Preparation process of two-dimensional Al-O-Cu-Fe single-crystalline-layer flaky material

A technology of al-o-cu-fe and flake materials, applied in the field of metal catalytic material preparation, can solve the problems of easy introduction of impurities, harsh conditions, complicated preparation methods, etc., and achieve strong process controllability, low cost, and easy preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) According to the atomic ratio is Al 63 Cu 25 Fe 12 , the pure metal of aluminum, copper and iron is melted into a 2Kg Al-Cu-Fe alloy ingot in a vacuum electromagnetic induction furnace.

[0021] (2) Break the above alloy, and use vacuum quick quenching strip equipment to prepare strips with a thickness of 40-60μm in an argon environment, with a strip speed of 15m / s and a distance of 2.5cm between the nozzle and the single roller. bring.

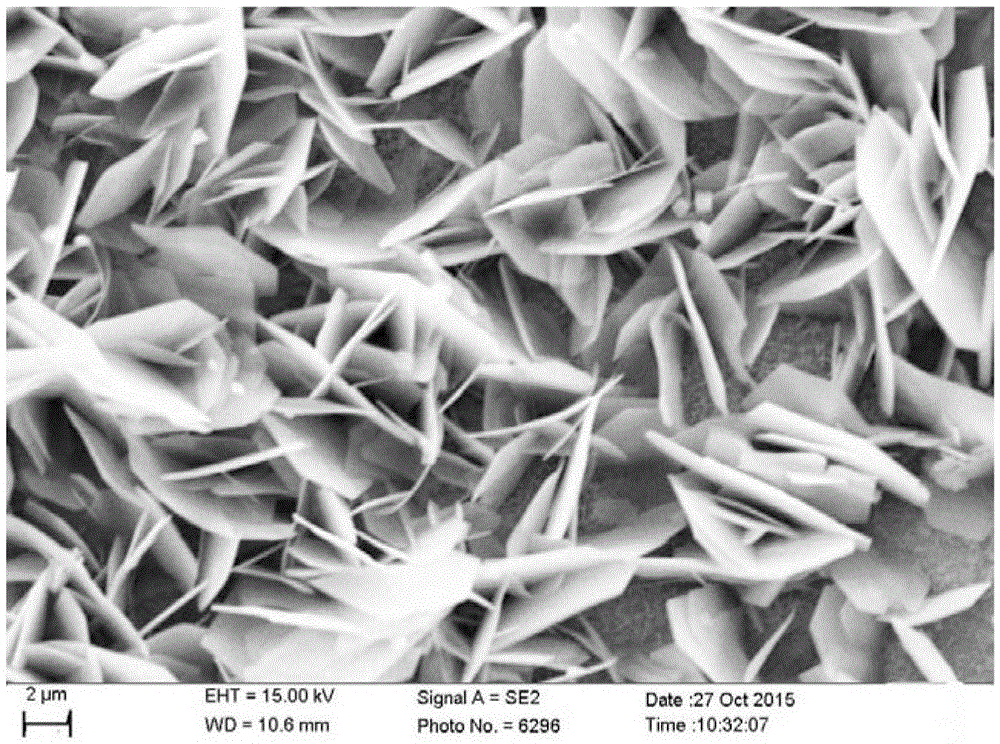

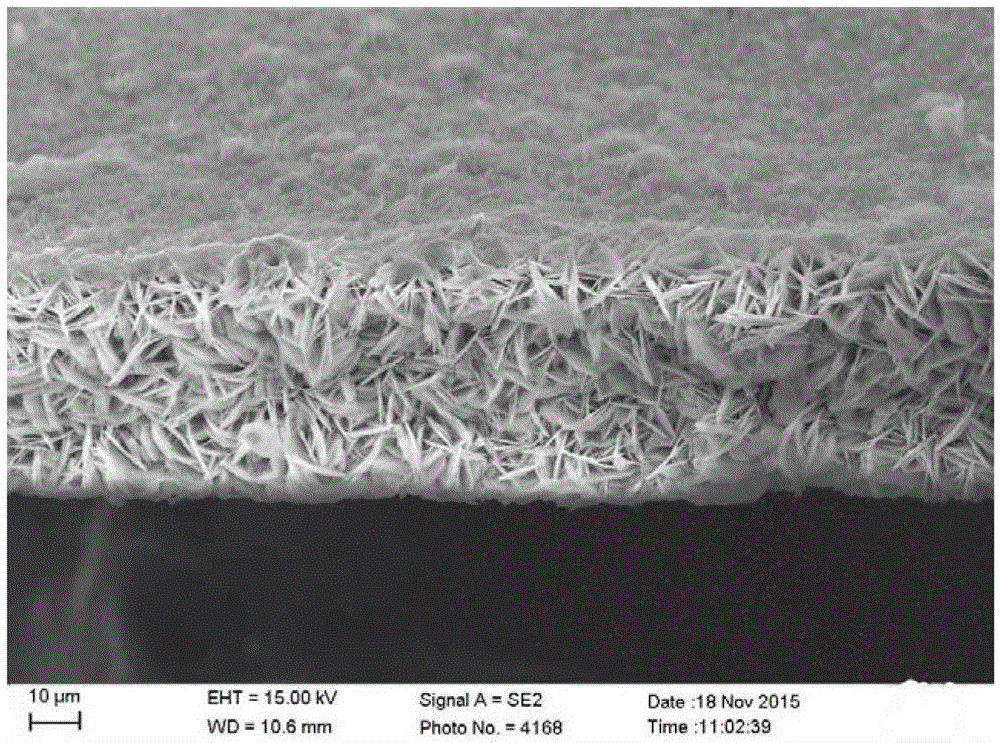

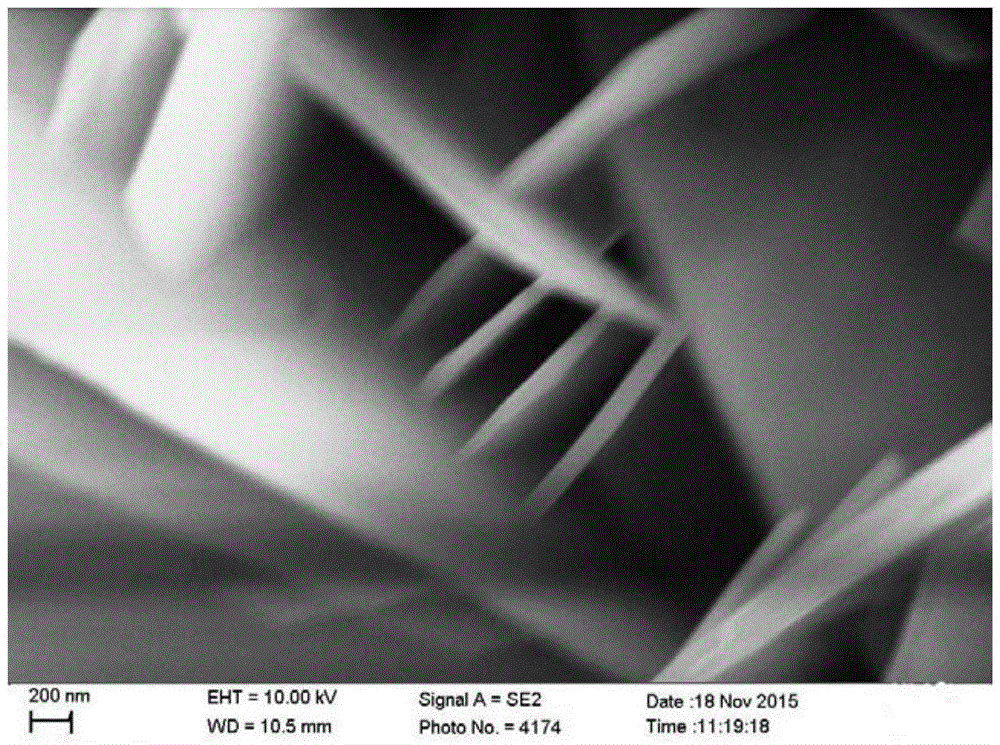

[0022] (3) Prepare a 0.8mol / L NaOH solution, put the strip sample into the prepared solution, wash it with deionized water after reacting for 7 hours, then ultrasonically clean it in alcohol for 3 minutes, and dry to obtain a two-dimensional layer Flake single crystal Al-O-Cu-Fe catalytic material. like figure 1 , figure 2 , image 3 , Figure 4 As shown, a large number of lamellar single crystal materials are generated on the surface of the substrate. The shape of the lamellar single crystal is irregular or hexagonal, the...

Embodiment 2

[0024] (1) According to the atomic ratio is Al 60 Cu 30 Fe 10 , the pure metal of aluminum, copper and iron is melted into a 2Kg Al-Cu-Fe alloy ingot in a vacuum electromagnetic induction furnace.

[0025] (2) Break the above alloy, and use vacuum quick quenching strip equipment to prepare strips with a thickness of 40-60μm in an argon environment, with a strip speed of 15m / s and a distance of 2.5cm between the nozzle and the single roller. bring.

[0026] (3) Prepare a 0.5mol / L NaOH solution, put the strip sample into the prepared solution, wash it with deionized water after reacting for 1 hour, then ultrasonically wash it in alcohol for 3 minutes, and dry to obtain a two-dimensional layer Flake single crystal Al-O-Cu-Fe catalytic material. The result is similar to the attached figure, a large number of lamellar single crystal materials are formed on the surface of the substrate, the shape is irregular or hexagonal, the thickness is 30-50nm, the single crystal size is bet...

Embodiment 3

[0028] (1) According to the atomic ratio is Al 70 Cu 13 Fe 17 , the pure metal of aluminum, copper and iron is melted into a 2Kg Al-Cu-Fe alloy ingot in a vacuum electromagnetic induction furnace.

[0029] (2) Break the above alloy, and use vacuum quick quenching strip equipment to prepare strips with a thickness of 40-60 μm in an argon environment, the strip strip speed is 15m / s, and the distance between the nozzle and the single roller is 2.0cm. bring.

[0030] (3) Prepare a 3.0mol / L NaOH solution, put the strip sample into the prepared solution, wash it with deionized water after reacting for 7 hours, then ultrasonically clean it in alcohol for 3 minutes, and dry to obtain a two-dimensional layer Flake single crystal Al-O-Cu-Fe catalytic material. The result is similar to the attached figure, the sheet single crystal shape is irregular or hexagonal, the thickness is 30-50nm, the single crystal size is 2-6μm, and the pore size is 1-10μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com