Biphase steel SA-240 S31803 handwork tungsten electrode argon arc GTAW welding process

A SA-240S31803, tungsten argon arc technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of duplex steel product production difficulties, duplex steel use and procurement difficulties, and product quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

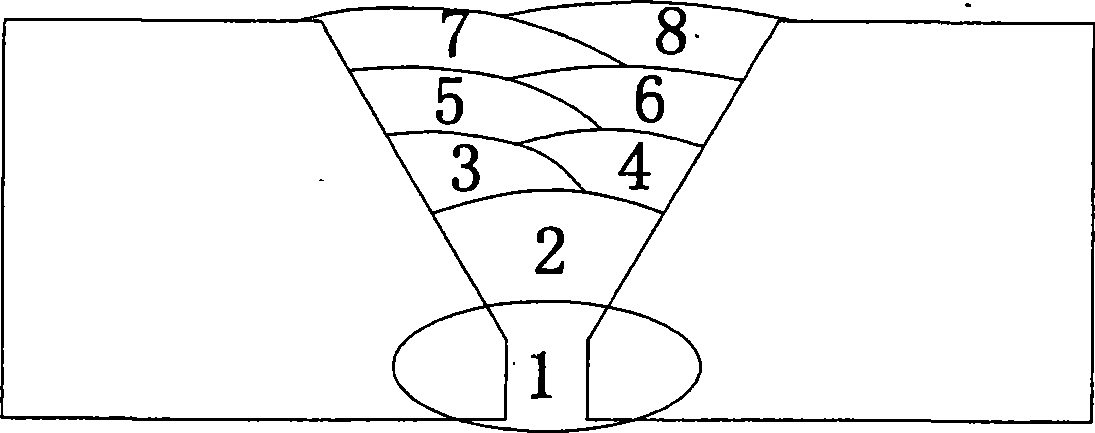

[0007] First of all, two duplex steel plates to be welded are mechanically planed on their respective welding surfaces with a groove of 30°+5°. The groove can be left with a blunt edge of 1 mm, and water should be removed from the groove surface and the extensions of both sides. , oil, rust, and welding wire can be removed within a range of 20mm along the extension. The welding machine is a WS-400IGBT inverter multifunctional DC tungsten arc welding machine produced by Shanghai Jintong Electronic Equipment Co., Ltd., and the welding torch is protected The gas is (Ar+(1%-2%)N 2 ) mixed gas, produced by Shanghai Shenxiang Industrial Gas Co., Ltd., the flow rate is 14-16L / min, the back protection gas is argon with a purity of 99.995%, and the flow rate is 13-15L / min. The welding wire is ER2209 solid wire with a diameter of 2.4mm produced by SANDVIK. The diameter of the welding tip of the inverter multifunctional DC tungsten argon arc welding machine is 12mm, the diameter of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com