Main oil duct sand core of diesel engine frame and manufacturing method thereof

A technology of oil channel sand core and main oil channel, applied in manufacturing tools, cores, casting and forming equipment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

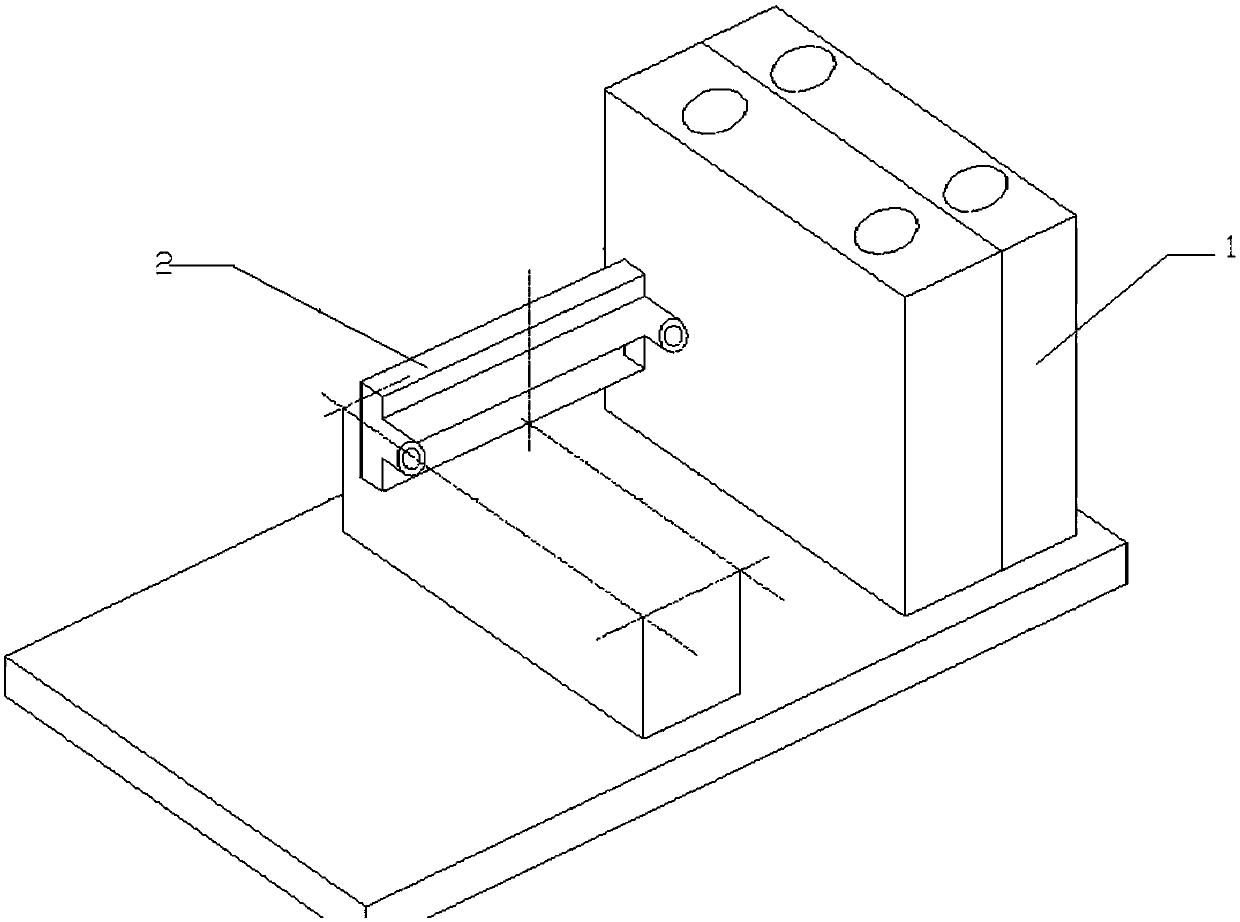

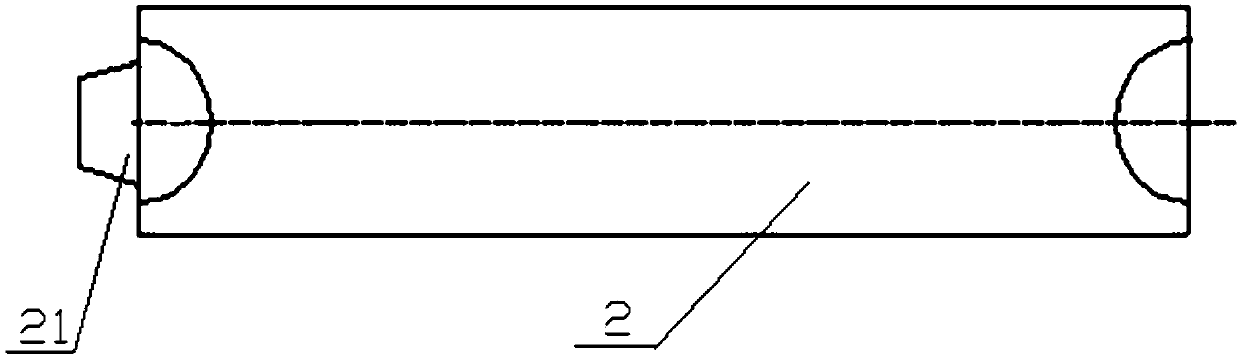

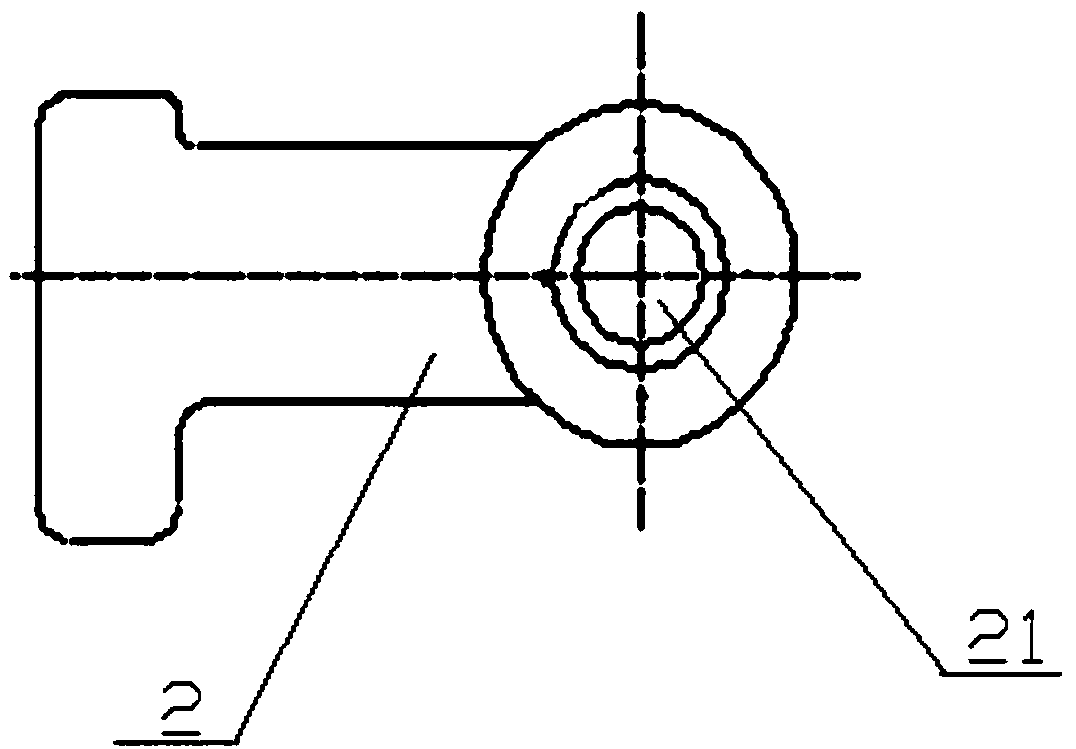

[0024] Such as Figure 1-Figure 7 As shown, the main core body 1 of the present invention and the main oil passage sand core arranged on the main core body, the main oil passage sand core is divided into several according to the number of frame cylinders and the center size of each gear crankshaft as the parting surface. Segmented oil channel sand core 2; the segmented oil channel sand core 2 is composed of a core bone 3 and a sand body wrapped on the core bone 3; one end of the segmented oil channel sand core 2 is provided with a positioning core head 21, and the other end is A positioning core groove 22 is provided; the positioning core head 21 of the oil channel sand core 2 of the previous segment is embedded in the positioning core groove 22 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com