Doped graphene electrode material, macro preparation method and application of doped graphene electrode material

A graphene electrode, graphene technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as graphene electrode instability, achieve low cost, simple process flow, and improve electrical conductivity and thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

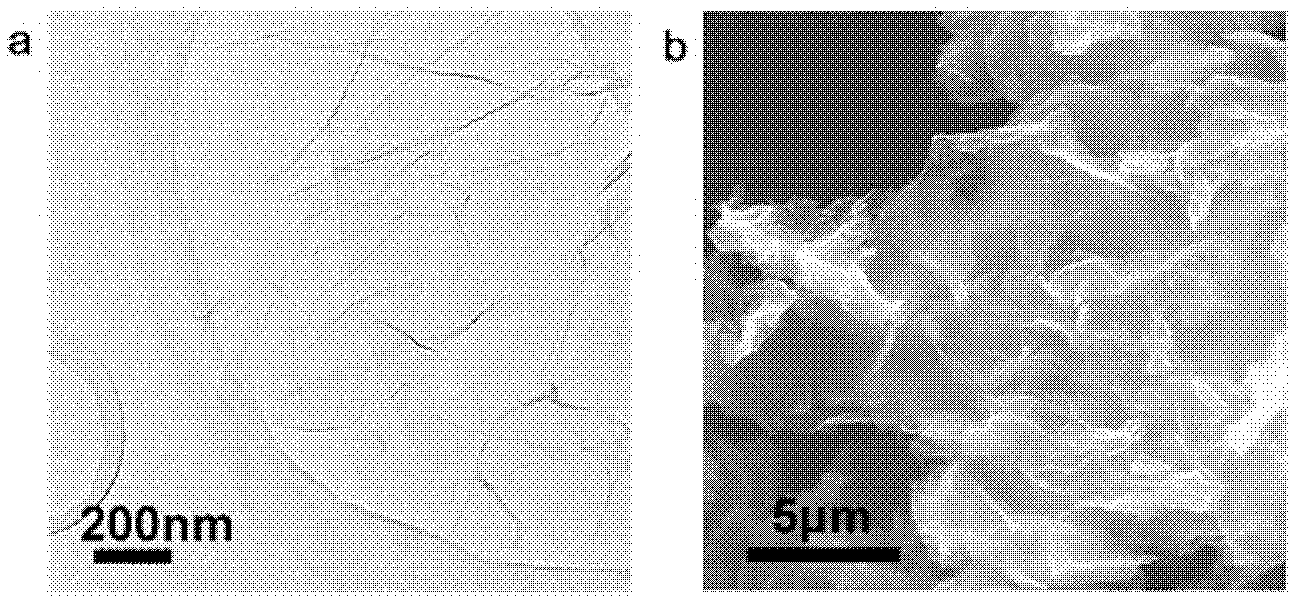

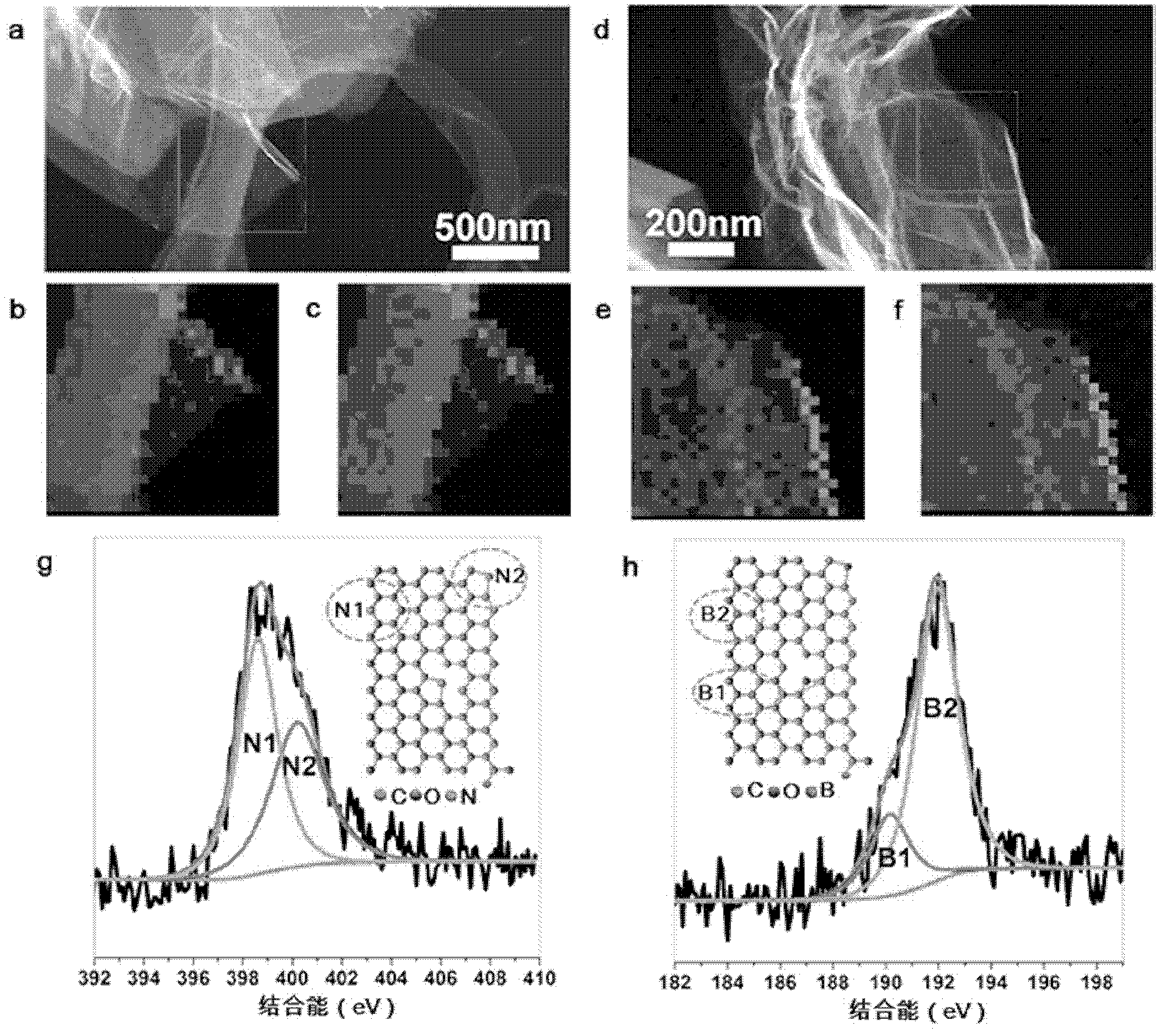

Embodiment 1

[0030] The lateral size prepared by chemical peeling method is 500nm~1μm, the number of layers is 1~3 layers, and the conductivity is 1×10 3 S / cm graphene is used as a raw material, and graphene (50 mg) with a C / O ratio (carbon-oxygen atomic ratio) of 10 is put into a SiC tube (1.5 m long and 40 mm in outer diameter), and under the protection of argon, The temperature was raised to 650°C at a heating rate of 10°C / min, and NH 3 (~99.0% pure by volume), retaining NH 3 The mixing volume ratio of argon and argon is 1:2, react for 1 h, and obtain nitrogen-doped graphene with a nitrogen content of 2.0 at%. Mix nitrogen-doped graphene, conductive carbon black, and polyvinylidene fluoride binder in a certain mass ratio (80:10:10), add N-methylpyrrolidone accounting for 200wt% of the mixture, and grind to form Uniform paste, then apply the slurry on Cu foil, dry at 100°C for 5h, make N-methylpyrrolidone volatilize, cut and press into tablets, dry at 100°C for 20h under vacuum as the ...

Embodiment 2

[0032] The difference from Example 1 is:

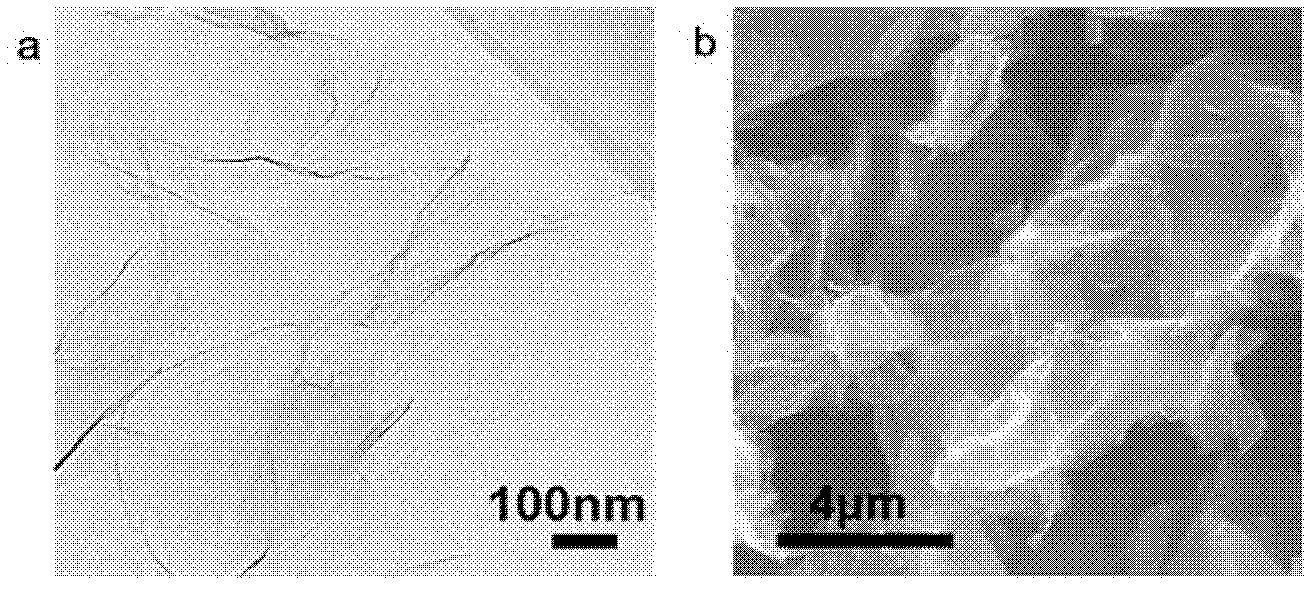

[0033] The lateral size prepared by chemical peeling method is 500nm~5μm, the number of layers is 1~3 layers, and the conductivity is 2×10 3 S / cm graphene is used as the raw material, graphene (50mg) with a C / O ratio of 9 is placed in a SiC tube (1.5m long, 40mm outer diameter), and the temperature is raised at 20°C / min under the protection of helium The temperature was raised to 700°C, and the NH 3 (~99.0% pure by volume), retaining NH 3 The mixing volume ratio of argon and argon is 1:3, react for 2 hours, and obtain nitrogen-doped graphene with a nitrogen content of 3.1 at%. Mix nitrogen-doped graphene, conductive carbon black, and polyvinylidene fluoride binder in a certain mass ratio (80:10:10), add N-methylpyrrolidone accounting for 300wt% of the mixture, and grind it into Uniform paste, then apply the slurry on Cu foil, dry at 100°C for 5h, make N-methylpyrrolidone volatilize, cut and press into tablets, dry at 100°C for 20h ...

Embodiment 3

[0035] The difference from Example 1 is:

[0036] The lateral size prepared by chemical peeling method is 500nm~5μm, the number of layers is 1~3 layers, and the conductivity is 2×10 3 S / cm graphene is used as raw material, graphene (150mg) with a C / O ratio of 9 is put into a SiC tube (1.5m long, 40mm outer diameter), and the temperature is raised at 30°C / min under the protection of helium The temperature was raised to 600°C, and the NH 3 (~99.0% pure by volume), retaining NH 3 The mixing volume ratio of argon and argon is 1:4, react for 4 hours, and obtain nitrogen-doped graphene with a nitrogen content of 3.2 at%. Mix nitrogen-doped graphene, conductive carbon black, and polyvinylidene fluoride binder in a certain mass ratio (70:15:15), add N-methylpyrrolidone accounting for 400wt% of the mixture, and grind it into Uniform paste, then apply the paste on Cu foil, dry at 110°C for 2h, make N-methylpyrrolidone volatilize, cut, press into pieces, dry at 100°C for 24h in vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com