Patents

Literature

38results about How to "The preparation process is highly controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

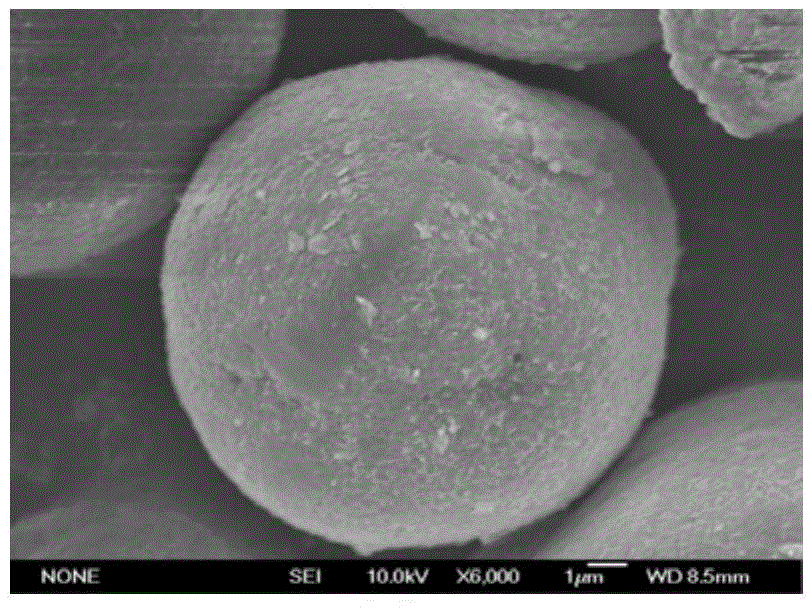

Multi-stage core and shell structure multi-element material, precursor thereof and preparation method for multi-stage core and shell multi-element material and precursor

InactiveCN102631875AHigh charge-discharge specific capacityGood cycle stability and thermal stability and safety performanceCell electrodesMicroballoon preparationLithium electrodeCompound structure

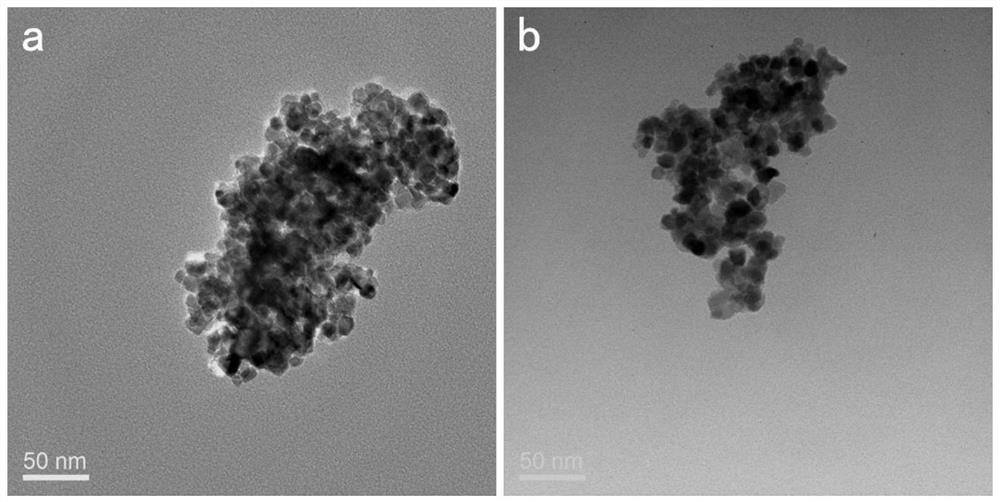

The invention relates to a multi-stage core and shell structure multi-element material precursor used for an anode material of a lithium ion battery. The molecular formula of the multi-stage core and shell structure multi-element material precursor is (1-x)Li[NiaMnbCo1-a-b][OH]2 x [NimConM1-m-n][OH]2, wherein M=Mn, Al, Mg andTi, the x is larger than or equal to 0.2 and smaller than or equal to 0.9, the a is larger than or equal to 1 / 3, the b is smaller than or equal to 1 / 2, the m is larger than or equal to 0.6 and smaller than 1, and the n is larger than or equal to 0 and smaller than or equal to 0.3. A core and shell multi-layered compound structure is adopted, a core of the core and shell multi-layered compound structure is made of a high-nickel-based and high-specific-capacity multi-element material, a shell of the core and shell multi-layered compound structure is made of a high-safety material with the identical nickel and manganese molar content, wherein the high-safety material contains a small quantity of cobalt or does not contain the cobalt, a space between the core and the shell is made of a multi-layered material and is configured according to proportions different from those of the shell and proportions of the core, the proportions of core materials in the multi-layered material from inside to outside are gradually reduced while the proportions of shell materials in the multi-layered material from inside to outside are gradually increased, and accordingly the multi-stage core and shell structure is formed. The multi-stage core and shell structure multi-element material precursor not only has a high specific capacity performance of the core materials, but also has characteristics of high circulatory stability and safety of the shell materials, and is low in large-scale manufacturing cost. The cost is not increased as compared with a homogeneous multi-element material. Besides, repeatability is high, batch stability is good, and the multi-stage core and shell structure multi-element material precursor meets requirements of large-scale commercial application.

Owner:SHANGHAI PYLON TECH CO LTD

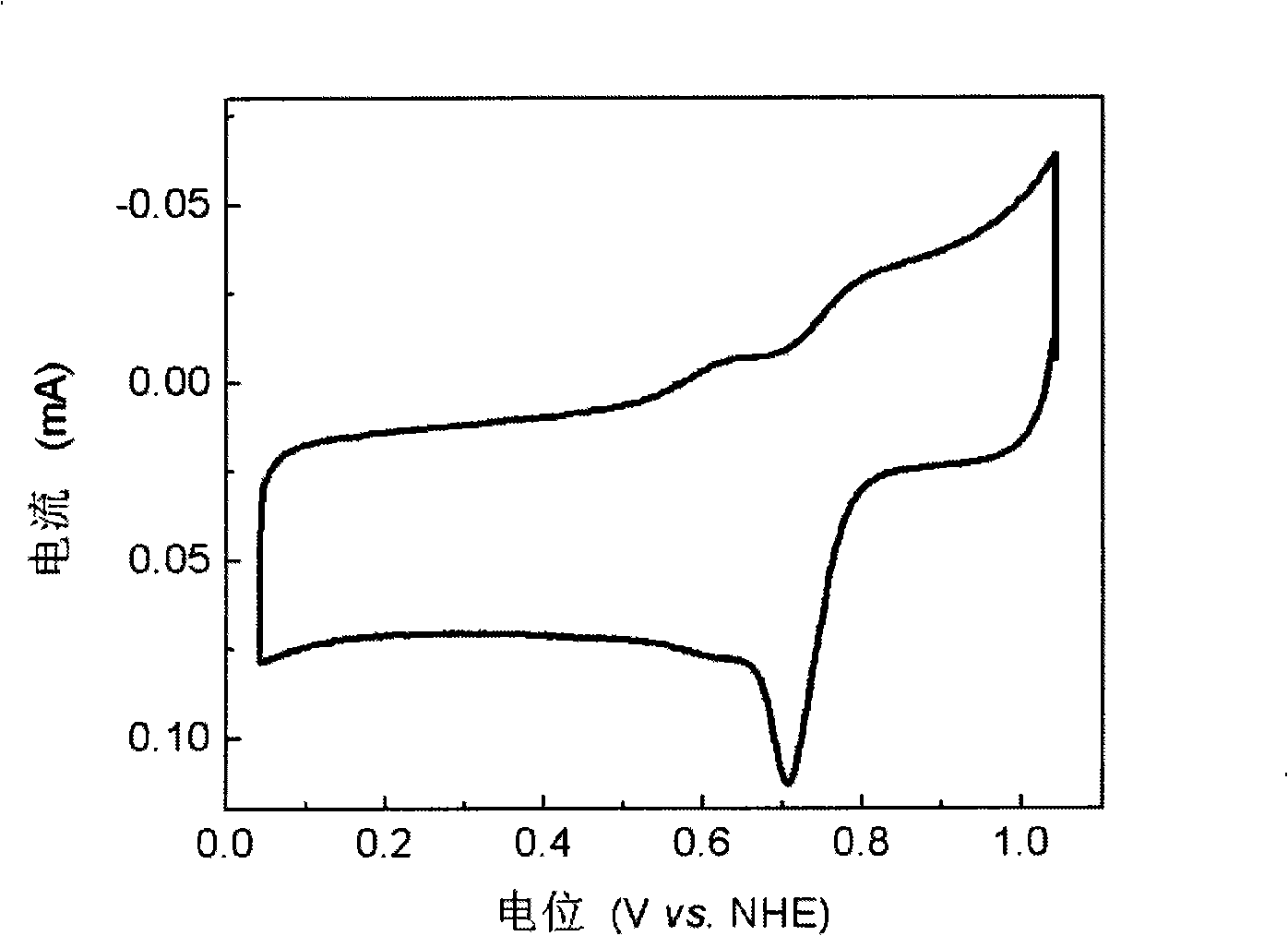

Oxygen reduction catalyst for fuel cell and preparation method thereof

InactiveCN101306385AOvercome costsOvercoming craftOrganic-compounds/hydrides/coordination-complexes catalystsCell electrodesPorphyrinPhthalocyanine

The invention discloses a fuel battery used oxygen reduction catalyst and the preparation method thereof, and relates to a loaded catalyst which is composed of a transition metal chelate and a carbon black carrier, wherein, the transition metal chelate is prepared through the reaction of transition metal salt and diethylene triamine. MN3 structure is included in the molecule of the transition metal chelate (M is transition metal and N is nitrogen atom), and an active site is provided for catalyzing the oxygen reduction reaction. The catalyst takes the diethylene triamine with low cost as the raw material; overcomes the problems of the traditional oxygen reduction catalyst of the macrocyclic compound, such as metalloporphyrin and metal phthalocyanine, that the cost of the raw materials is high, and the traditional oxygen reduction catalyst is not suitable for the large scale production industrial production; and has the advantages of simple preparation technology, mild condition, secure process, low cost, and so on. The catalytic performance of the catalyst is equivalent to the oxygen reduction of the metalloporphyrin, the catalytic has good anti carbinol oxygenic property, and can be applied to the oxygen reduction reaction of the cathode of the battery.

Owner:SHANGHAI JIAO TONG UNIV

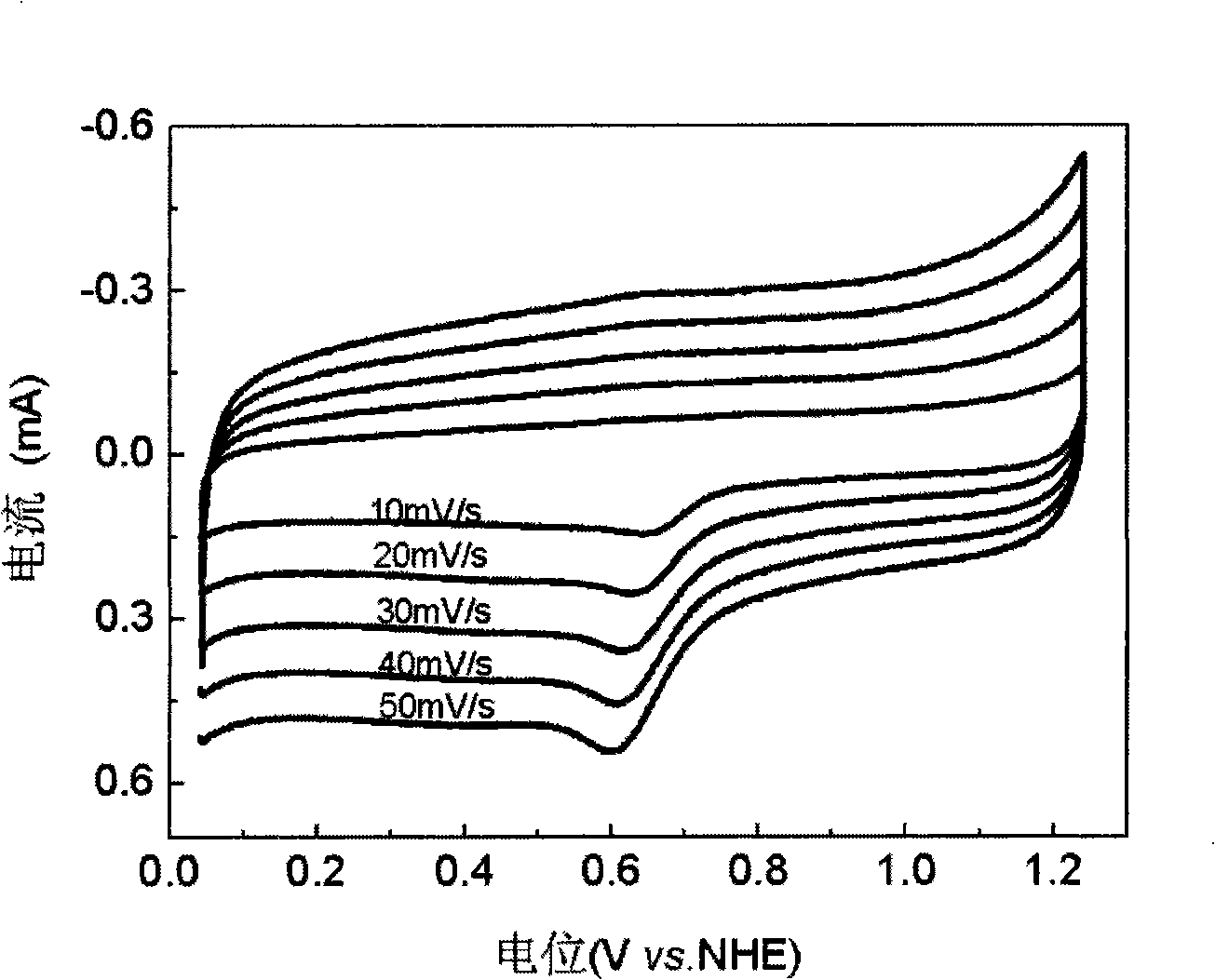

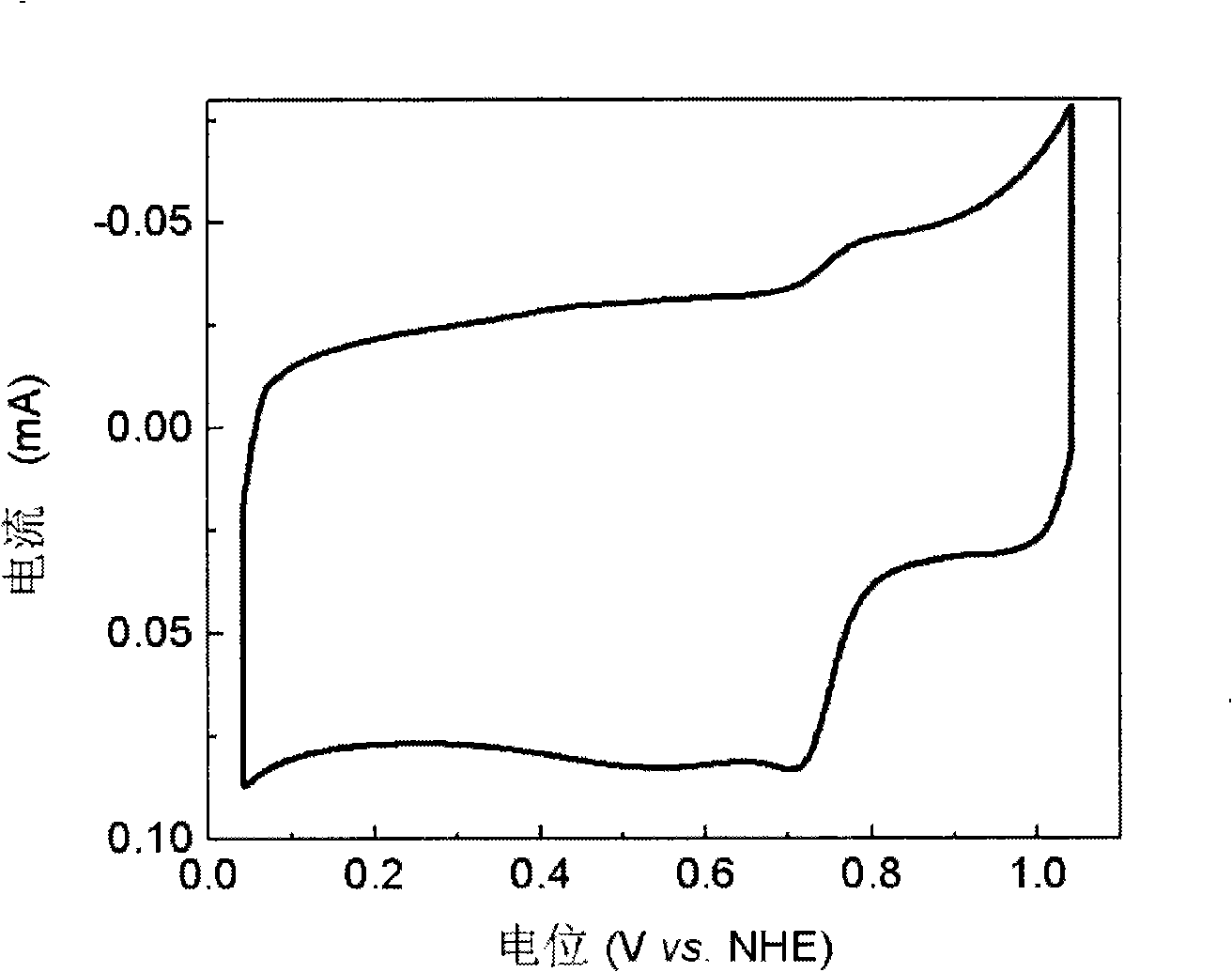

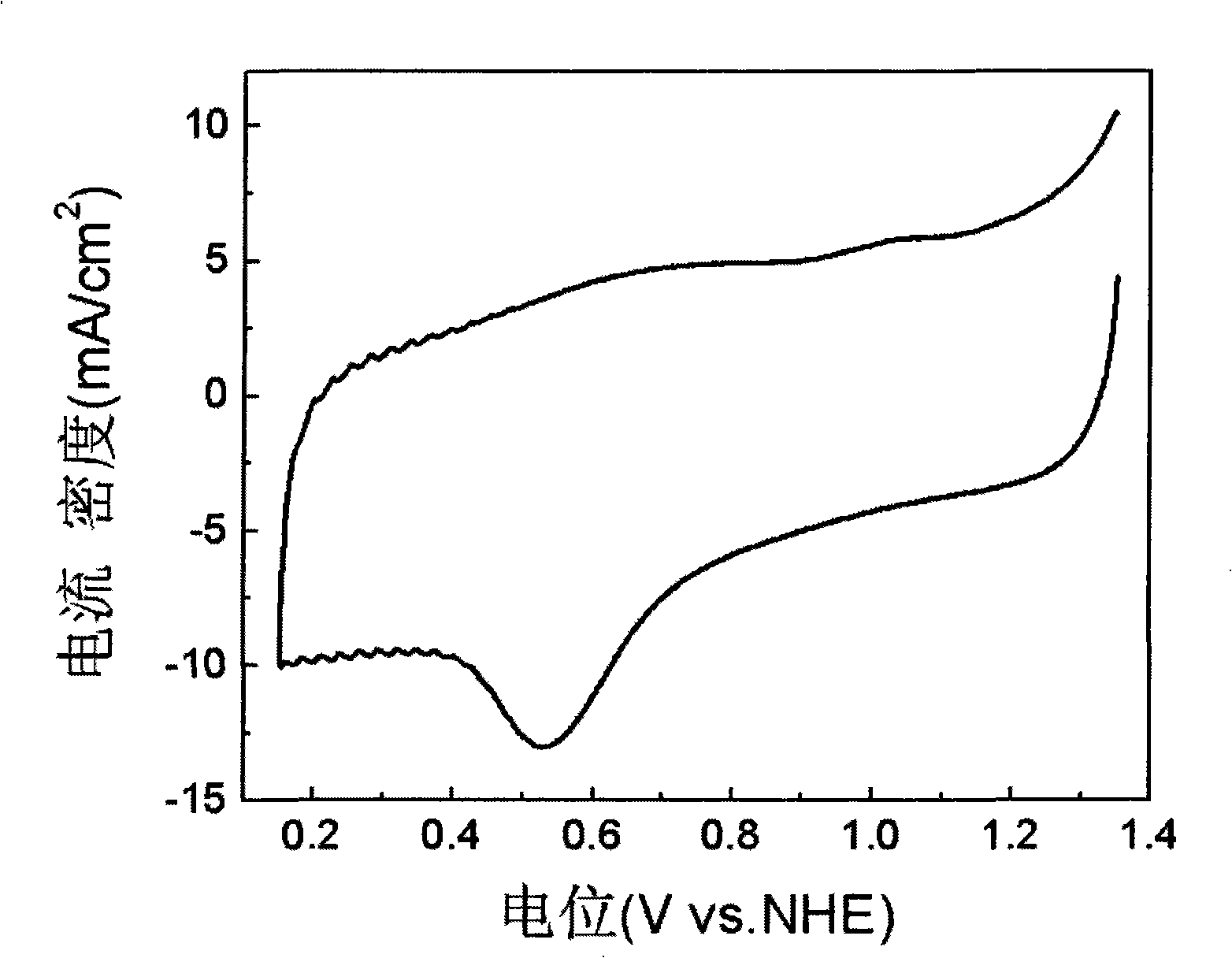

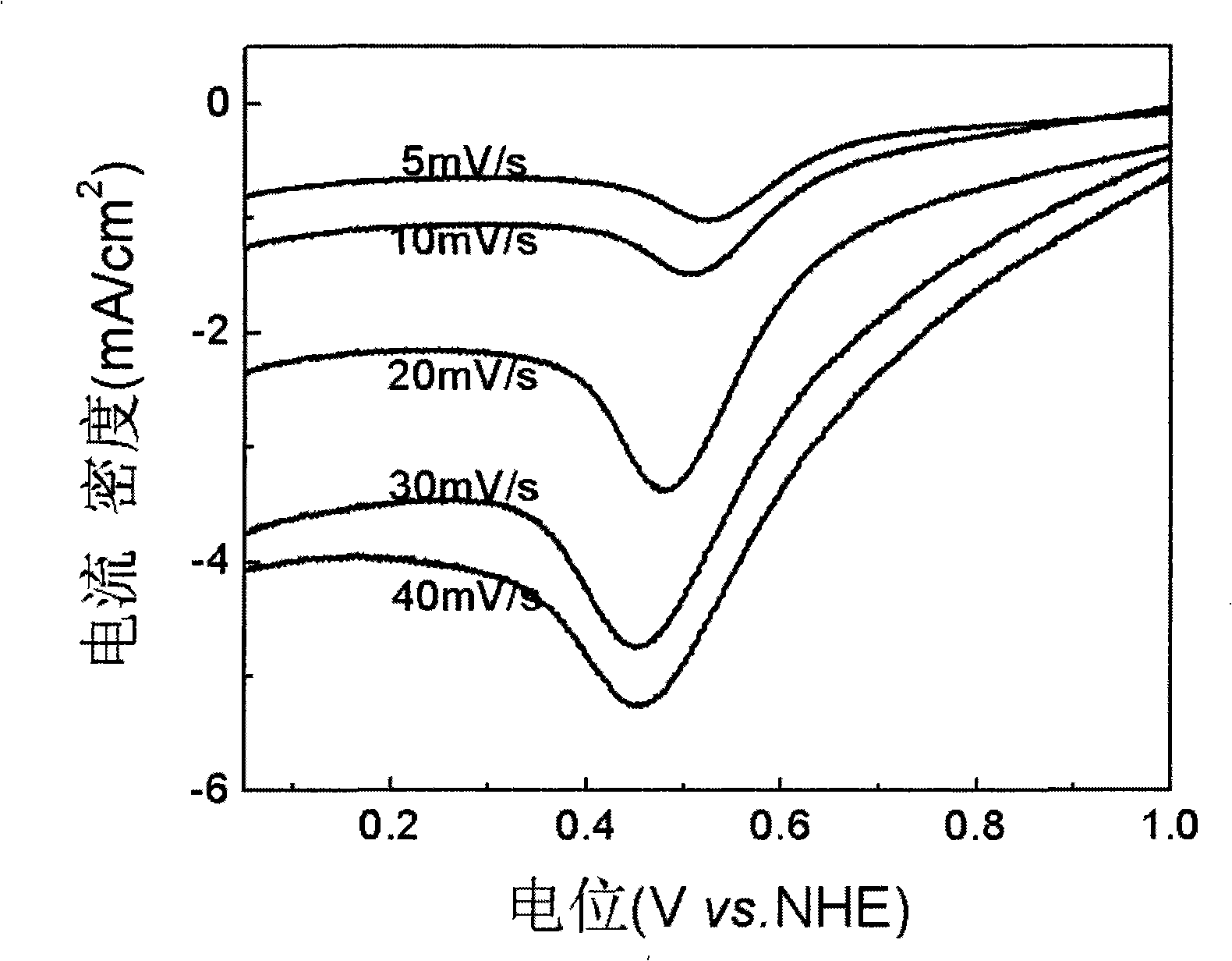

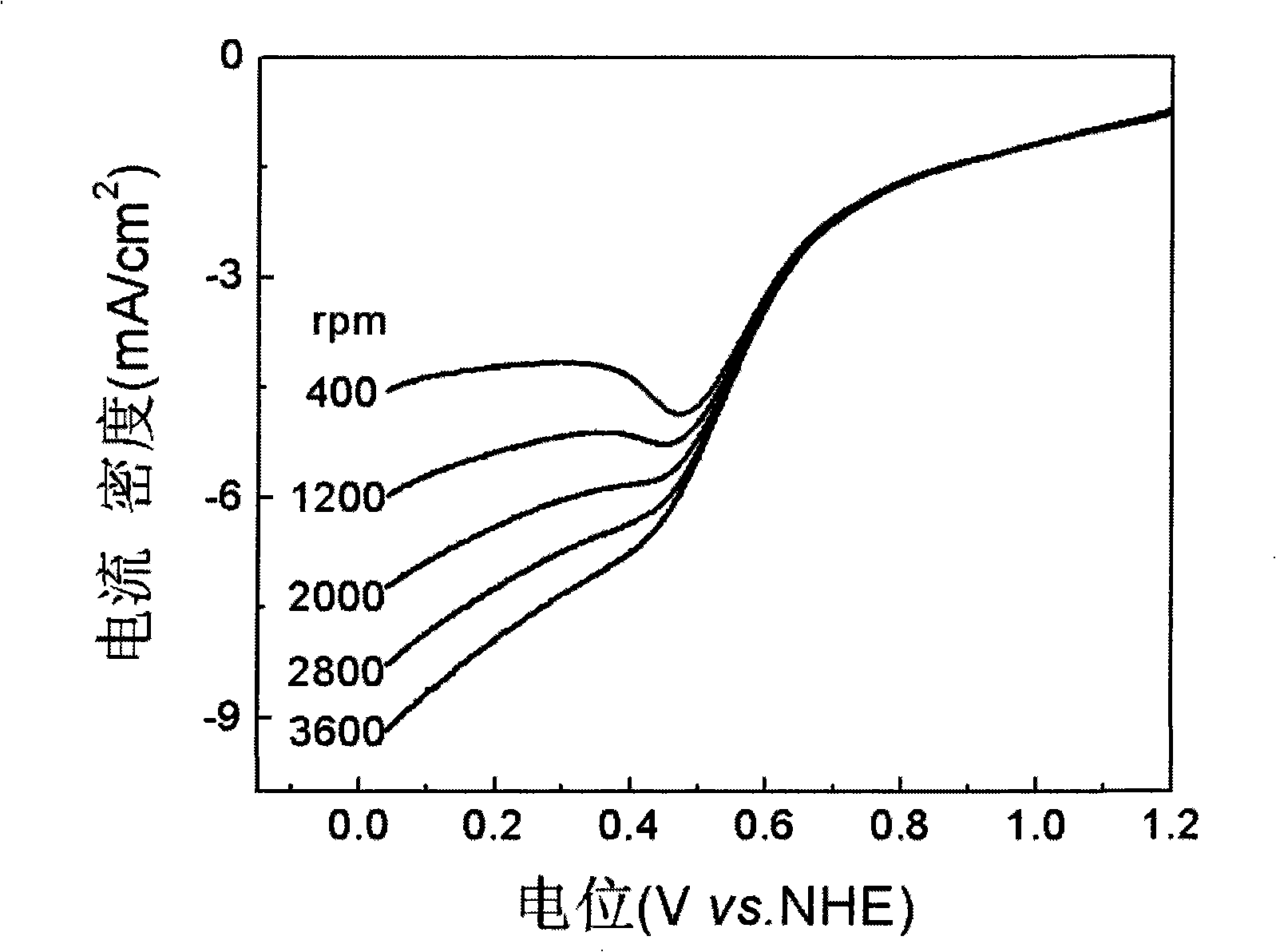

Oxygen reduction electrocatalyst and preparation thereof

InactiveCN101259437AReduce manufacturing costOvercome costsCell electrodesOrganic-compounds/hydrides/coordination-complexes catalystsAlcohol fuelPorphyrin

The invention discloses an oxygen reduction electrocatalyst and a preparation method thereof, which is a load type catalyst and consists of a transition metal triethylene tetramine chelate complex and a carbon black carrier; wherein, the transition metal triethylene tetramine chelate complex is obtained by the reaction of transition metal-salt and triethylene tetramine. The oxygen reduction electrocatalyst of the invention uses the triethylene tetramine having simple structure and low cost, which overcomes the defects of traditionally used macrocyclic compound porphyrin and Phthalocyanine and derivatives thereof and has simple preparation technique, low cost, friendly environment and a better catalytic activity; a oxygen reduction peak potential is 0.6745 (vs. NHE) and a oxygen reduction peak current is 1.493mA / m<2>; stability is relatively high, and oxygen reduction catalytic performance is not obviously reduced after recycling for 24 hours. The oxygen reduction electrocatalyst of the invention can be applied to the fields of proton exchange membrane fuel batteries, direct alcohol fuel cells, and cathode materials of metal-air battery, etc.

Owner:SHANGHAI JIAO TONG UNIV

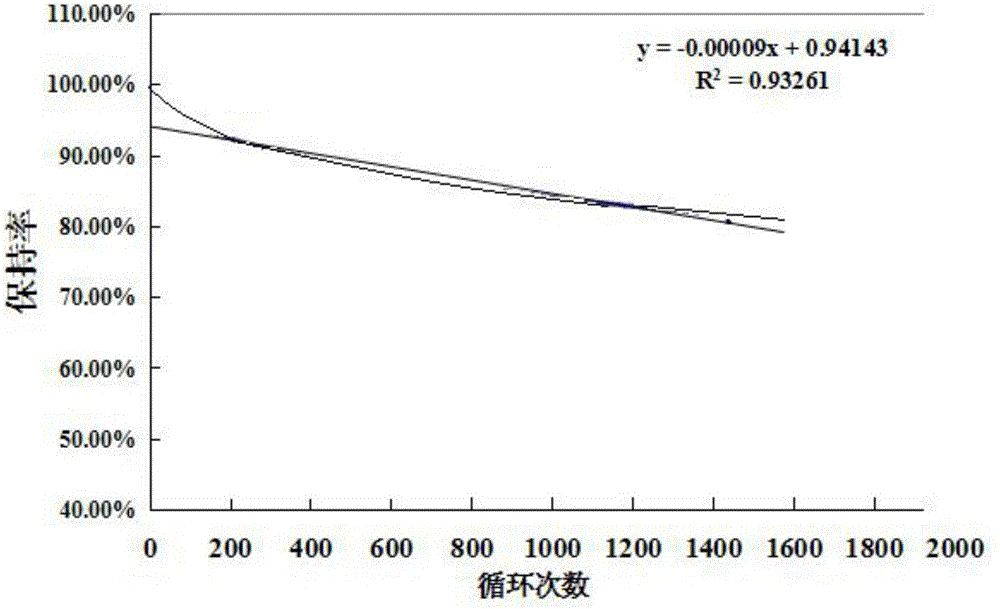

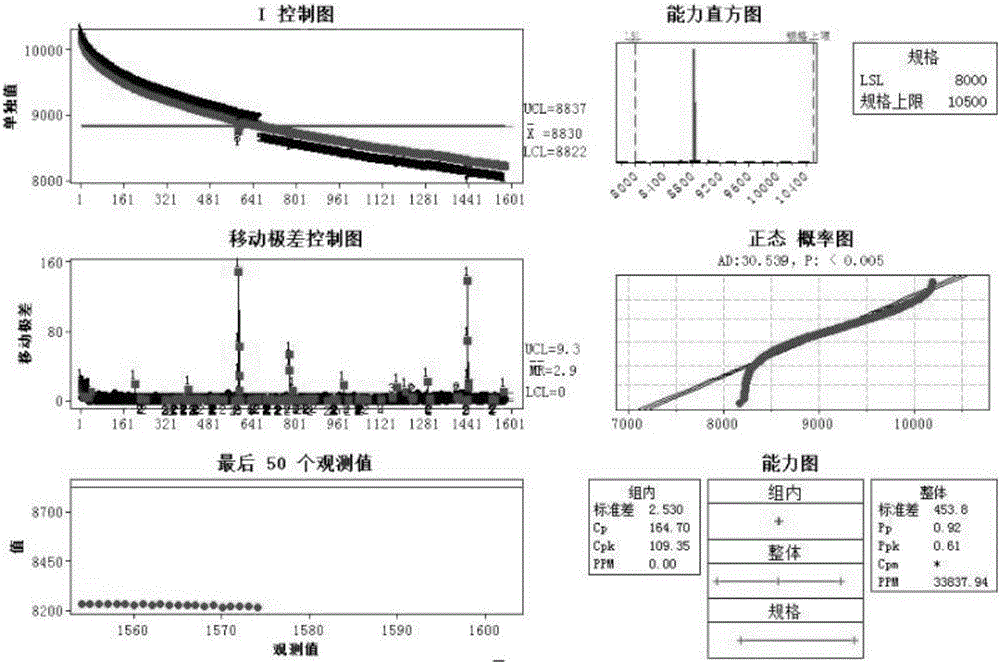

Lithium ion battery and preparation method thereof

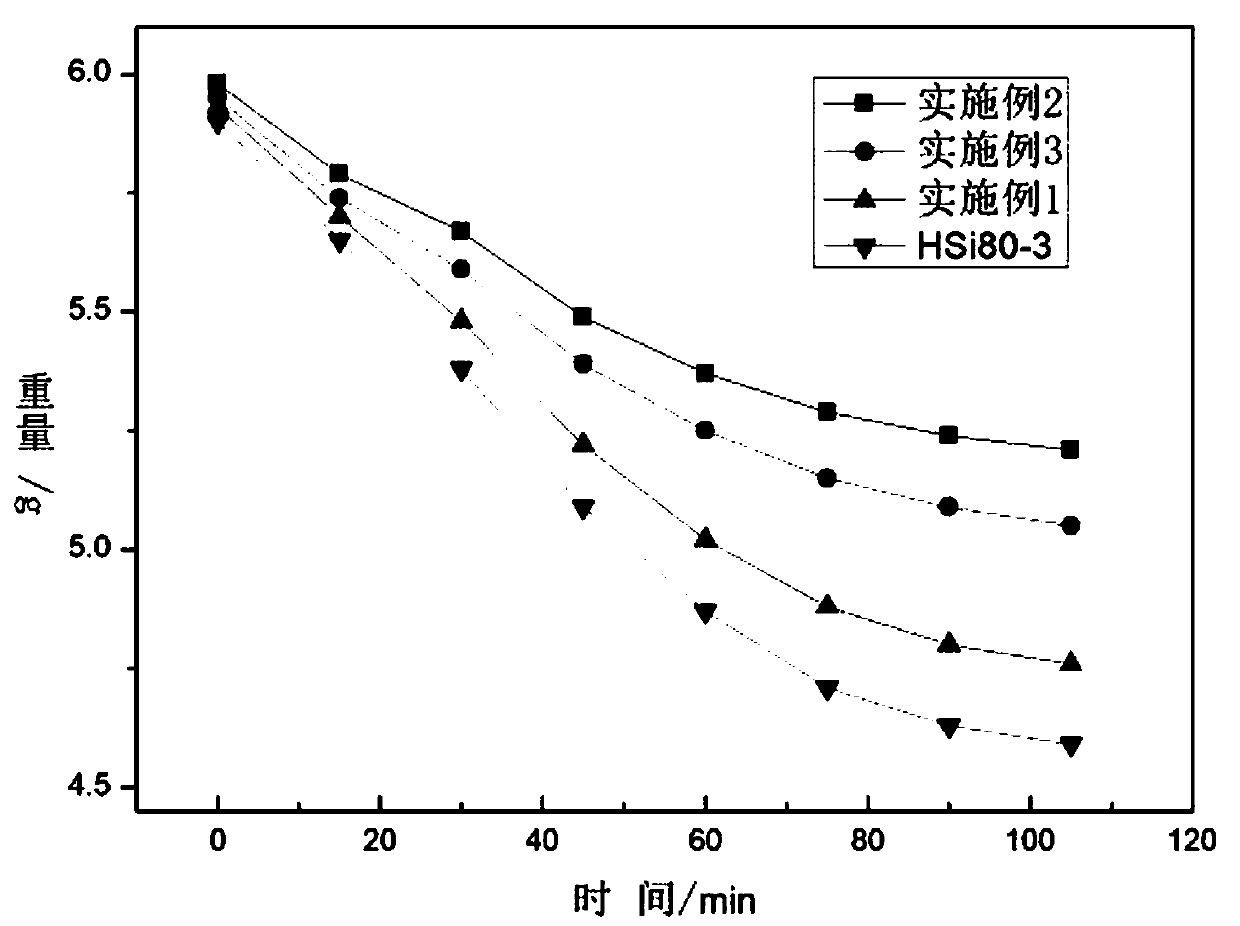

InactiveCN105932282AThe preparation process is highly controllableImprove consistencyFinal product manufactureCell electrodesHigh rateHigh energy

The invention discloses a lithium ion battery and a preparation method thereof. The lithium ion battery comprises cathode slurry and anode slurry, wherein the solid content of the cathode slurry is 50.0%-60.0% and the viscosity number is 6000-8000 cp; the solid content of the anode slurry is 40.0%-50.0% and the viscosity number is 3000-5000 cp. The invention further comprises the preparation method. After circulation for 1500 times, the capacity retention ratio of a lithium iron phosphate system lithium ion battery with high magnification, high energy density and long service life is higher than 80.0% and the energy density is greater than 175 Wh / Kg under the high-rate charge-discharge system of 10-20 C; the preparation method has the advantages of simple selected material system, strong controllability of the preparation process, good product consistency and high section first pass yield; the processing first pass yield of a lithium ion battery with the rated capacity of 10 AH reaches up to 87.5%, and the product percent of pass is high and reaches up to 95.3%.

Owner:湖南锂顺能源科技有限公司

Preparation method of water soluble fluorescent nano-particles

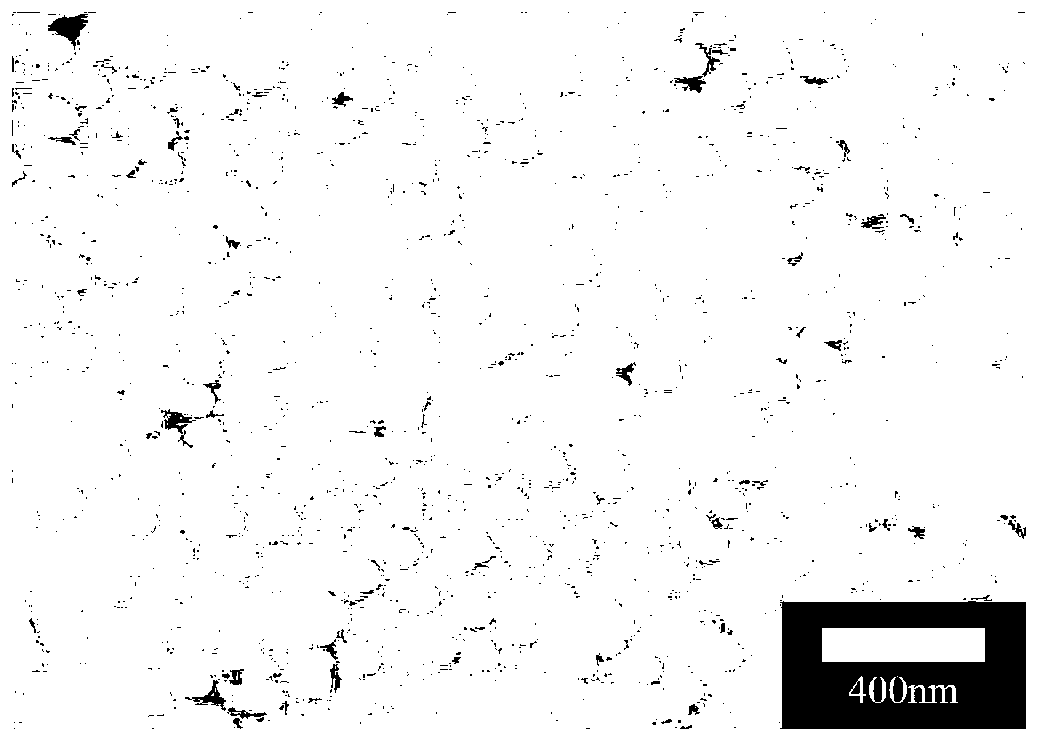

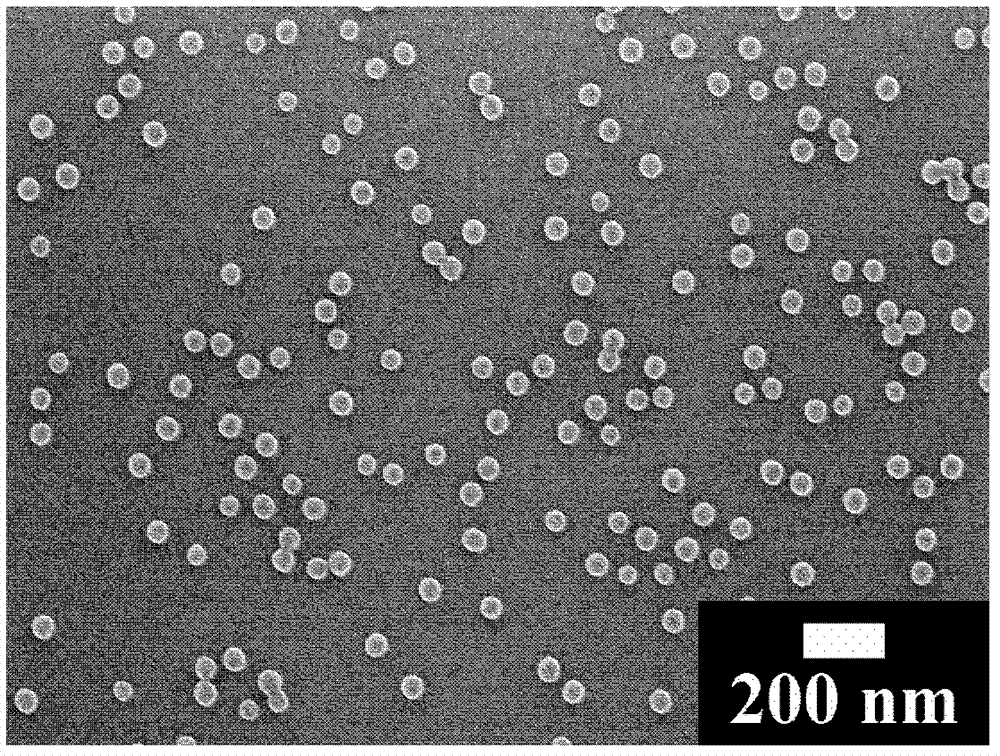

InactiveCN103012812AGood dispersionSensitive fluorescence intensityLuminescent compositions2-VinylpyridinePolystyrene

The invention relates to a preparation method of water soluble fluorescent nano-particles which are even and adjustable in size and have fluorescent marks; the preparation method comprises the following detailed steps of: mixing a segmented copolymer, a fluorescent material and an organic solvent in a certain ratio, heating the mixed solution and then holding for a certain time, adding a quanternization reagent in the obtained solution, heating and holding for a certain time; centrifuging, re-dispersing precipitate in water, and heating at a certain temperature, thereby obtaining the water soluble fluorescent nano-particles which are even and adjustable in size and have fluorescent marks, wherein the copolymer consists of a hydrophobic chain and a hydrophilic chain, preferably, the hydrophobic chain consists of the hydrophobic chain and polymethyl methacrylate, and the hydrophilic chain consists of poly(2-vinyl pyridine), poly(4-vinyl pyridine) and polymethyl methacrylate dimethylamino ethyl ester; the fluorescent nano-particles obtained by the method are even in size and have the hygrometric state particle size effectively adjustable within the range of 50nm to 400nm; and the method is simple, short in technological process, excellent in fluorescence effect and low in cost, and is suitable for large-scale production.

Owner:NANJING UNIV OF TECH

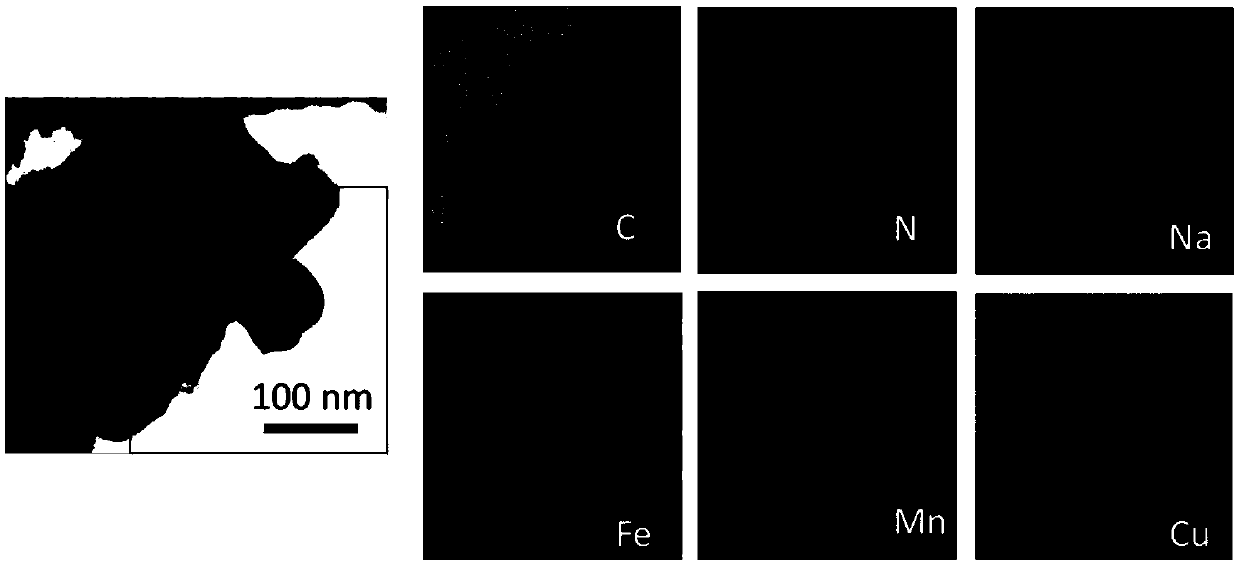

Copper-doped Prussia white analogue sodium-ion battery positive electrode material and preparation method thereof

InactiveCN107565130AImprove electrochemical performanceImprove crystal structure stabilityCell electrodesSecondary cellsPhysical chemistrySodium-ion battery

The invention relates to a copper-doped Prussia white analogue sodium-ion battery positive electrode material. The copper-doped Prussia white analogue sodium-ion battery positive electrode material ischaracterized in that the chemical formula of a Prussia white analogue is Na<1+Delta>Cu<x>Mn<y>[Fe(CN)6]<z>.nH2O, wherein the value range of Delta is 0-1, the value range of x is 0.05-0.25, the valuerange of Mn is 0.60-0.95, the value range of z is 0.9-1, and the value range of n is 0-4. The invention simultaneously provides a preparation method of the material.

Owner:TIANJIN UNIV

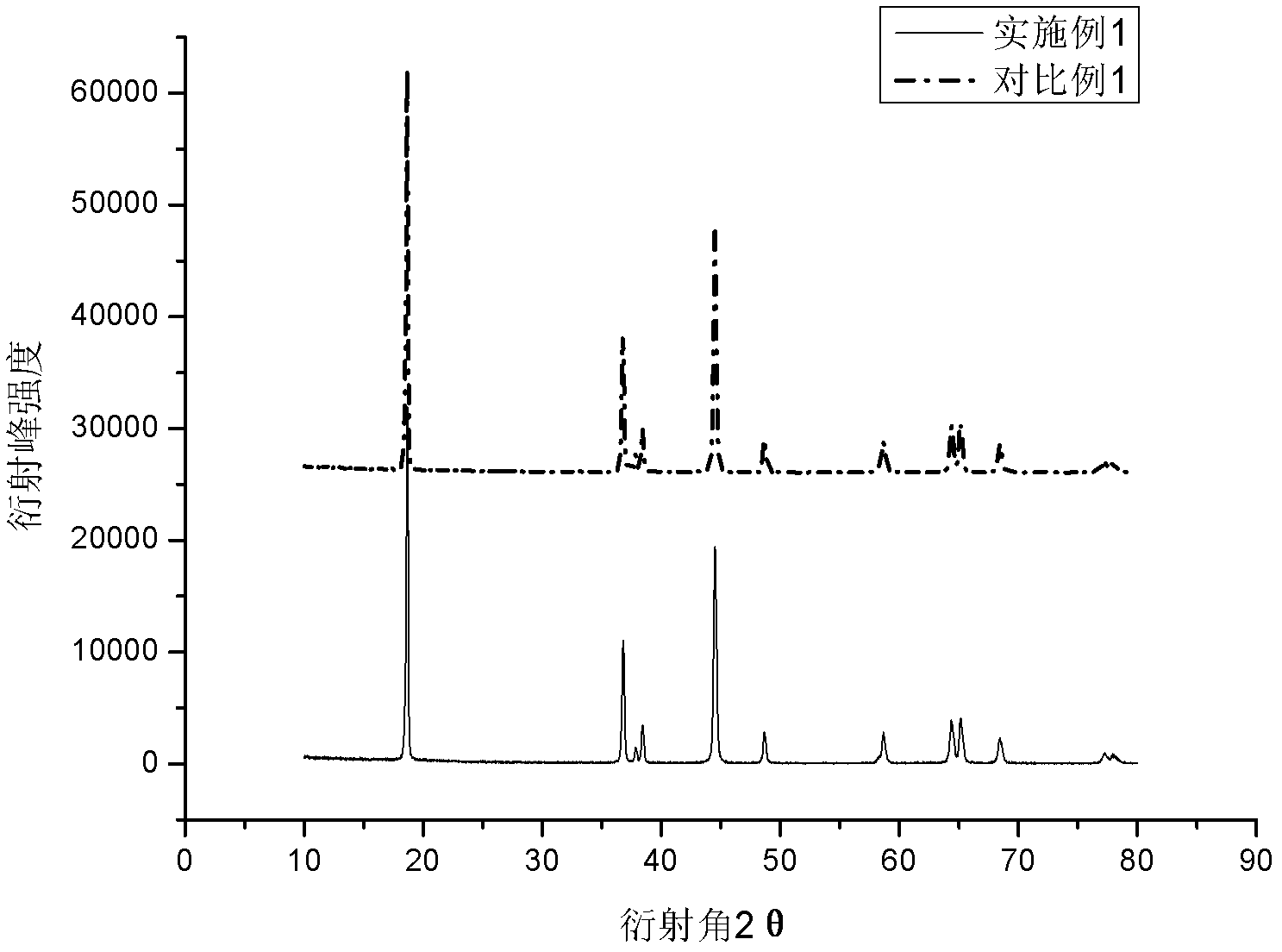

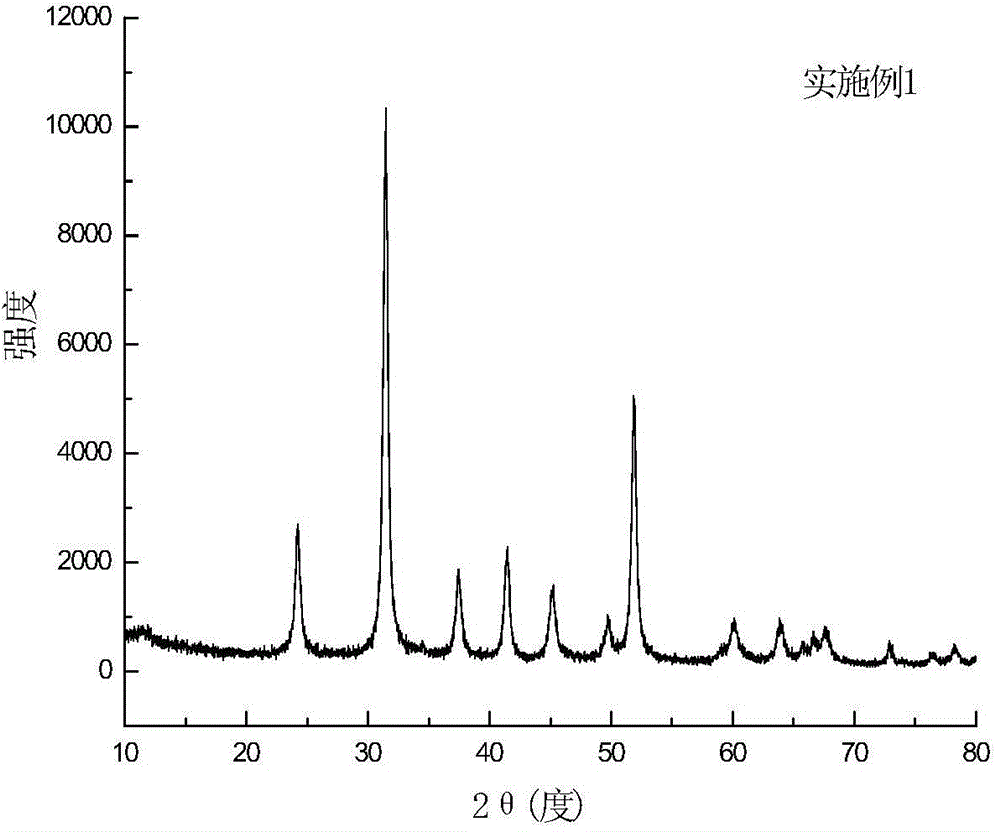

Modified spinel type lithium battery cathode material and preparation method thereof

InactiveCN104319392AExpand the voltage application rangeImprove performanceCell electrodesDischarge efficiencyManganese

The invention relates to a modified spinel type lithium ion battery cathode material, which is a layered composite material with a core-shell structure formed by a spinel phase material as the core material and a lithium-rich phase material as the shell material. The preparation method comprises the steps of carrying out co-precipitation reaction on nickel-manganese mixed salt solution and mixed solution of aqueous ammonia and sodium carbonate to obtain a nickel magnesium carbonate precursor; uniformly mixing the precursor with Li2CO3 according to the stoichiometric ratio, and roasting to obtain a powder granular core material with a spinel structure; uniformly mixing the core material with Li2CO3 according to the stoichiometric ratio, and roasting to obtain the target product. The modified spinel type lithium battery cathode material and the preparation method thereof have the advantages the modified spinel type cathode material is high in specific capacity, high in cycling stability, and high in the first discharge efficiency; the preparation process of the material is excellent in controllability, low in manufacture cost, and good for large-scale production so as to meet the demands for high voltage / high specific capacity materials in the market.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

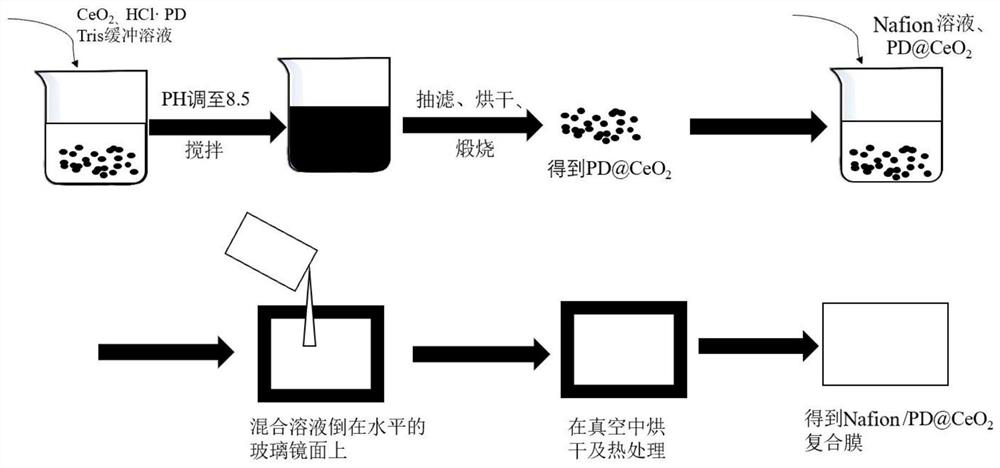

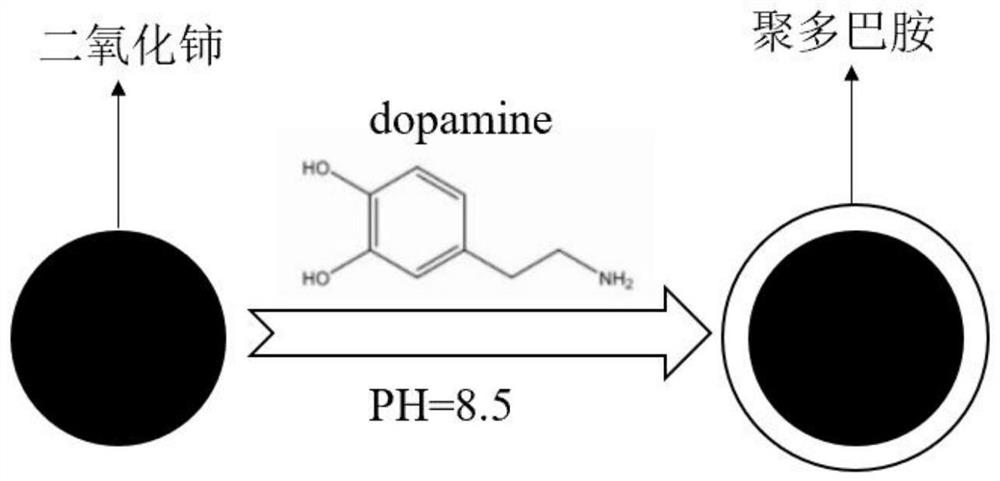

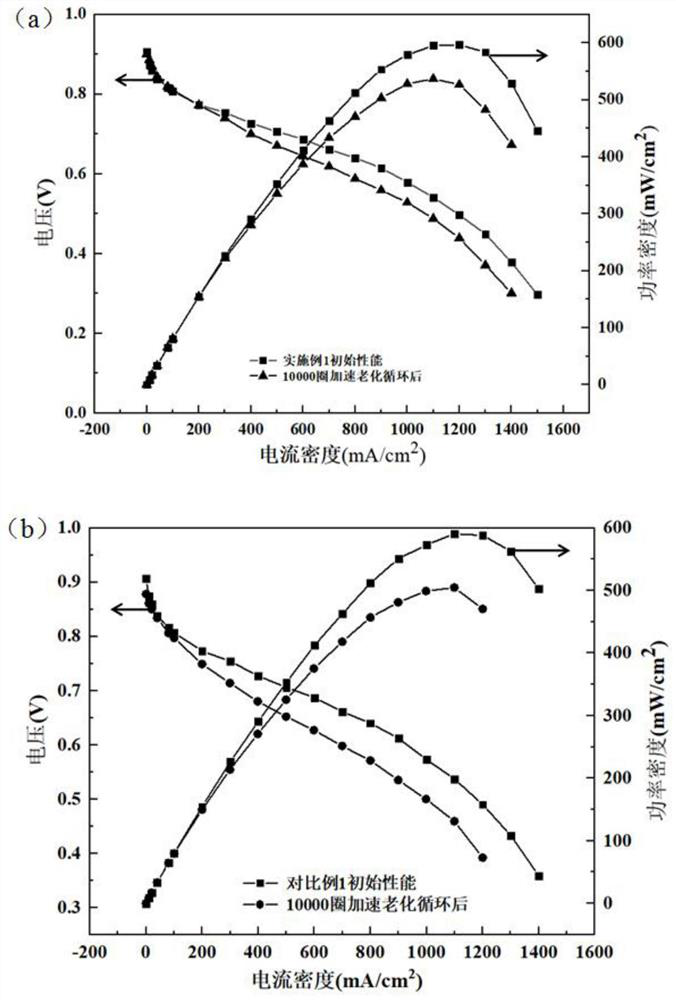

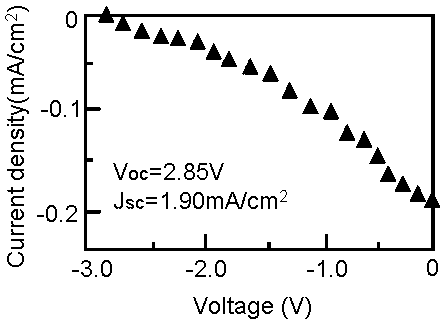

High-durability fuel cell composite proton exchange membrane, and preparation method and application thereof

ActiveCN112687927AGood chemical resistanceThe preparation process is highly controllableFinal product manufactureFuel cellsFuel cellsPhysical chemistry

The invention discloses a high-durability fuel cell composite proton exchange membrane, and a preparation method and an application thereof. The high-durability fuel cell composite proton exchange membrane comprises a membrane matrix and a metal oxide free radical quenching agent dispersed in the membrane matrix, and the surface of the free radical quenching agent is provided with an organic matter coating layer. Compared with a common Dupont Nafion membrane, the durability of the composite membrane coated with the polydopamine is greatly improved. The preparation process is simple, safe and low in cost, and can be used for industrial production of the composite proton exchange membrane.

Owner:NANJING UNIV

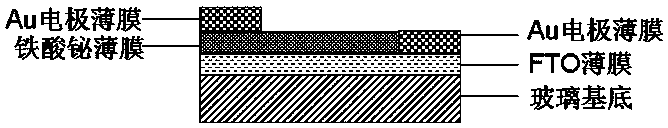

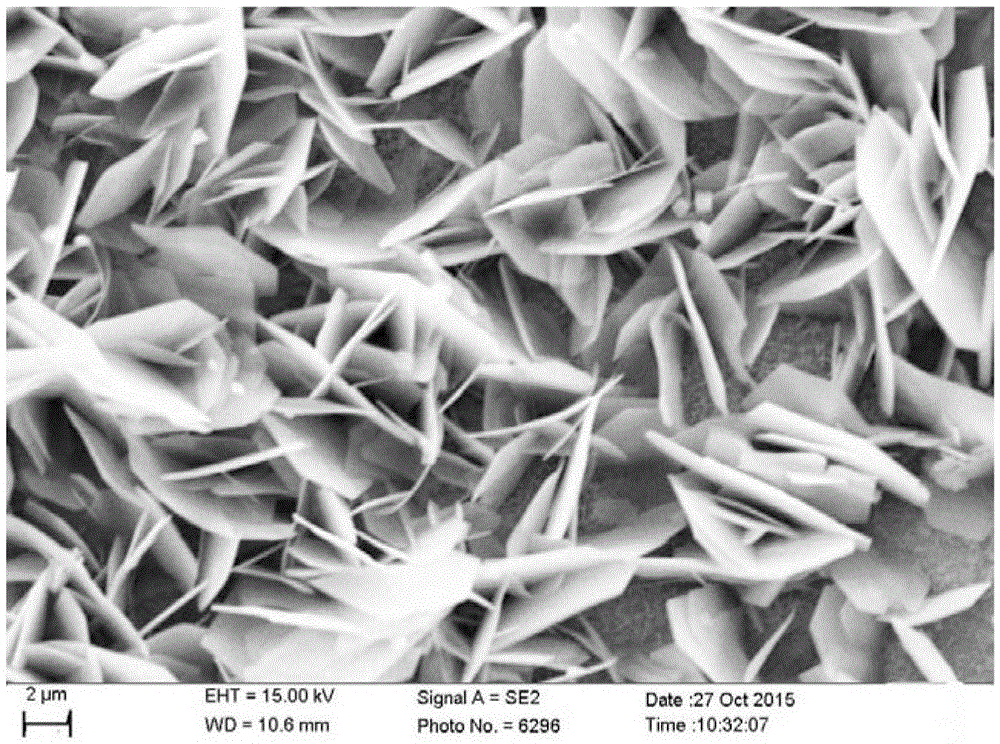

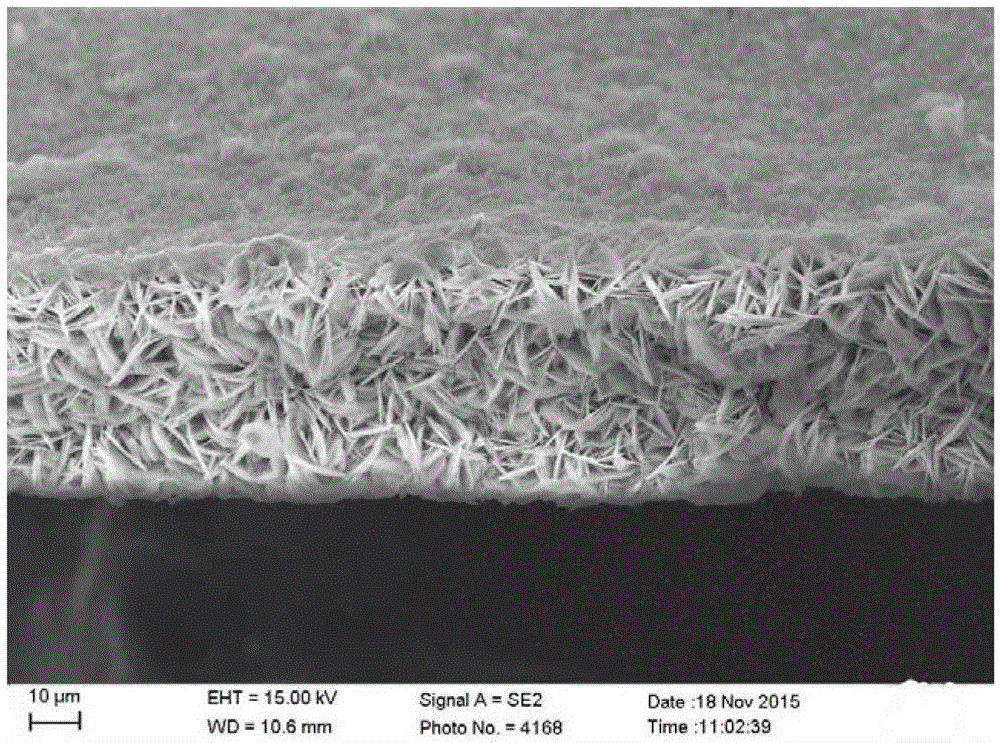

Method for preparing high-quality bismuth ferrite ferroelectric photovoltaic films by magnetron sputtering

InactiveCN108085650AImprove performanceThe preparation process is highly controllableVacuum evaporation coatingSputtering coatingLanthanideSolar cell

The invention provides a method for preparing high-quality bismuth ferrite (BFO) ferroelectric photovoltaic films. The method comprises the specific steps of adopting BFO ceramic targets mixed with lanthanide, placing a cleaned FTO / glass substrate into a vacuum chamber, and adjusting the distance between a sample stage and a target stage to be 50-150 mm; introducing O2 and Ar according to the gasflow ratio O2 / Ar of 1 / 10-1 / 4 when the background vacuum degree is higher than 8x10<-4> Pa, making the working pressure reach 1-10 Pa, setting the power of a radio frequency power supply to be 10-100 W, the rotation speed of the sample stage to be 5-15 rpm, and the pre-sputtering time to be 5-15 min separately, and setting the sputtering time according to the thickness of the BFO film; and continuously introducing Ar insert protective gas upon completion of sputtering for in-situ annealing treatment to the BFO film, wherein the heating temperature is 300-600 DEG C, and the holding time is 30-180 min. The method provided by the invention is a physical vapor deposition method, and the BFO ferroelectric photovoltaic films are prepared by a conventional magnetron sputtering system, and are highin technological controllability and applicability, and easy to produce on a large scale; and a new way is opened up for development of solar cells based on the BFO ferroelectric photovoltaic films.

Owner:YUNNAN NORMAL UNIV

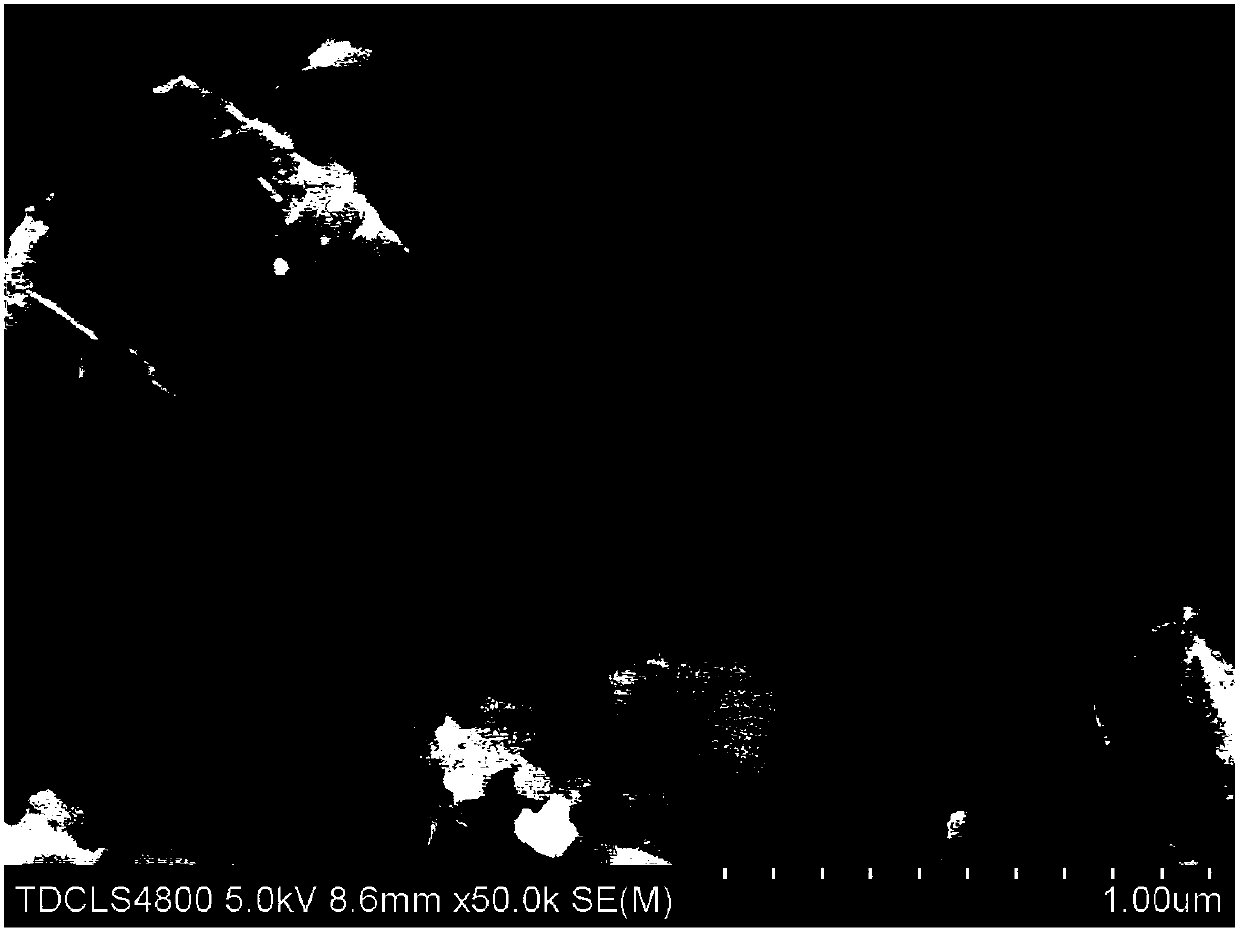

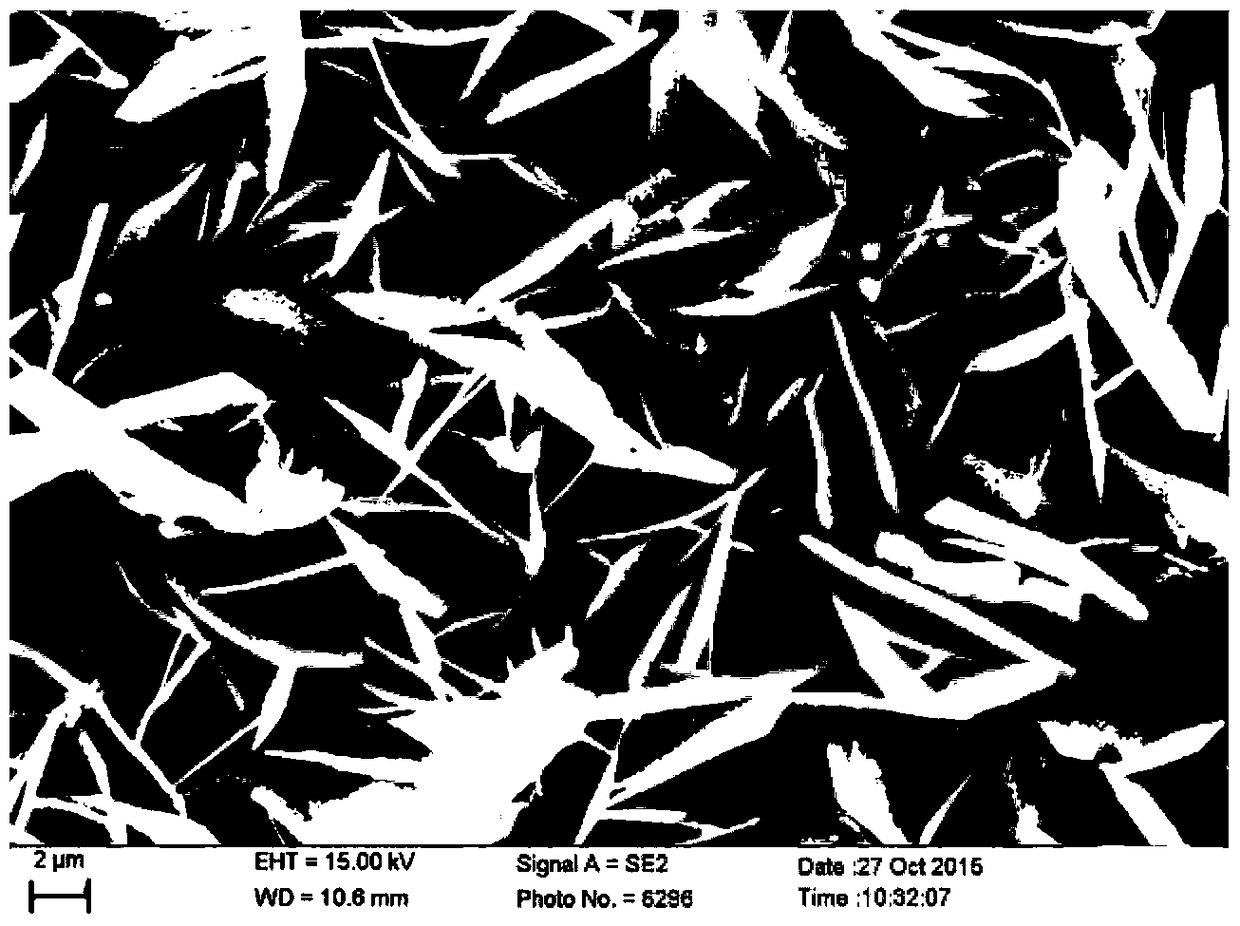

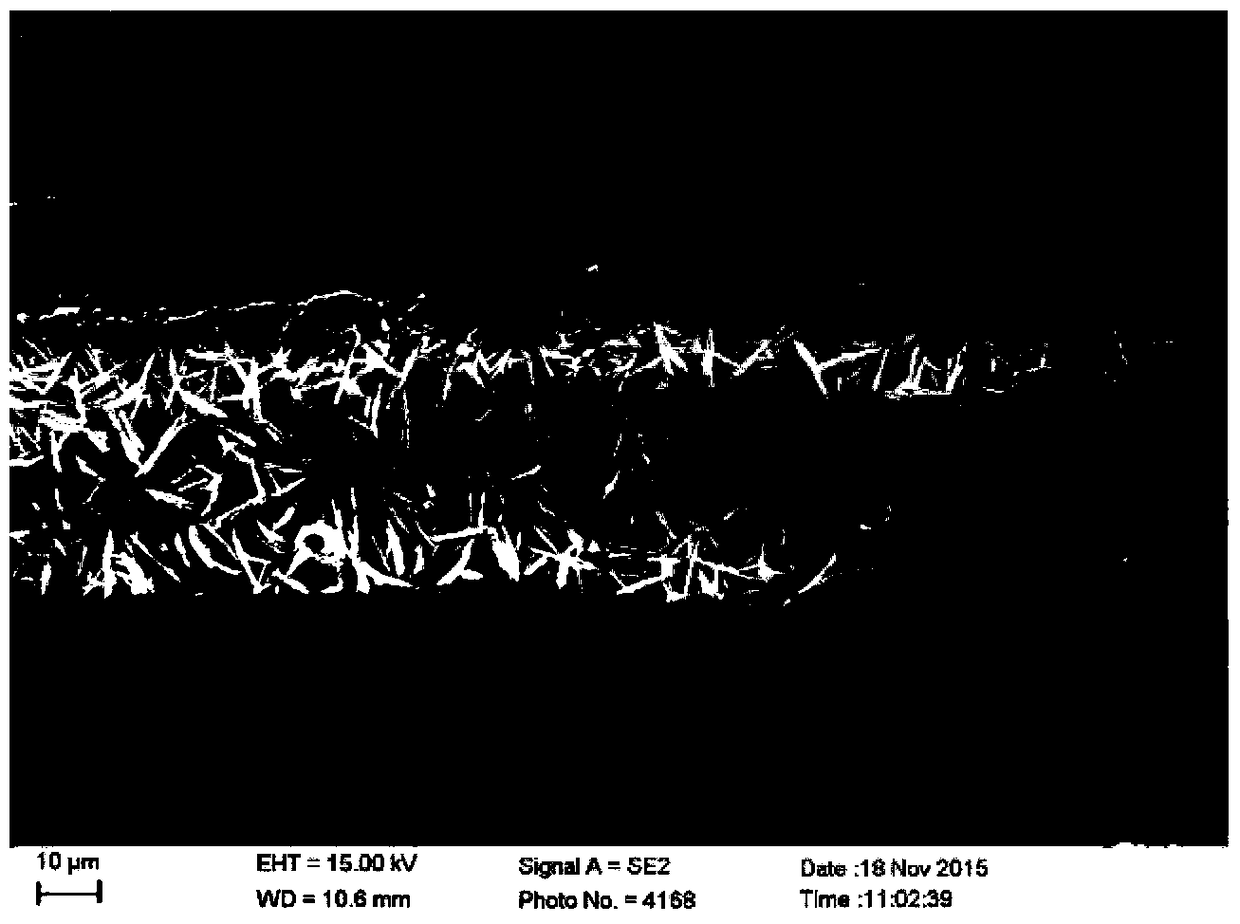

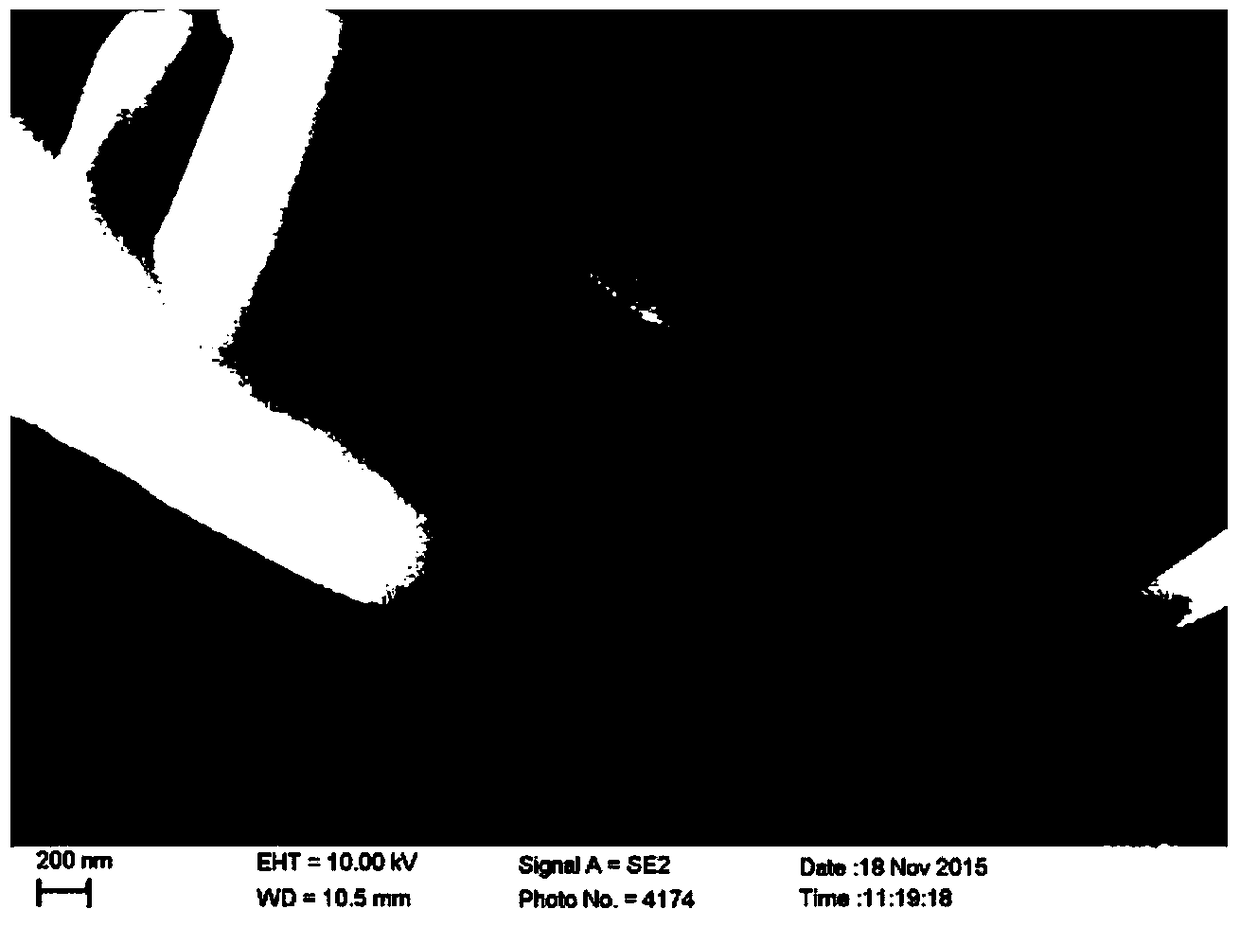

Preparation process of two-dimensional Al-O-Cu-Fe single-crystalline-layer flaky material

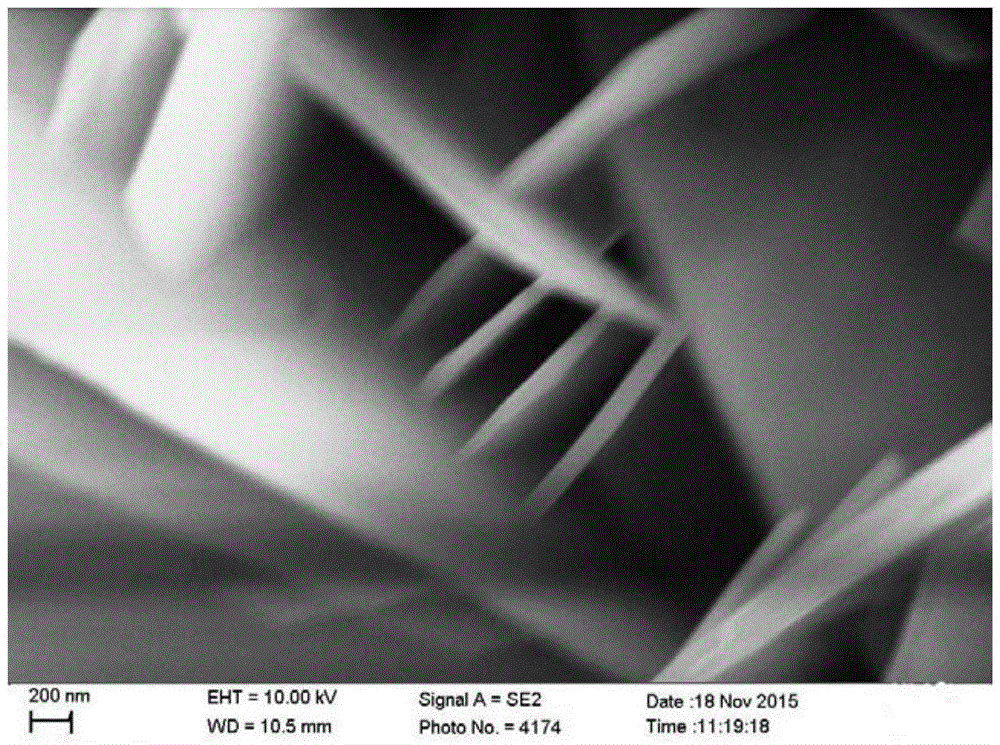

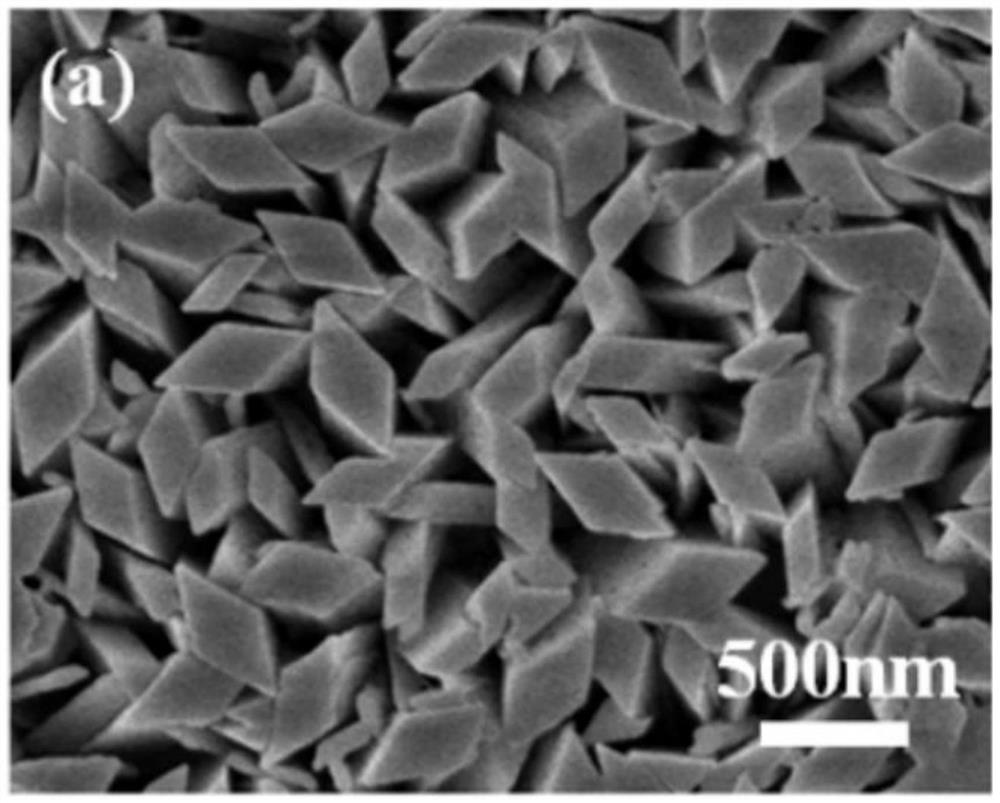

InactiveCN105568389AEasy to makeLow costPolycrystalline material growthSingle crystal growth detailsMaterials preparationMicrometer

The invention discloses a preparation process of a two-dimensional Al-O-Cu-Fe single-crystalline-layer flaky material, and belongs to the field of preparation of two-dimensional flaky and catalytic materials. The preparation process includes the steps of conducting alloy material preparation according to the alloy atom ratio AlxCuyFez, wherein the sum of x, y and z is equal to 100, x is larger than or equal to 60 and smaller than or equal to 70, y is larger than or equal to 13 and smaller than or equal to 30, and z is larger than or equal to 10 and smaller than or equal to 17; preparing Al-Cu-Fe alloy strips through a vacuum rapid quenching melt-spinning method; preparing the two-dimensional Al-O-Cu-Fe single-crystalline-layer flaky material through the method of NaOH room-temperature chemical dealloying. The thickness of each flake layer is 30-50 nm, and the diameter of a single crystal wafer is between 2 micrometers and 6 micrometers. The flake layers are intercrossed to form pores, the pore size is 1-10 micrometers, and a porous structure is formed. The preparation process is simple, cost is low, the yield of the generated material of the two-dimensional flaky structure is high, and a solution is provided for industrially and controllably preparing the two-dimensional Al-O-Cu-Fe single-crystalline-layer flaky catalytic material.

Owner:UNIV OF SCI & TECH BEIJING

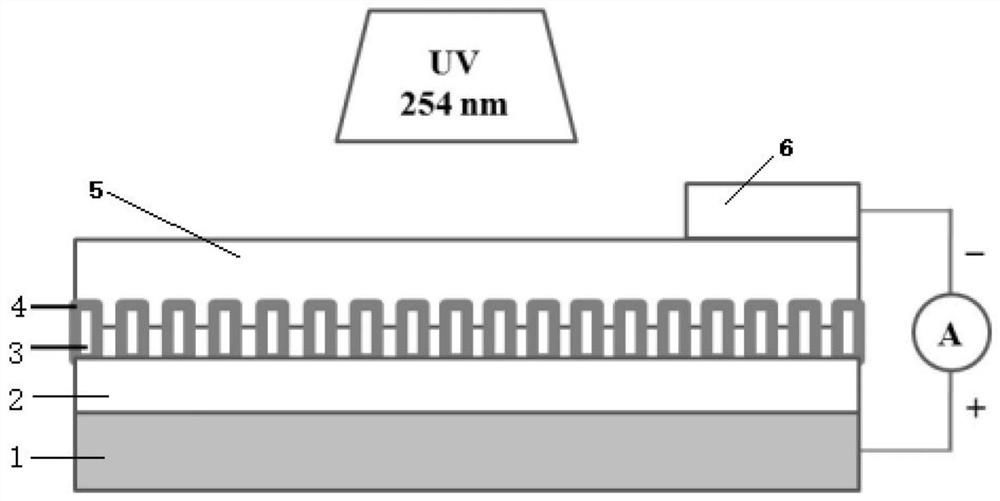

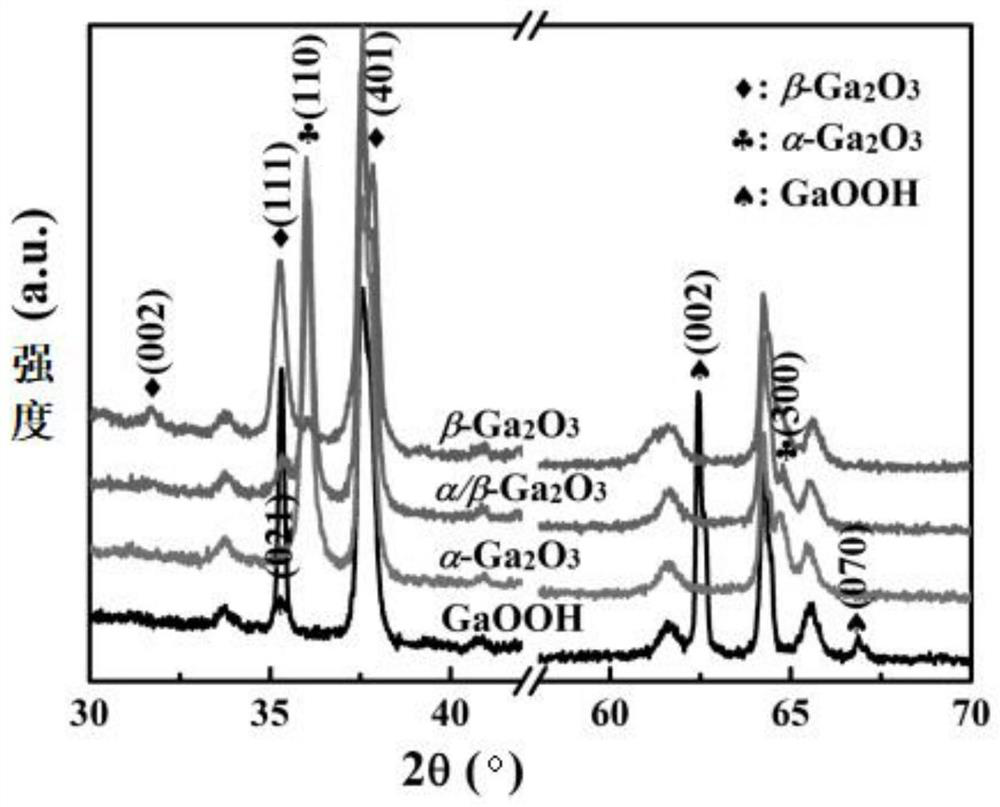

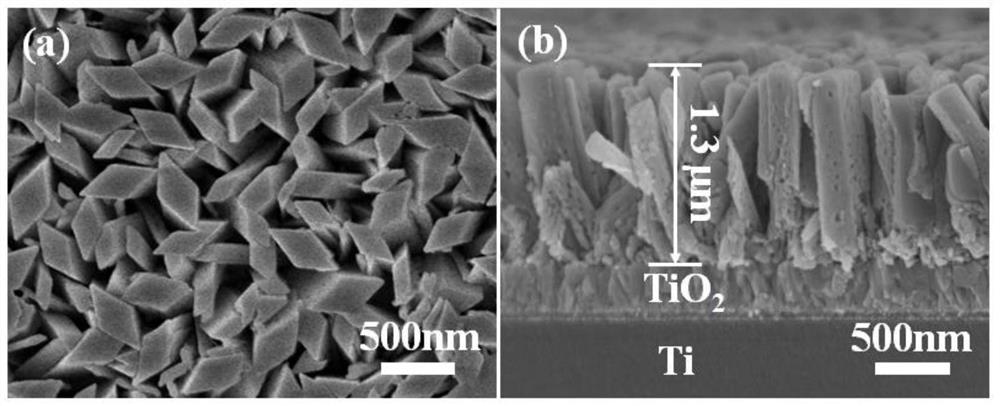

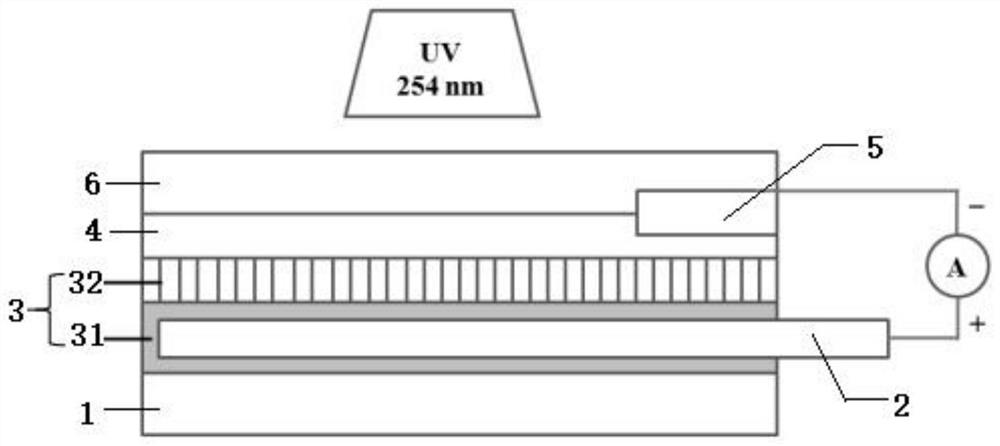

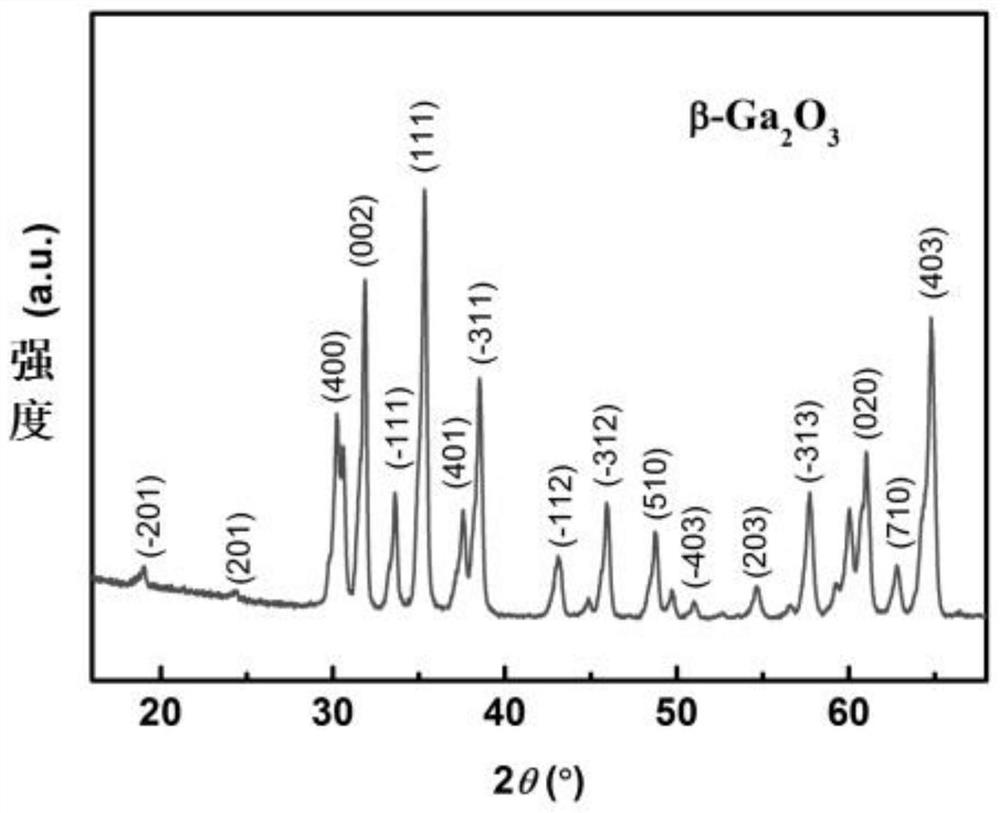

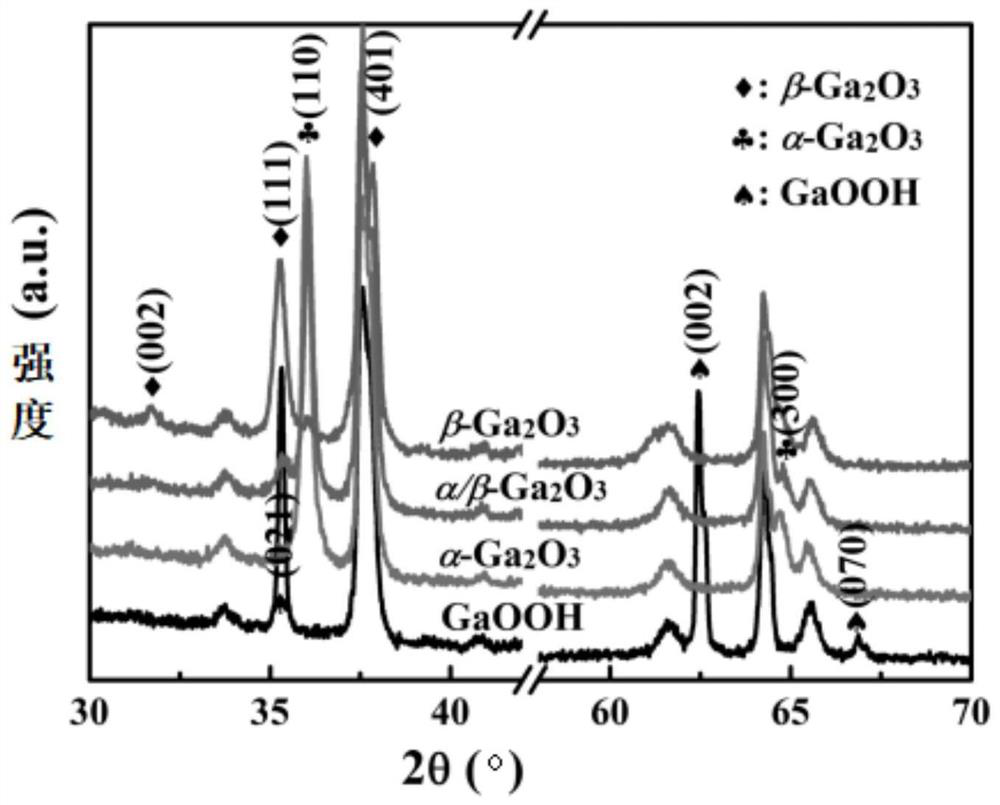

Flexible solar blind ultraviolet detector based on TiO2/Ga2O3 nano-phase junction and preparation method of flexible solar blind ultraviolet detector

PendingCN112635587AImprove performanceGood size controlMaterial nanotechnologyFinal product manufactureHeterojunctionUltraviolet detectors

The invention relates to a flexible solar blind ultraviolet detector based on a TiO2 / Ga2O3 nano-phase junction and a preparation method thereof, the detector comprises an Ag upper electrode, a flexible titanium sheet lower electrode, a TiO2 / alpha / beta-Ga2O3 nano-phase junction nanorod array located between the Ag upper electrode and the flexible titanium sheet lower electrode, and a graphene / Ag nanowire composite electrode, wherein a flexible titanium sheet is used as a flexible titanium sheet substrate, the TiO2 / alpha / beta-Ga2O3 phase junction nanorod array comprises a TiO2 layer located on the flexible titanium sheet substrate and an alpha / beta-Ga2O3 phase junction nanorod array located on the TiO2 layer, and the alpha / beta-Ga2O3 phase junction nanorod array comprises a plurality of alpha / beta-Ga2O3 phase junction nanorods arranged at intervals; the graphene / Ag nanowire composite electrode is located at one end, deviating from the TiO2 layer, of the alpha / beta-Ga2O3 phase junction nanorod, and the Ag upper electrode partially covers the graphene / Ag nanowire composite electrode. The solar blind ultraviolet detector with the multi-heterojunction structure is stable in solar blind characteristic, has excellent chemical and thermal stability, and is expected to be widely applied to the field of wearable and convenient ultraviolet detectors.

Owner:杭州紫芯光电有限公司

UV transfer glue formula and manufacturing process

InactiveCN109943270AFast curingEasy to diluteNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesShrinkage ratePliability

The invention discloses an UV transfer glue formula and a manufacturing process. The UV transfer glue formula is prepared from the following components in parts by weight: 30-38 parts of prepolymer, 56-65 parts of an acrylate monomer, 1-4 parts of a photoinitiator and 0.2-1 part of an auxiliary agent, wherein the acrylate monomer is a complex of single functional acrylate and double functional acrylate; the single functional acrylate is isobornyl acrylate and the double functional acrylate is 1,6-hexadiol diacrylate; the weight ratio of the single functional acrylate to the double functional acrylate is (3-4): (1-1.5). The manufacturing process comprises the following steps: first, preparing a complex of isobornyl acrylate and 1,6-hexadiol diacrylate; then preparing a prepolymer; and thenmixing the prepolymer, the acrylate monomer, the photoinitiator and the auxiliary agent to obtain the UV transfer glue. The UV transfer glue has the advantages of being high in curing speed, increasedin film forming crosslinking density, good diluting property, excellent glue flatting property, relatively small in volatility, relatively slight in smell, low in shrinkage rate and extremely good inadhesive force and has hardness, flexibility and scratch resistance.

Owner:广东信毅新材料有限公司

Preparation method of self-supporting flexible conductive super-hydrophobic film

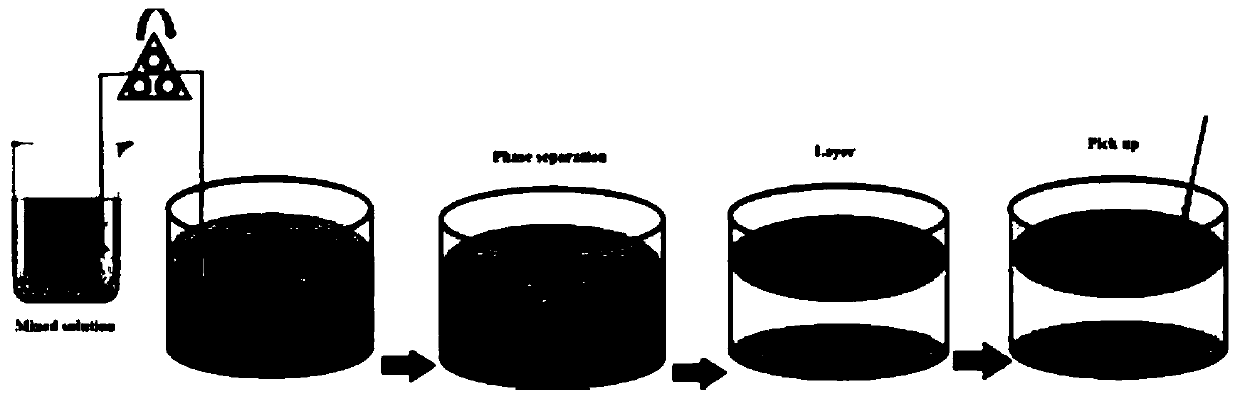

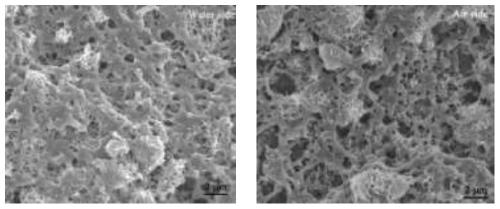

The invention discloses a self-supporting flexible conductive super-hydrophobic film and a preparation method thereof, and the self-supporting flexible conductive super-hydrophobic film comprises surface microstructure design of a film material. The preparation method comprises the following steps: forming a self-supported flexible conductive super-hydrophobic film on the surface of a liquid phasesystem by using a solvent-non-solvent method, wherein the effective regulation and control of a high-molecular polymer on the microstructure of the conductive nano material on the surface of the liquid phase system is an important condition for the synergy of conductivity and super-hydrophobic performance. The process is simple. Expensive preparation instruments, high-temperature action and catalysts are not needed, consumed time is short, and film materials can be continuously collected on a large scale. The self-supporting film produced by the invention has good strength, can form a stableself-supporting structure, has good conductivity, stable super-hydrophobic performance and certain elastic conductive super-hydrophobic performance, and can effectively improve the performance of flexible conductive super-hydrophobic electronic equipment.

Owner:SHAANXI UNIV OF SCI & TECH

Radix acanthopanacis senticosi and vitis amurensis wine and preparation method thereof

InactiveCN107299019AGood health benefitsImprove qualityNervous disorderMetabolism disorderChemistryFlavor

The invention provides radix acanthopanacis senticosi and vitis amurensis wine and a preparation method thereof and belongs to the field of wine brewing. The preparation method comprises the following steps: mixing vitis amurensis and radix acanthopanacis senticosi according to the mass ratio of (3 to 4) to 1 and crushing to obtain a first fixed material; mixing white granulated sugar, potassium metabisulfite, active dry yeast and the first fixed material to obtain a second mixed material; pre-fermenting the second mixed material for 12 to 18 days at 20 DEG C to 25 DEG C; after separating peel pomace, obtaining first fermented liquid; fermenting the first fermented liquid for 35 to 45 days at 18 DEG C to 22 DEG C; separating fruit pulp to obtain second fermented liquid and aging. The radix acanthopanacis senticosi and vitis amurensis wine prepared by the method has a good health-care effect and high quality; the mouthfeel, flavor, color and luster and aroma of the radix acanthopanacis senticosi and vitis amurensis wine are relatively excellent.

Owner:INST OF SPECIAL ANIMAL & PLANT SCI OF CAAS

Preparation process and application of photosensitive resin for 3D printing

InactiveCN109929080AImprove performanceImprove light curing efficiencyAdditive manufacturing apparatusAcetic acidPolymer science

The invention discloses a preparation process and application of photosensitive resin for 3D printing. The process comprises the following steps of: 1) weighing organic silicon resin powder, an organic solvent and a silane coupling agent in parts by weight and adding the components into a first container to be stirred and mixed in a forward and reverse rotation alternating mode, the silane coupling agent being prepared by weighing silane, alcohol, water and acetic acid in parts by weight and mixing the components; 2) adding a catalyst, mixing and stirring the components until a transparent anduniform first liquid is obtained, respectively weighing a complexing agent and metal alkoxide according to parts by weight, and adding the components into a second container, mixing and stirring themetal alkoxide and the complexing agent in a forward and reverse rotation alternating manner until a transparent and uniform second liquid is obtained; 2) adding the first liquid into a third container, pre-stirring the first liquid, adding a second liquid, mixing and stirring the first liquid and the second liquid, adding an active diluent, and mixing and stirring all the components; 3) adding aphotoinitiator into the third container, and continuously stirring the mixture to obtain the 3D printing photosensitive resin.

Owner:广东信毅新材料有限公司

Copper zinc silicon base powdery brazing material containing alterant and preparation method thereof

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Preparation process of a two-dimensional al-o-cu-fe single crystal layer sheet material

InactiveCN105568389BEasy to makeLow costPolycrystalline material growthSingle crystal growth detailsMaterials preparationMicrometer

The invention discloses a preparation process of a two-dimensional Al-O-Cu-Fe single-crystalline-layer flaky material, and belongs to the field of preparation of two-dimensional flaky and catalytic materials. The preparation process includes the steps of conducting alloy material preparation according to the alloy atom ratio AlxCuyFez, wherein the sum of x, y and z is equal to 100, x is larger than or equal to 60 and smaller than or equal to 70, y is larger than or equal to 13 and smaller than or equal to 30, and z is larger than or equal to 10 and smaller than or equal to 17; preparing Al-Cu-Fe alloy strips through a vacuum rapid quenching melt-spinning method; preparing the two-dimensional Al-O-Cu-Fe single-crystalline-layer flaky material through the method of NaOH room-temperature chemical dealloying. The thickness of each flake layer is 30-50 nm, and the diameter of a single crystal wafer is between 2 micrometers and 6 micrometers. The flake layers are intercrossed to form pores, the pore size is 1-10 micrometers, and a porous structure is formed. The preparation process is simple, cost is low, the yield of the generated material of the two-dimensional flaky structure is high, and a solution is provided for industrially and controllably preparing the two-dimensional Al-O-Cu-Fe single-crystalline-layer flaky catalytic material.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of rubber with strong weather resistance

ActiveCN104530516AImprove waterproof performanceStrong weather resistanceWeather resistancePolymer science

The invention provides a preparation method of rubber with strong weather resistance. The preparation method specifically comprises the following steps: preparing a mixture containing vulcanized rubber particles and organic silicon resin; dividing the mixture into a first material flow and a second material flow; carrying out phase inversion on the first material flow, mixing with the second material flow, and carrying out phase inversion to form a vulcanized rubber body; adding inorganic powder and a functional auxiliary into melt glue; and extruding. The preparation method provided by the invention is simple in process and strong in controllability of preparation process. The rubber prepared by the method provided by the invention has extremely strong waterproofness and weather resistance and is strong in practicality.

Owner:江苏木克体育器材有限公司

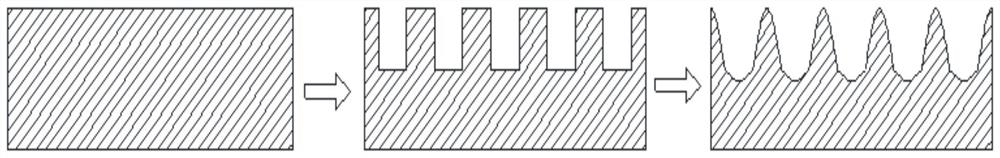

A kind of suspended black dielectric thin film and its preparation method and application

ActiveCN110143567BImprove absorption efficiencyGood uniformity of absorption efficiencyDecorative surface effectsSolid-state devicesPhysical chemistrySingle crystal substrate

The present invention provides a suspended black dielectric film and its preparation method and application, including: S1: providing a semiconductor single crystal substrate, preparing a film mask on the surface of the substrate, and etching a window array to expose the window The surface of the semiconductor single crystal substrate in the array; S2: use wet technology to etch the surface of the semiconductor single crystal substrate to form a micro-nano pyramid structure; S3: remove the film mask, and then prepare on the surface of the semiconductor single crystal substrate film, preparing a black dielectric film on the surface of the micro-nano pyramid structure; S4: patterning the film and etching the film to form a release area; and S5: using dry etching technology or wet etching technology to release the black dielectric film and The supporting membrane structure is obtained. The present invention adopts micro-processing technology, and uses the micro-nano pyramid structure as a mold to prepare suspended black dielectric films in batches. The films can be widely used in the fields of light detection and light sources for enhancing light absorption radiation and reducing heat loss in the future.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Method for preparing polystyrene with low heat conductivity

InactiveCN103965408AImprove flame retardant performanceImprove mechanical propertiesPolymer sciencePolystyrene bead

The invention provides a method for preparing polystyrene with low heat conductivity. The method comprises the following steps: preparing a mixture of phenethylene, ethylene copolymer and polystyrene; separating and converting the mixture, and preparing a polystyrene colloid; adding heat insulating materials and flame-retardant materials in a reaction kettle; cooling down for discharging, washing, and drying to obtain polystyrene beads; foaming, slaking and molding to obtain polystyrene with the low heat conductivity. The method has the characteristics that the preparation technology is strong in controllability, and the polystyrene obtained by the method is good in heat preservation, favorable in flame retardancy, good in mechanical property and long in service life.

Owner:JIANGSU SAIBAOLONG PETROCHEM

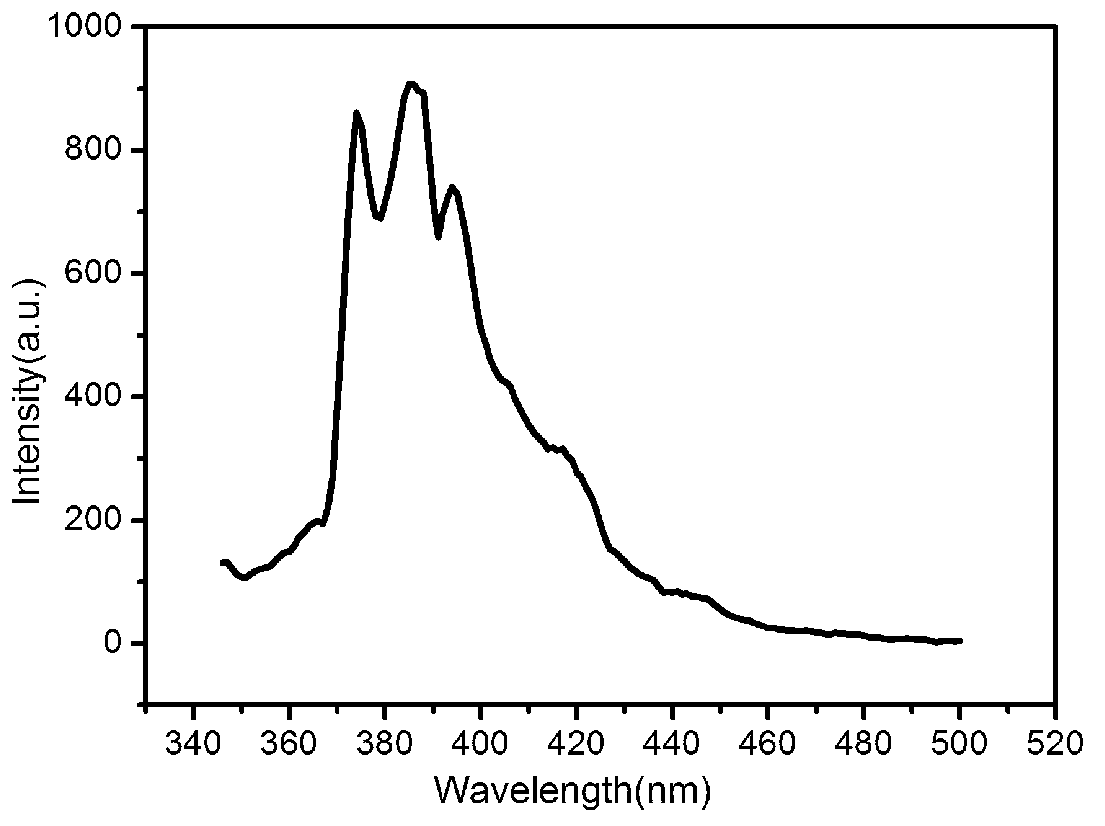

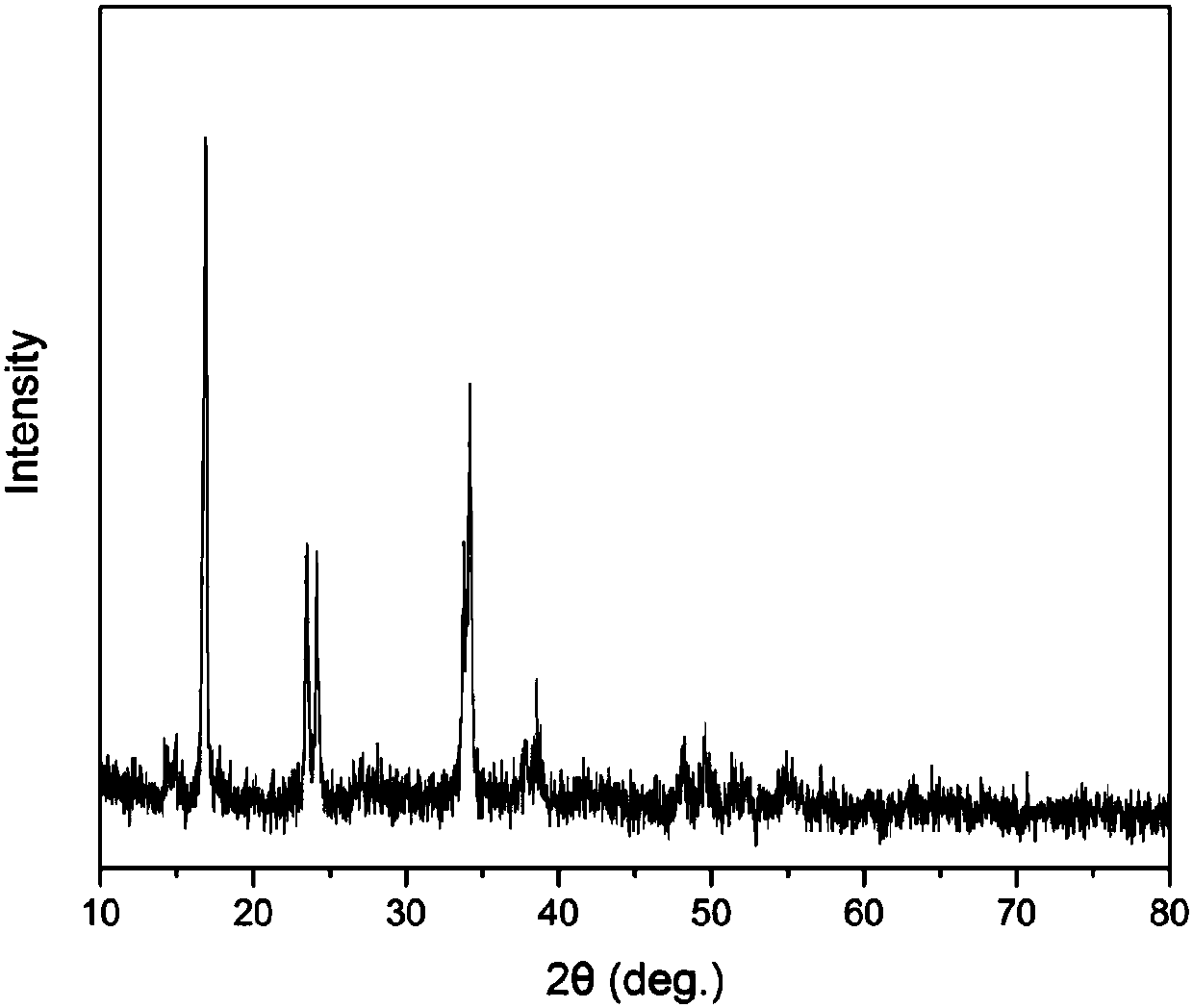

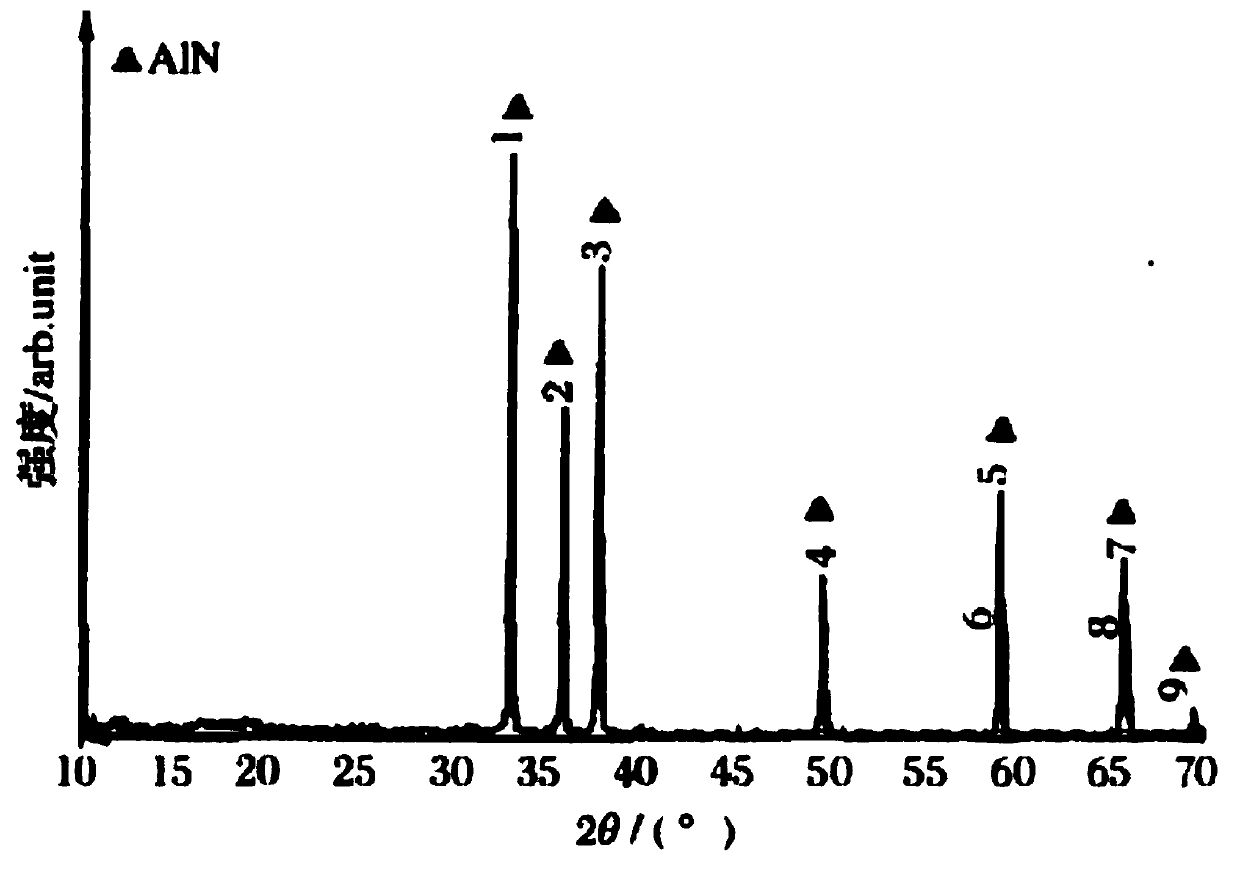

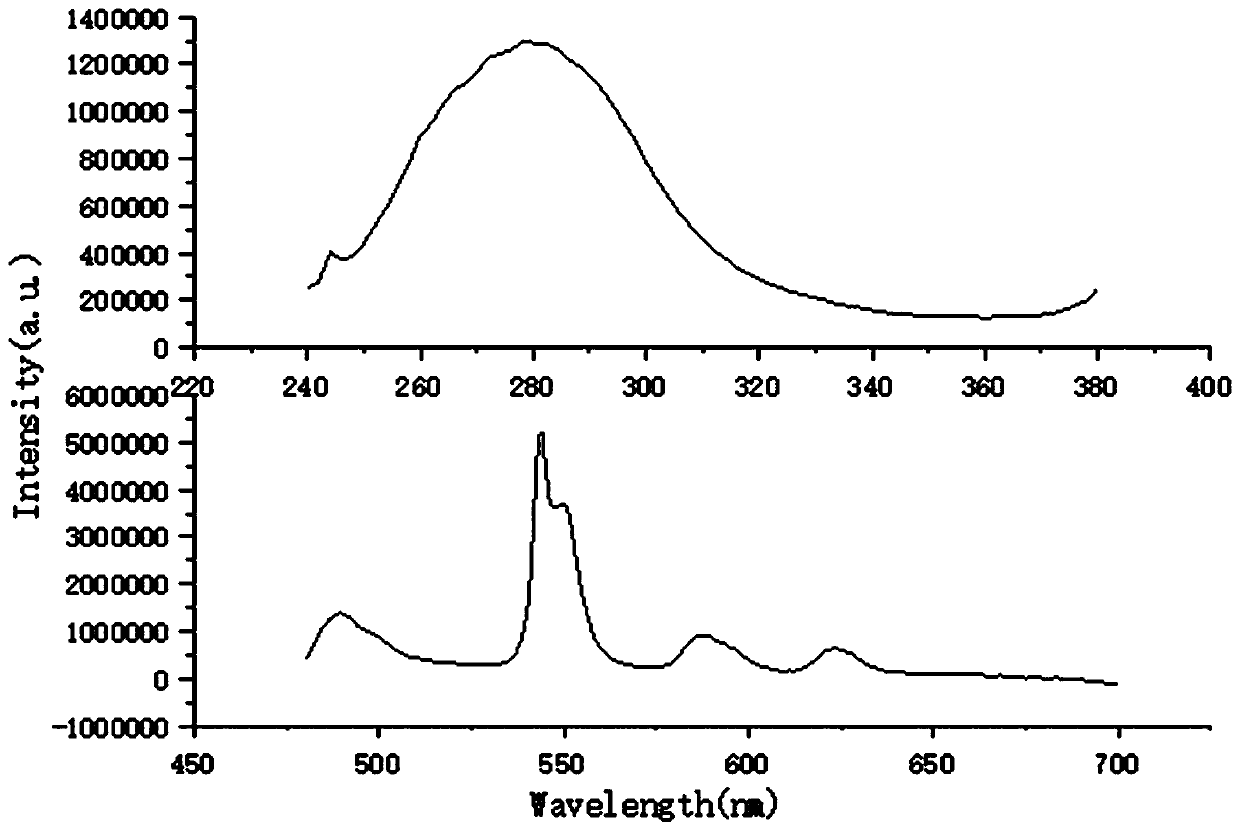

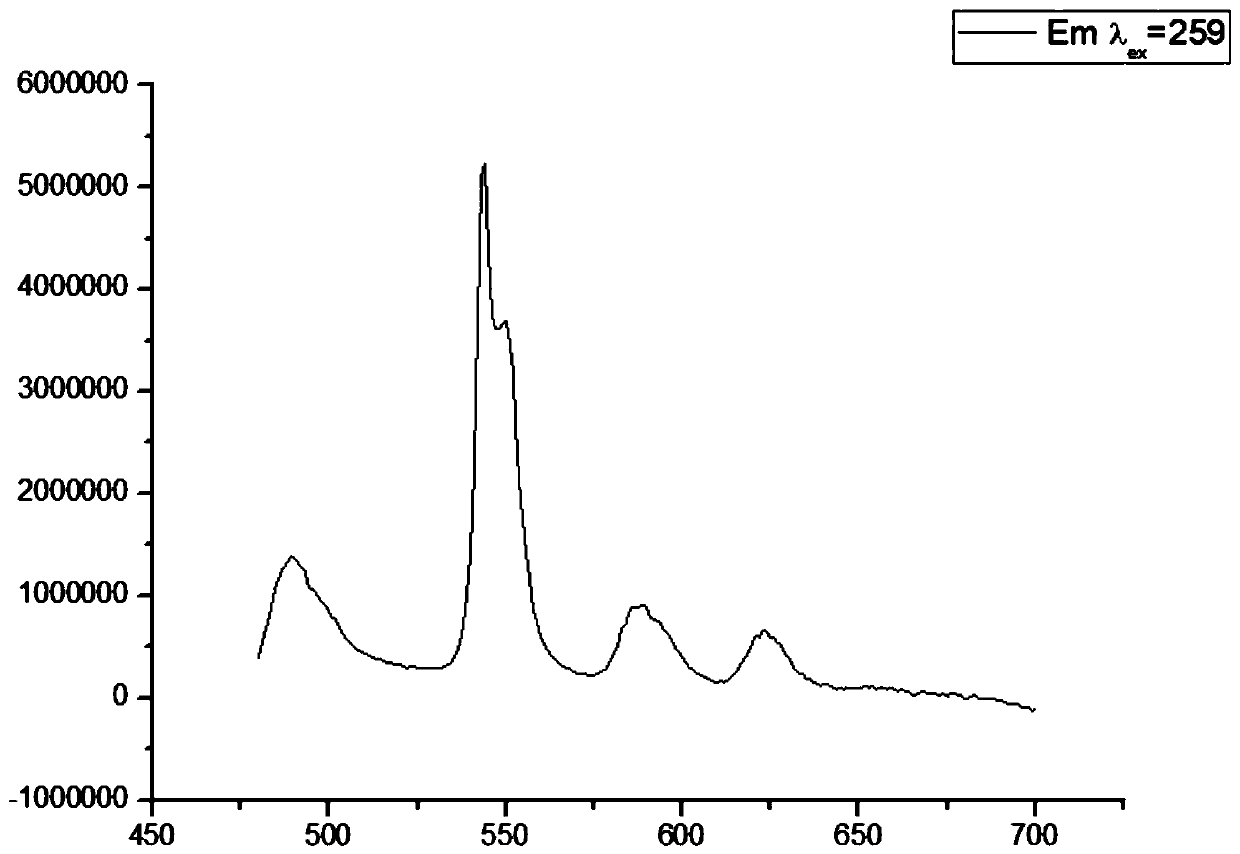

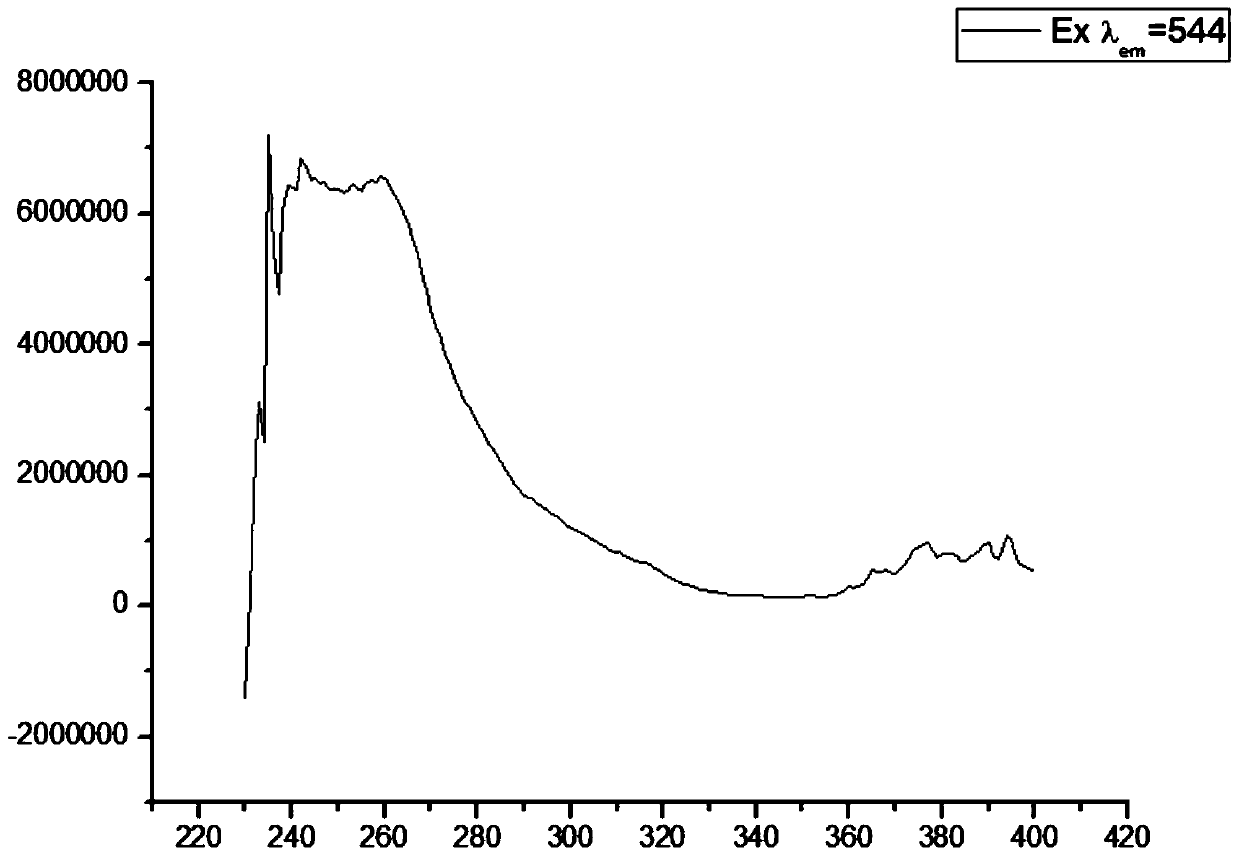

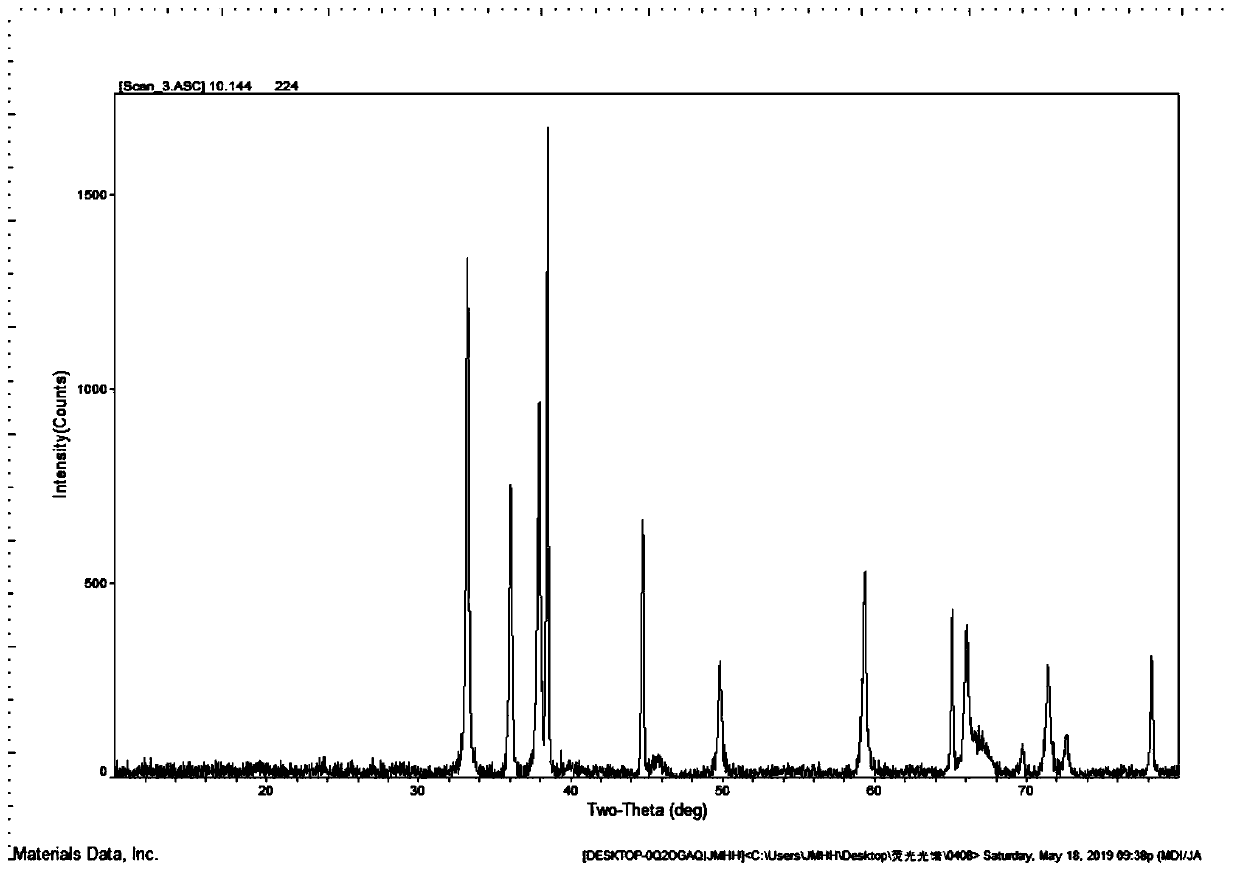

Preparation method of green AIN:Tb fluorescent powder material

InactiveCN110079307AImprove nitriding rateSimple preparation processLuminescent compositionsFluorescenceThermal insulation

The invention relates to a preparation method of a green AIN:Tb fluorescent powder material. The preparation method comprises following steps: S1), aluminum powder, magnesium powder, ammonium chlorideand terbium powder are sufficiently mixed by grinding, the mixture is transferred into an alumina ceramic ark, and reaction precursor powder is obtained; S2), the alumina ceramic ark is transferred into a tube type resistance furnace, nitrogen gas is introduced for nitrogen treatment, and the green AIN:Tb fluorescent powder material is obtained by thermal insulation and cooling. The preparation method has the advantages that the preparation process is simple, the preparation cost is low, the nitriding temperature is low and the material has good performance, high purity, small particles anduniform particle size, the nitridation rate of a product is increased by adding magnesium powder and ammonium chloride as catalysts, nitridation can be realized at a lower temperature, and the preparation process is high in controllability and convenient to implement; the green AIN:Tb fluorescent powder material has the characteristic of green fluorescence property, a sample is subjected to crystal phase analysis through X-ray diffraction, and a diffraction peak is free of impurity phase and is relatively sharp.

Owner:WUYI UNIV

Method for preparing polyvinylidene fluoride conductive plastics

InactiveCN1861375ADoes not damage insulationImprove conductivityPolyvinylidene difluoridePolyvinylidene fluoride

A process for preparing the electrically conductive polyvinylidene fluoride (PVDF) plastics by excimer laser radiation features that the KrF laser with 4-10 Hz for frequency and 248 nm for wavelength and the ArF laser with 193 nm for wavelength are used to radiate a chosen region on a high-insulation PVDV plastics by 140-290 mj / sq.cm for energy density.

Owner:CHENGDU 3D CHANGE TECH

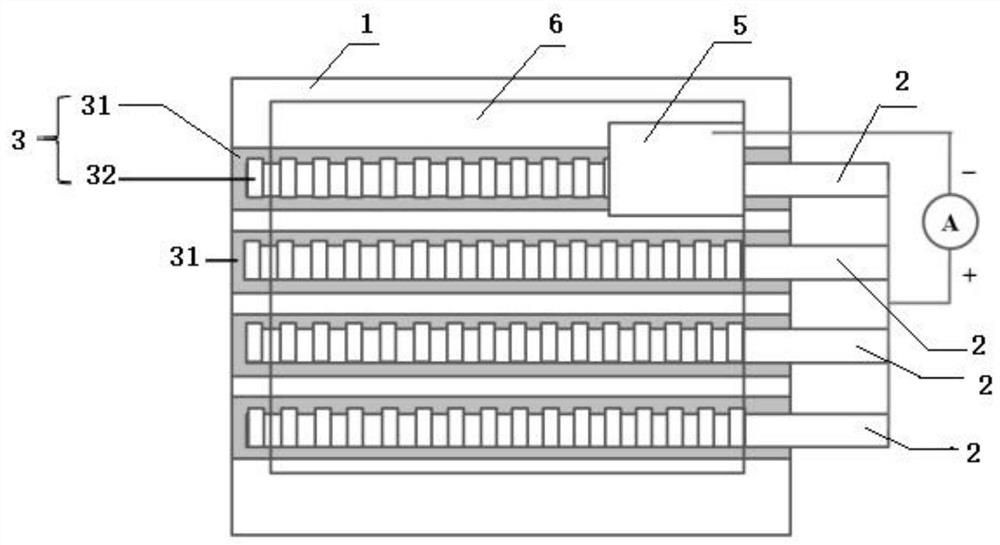

Solar-blind UV detector based on flexible titanium wire/gallium oxide nanoarray and preparation method thereof

ActiveCN111463297BImprove fit firmnessHigh sensitivityMaterial nanotechnologyFinal product manufactureNanopillarNanowire

The invention relates to a solar-blind ultraviolet detector based on a flexible titanium wire / gallium oxide nanoarray and a preparation method thereof. The detector sequentially includes a lower PE protective film, a flexible Ti metal wire lower electrode, and a TiO 2 / β‑Ga 2 o 3 Nano-column array, graphene / Ag nanowire composite electrode, Ag upper electrode and upper PE protective film, wherein the flexible Ti metal wire is a cylinder, and the outside of the Ti metal wire has TiO 2 , β‑Ga 2 o 3 nanopillars located on the TiO 2 top, forming TiO 2 / β‑Ga 2 o 3 array of nanopillars. The solar-blind ultraviolet detector with a PN junction structure of the present invention has a three-dimensional space structure, is flexible and bendable, has stable solar-blind characteristics, good repeatability, excellent chemical and thermal stability, and strong bonding force between the packaged device and the substrate. It can be prepared in a large area and has good repeatability, and is expected to be widely used in the field of wearable and portable ultraviolet detectors.

Owner:杭州紫芯光电有限公司

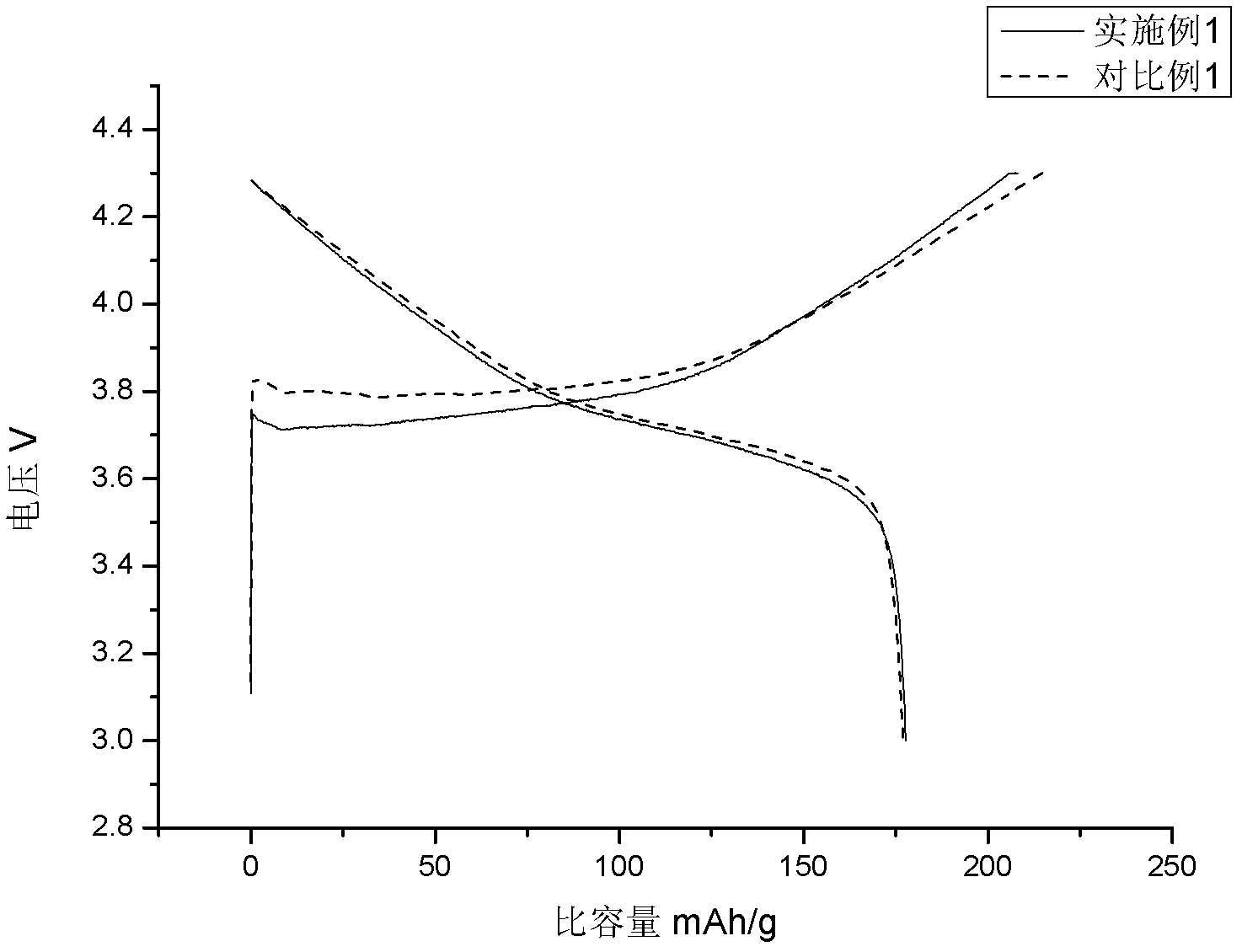

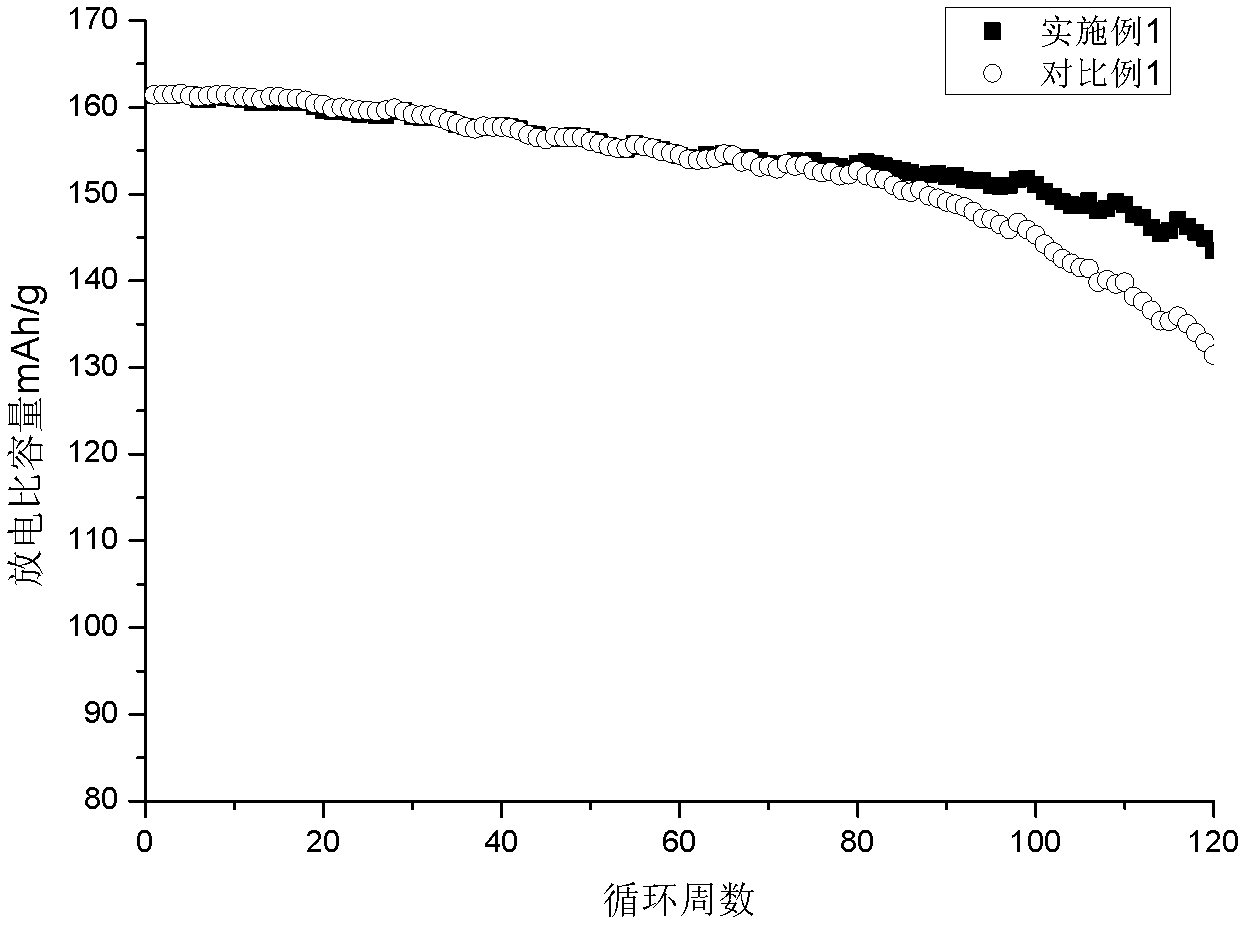

An in-situ developed heterogeneous core-shell structure lithium-ion battery positive electrode material and preparation method thereof

ActiveCN105514362BImprove first-time efficiencyImprove cycle stabilityMaterial nanotechnologyCell electrodesCarbonateMaterials science

The invention provides a lithium ion battery anode material adopting an in-situ developed heterogeneous core-shell structure and a preparation method of the material. The lithium ion battery anode material is a composite with a lithium-rich lamellar phase material as a core layer and a heterogeneous spinel phase generated on the surface of the core layer in an in-situ manner. The lithium ion battery anode material is prepared in the steps as follows the lithium-rich lamellar phase material containing Ni, Mn and M is prepared from carbonate or hydroxides with a coprecipitation method and then dispersed in a mixed salt solution of Ni, Mn and M, the amount-of-substance ratio of Ni to Mn to M in the solution is the same with that in the lithium-rich lamellar phase material, the coprecipitation reaction is performed again, and the mixed metal carbonate (or metal hydroxide) coated lithium-rich lamellar phase material is obtained, the lithium-rich lamellar phase material is sintered at the high temperature in the absence of a Li source, and the lithium ion battery anode material adopting the in-situ developed heterogeneous core-shell structure can be obtained. The lithium ion battery anode material adopting the in-situ developed heterogeneous core-shell structure has the advantages as follows the shell layer coats the core layer in a uniform, complete and thickness-controllable manner, no obvious phase boundaries exist between the core layer and the shell layer, and the electrochemical performance of the material is improved.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

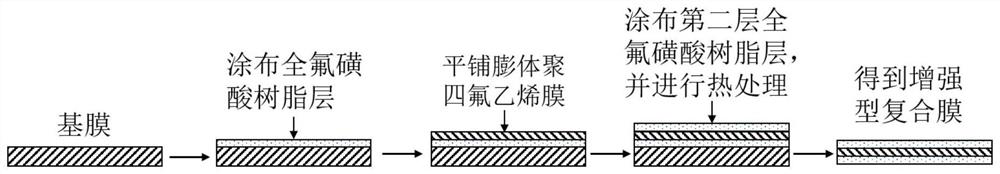

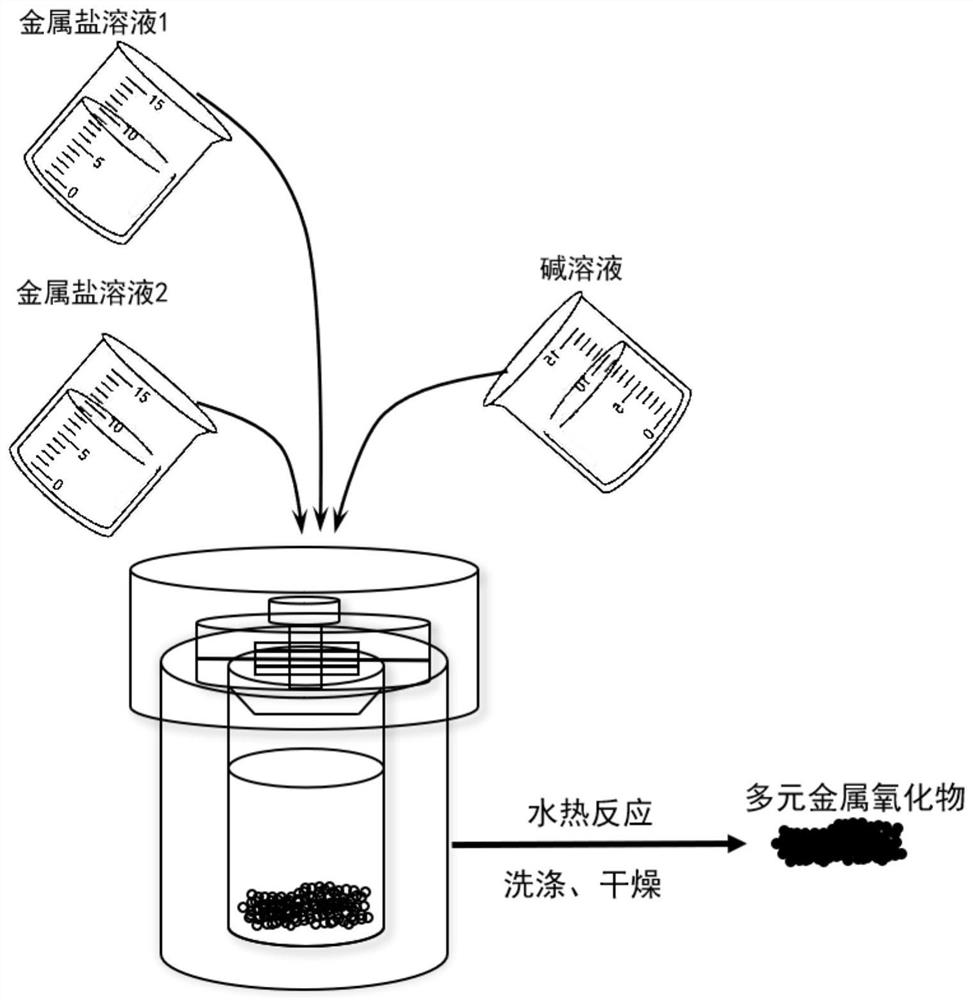

A kind of high durability enhanced proton exchange membrane and its preparation method and application

ActiveCN112757731BExtend your lifeReduce performance decay rateFinal product manufactureSynthetic resin layered productsPhysical chemistryFluorosulfonic acid

The invention discloses a high-durability enhanced proton exchange membrane and its preparation method and application. The proton exchange membrane includes an expanded polytetrafluoroethylene membrane for support and a perfluorosulfonic acid resin membrane for proton conduction. The fluorosulfonic acid resin membrane is located on both sides of the expanded polytetrafluoroethylene membrane and in the internal pores, and the perfluorosulfonic acid resin membrane is dispersed with a multi-element metal oxide free radical quencher for reducing the decay rate of fuel cell performance. The multi-element metal oxide free radical quencher was introduced into the perfluorosulfonic acid resin, and introduced into the expanded polytetrafluoroethylene membrane by scraping method, and the enhanced proton exchange membrane was prepared. The chemical corrosion resistance of the composite proton exchange membrane prepared by the present invention is greatly improved, it can adapt to harsh fuel cell working conditions such as idling, start-stop, etc., and can be applied to various usage scenarios. It is a promising composite proton exchange membrane, and the preparation process is highly controllable, and the single-shot yield is large, which can be directly used in continuous production.

Owner:NANJING UNIV

How to make weather-resistant rubber

ActiveCN104530516BImprove waterproof performanceStrong weather resistancePolymer scienceWeather resistance

Owner:江苏木克体育器材有限公司

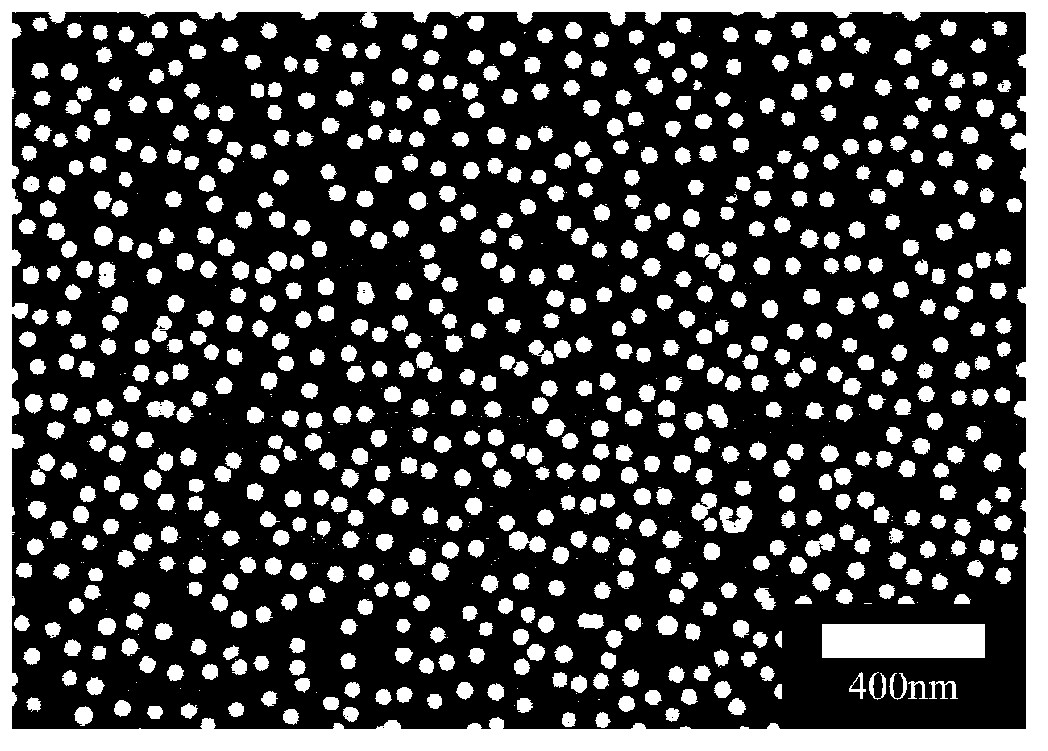

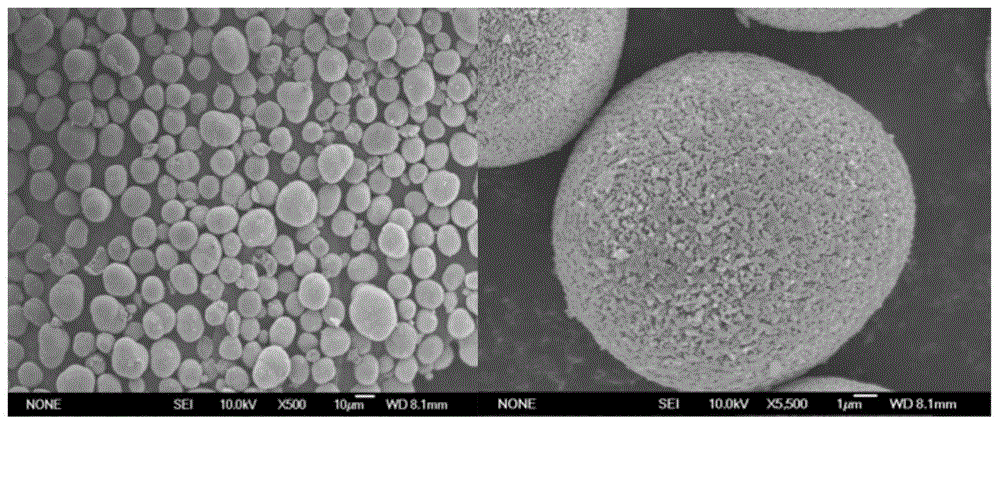

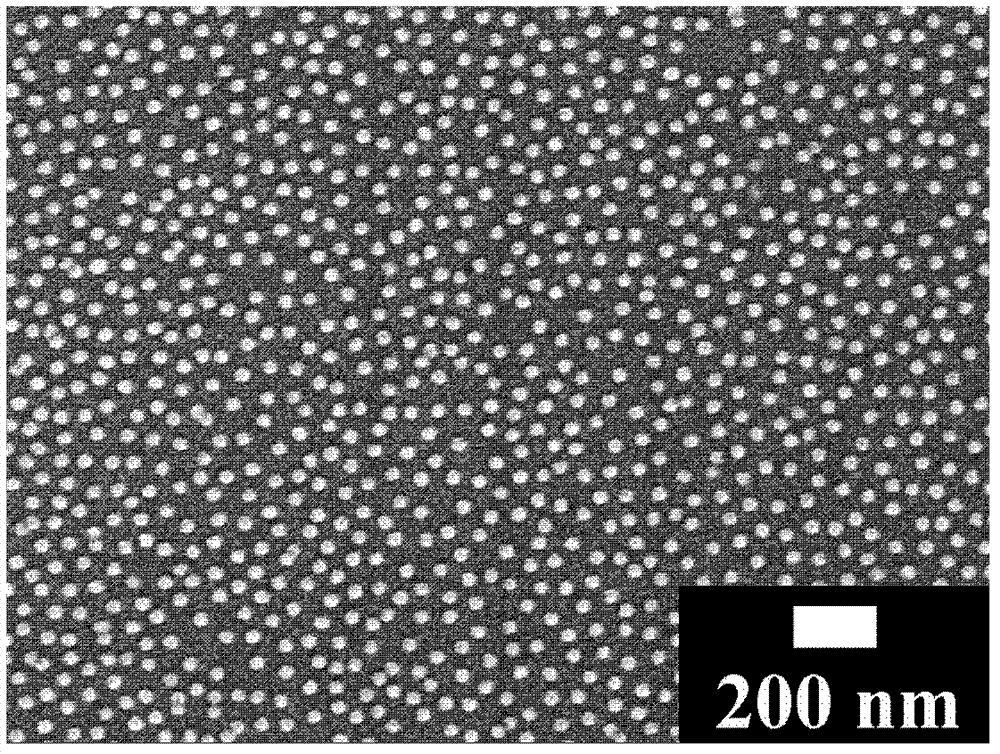

Preparation method of uniform-dimension polymer nano microspheres

The invention relates to a preparation method of uniform-dimension polymer nano microspheres, which comprises the following steps: mixing copolymer and solvent in a certain proportion, and putting the mixture in a container; and heating the container containing the polymer and solvent to a certain temperature, and keeping for some time, thereby obtaining the polymer microspheres dispersed in solvent, wherein the copolymer is composed of a chain segment A and a chain segment B; the chain segment A is polystyrene, polymethylstyrene or polyacrylonitrile; and the chain segment B is polymethyl methacrylate, poly(N,N-dimethylaminoethyl methacrylate), dimethylamino methyl polymethacrylate, poly(2-vinyl pyridine), poly(4-vinyl pyridine) or polyoxyethylene. The polymer microspheres obtained by themethod provided by the invention have highly uniform dimension, and the particle size can be regulated within the range of 20-200nm. The method provided by the invention is simple, is not related to chemical reaction, has the advantages of short technical process, low cost and high yield, and is especially applicable to large-scale production.

Owner:NANJING UNIV OF TECH

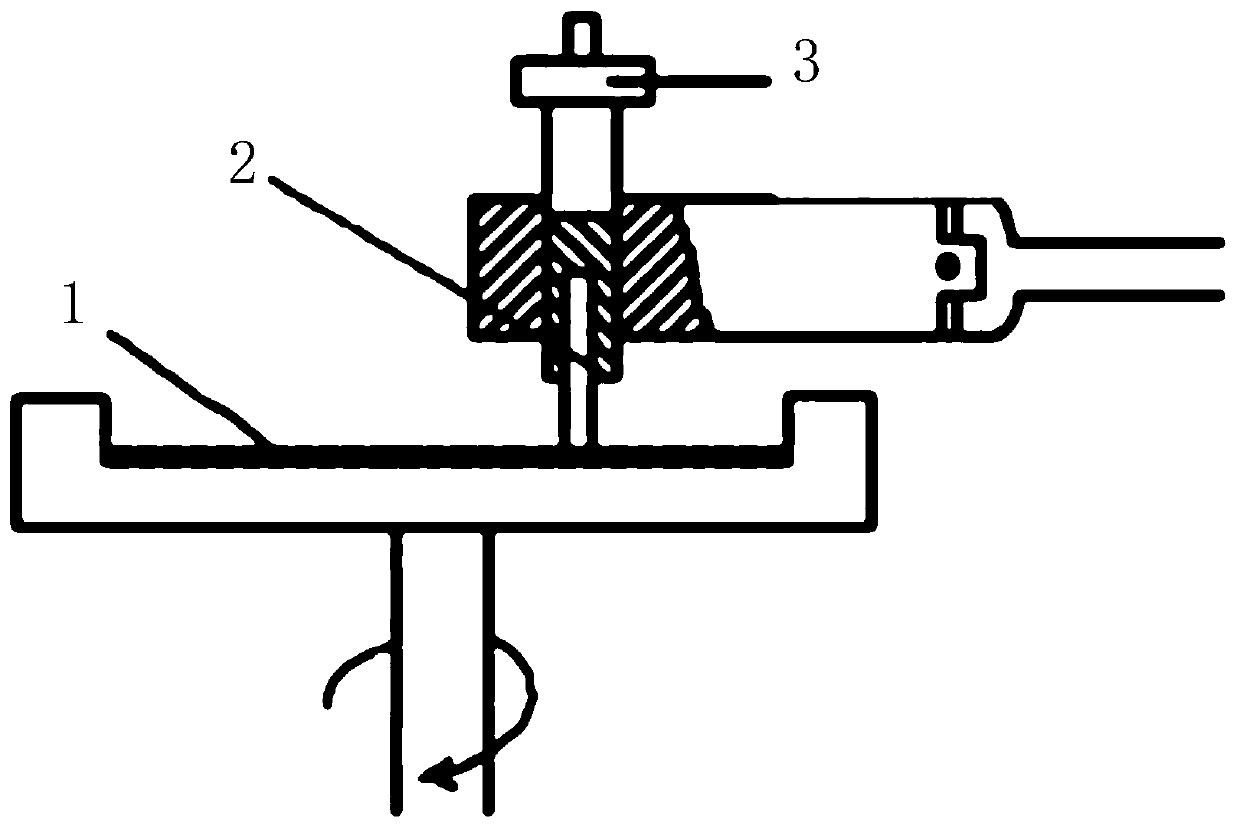

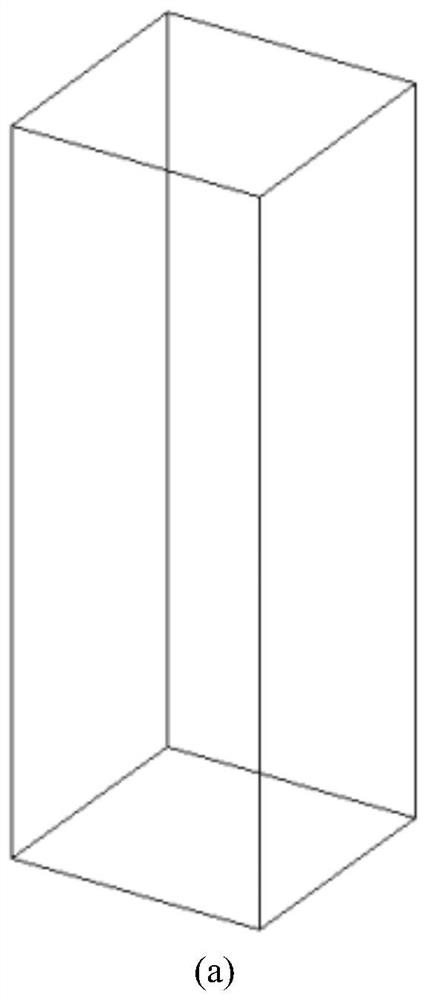

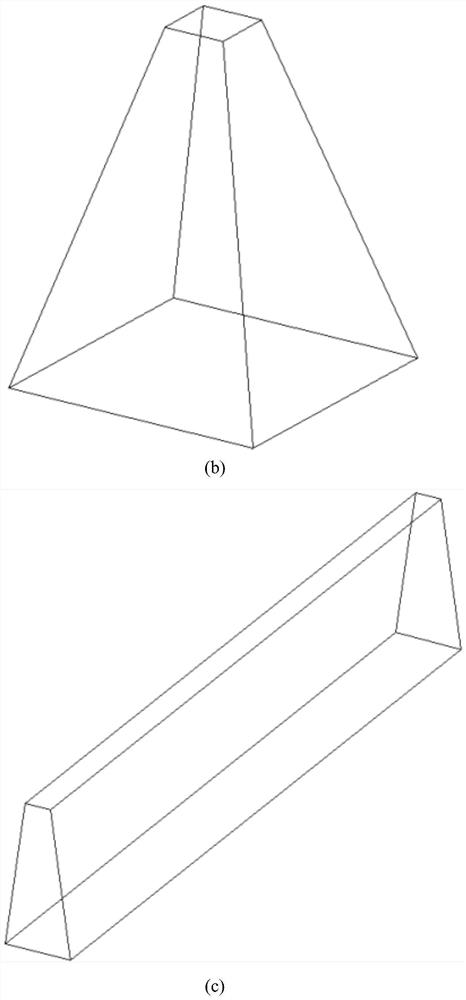

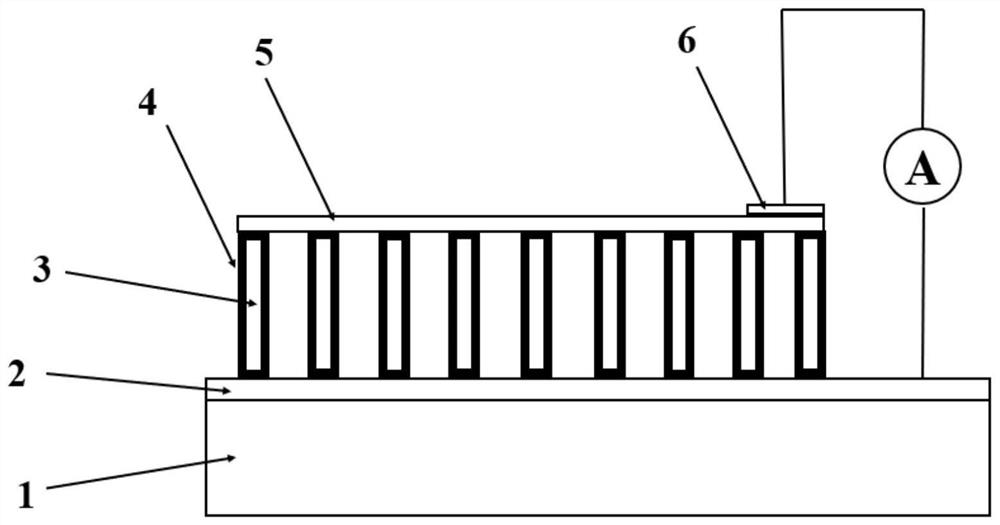

A kind of preparation method of field emission array cathode

ActiveCN108807109BReduce usageSimple processDischarge tube/lamp detailsCold cathode manufactureEngineeringPhotolithography

The invention discloses a method for preparing a field emission array cathode, which belongs to the technical field of cathode field emission. In the present invention, the field emission cathode substrate is installed on a cutting machine, and the cutting parameters are set to obtain an initial emitter array formed by a prismatic emitter, and the obtained emitter is further etched to form a pointed emitter, thereby obtaining Field emission cathode cone array. The present invention combines mechanical processing technology and etching technology to prepare field emission array cathodes, which simplifies the process flow and reduces production costs compared with the existing photolithography technology combined with etching technology; at the same time, by adjusting mechanical processing parameters and etching process parameters , field emission array cathodes with different array sizes, array heights and array spacings can be obtained, the preparation process is highly controllable, and the use of toxic and harmful reagents is avoided at the same time, which conforms to the concept of modern green and environmental protection; the preparation method of the present invention has good repeatability and is effective It is beneficial to the popularization and application of the field emission array cathode.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Power grid corona monitor and preparation method thereof

ActiveCN114744060AGood size controlImprove performanceMaterial nanotechnologyNanosensorsHeterojunctionNanowire

The invention discloses a power grid corona monitor and a preparation method thereof, the power grid corona monitor comprises an FTO substrate, at least one side of the FTO substrate is provided with a fluorine-doped tin oxide layer, a GaOOH nano-pillar array grows on the fluorine-doped tin oxide layer, the GaOOH nano-pillar array forms an alpha / beta-Ga2O3 phase junction nano-pillar array after annealing, and the alpha / beta-Ga2O3 phase junction nano-pillar array forms an alpha / beta-Ga2O3 phase junction nano-pillar array. A Ti3C2 / Ag nanowire composite layer is arranged on the alpha / beta-Ga2O3 phase junction nano-pillar array, an Ag electrode is arranged on the Ti3C2 / Ag nanowire composite layer, a Ti3C2 / alpha / beta-Ga2O3 nano-pillar array Van der Waals heterojunction is formed between a Ti3C2 layer on the Ti3C2 / Ag nanowire composite layer and the alpha / beta-Ga2O3 phase junction nano-pillar array, a three-dimensional space heterojunction interface structure and the solar blind characteristic are achieved, and the solar blind property is improved. The self-powered power grid corona monitor has the advantages of excellent chemical and thermal stability, high voltage resistance, low working temperature and power consumption and good repeatability, is a self-powered power grid corona monitor with ultrahigh responsivity, and can directionally identify ultraviolet light with the wavelength of 200-280nm in a solar blind wave band.

Owner:ZHEJIANG SCI-TECH UNIV

Preparing method of rare earth doped aluminum nitride base green fluorescent powder

PendingCN110205119AImprove nitriding rateSimple preparation processLuminescent compositionsFluorescenceGranularity

The invention provides a preparing method of rare earth doped aluminum nitride base green fluorescent powder. The method includes the following steps of S1, adding a certain amount of aluminum powder,magnesium powder, ammonium chloride and TbCl3.6H2O solid into a mortar to be ground and evenly mixed; S2, adding the ground powder into a muffle furnace for sintering reaction, raising the temperature to 800-1200 DEG C at the temperature raising rate of 5 DEG C / min, and then conducting sintering for 2-5 hours to obtain the terbium doped aluminum nitride base fluorescent powder. The method is simple in preparing process; by adding the magnesium powder and ammonium chloride as catalysts, the nitriding rate of the product is increased; by doping the green fluorescent powder with rare earth Tb, nitriding can be realized at a low temperature, the carbonizing effect is good, the preparing process is high in controllability and convenient to implement, and production cost is further reduced; thegreen fluorescent powder has the advantages of being low in nitriding temperature, good in performance, high in purity, small in grain size and uniform in granularity and has the characteristic of the green fluorescent property.

Owner:WUYI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com