High-durability fuel cell composite proton exchange membrane, and preparation method and application thereof

A proton exchange membrane and fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of high cost and poor durability of hydrogen fuel cells, and achieve process safety, low hydrogen permeation current density, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

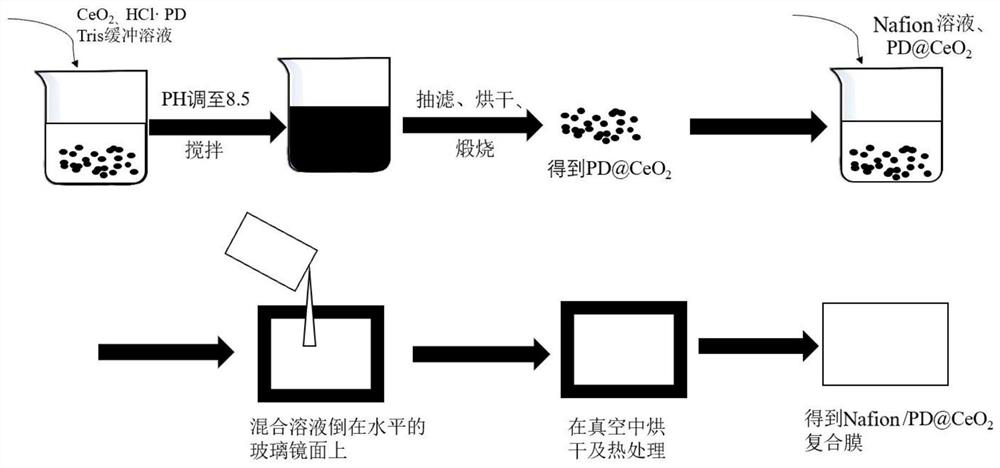

[0033]The present invention provides a highly durable hydrogen fuel cell proton microfine, and the preparation method thereof comprises the steps of:

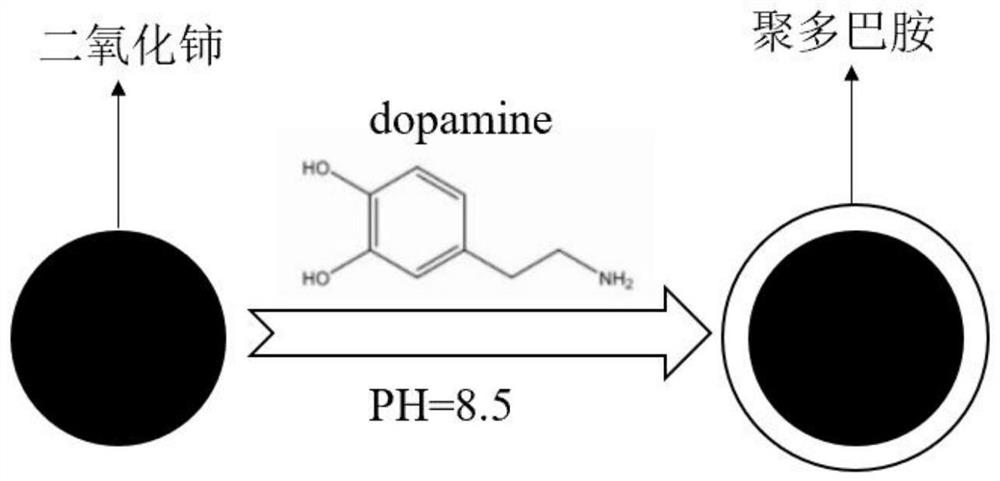

[0034]Step (1): Demine the cerium oxide, Tris, and hydrochloride is dissolved in deionized water, and the magnetic force is stirred until a transparent uniform solution is formed, while stirring while slowly adding an appropriate amount of NaOH solution to a pH of the mixed solution having a pH of 8.5. The alkaline mixed solution was stirred at normal temperature for 2 h, and then the mixed solution was subjected to filtration, dried to obtain a dopamine coated cerium oxide;

[0035]Step (2): Polymer resin solution obtained by obtaining a polyamine-coated metal oxide free radical quarantin free radical quarantin and a solvent having a N, N-dimethyl amide or dimethyl sulfoxide in step (1), in a certain proportion Mixing, stirred to form a uniform dispersion;

[0036]Step (3): Pour the uniform dispersion into a pre-horizontal glass mold, 40 to ...

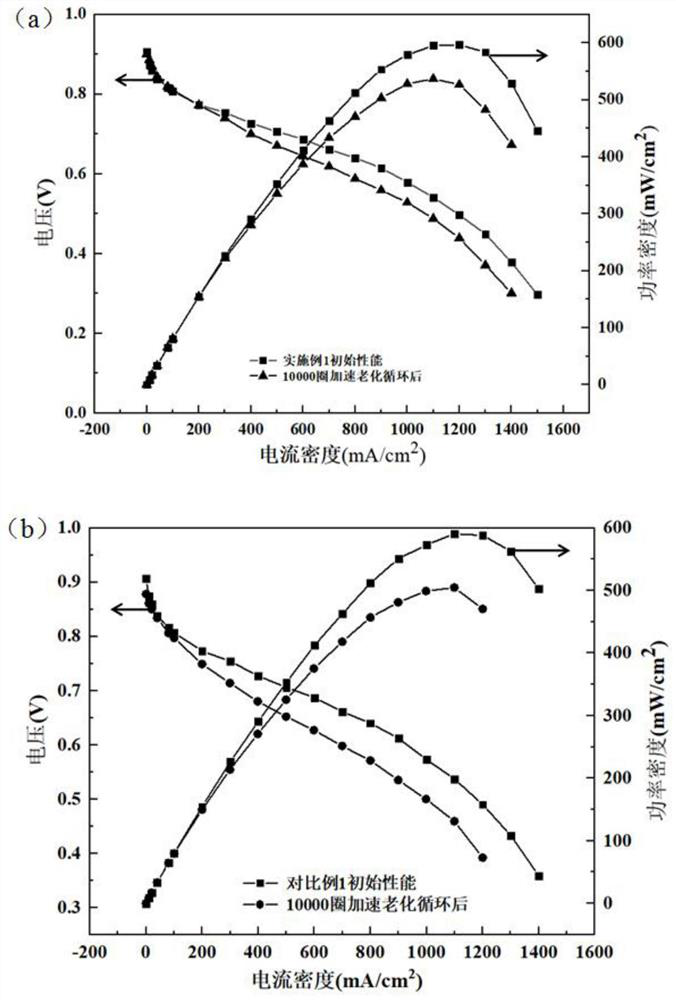

Embodiment 1

[0043]The fuel cell proton exchange membrane preparation method in this embodiment includes the following steps:

[0044](1) Use electronic balance of 80mg commercial CEO280 mg of dopamine, 63 mg of Tris is dissolved in 40 ml deionized water, and stirred on a magnetic stirrer to completely dissolve; 0.5 to a solution pH of the solution until the solution is 8.5, and stirred on a magnetic stirrer 2H; The mixed solution was subjected to filtration, and the mixture was allowed to obtain a polyvino coated cerium oxide particles at 60 ° C; the polydamine in this example was about 0.76 nm.

[0045](2) Electronic sacral title 3 g 10 wt% Nafion / DMSO solution was coated with 3 mg of polybatamine, and mixed with ultrasound cleaning is mixed and uniform, resulting in a translucent suspension.

[0046](3) Place the film forming glass mold on the precision slide, and transfer the overall to the vacuum drying tank, and adjust the glass mold to the level with a universal equalizer, followed by pouring th...

Embodiment 2

[0058]The metal oxide free radical quenner in this embodiment is cerium oxide.

[0059]The present embodiment is substantially identical to the first embodiment, and the difference is in that step (1), and controls the amount of the cerium oxide and the polymer resin to obtain a compound of the cerium oxide content of 0.8 wt% of the composite proton exchange membrane.

[0060]Step (1), commercial CEO2Popular hydrochloride, Tris is dissolved in deionized water, stirred on a magnetic stirrer to completely dissolve; 0.5H of 1 mol / L NaOH solution until the solution pH is 9, stirred on a magnetic stirrer; then press the mixed solution The filtration was carried out, and the dried 60 ° C was dried all night.

[0061]Among them, in the mixed solution, the concentration of dopamine hydrochloride is 3 mg / ml, and the concentration of the metal oxide free radical quencher is 3 mg / ml. The polydamine in this example is about 0.7 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com