Biological enzyme cold-pad-batch short-process open-width continuous-scouring bleaching and dyeing production technology of cotton knitted fabric

A cotton knitted fabric and production process technology, which is applied in the field of cotton knitted fabric biological enzyme cold pad stacking short-process open-width continuous scouring, bleaching and dyeing production process, can solve the problems of affecting the ecological environment, long process, large fabric damage, etc., and achieves sewage discharge. The effect of reducing the quantity, improving the internal quality, and reducing the overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0046] Implementation case 1: Dyeing process of 26-count semi-combed yarn double-knitted rib fabric

[0047] Process ① bleaching → process ② washing after scouring → process ③ dyeing → process ④ washing after dyeing

[0048] Process ① Opening and shaping of gray cloth→open cloth feeding→continuous impregnation of the first compound enzyme preparation and loose stacking for pretreatment→continuous impregnation of the second compound enzyme preparation and loose stacking for refining→continuous impregnation of the third Composite enzyme preparation and rolled → after rolling, turn and keep warm and stack.

[0049] The composition and pretreatment process conditions of the first compound enzyme preparation:

[0050] WCK125-1, 3~5 g / L, non-ionic surfactant SFQ-320, 1~2g / L, pH 4.5~5, treatment temperature 40-60℃, vehicle speed 30~50 m / min, liquid carrying rate 110 %, 30°C heat preservation and stacking for 20 minutes;

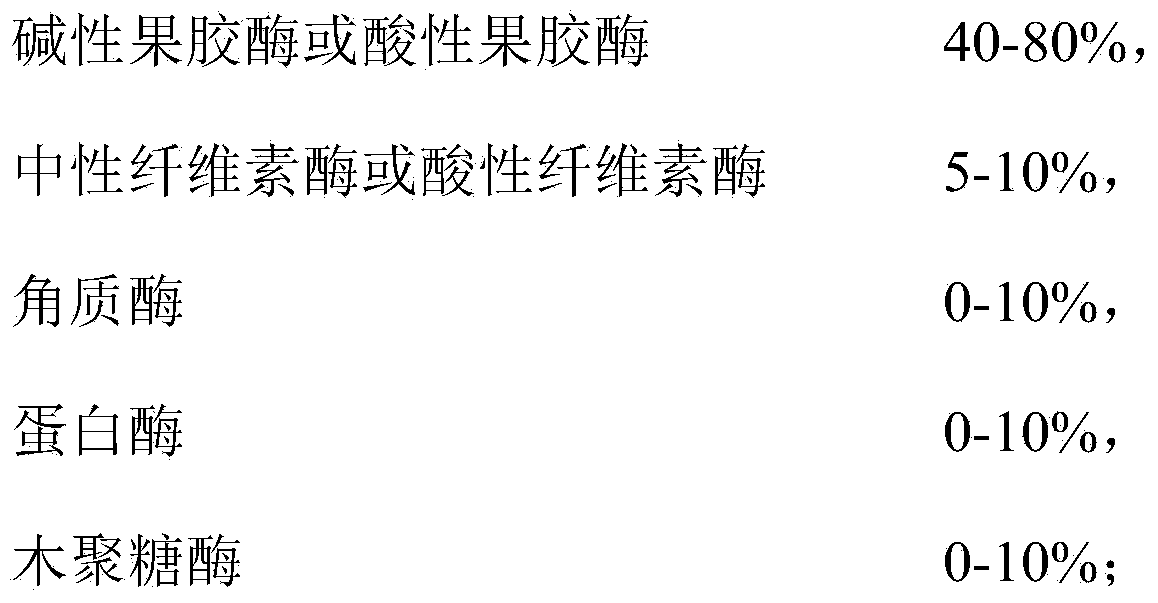

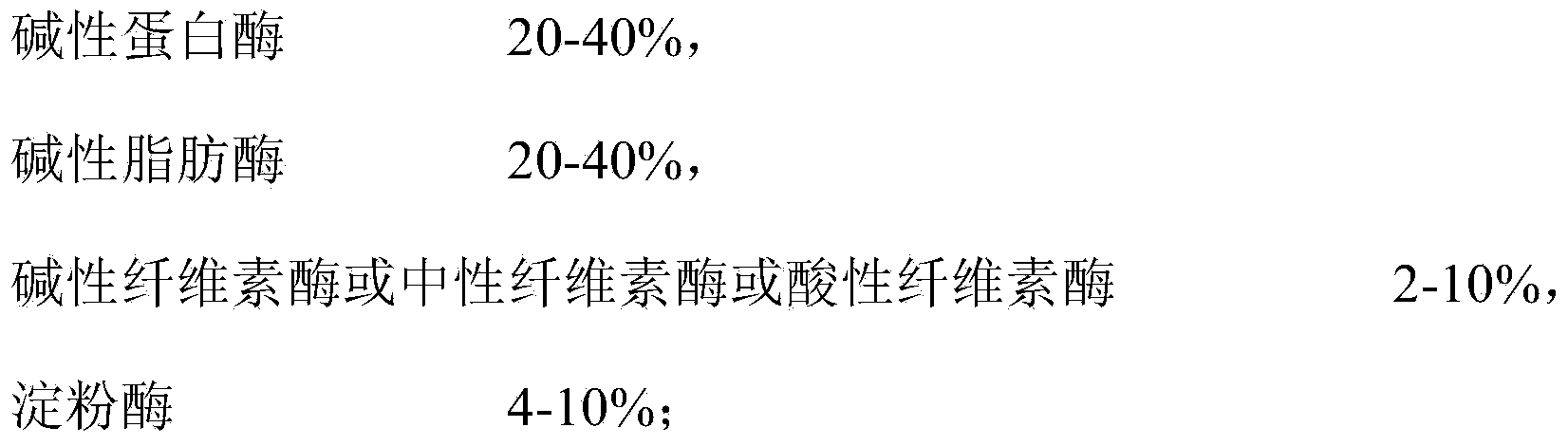

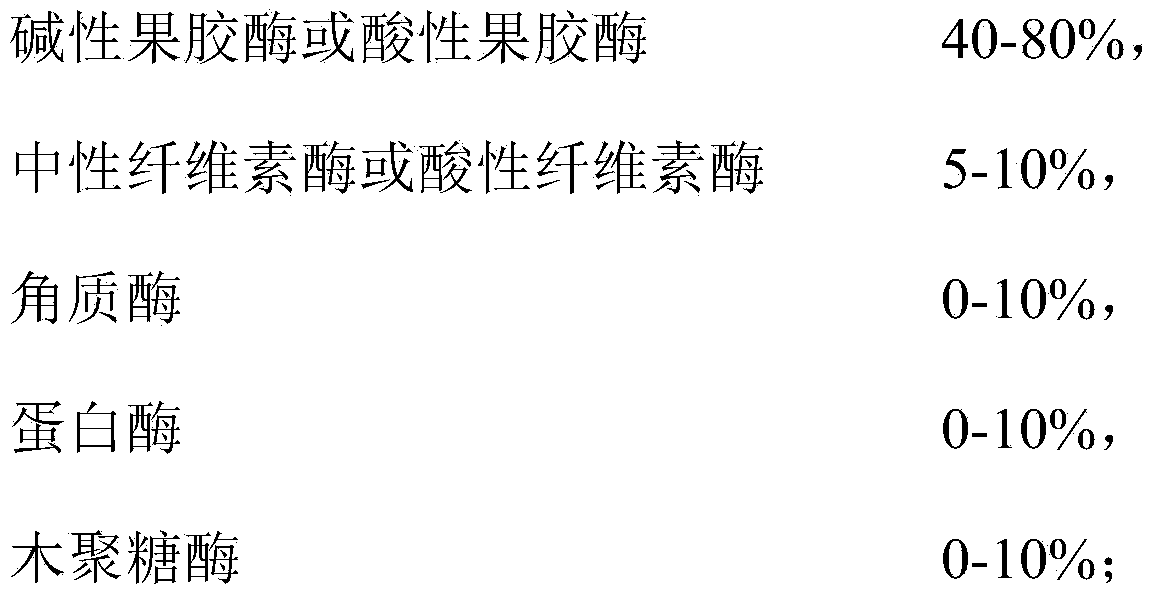

[0051] The composition and refining process conditions of t...

Embodiment example 2

[0068] Implementation Case 2: Single-sided scouring, bleaching and dyeing of polyester-cotton knitted flannelette

[0069] Technological process: Opening and shaping → Open width cloth feeding → Pretreatment of the first compound enzyme preparation → Refining of the second compound enzyme preparation → Oxygen bleaching of the third compound enzyme preparation → Insulation stacking → Water washing → The fourth compound enzyme preparation Deoxygenation→water rolling, drying→stenter drying→dyeing→insulation stacking→water washing→the fifth compound enzyme preparation soaping→water washing→stenter drying and setting→finished product.

[0070] The composition of the first compound enzyme preparation and pretreatment process conditions:

[0071] WCK125-1, 3~5g / L, non-ionic surfactant SFQ-320, 1~2g / L, pH4~5, treatment temperature 55~60℃, vehicle speed 30~50m / min, liquid carrying rate 110%, 30 ℃ insulation stacking for 20 minutes;

[0072] The composition of the second compound enzy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com