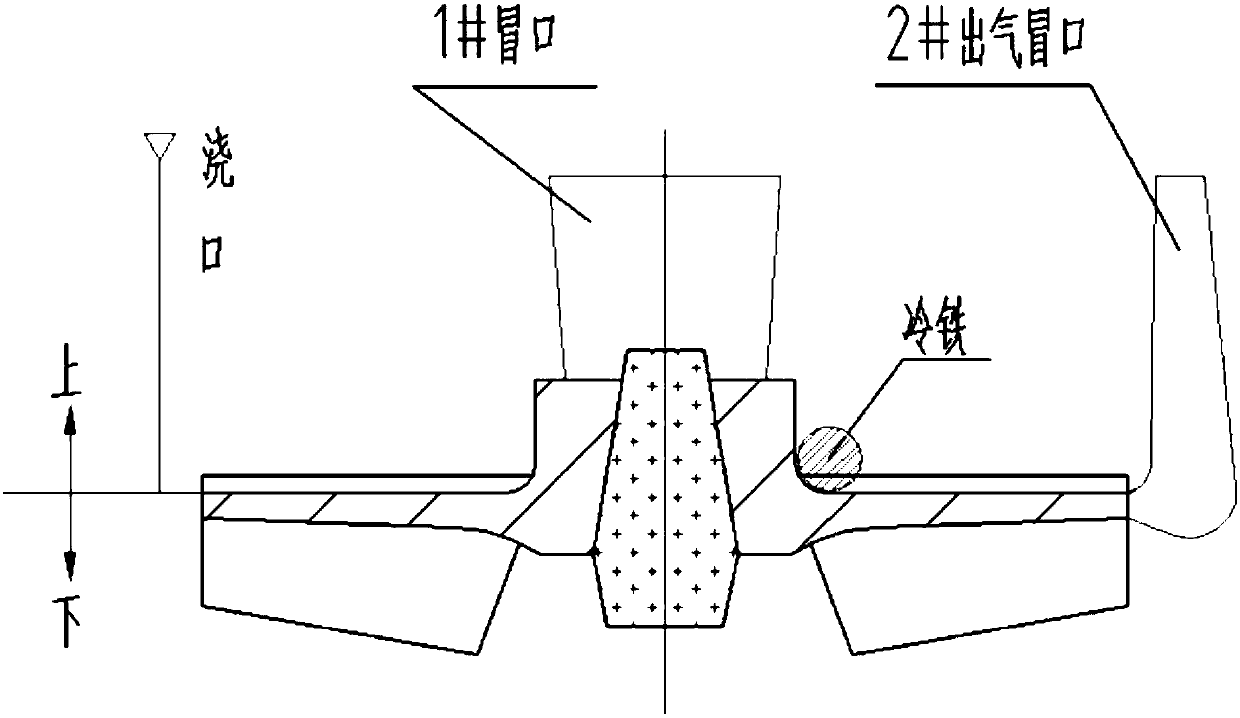

[0195] Such as figure 2 Shown, a kind of production method of 2507 stainless steel impeller, auxiliary impeller, this method comprises the following steps:

[0196] (1) Mold design and production

[0197] Make wooden molds and check and accept them;

[0198] (2) Modeling and core making

[0199] 2.1 Sand mixing

[0200] Dry mix the quartz sand and bentonite for 6 minutes until uniform, then add water glass and sodium hydroxide solution and mix for 9 minutes until uniform, and then produce sand;

[0201] 2.2 Modeling

[0202] Wooden molds are used for manual molding to obtain sand molds, and heavy objects are used for manual compaction and uniformity;

[0203] 2.3 Set stomata

[0204] The cover box of the sand mold adopts the vent needle to insert the air outlet connected with the sand mold cavity as the exhaust channel, and the air outlet is set at an interval of 75mm, and the bottom box of the sand mold is 15mm away from the wooden mold, and multiple exhaust channels a...

specific Embodiment 3

[0246] A production method of 2507 stainless steel pump cover, the method comprises the following steps:

[0247] (1) Mold design and production

[0248] Make wooden molds and check and accept them;

[0249] (2) Modeling and core making

[0250] 2.1 Sand mixing

[0251] Dry mix the quartz sand and bentonite for 8 minutes until uniform, then add water glass and sodium hydroxide solution and mix for 10 minutes until uniform, and then produce sand;

[0252] 2.2 Modeling

[0253] Wooden molds are used for manual molding to obtain sand molds, and heavy objects are used for manual compaction and uniformity;

[0254] 2.3 Set stomata

[0255] The cover box of the sand mold adopts the vent needle to insert the air outlet connected with the sand mold cavity as the exhaust channel, and the air outlet is set at an interval of 100mm, and the bottom box of the sand mold is 20mm away from the wooden mold, and multiple exhaust channels are also opened;

[0256] 2.4 stereotypes

[0257]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com