Compound pipeline welding process of L245NB+316L

A welding process and composite pipeline technology, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of reducing the first pass rate of pipeline welding, affecting the smooth progress of pipeline welding, etc., to reduce the labor intensity of workers, Improve the first pass rate and the effect of reasonable process

Inactive Publication Date: 2012-04-18

LIAOHE GASOLINEEUM EXPLORATION BUREAU

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, since most of the existing pipe welding materials use L245NB+316L composite pipes, the original welding process is no longer suitable for the composite welding requirements of such composite pipes, which reduces the pass rate of pipe welding and affects the smoothness of pipe welding construction. conduct

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

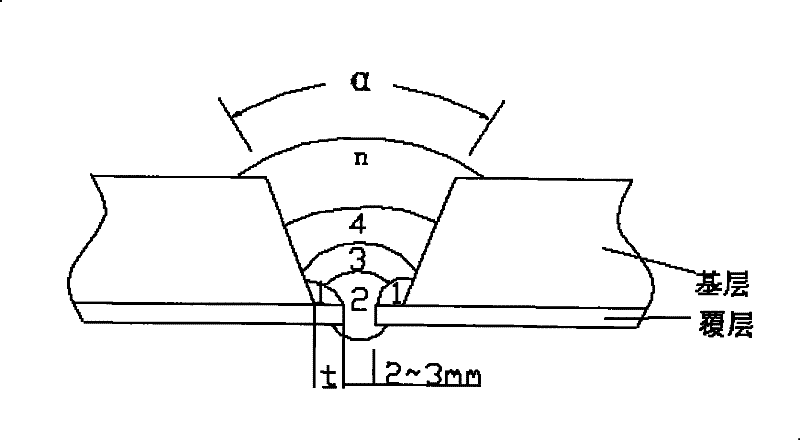

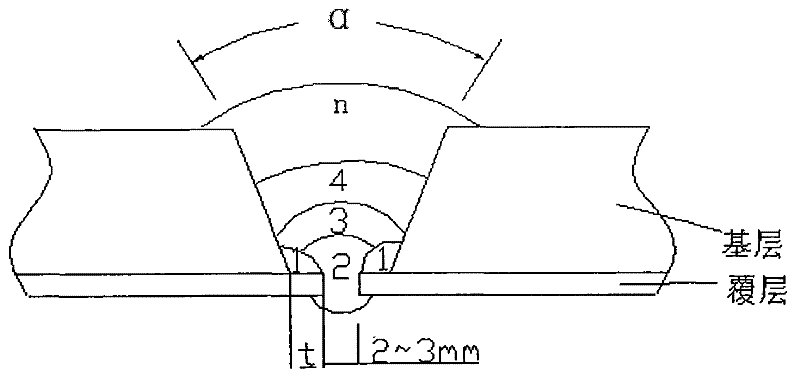

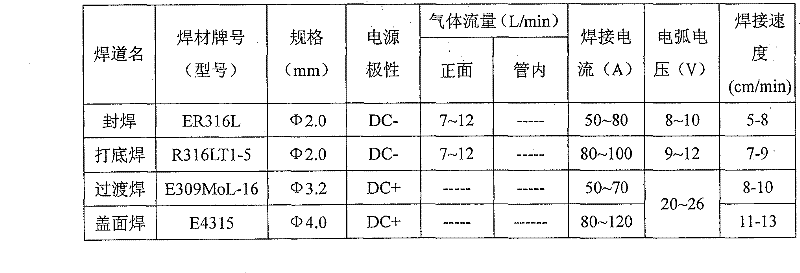

[0019] In the figure, the label "1" is sealing welding, "2" is backing welding, "3" is transition welding, "4" is filling welding, "n" and above is capping welding; in the figure t is the length of blunt edge, 2-3mm, α is the groove angle, which is determined according to the welding process design. The welding process parameters of this composite pipe are shown in the table below:

[0020]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a L245NB? compound pipeline welding process, which uses a compound bevel and comprises the steps of sealing welding, backing welding, transitional welding and filling cosmetic welding according to the operation sequence of bevel processing, sealing welding, assembly, backing welding, transitional welding and cosmetic welding on site. The compound pipeline welding process has reasonable work procedures and is easy to apply. Due to the adoption of the compound pipeline welding process, the labor intensity of the worker can be greatly reduced, the one-time compound pipeline welding qualified rate is improved, the step of supplying argon into the pipe during the common welding-wire welding is omitted, the time is saved, the argon expense is reduced, and excellent benefit is obtained.

Description

Technical field: [0001] The invention relates to a pipeline welding process method used in the construction of petroleum, chemical production, water supply, gas supply and other civil supply and transportation pipelines. Background technique: [0002] In the production process of petroleum and chemical factories and mines, as well as in the construction and maintenance of urban civil water supply, gas supply, and heating pipelines, a large number of pipeline welding work is required. At present, the pipeline welding process used on site is usually operated separately for the material of the composite steel plate used, and different welding rods are used according to the material of the steel plate. When the base metal is 316L+20R, the welding rod used for the base layer is J422, and the welding rod used for the transition layer is A042. The electrode used for the double layer is A022; when the base material is 316L+16MnR, the electrode used for the base layer is J507, the el...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23K9/16B23K9/235B23K33/00B23K103/16B23K101/06

Inventor 段占军任志勇杨利娜金作相陈晓霞汪澜钟宏王冬梅苑学松

Owner LIAOHE GASOLINEEUM EXPLORATION BUREAU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com