Ultrahigh-strength steel laser tailor welded blank and forming process thereof

A technology of ultra-high-strength steel and laser tailor welding, which is applied in the field of material processing to achieve the effects of improving assembly accuracy, meeting safety and energy saving and emission reduction, and solving difficulties in cold forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

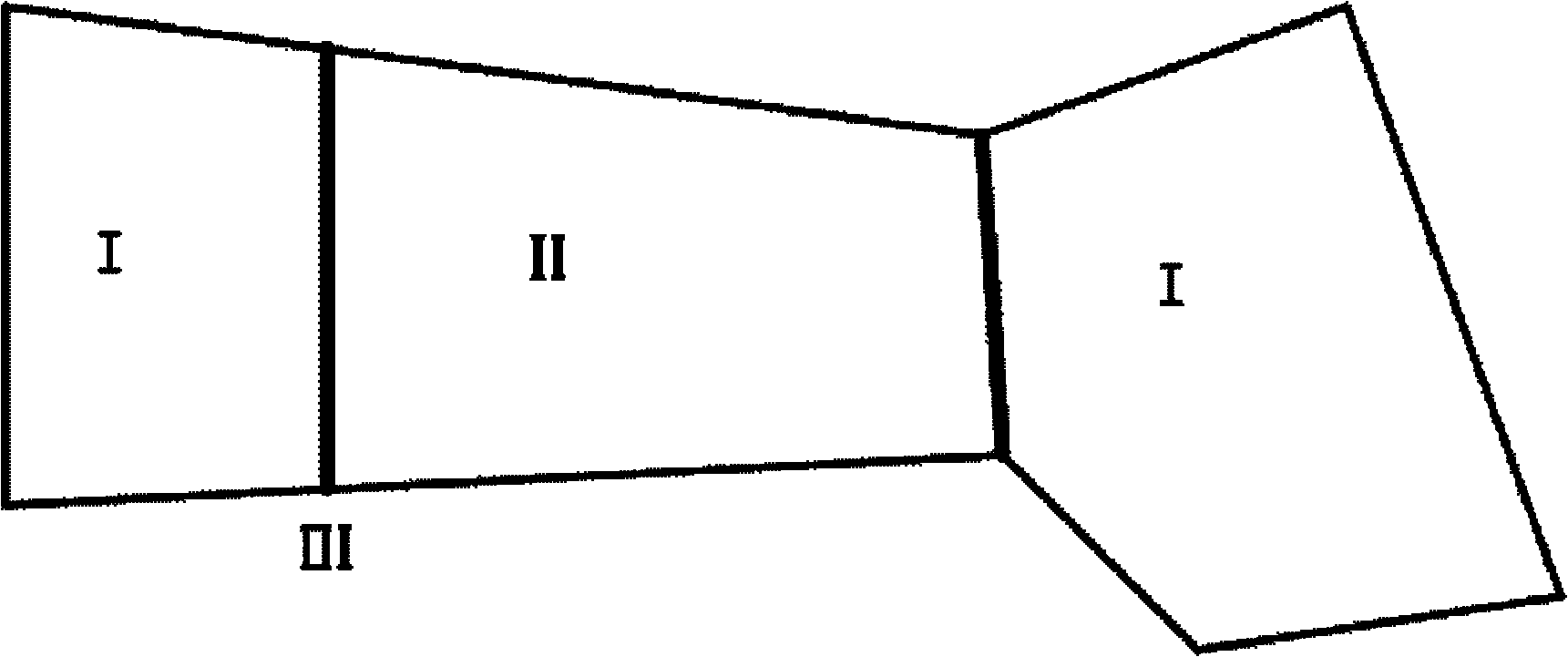

[0026] Ultra-high-strength steel laser tailor-welded blank forming part B-pillar reinforcement ( figure 1 As shown), Baosteel’s ultra-high-strength boron steel B1500HS with a thickness of 1.5mm is used for the front part with high safety requirements; while the upper and lower ends of the reinforcement that require both formability and energy absorption are used with a thickness of 1.5 mm. 1.0mm Baosteel high-strength steel HC340 ( figure 2 shown), laser welding followed by hot stamping. When a crash occurs, the role of the HC340 steel is to absorb the crash energy, while the role of the boron steel B1500HS is to move the load away from the cockpit, thereby avoiding catastrophic plastic deformation of the cockpit.

[0027] Forming process steps:

[0028] 1) blanking;

[0029] 2) Tailored laser welding;

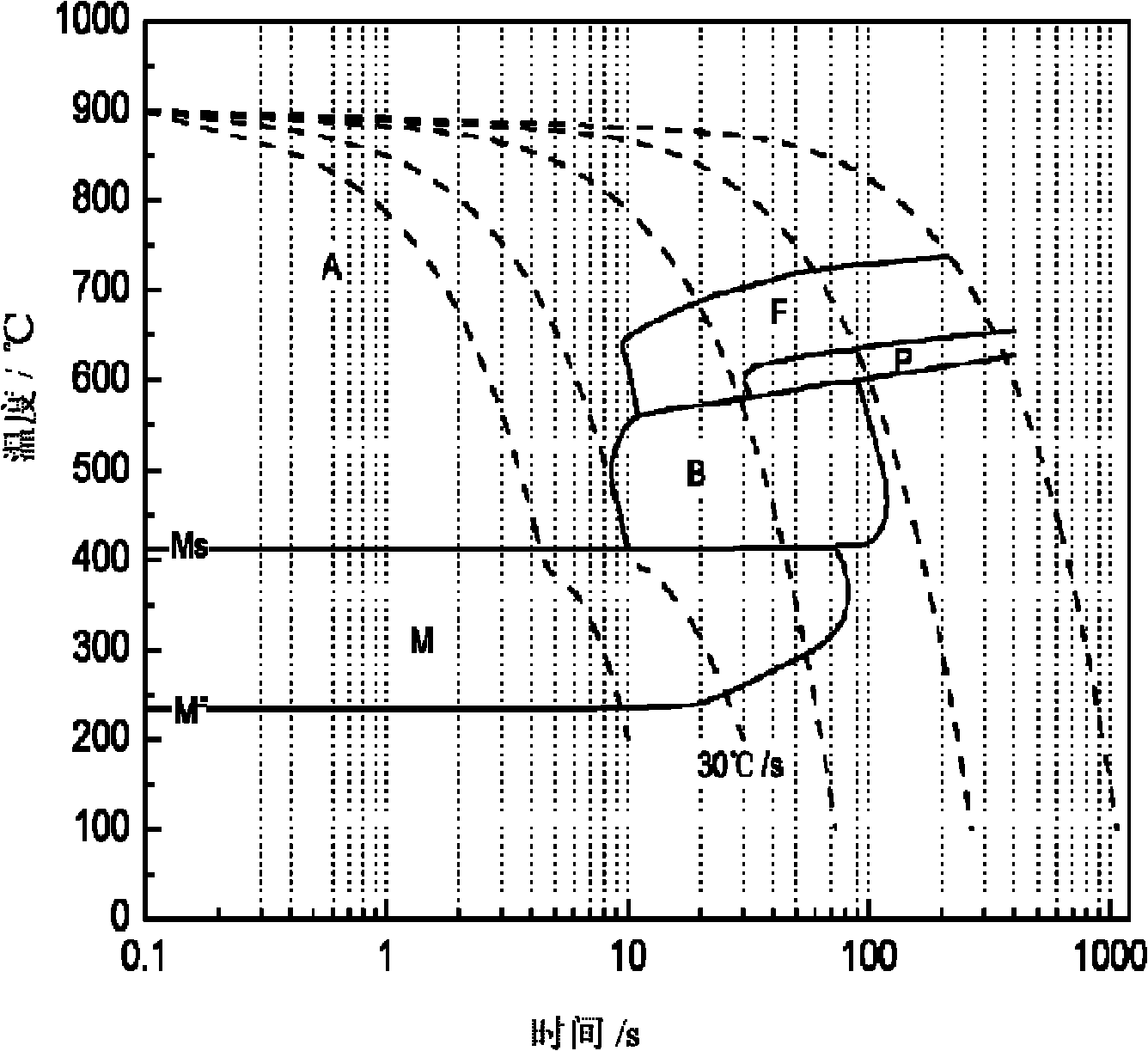

[0030] 3) Heating to 920-940°C in a walking furnace for at least 5 minutes to fully austenitize;

[0031] 4) Quick transfer to the press;

[0032] 5) Rapid mold clampin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com