A kind of submerged arc automatic welding method of nickel base alloy

A technology of submerged arc automatic welding and nickel-based alloys, which is applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve problems such as easy-to-produce defects, achieve the effects of improving welding quality, improving the first pass rate, and preventing hot cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

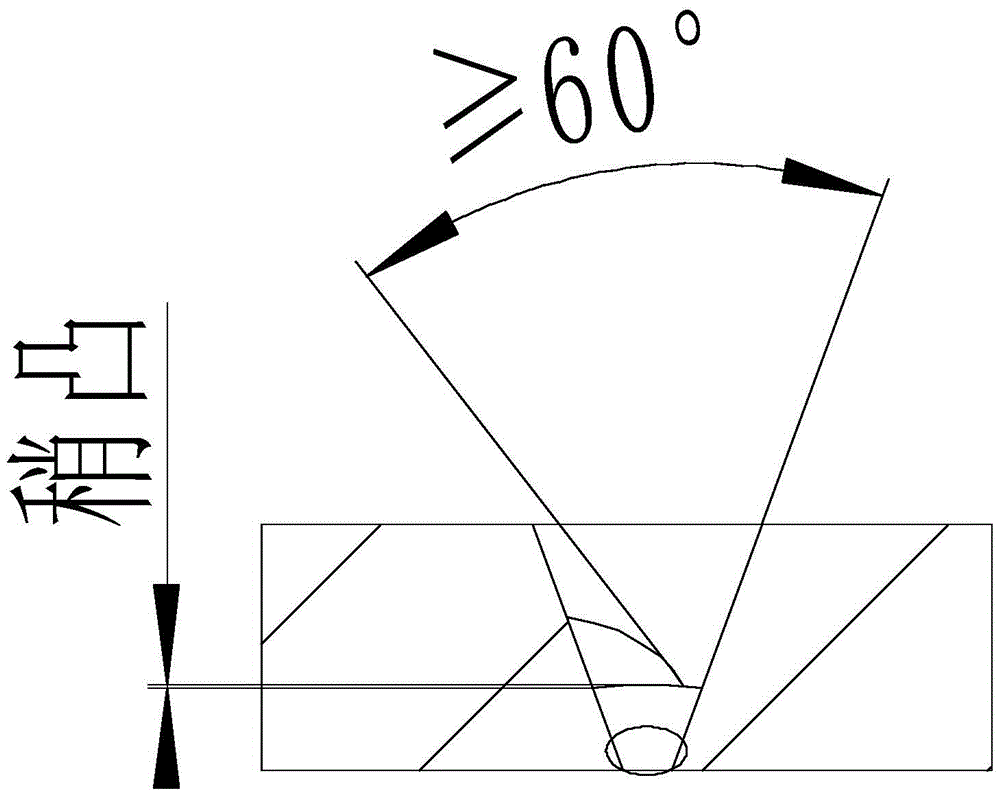

[0030] Embodiment 1: a kind of submerged arc automatic welding welding method of 18mm thick nickel base alloy N10276, such as Figure 1-2 shown, including the following steps:

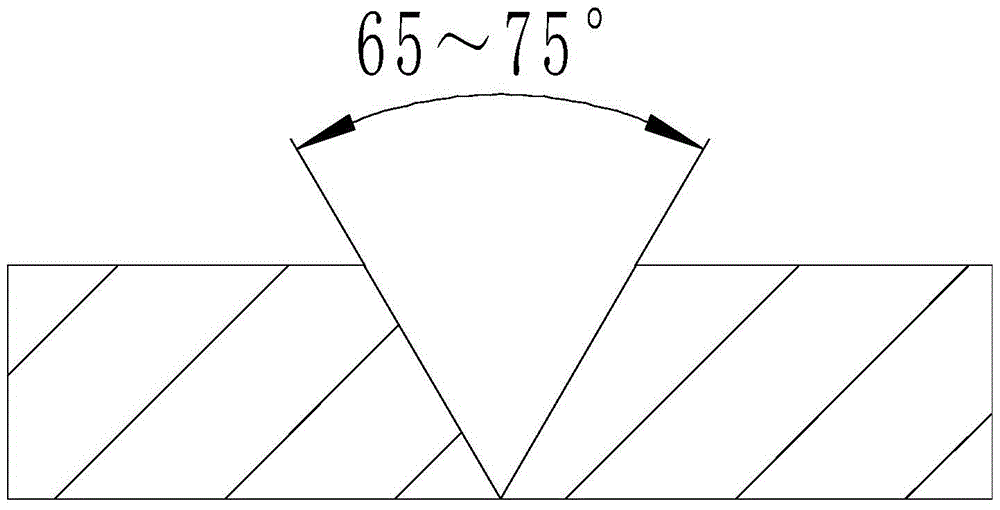

[0031] Among them, the groove form is as image 3 As shown, the V-shaped groove is adopted, the groove angle is 65°, the blunt edge is 2±1mm, the pair gap is 3+1mm, and the welding sequence of the weld bead is as follows Figure 4 As shown, the welding process parameters are shown in Table 2.

[0032] Table 2 Welding process parameters of embodiment 1 of the present invention

[0033]

[0034] 1) The groove is processed into a V shape, and the groove angle is 65°. Compared with steel, the groove angle is larger and the gap is larger, so as to overcome the defects of poor liquid fluidity, easy generation of pores and unfused defects of the base metal;

[0035] 2) Use a stainless steel wire brush to clean the welding wire, the surface of the groove and the range of 50mm on both sides of the groove,...

Embodiment 2

[0039] A kind of submerged arc automatic welding welding method of 12mm thick nickel-based alloy N10276, such as Figure 1-2 shown, including the following steps:

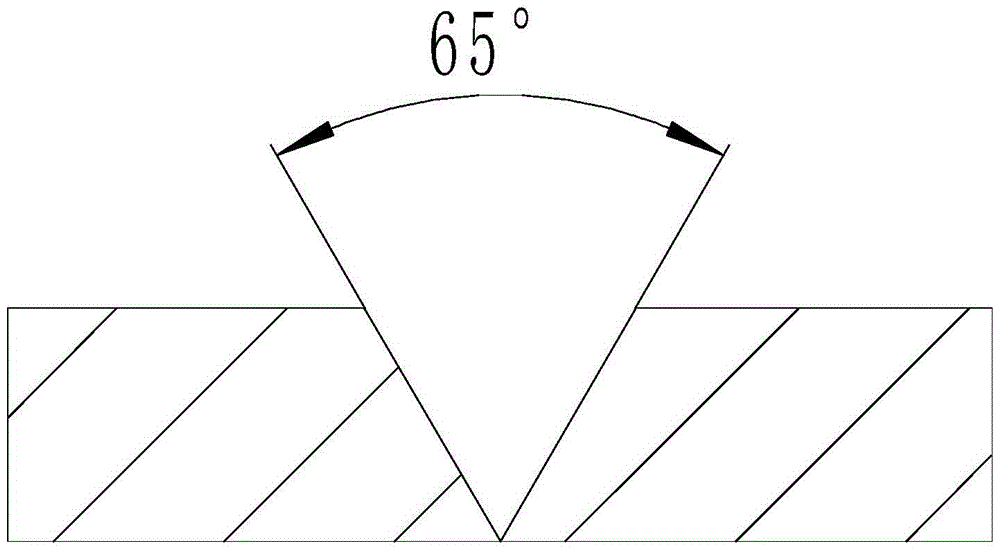

[0040] Among them, the groove form is as Figure 5 As shown, the V-shaped groove is adopted, the groove angle is 75°, the blunt edge is 2±1mm, the pair gap is 3+1mm, and the welding sequence of the weld bead is as follows Figure 6 As shown, the welding process parameters are shown in Table 3.

[0041] Table 3 welding process parameter of embodiment 2 of the present invention

[0042]

[0043] 1) Process the groove into a V shape with a groove angle of 75°;

[0044] 2) Use a stainless steel wire brush to clean the welding wire, the surface of the groove and the range of 50mm on both sides of the groove, and use ethanol to clean if necessary according to the degree of surface pollution;

[0045] 3) Determine the welding parameters of the bottom layer, and use argon tungsten arc welding for bottom layer welding....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com