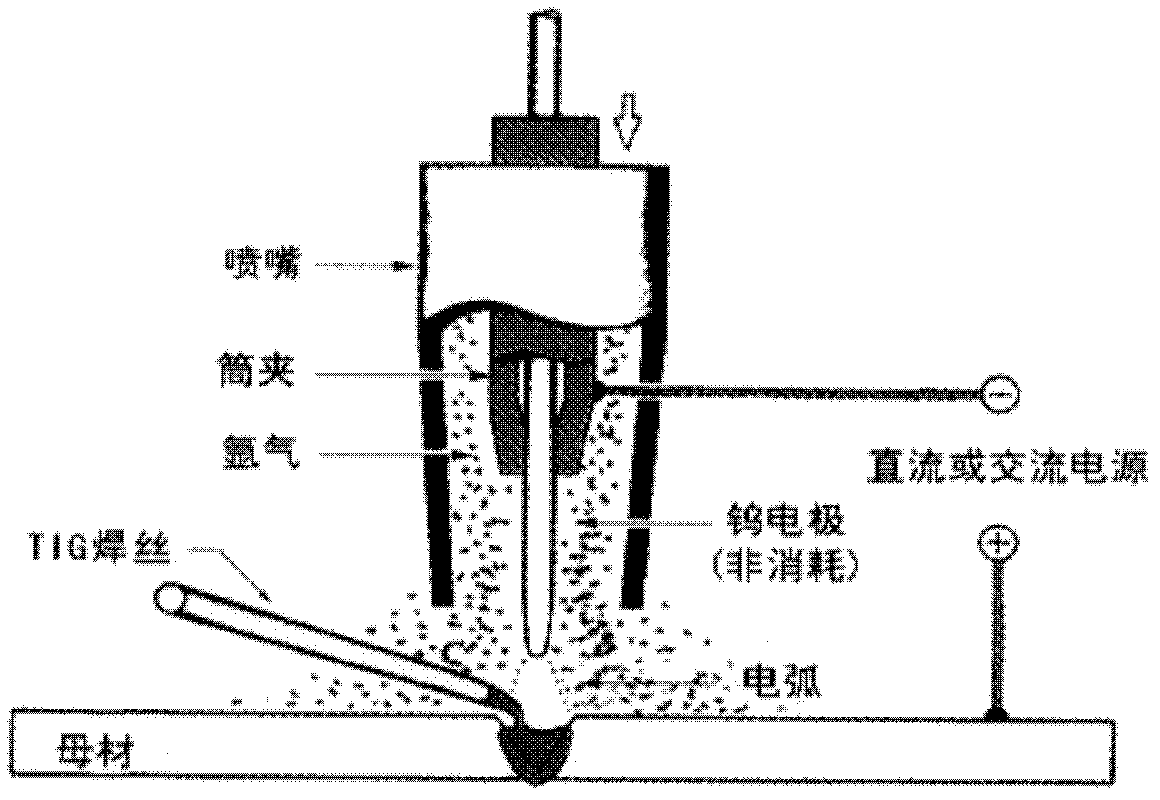

Gas tungsten arc welding (GTAW) system and welding method thereof

A gas shielding and welding system technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of increasing deposition efficiency and achieve the effect of improving heating efficiency and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

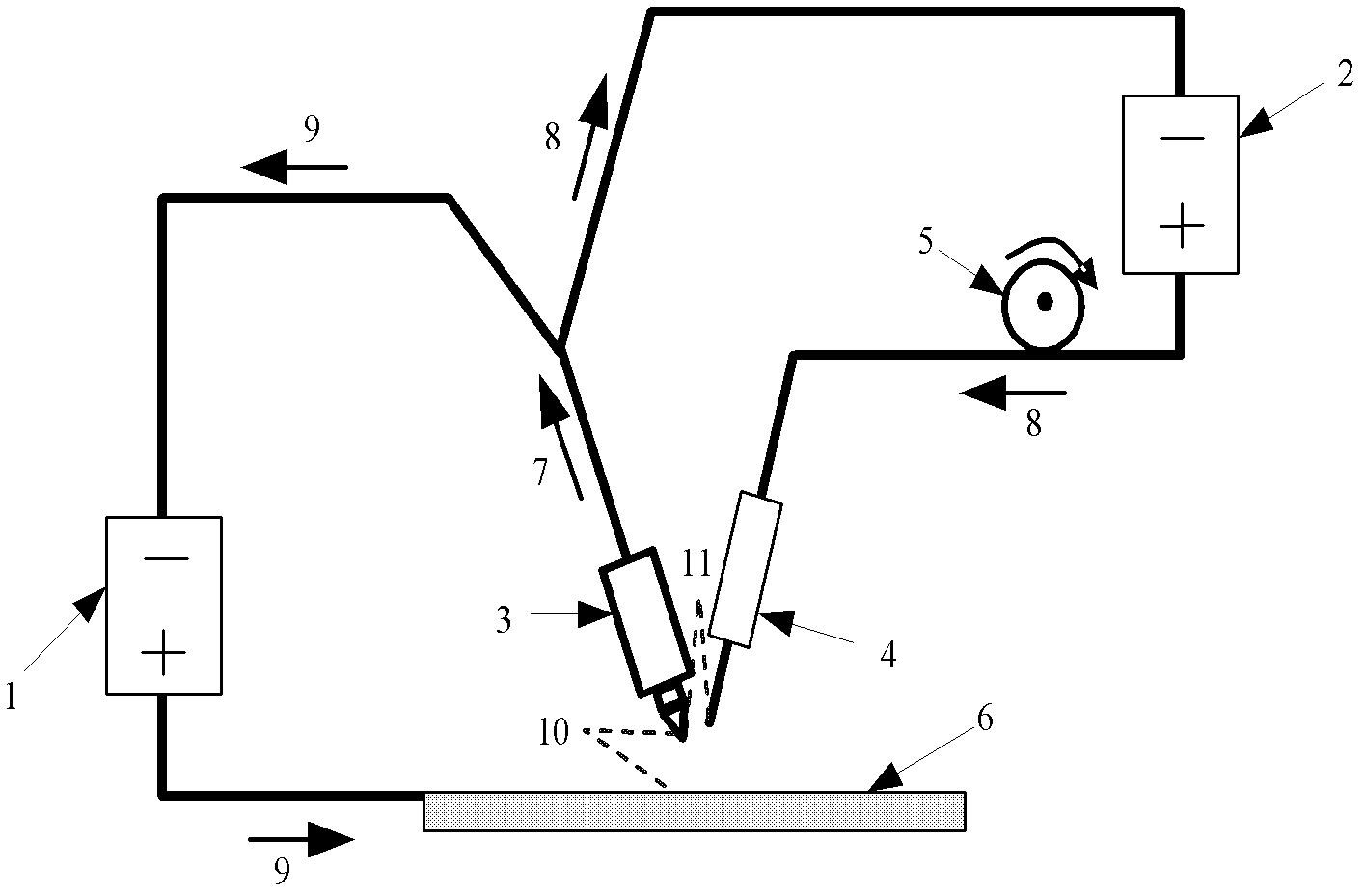

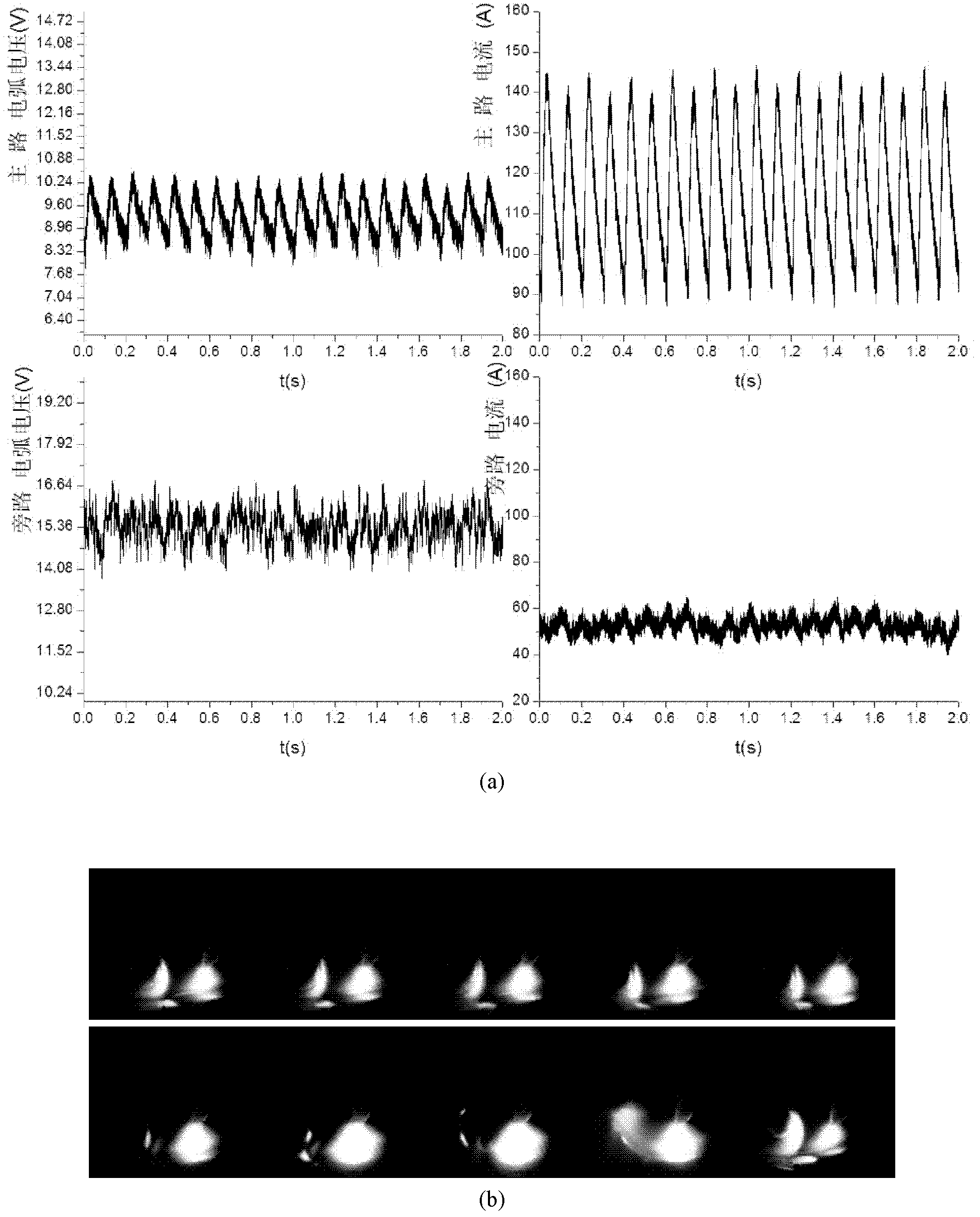

[0050] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

[0051] The non-melting electrode gas shielded welding system constructed by the present invention includes: TG300P welding machine (1 set, used as the first welding machine) produced by WIM company, NBC-500 inverter type gas shielded welding machine (1 set) produced by Times Welding Company Taiwan, used as the second welding machine), SB-10 series wire feeder of Times Welding Company (1 unit), double-gun fixture with adjustable angle and position (1 unit), linear workbench (1 unit), gas cylinder and air valves etc. Schematic diagram of the welding system figure 2 As shown, the distance d between the tungsten electrode of the first welding torch and the workpiece 1 is 5mm; the distance d between the contact tip of the second welding torch and the workpiece 2 7mm; the projection distance d between the tungsten electrode of the first torch and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com