Mechanical automatic butt-joint releasing device

A technology of automatic docking and releasing device, applied in the directions of transportation and packaging, underwater operation equipment, ships, etc., can solve the problems of safety and complex structure, and achieve the effect of avoiding danger and inconvenience, and being easy to use and maintain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is a further detailed description of the mechanical automatic docking release device of the present invention in conjunction with the accompanying drawings and a preferred embodiment:

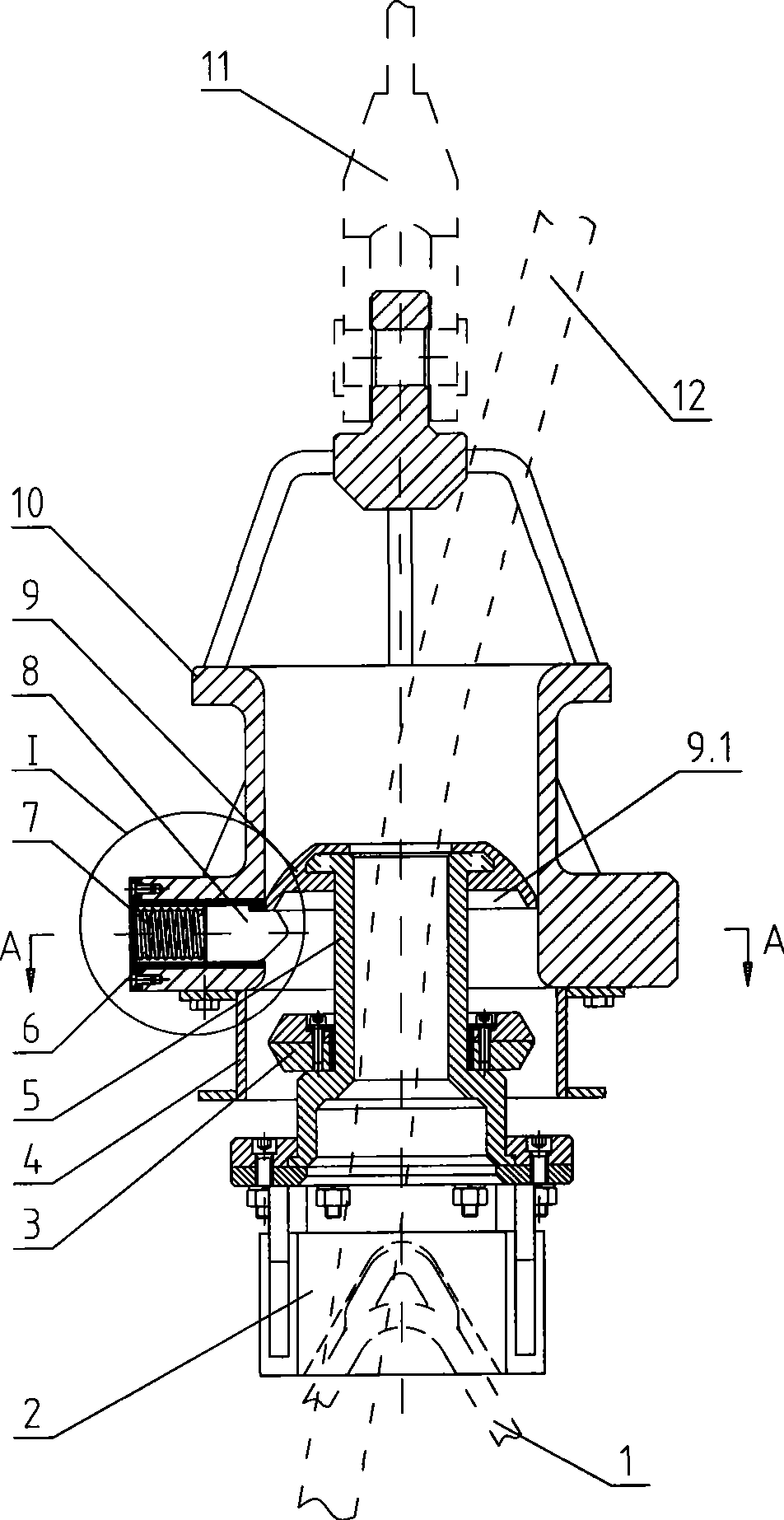

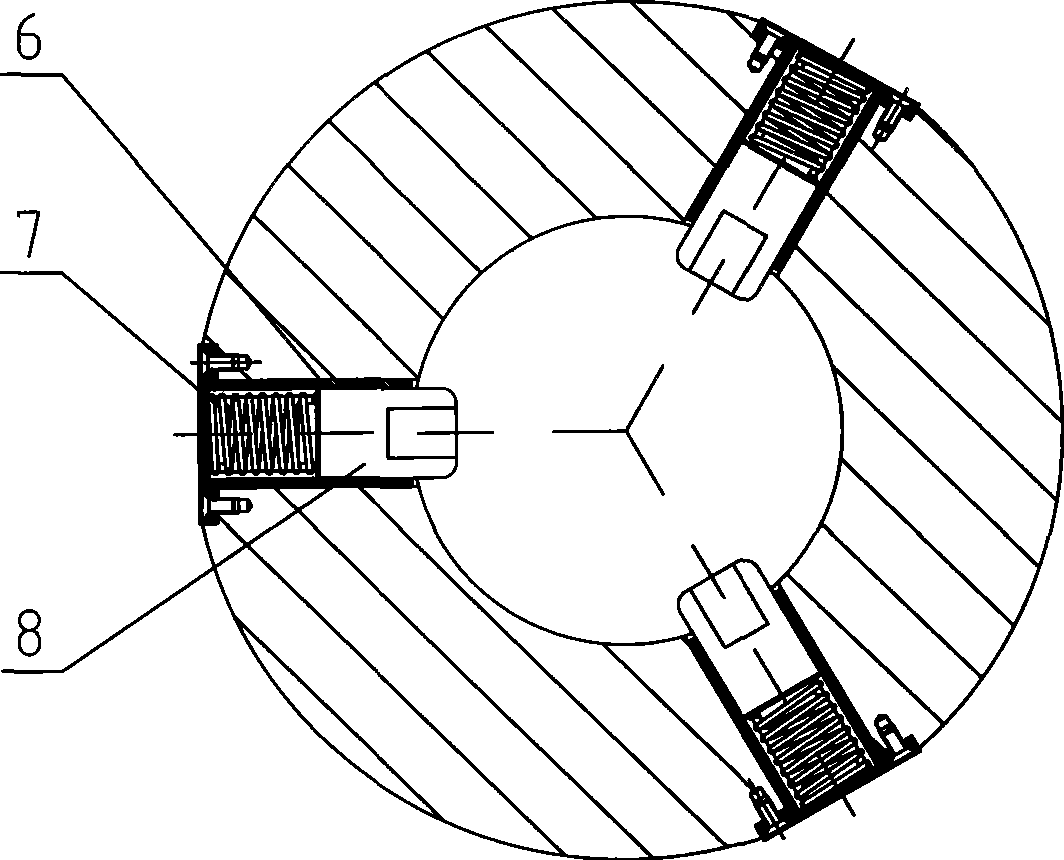

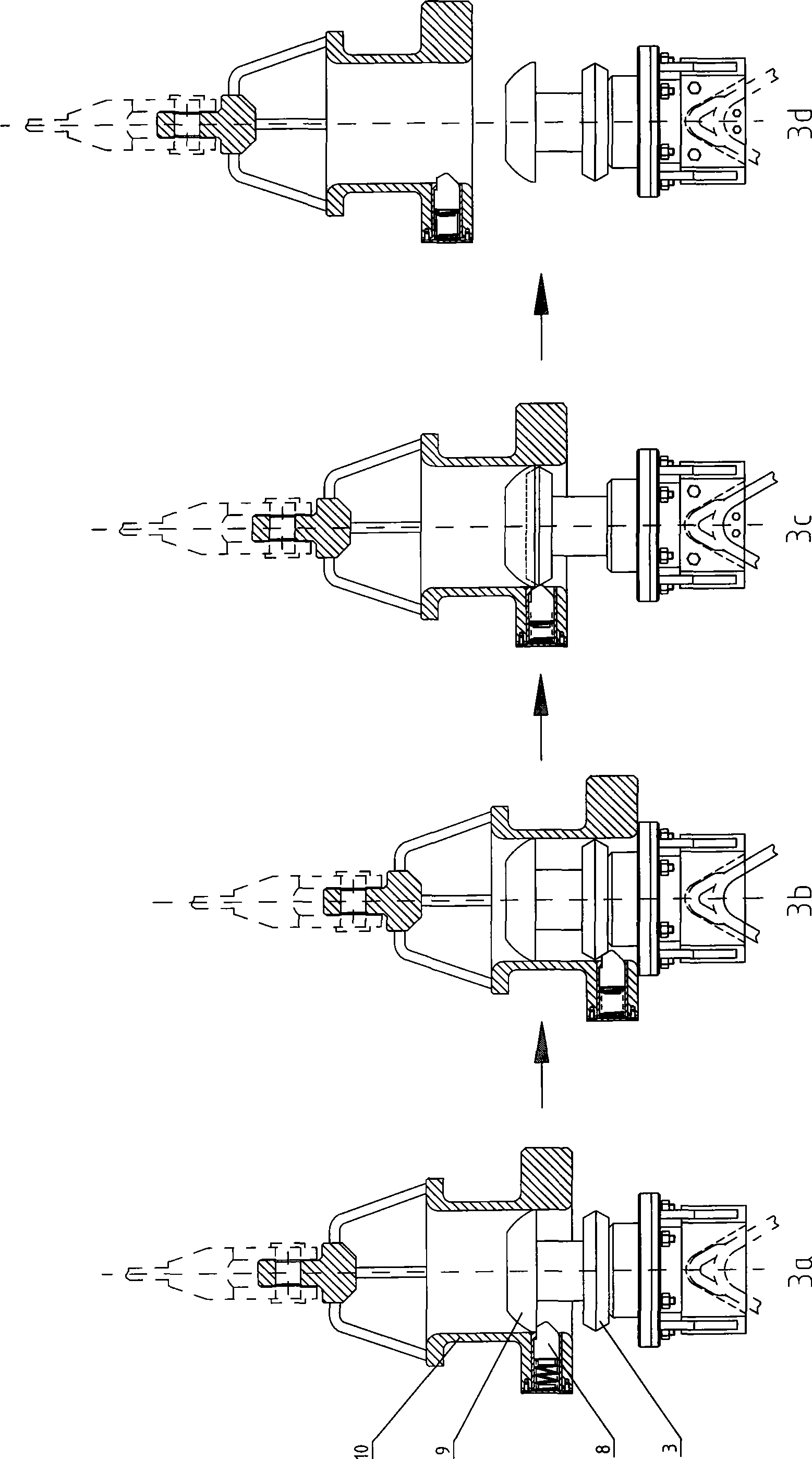

[0022] Such as figure 1 , figure 2 and Figure 10 , The docking release device of the present invention includes a hook part connected with the hoisting cable and a boom part connected with the hoisted equipment. The hook portion includes a cylindrical hook body 10 capable of passing through an umbilical 12 of the work equipment. The upper flange of the hook body 10 can be connected with the hoisting cable through the cable joint 11. In the lower end flange of the hook body 10, three shaft pin sliding sleeves 6 are evenly arranged radially on the same axial section. Each shaft pin sliding sleeve 6 is provided with a spring shaft pin 8 that can expand and contract under the force of the compression spring 7, and the front end of the spring shaft pin 8 always extends out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com