Method for welding dissimilar metals

A metal and base metal technology, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve problems affecting the quality of titanium and stainless steel joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following description of a number of specific and alternative embodiments is provided to provide an understanding of the inventive features of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without such specific details. Some details may not be described at length so as not to obscure the invention. For ease of reference, common reference numerals are used throughout the figures when referring to the same or similar features common to the figures.

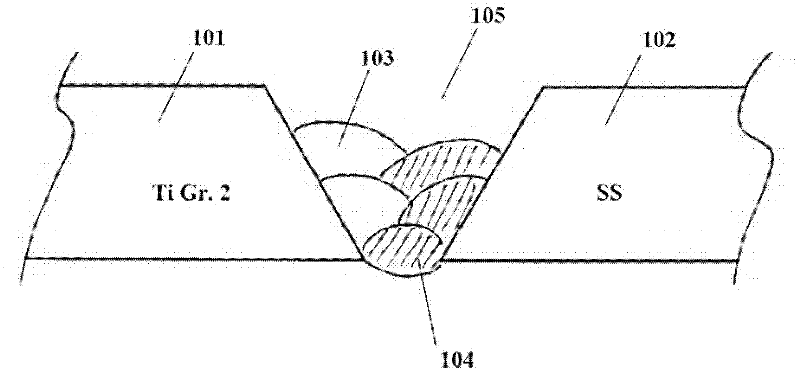

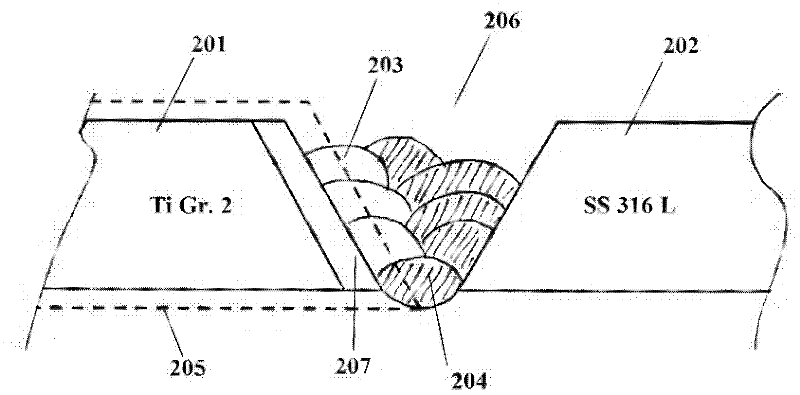

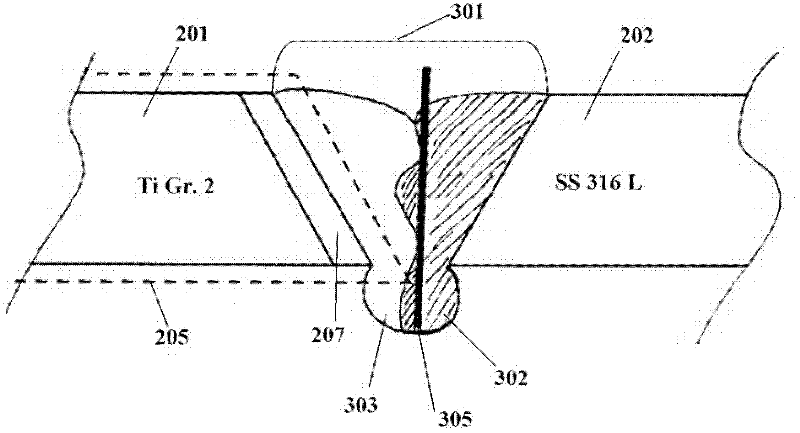

[0017] The invention provides a gas tungsten arc welding method using a V-shaped butt joint for connecting a titanium base metal part and a stainless steel base metal part. In the arc welding method of the present invention, two intermediate electrodes, vanadium and aluminum copper, are introduced between the titanium base metal and the stainless steel base metal. This method provides a strong weld between the two dissimilar base metals.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com