Patents

Literature

31results about How to "Adjust reaction time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot aerosol fire extinguishing agent

The invention discloses a hot aerosol fire extinguishing agent which is prepared by an oxidant, a reductant, a performance modifying agent, and an adhesive. The invention not only has good fire extinguishing effect, but also is energy-saving, environment-friendly, and low in cost; meanwhile, the invention does not cause corrosion or damage of equipment after utilization, and can effectively prevent secondary combustion of files and equipment.

Owner:浙江华神消防科技有限公司

Spherical ferrate having hollow structure and preparation method thereof

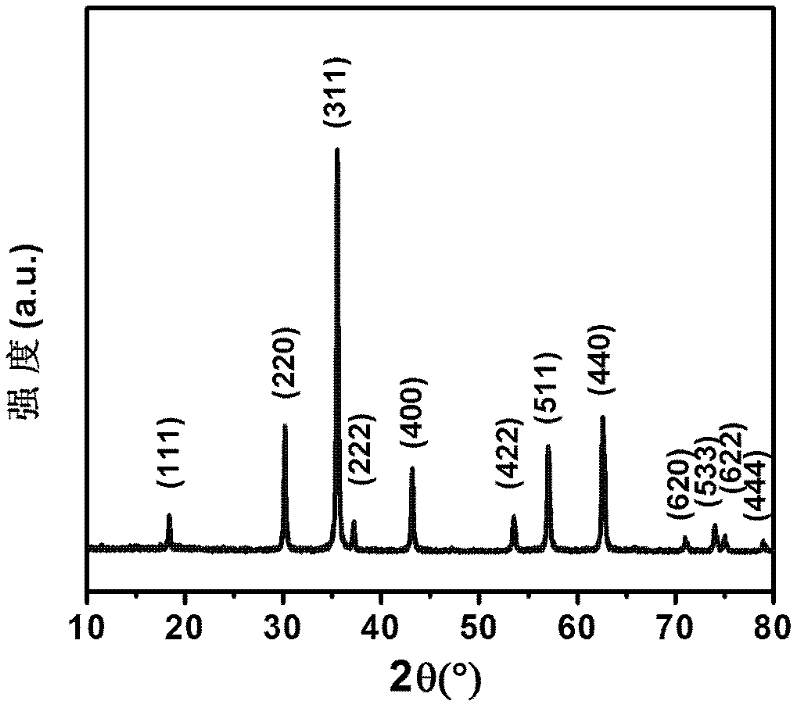

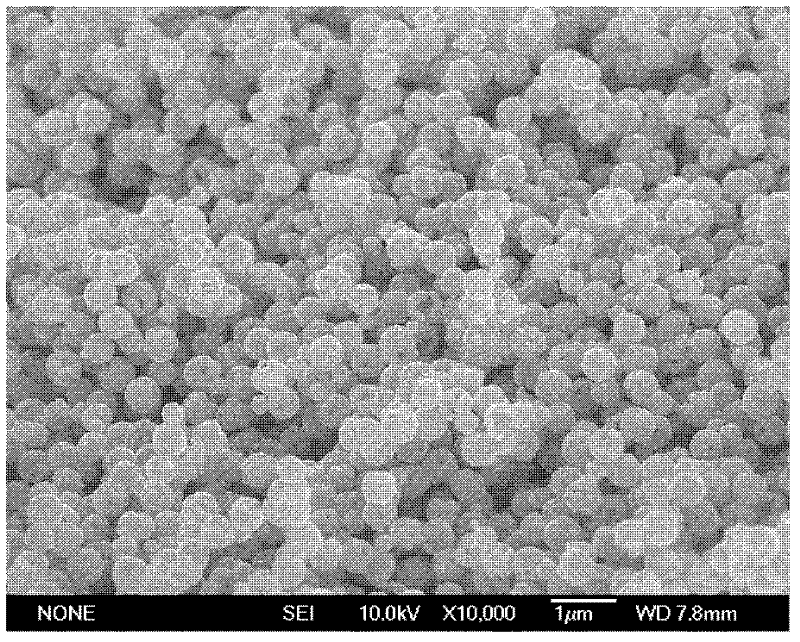

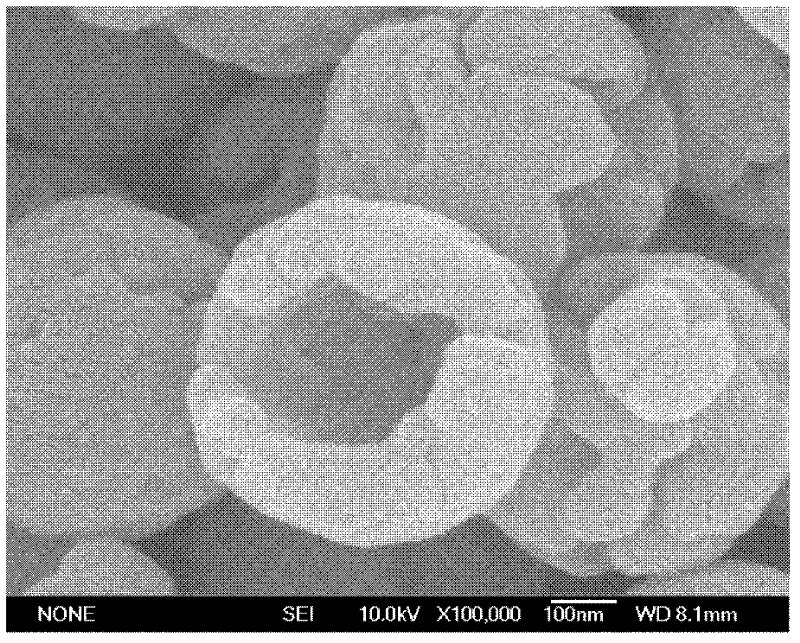

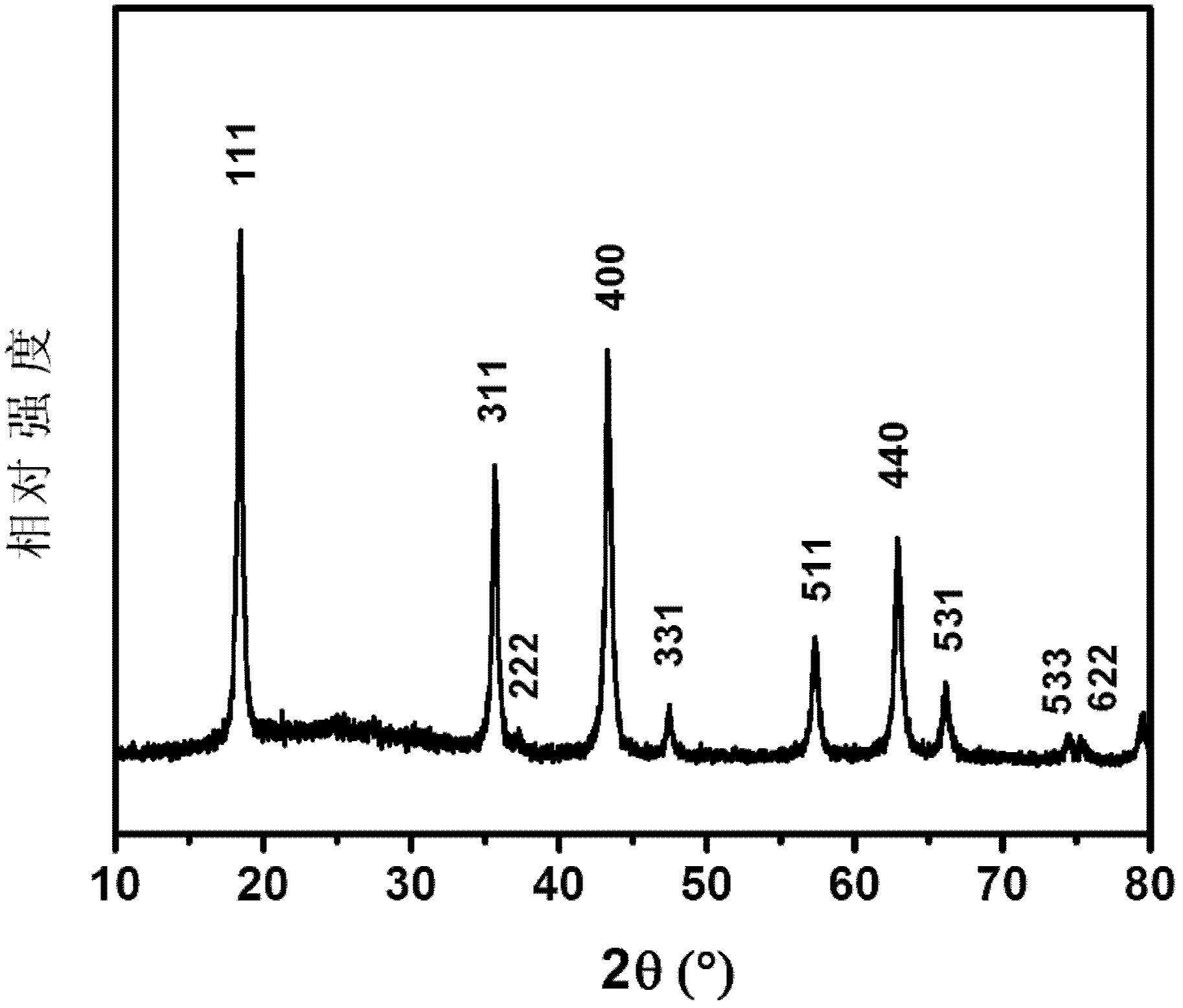

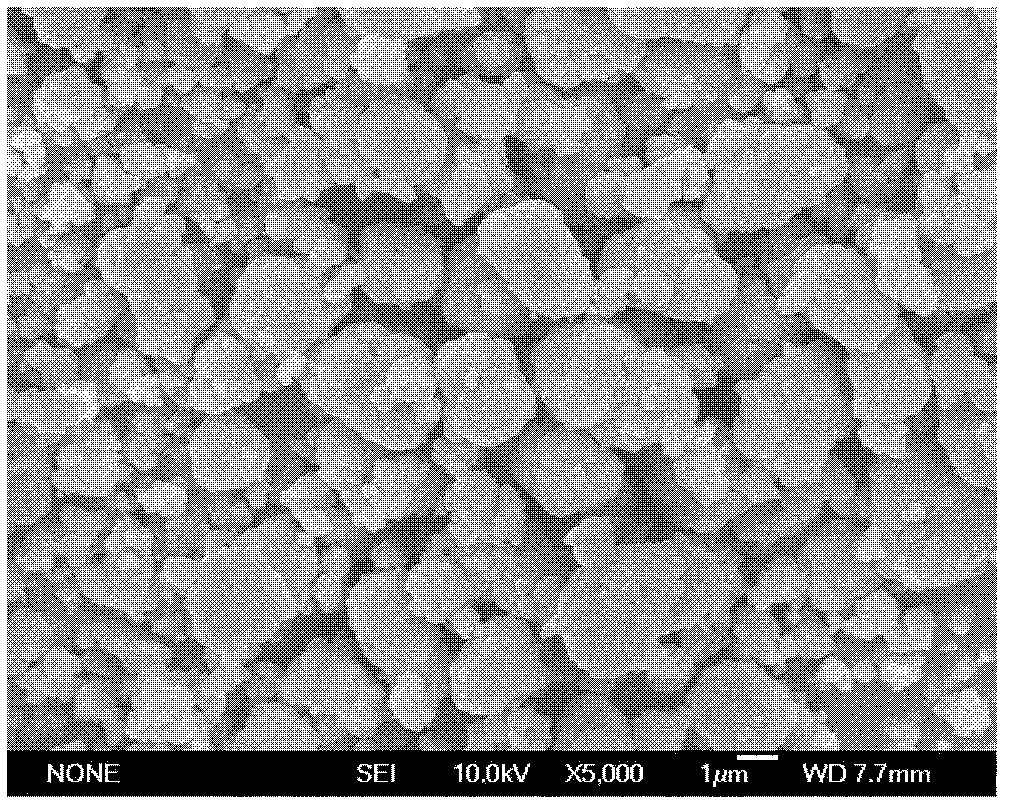

InactiveCN102531066APromote formationHigh viscosityNanotechnologyIron compoundsPhysical chemistryNanocrystal

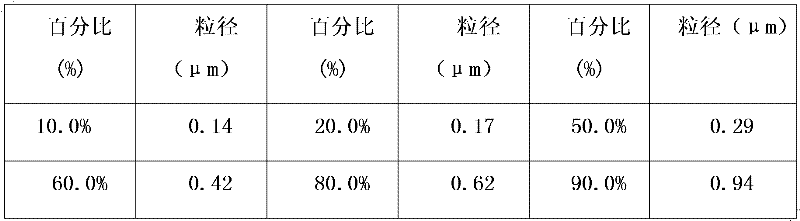

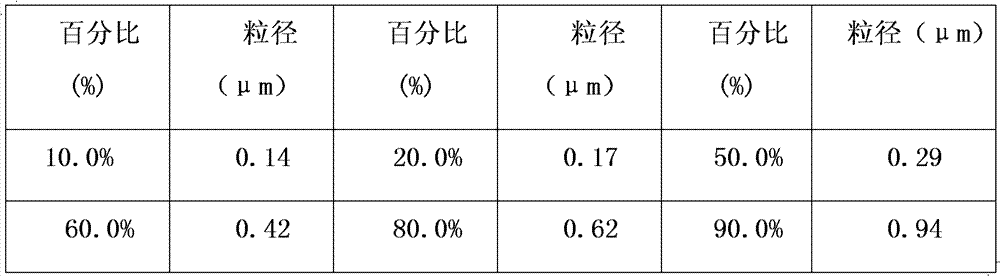

The invention discloses spherical ferrate having a hollow structure and a preparation method thereof. The ferrate MFe2O4 is of a hollow-structured spherical particle formed by self-assembling of nanocrystals having a particle size of 10-50nm, wherein M is Co, Ni or Zn, the diameter of the particle is 0.1-1mu m, and the thickness of a shell layer is 30-200nm. The spherical ferrate can be used as a negative electrode material of a lithium ion battery.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

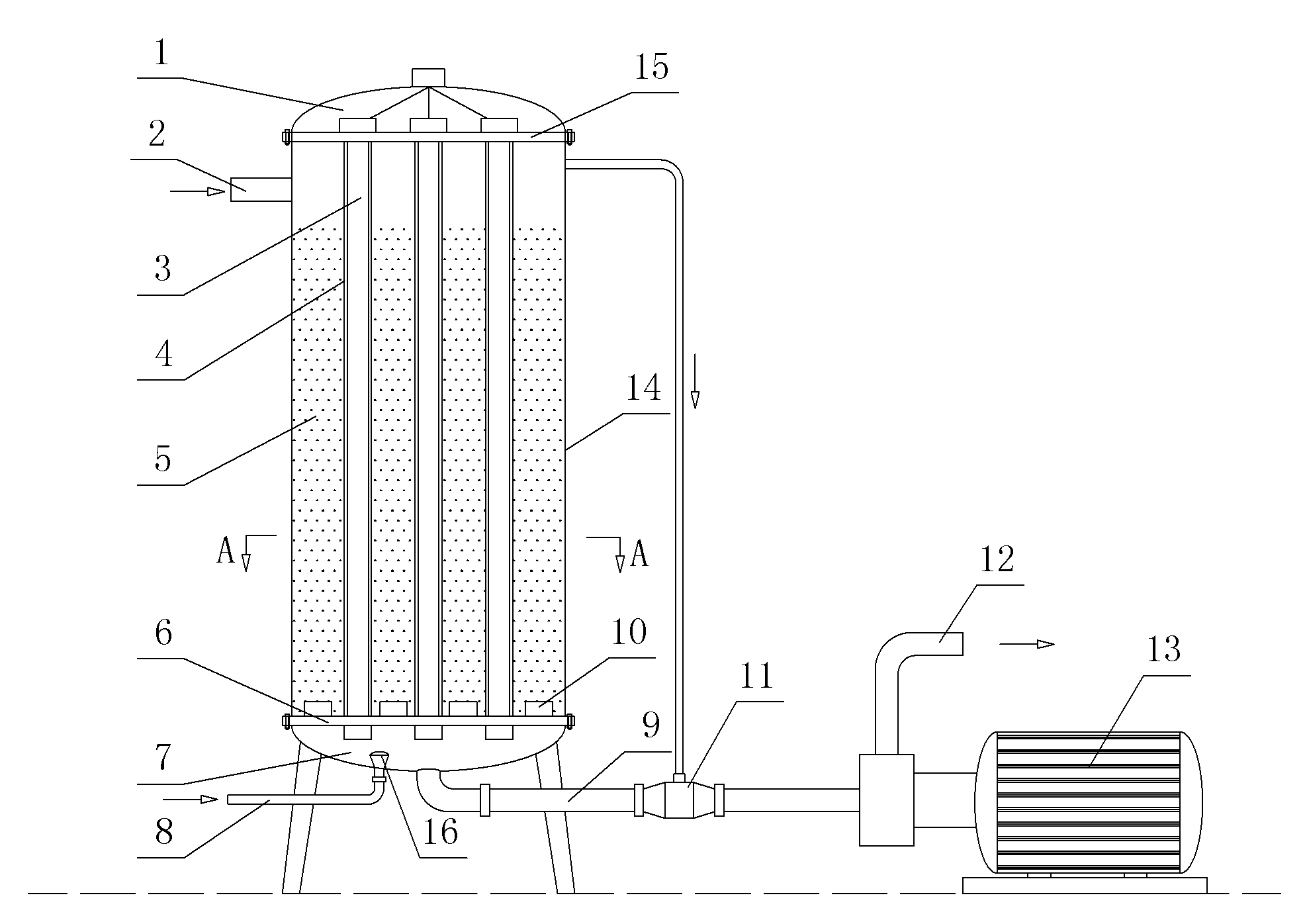

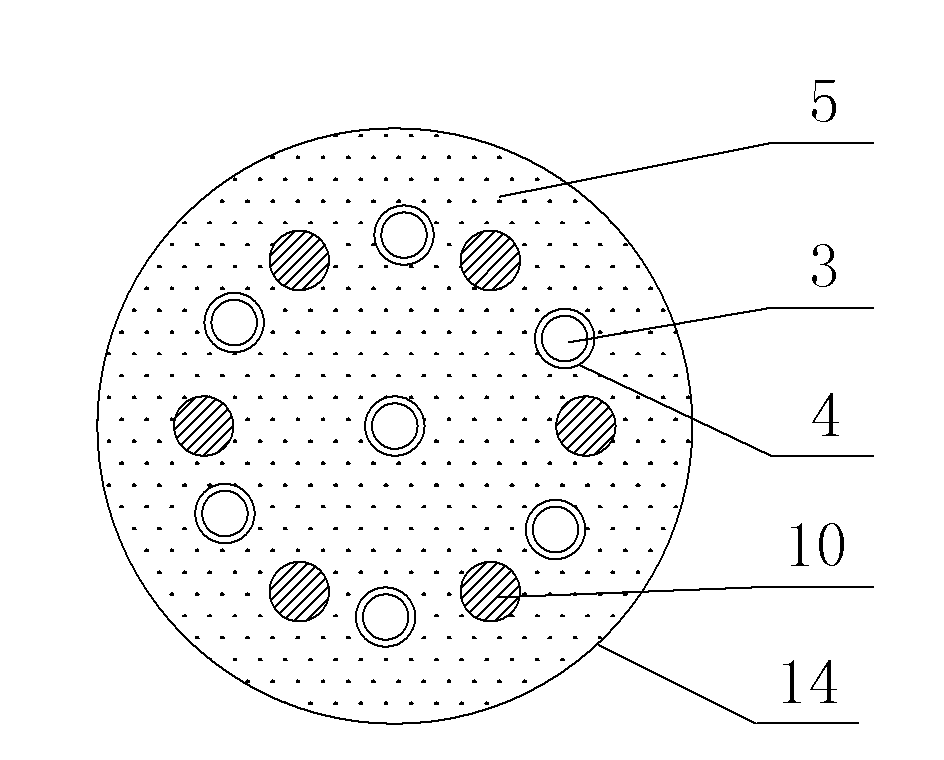

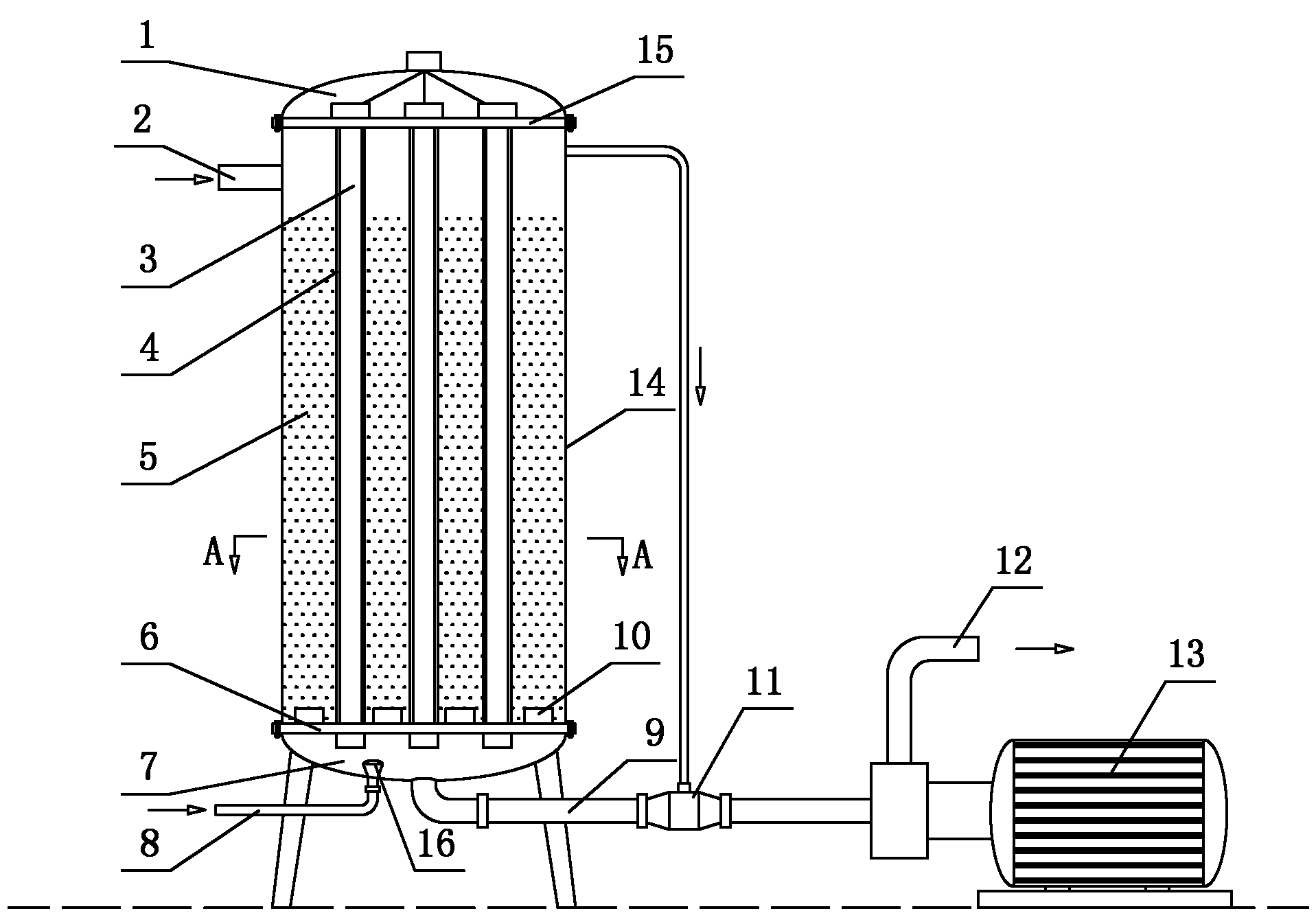

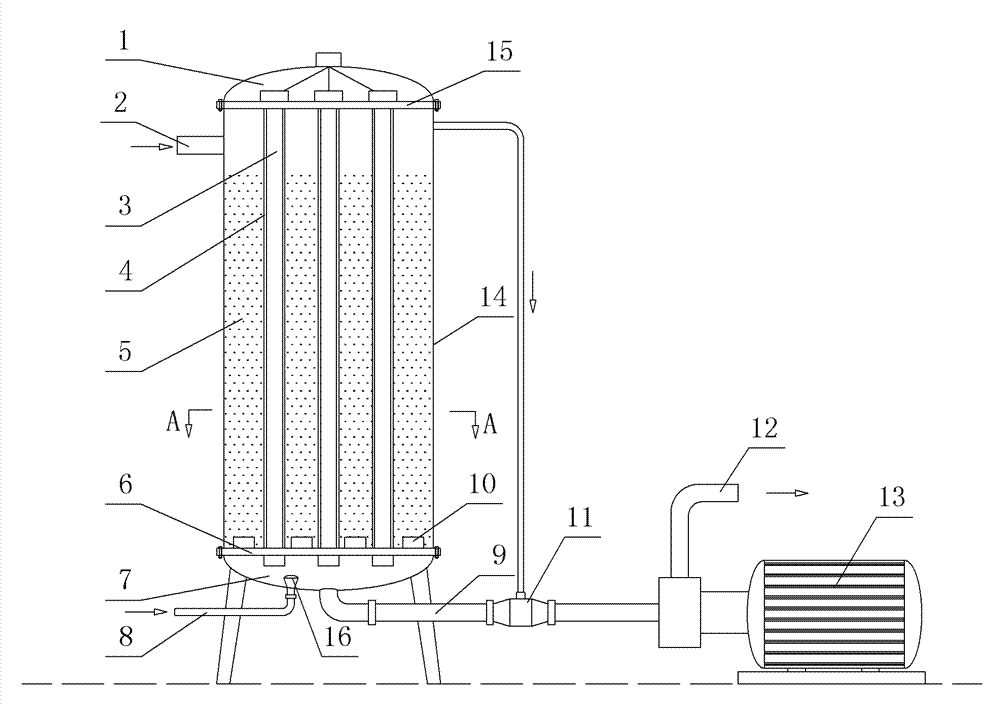

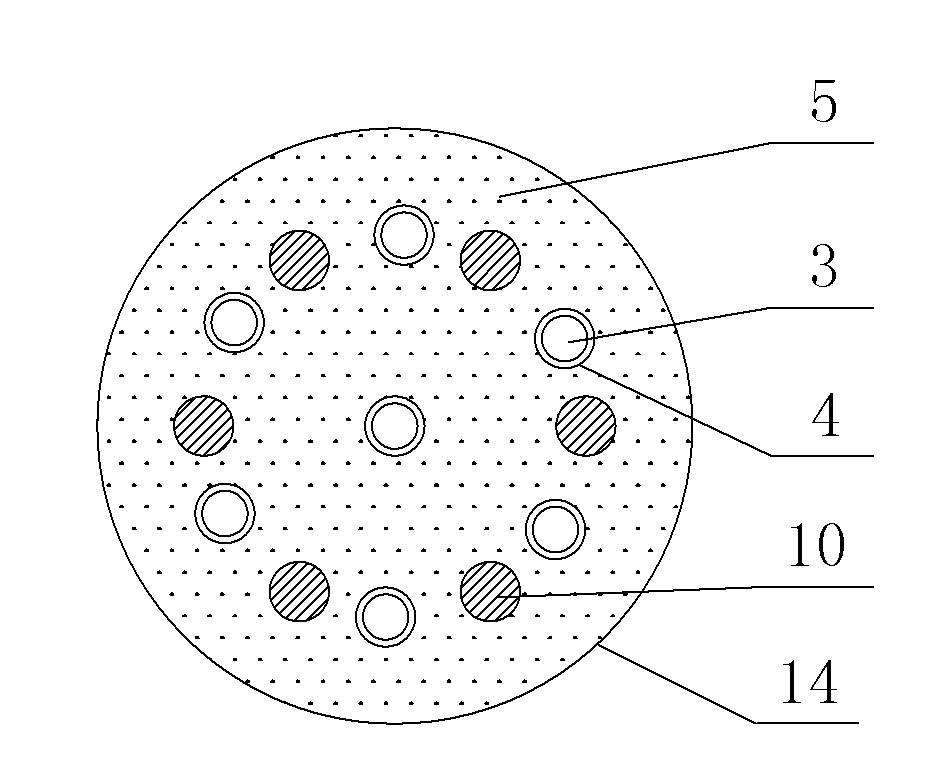

Method and device for purifying vinosity

InactiveCN101948732AImprove inner qualityReduce flow rateAlcoholic beverage preparationUltraviolet lightsSolid particle

The invention discloses a method for purifying vinosity, comprising an oxidation reduction reaction which is carried out on the surfaces of solid particles attached with TiO2 photochemical catalyst layers under the irradiation of ultraviolet light after the body is mixed with oxygen or ozone. The invention also discloses a device for realizing the method for purifying the vinosity. In the invention, multiple groups of ultraviolet light sources are evenly arranged at each part of a reaction chamber to directly irradiate the body and the surface of the photocatalyst; the ultraviolet light can efficiently decompose unsaturated compounds in the body, such as aldehydes, fusel oil, sulfide and other harmful components under the action of catalyst, eliminates impurities and peculiar smell in thewine, eliminates spicy, stimulated and bran taste of green wine, eliminates the off-flavor of edible alcohol, and deeply promotes the inherent quality of the wine.

Owner:李建东

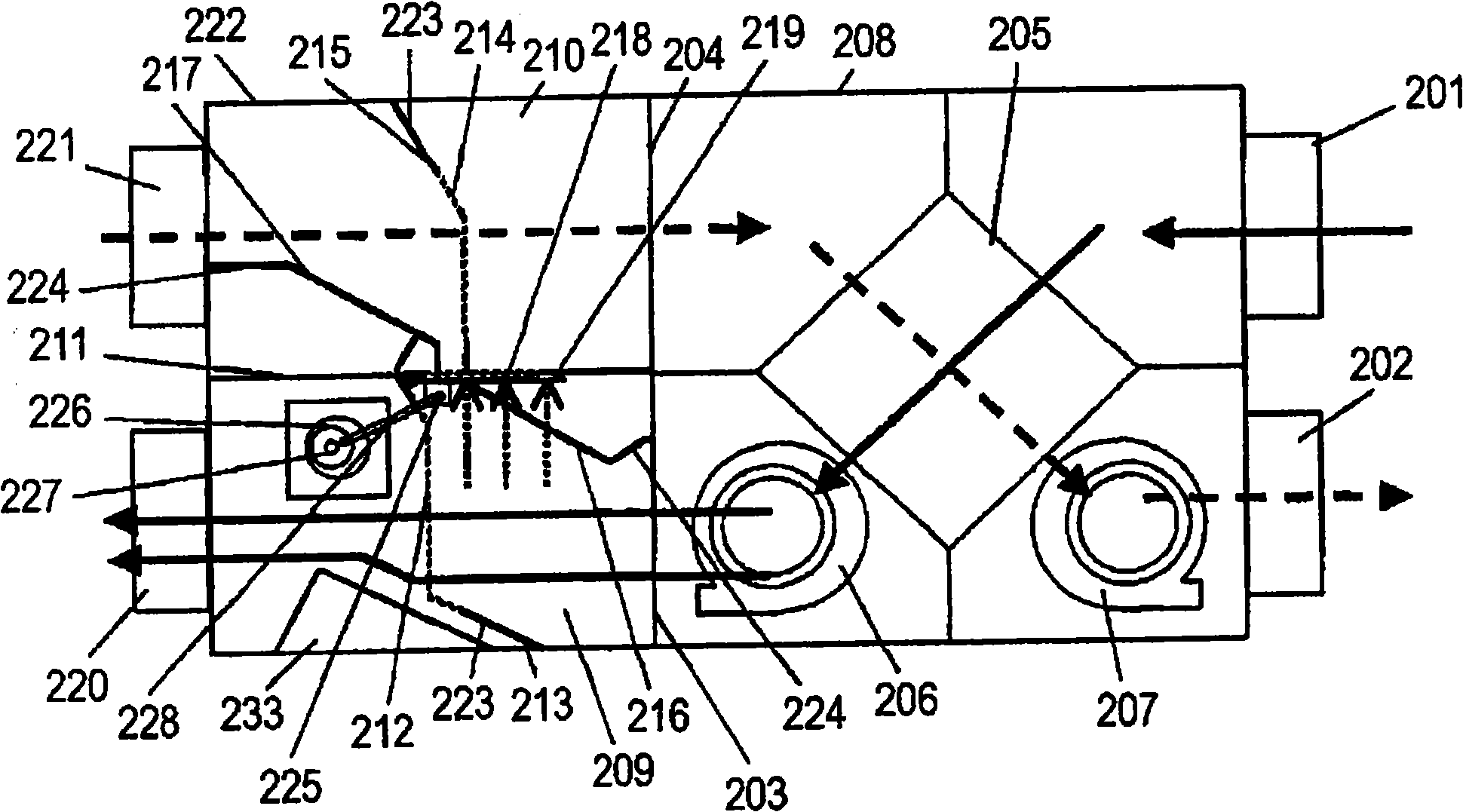

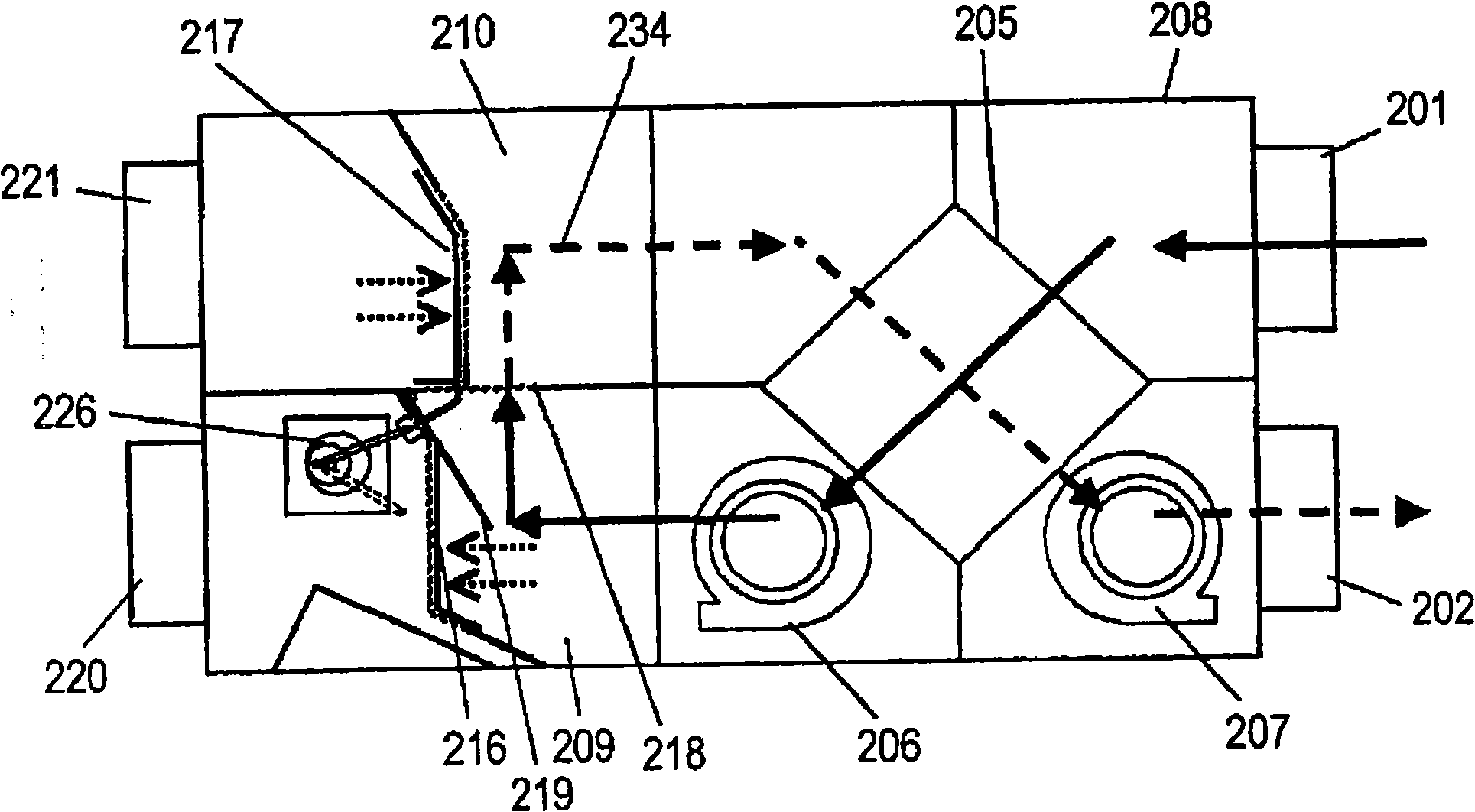

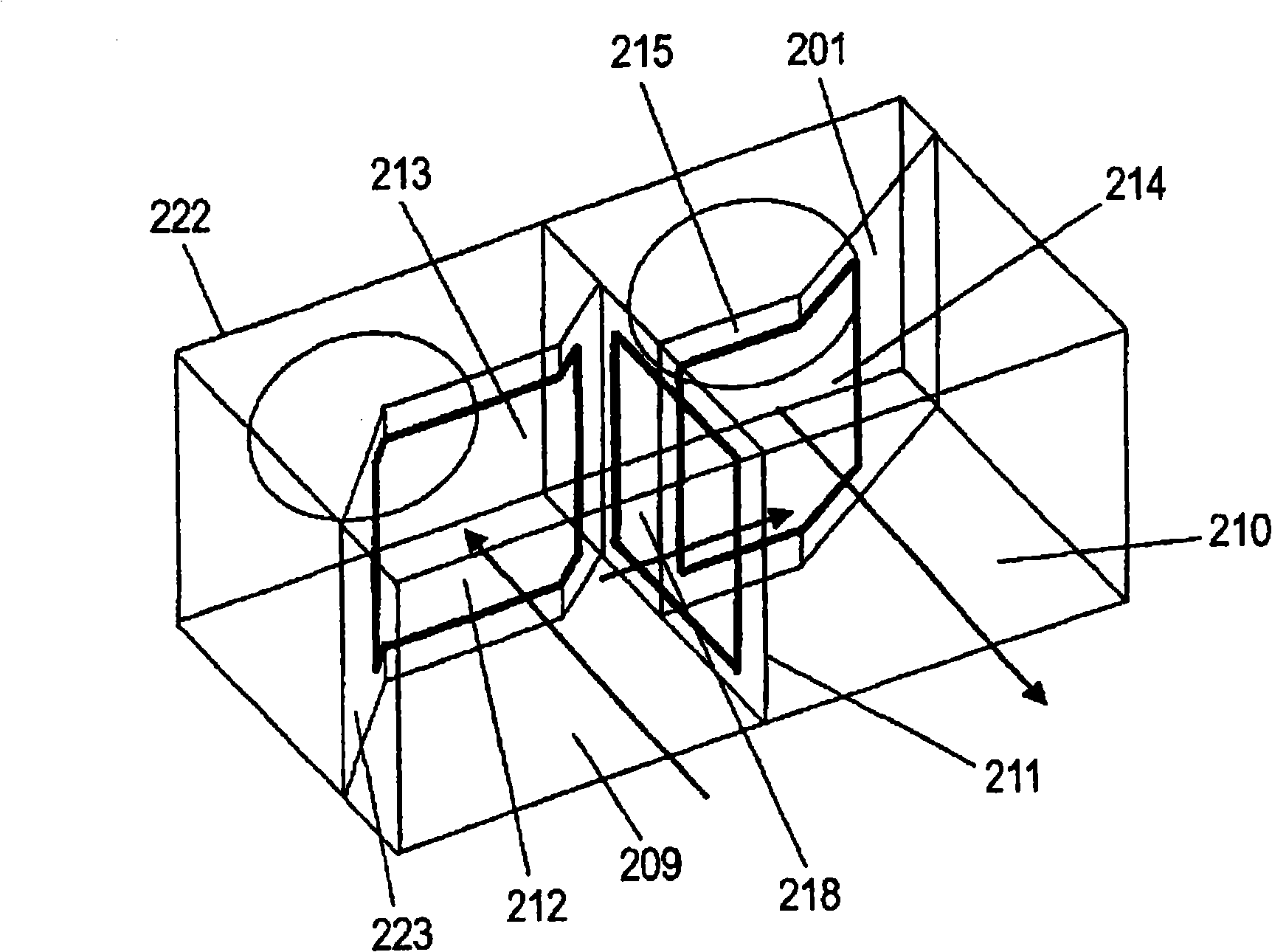

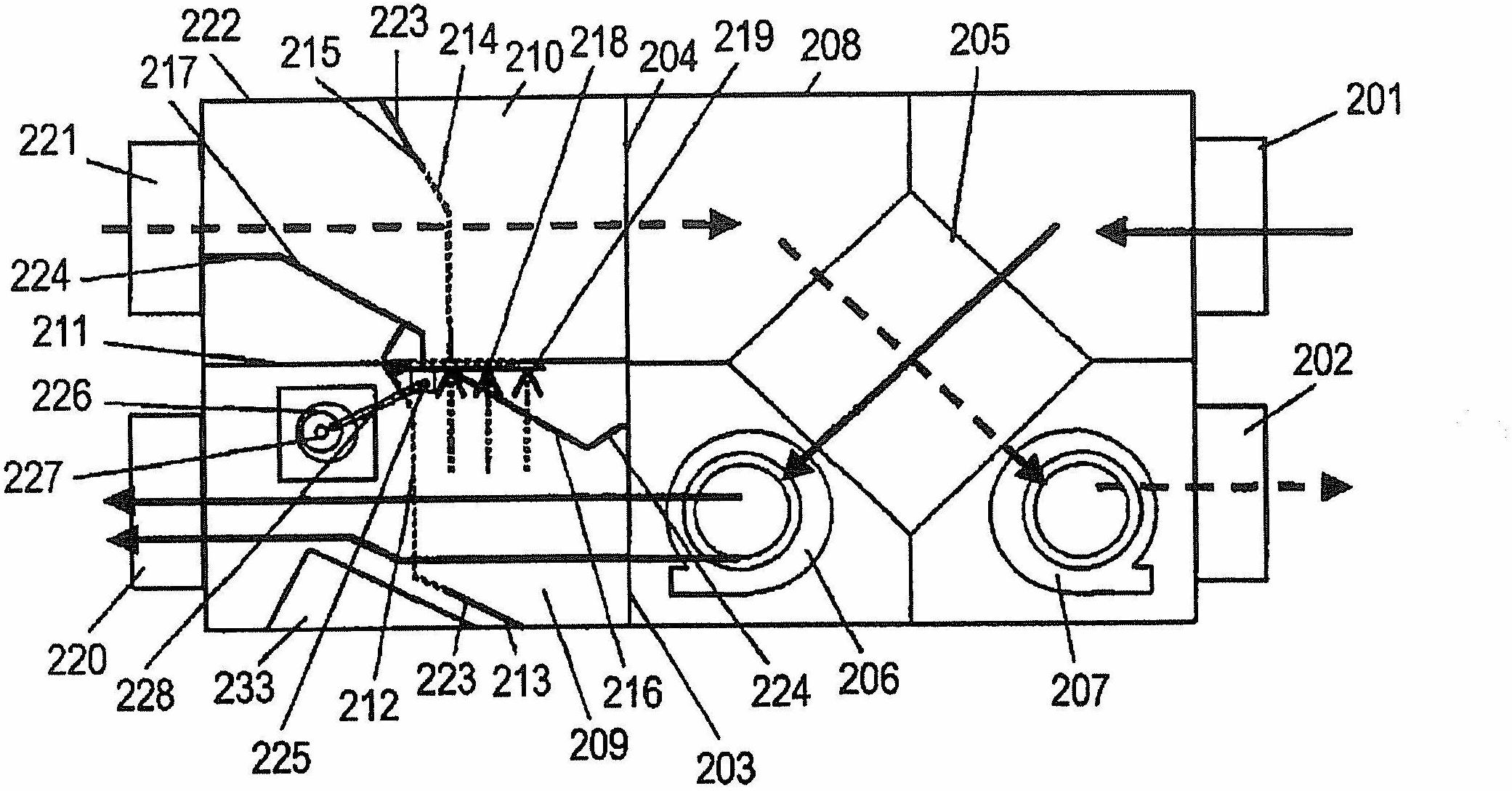

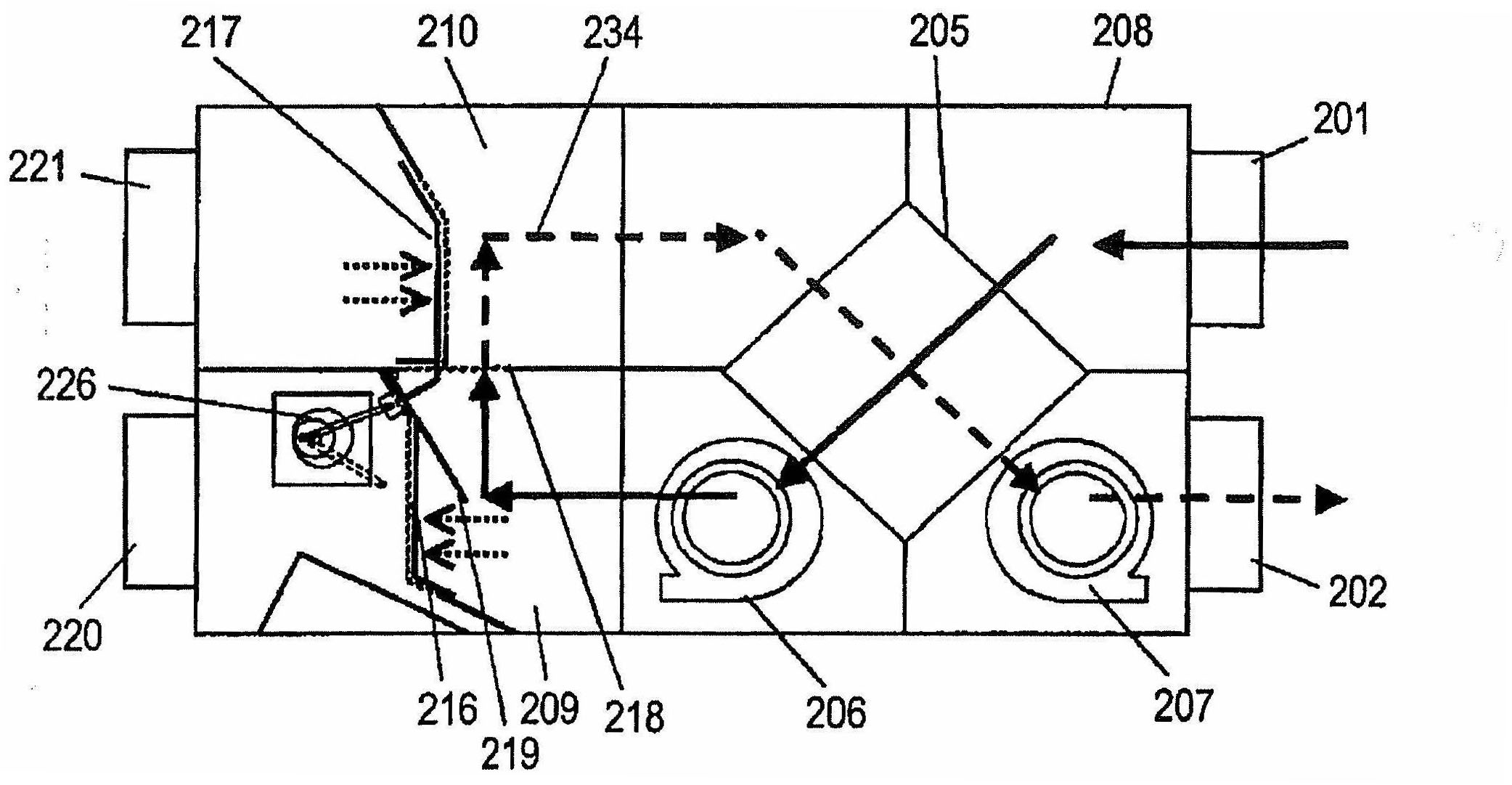

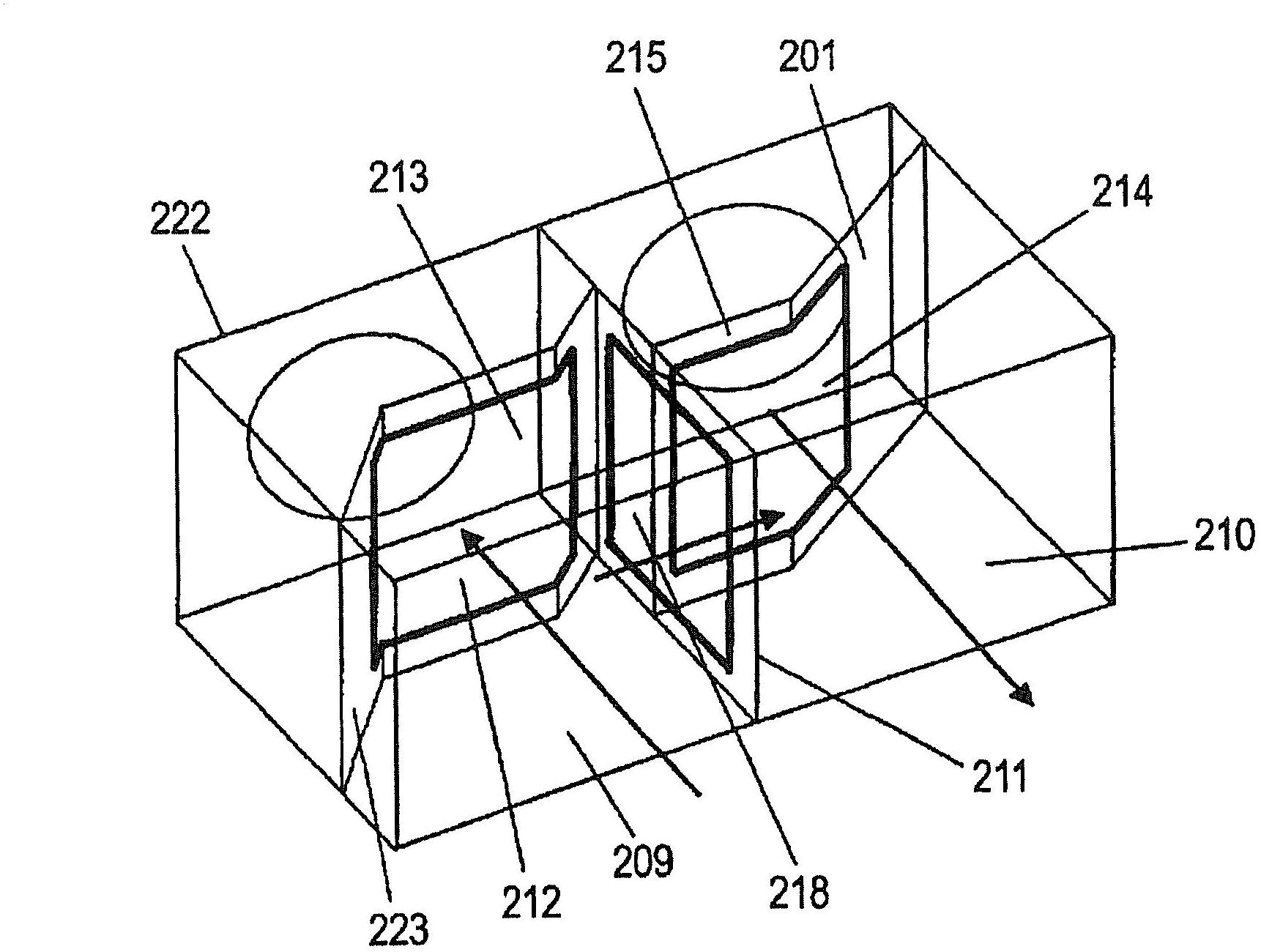

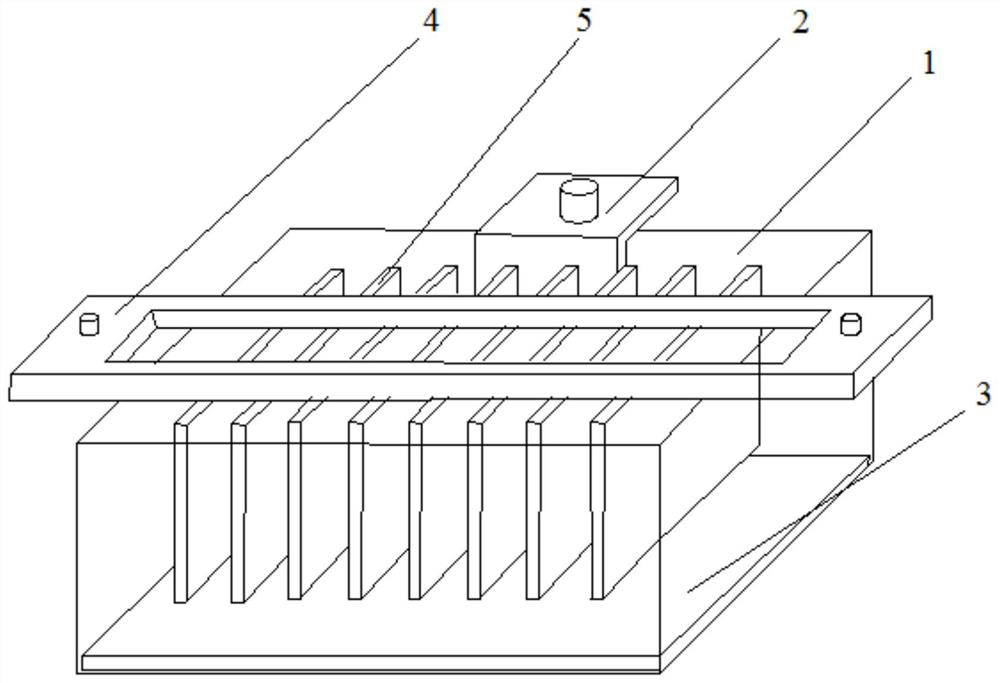

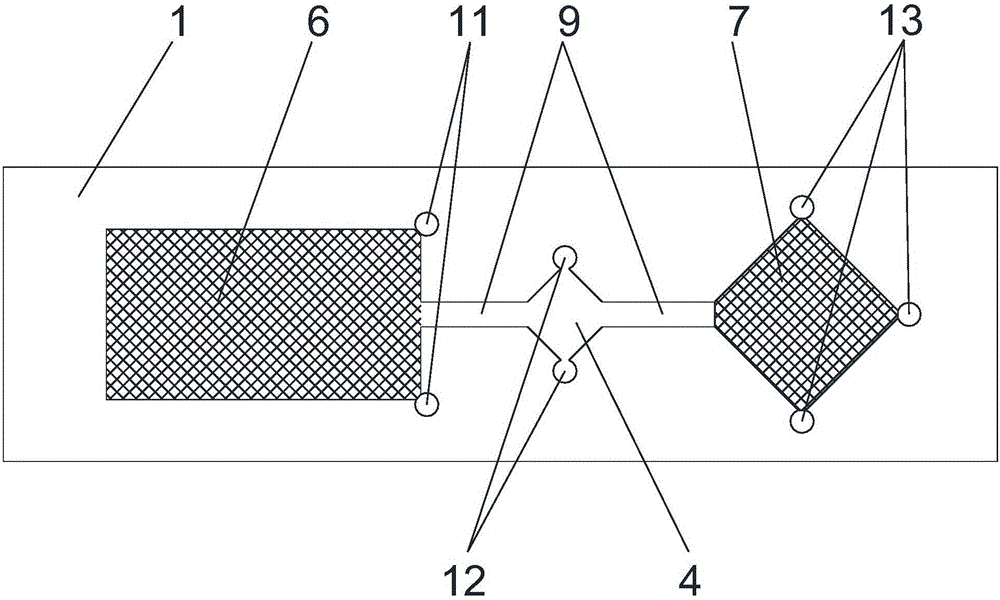

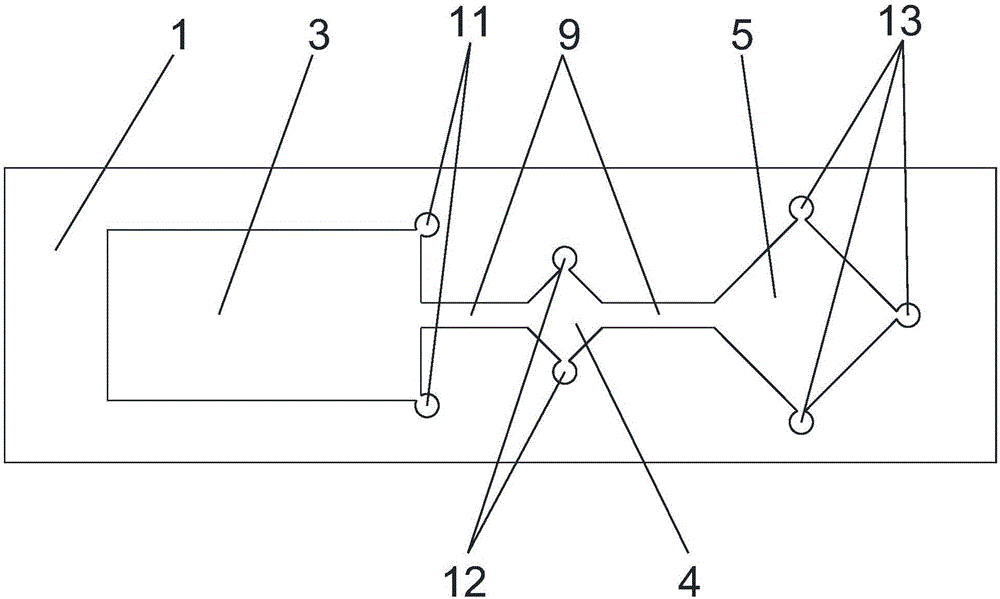

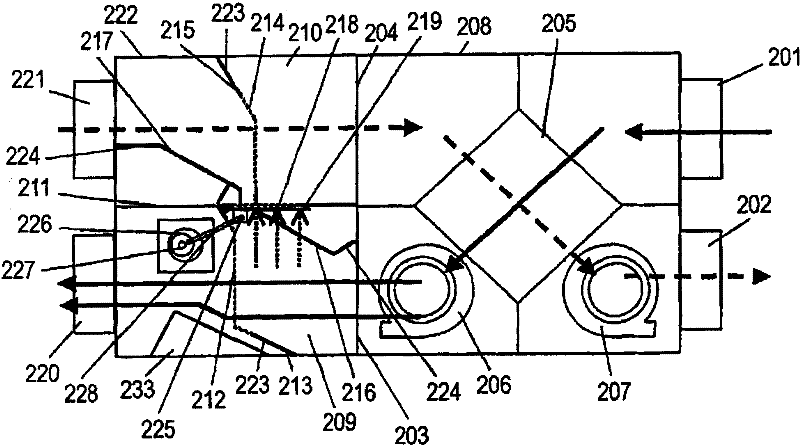

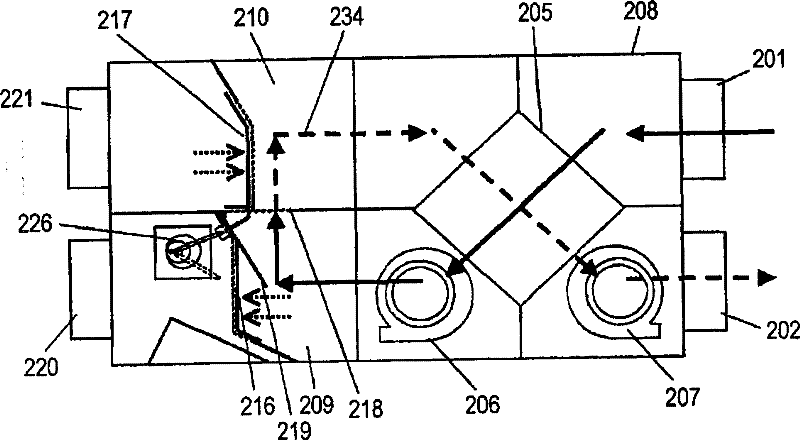

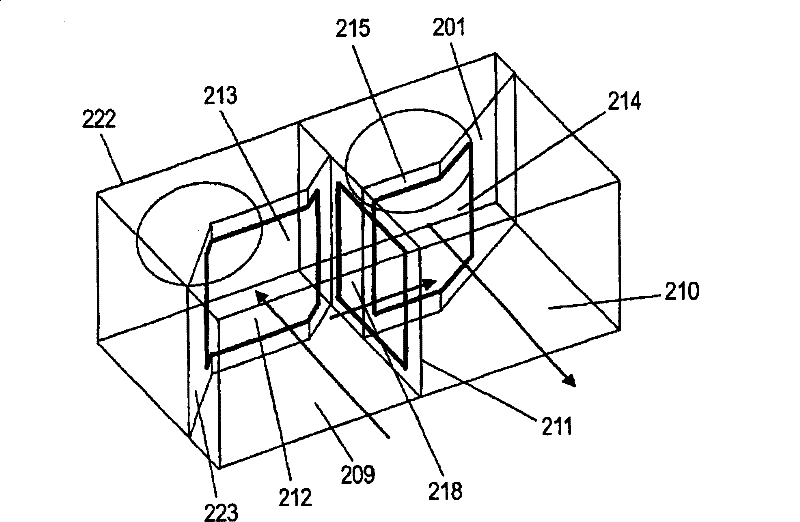

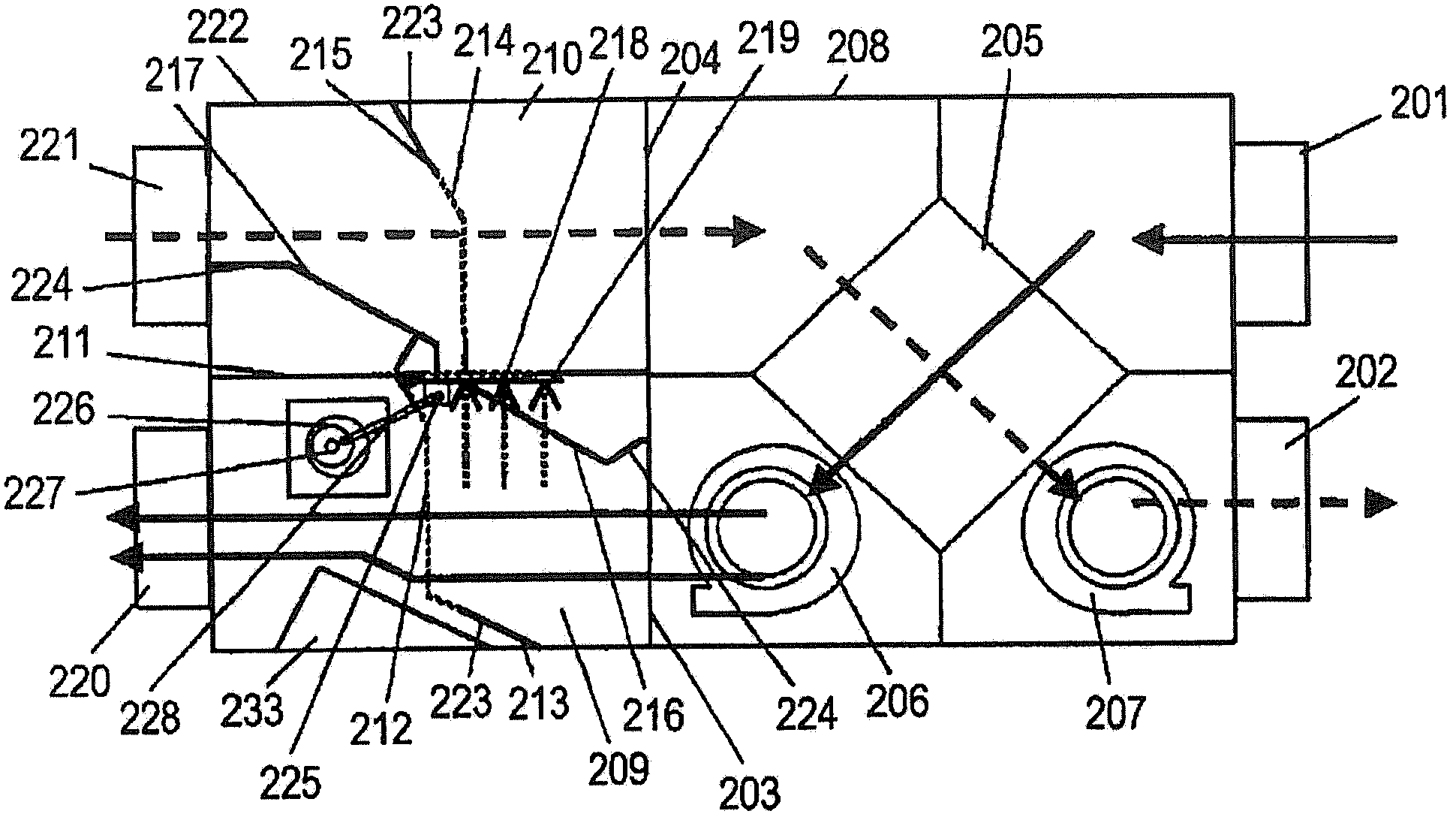

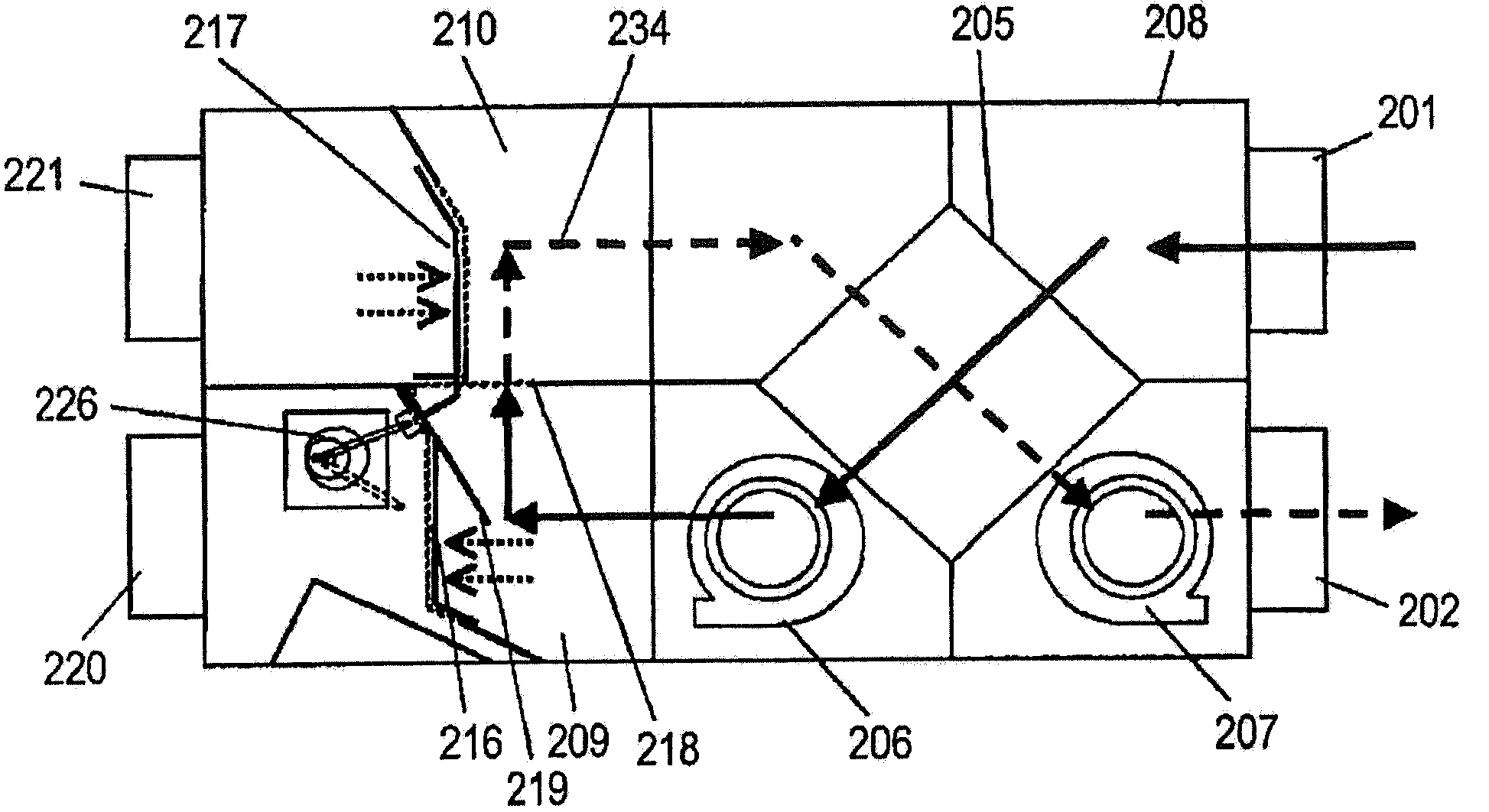

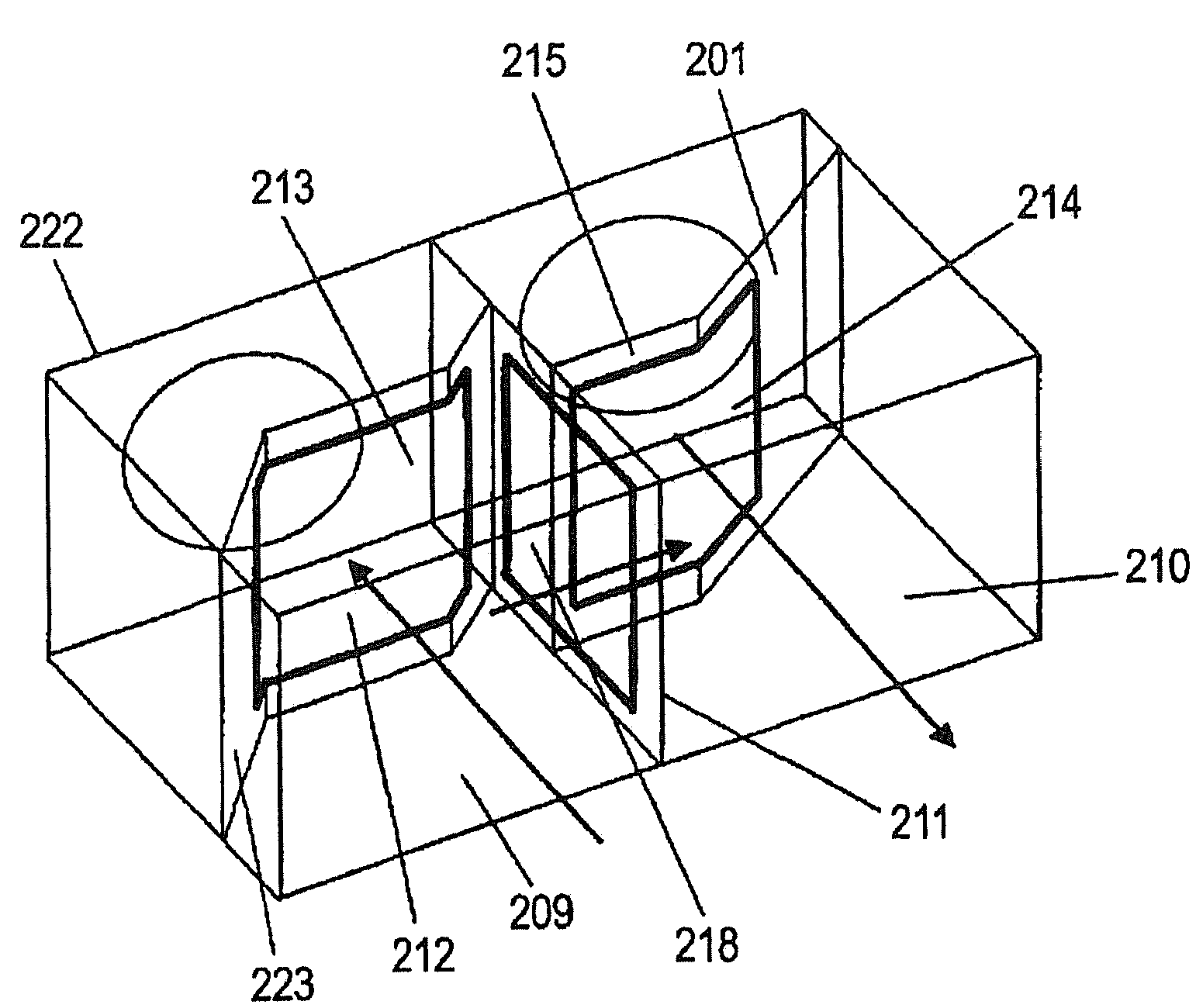

Heat exchange type ventilator

ActiveCN101317041AMiniaturizationEasy maintenanceLighting and heating apparatusVentilation systemsType ventilatorControl theory

The present invention provides a heat exchange type ventilator in which the size of a flow passage changing unit provided with a damper can be reduced. The ventilator includes a partition plate (211) partitioning an exhaust flow passage (209) from an intake flow passage (210), an exhaust damper receiver (213) having an exhaust opening (212), and an intake opening (214). The ventilator further includes a flow passage changing unit (222) having an intake damper receiver (215), an exhaust damper (216) opening and closing the exhaust opening (212), and an intake damper (217) opening and closing the intake opening (214). A damper side bent part (224) is provided in the exhaust damper (216) and the intake damper (217), and a receiving side bent part (223) is provided near the end parts of the exhaust damper receiver (213) and the intake damper receiver (215) along the damper side bent part (224).

Owner:PANASONIC CORP

Heat exchange type ventilator

ActiveCN102661621AAchieve purificationLow costEnergy recovery in ventilation and heatingMechanical apparatusPath switchingType ventilator

There is provided a heat exchange type ventilator capable of downsizing of a flow path switching unit in which dampers are provided. A flow path switching unit includes a partition plate (211) that partitions into an exhaust flow path (209) and an air supply flow path (210), an exhaust damper receiver (213) including an exhaust opening (212), and an air supply opening (214). Moreover, the flow path switching unit (222) includes an air supply damper receiver (215), an exhaust damper (216) that opens and closes an exhaust opening (212), and an air supply damper (217) that opens and closes the air supply opening (214), Damper-side bent portions (224) are provided in the exhaust damper and the air supply damper, and receiver-side bent portions (223) are provided along the damper-side bent portions in the vicinity of end portions of the exhaust damper receiver and the air supply damper receiver.

Owner:PANASONIC CORP

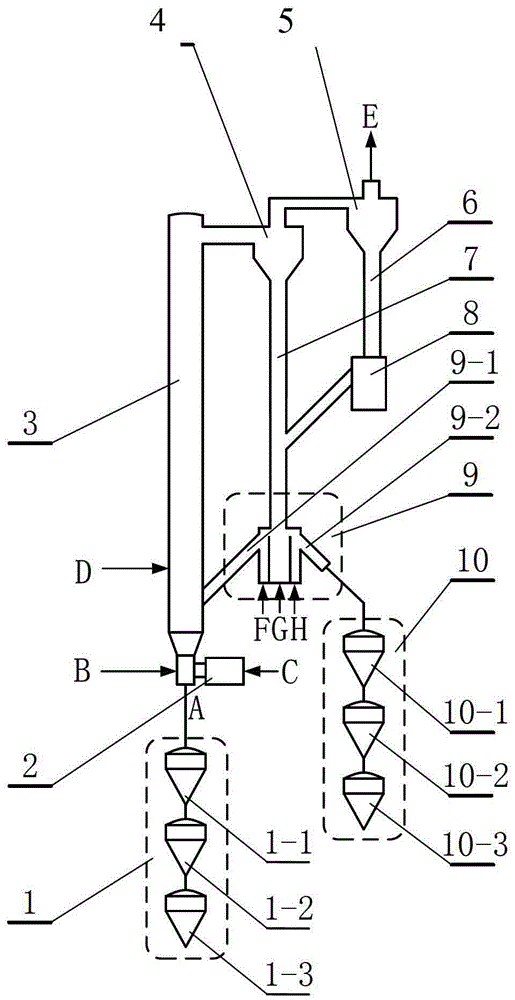

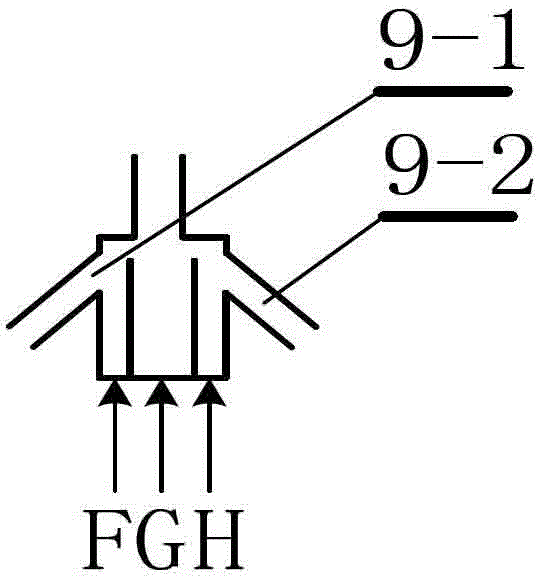

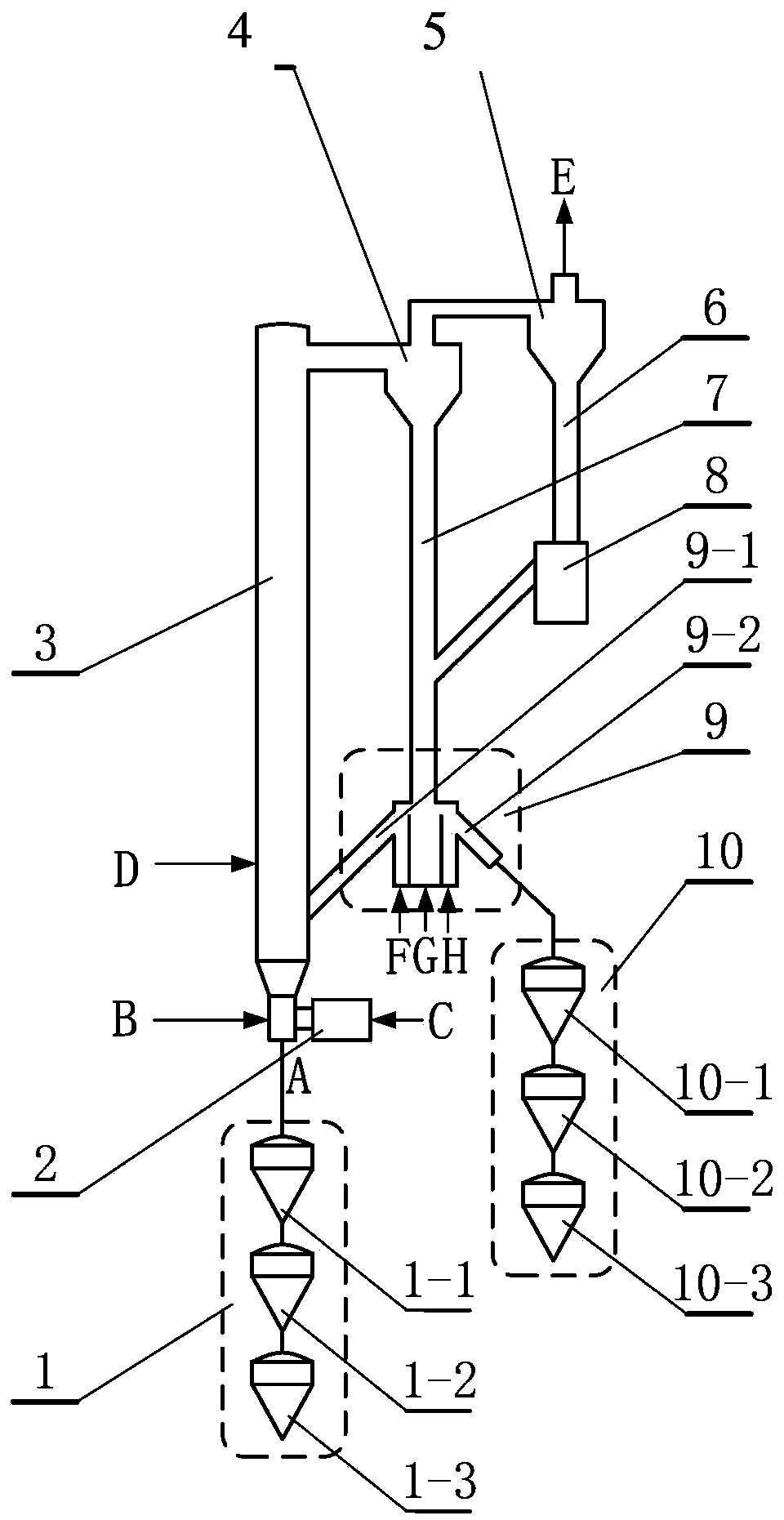

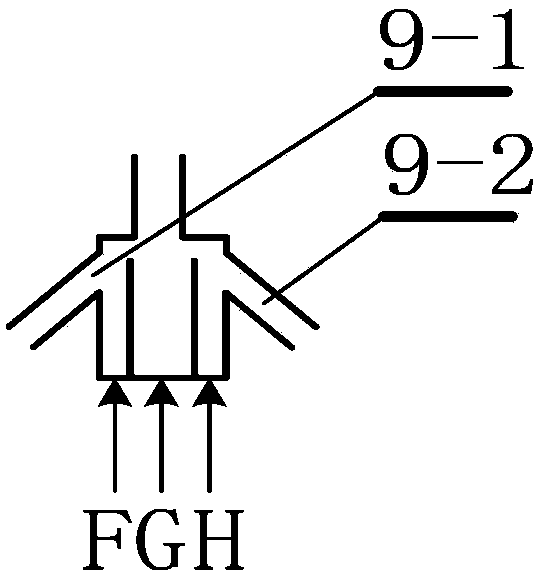

Coal gasification device for circulating fluidized bed

InactiveCN102911741AEasily adjust the ash dischargeImprove controllabilityGranular/pulverulent flues gasificationCycloneCombustion chamber

The invention discloses a coal gasification device for a circulating fluidized bed. The coal gasification device comprises a start combustion chamber, a raising pipe and a primary cyclone separator, wherein the start combustion chamber is arranged at the lower end of the raising pipe; a slag discharge opening and a fuel inlet are further arranged in the lower end of the raising pipe; a pulverized coal inlet is arranged in the middle part of the raising pipe; a smoke outlet is arranged in the upper end of the raising pipe; the primary cyclone separator is connected with the smoke outlet of the raising pipe; an M-shaped material returner is arranged at the lower end of the primary cyclone separator; a material returning tuyere, a loosening tuyere and an ash discharge tuyere are respectively arranged at the bottom of the M-shaped material returner; a material returning pipe is arranged at the upper end of the material returning tuyere; an ash discharge pipe is arranged at the upper end of the ash discharge tuyere; and the material returning pipe is connected to the middle part of the raising pipe. According to the coal gasification device disclosed by the invention, ash discharge operations are carried out at the bottom of the raising pipe and inside the M-shaped material returner respectively. Compared with the situation of singly discharging slag at the bottom of the raising pipe in the prior art, the M-shaped material returner obviously has a lower carbon content.

Owner:SOUTHEAST UNIV

Method for preparing semiconductor quantum-point material by low-temperature solvent method

InactiveCN1553476ALow priceLow toxicityNanostructure manufactureLaser detailsPolyvinyl alcoholReaction temperature

In the invention, inorganic salt is as raw material including cadmium acetate, cadmium chloride or cadmium oxide. Solvent in high boiling point and strong polarity is selected as reaction medium. Surface-active agents: oleic acid, phospholipid, lecithin and polyvinyl alcohol pyridine are selected to modify surface of quantum point. Dispersed single material of semiconductor quantum point in adjustable size can be obtained through reaction in glass flask under lower reaction temperature 1l0 deg.C - 170 deg.C. Features of the invention are: easy to obtain all raw materials, low cost and toxicity, even dispersed single material of semiconductor quantum point in adjustable size.

Owner:SHANGHAI JIAO TONG UNIV

Carbon-coated mesoporous lithium titanate anode material of lithium ion battery and method for preparing carbon-coated mesoporous lithium titanate anode material

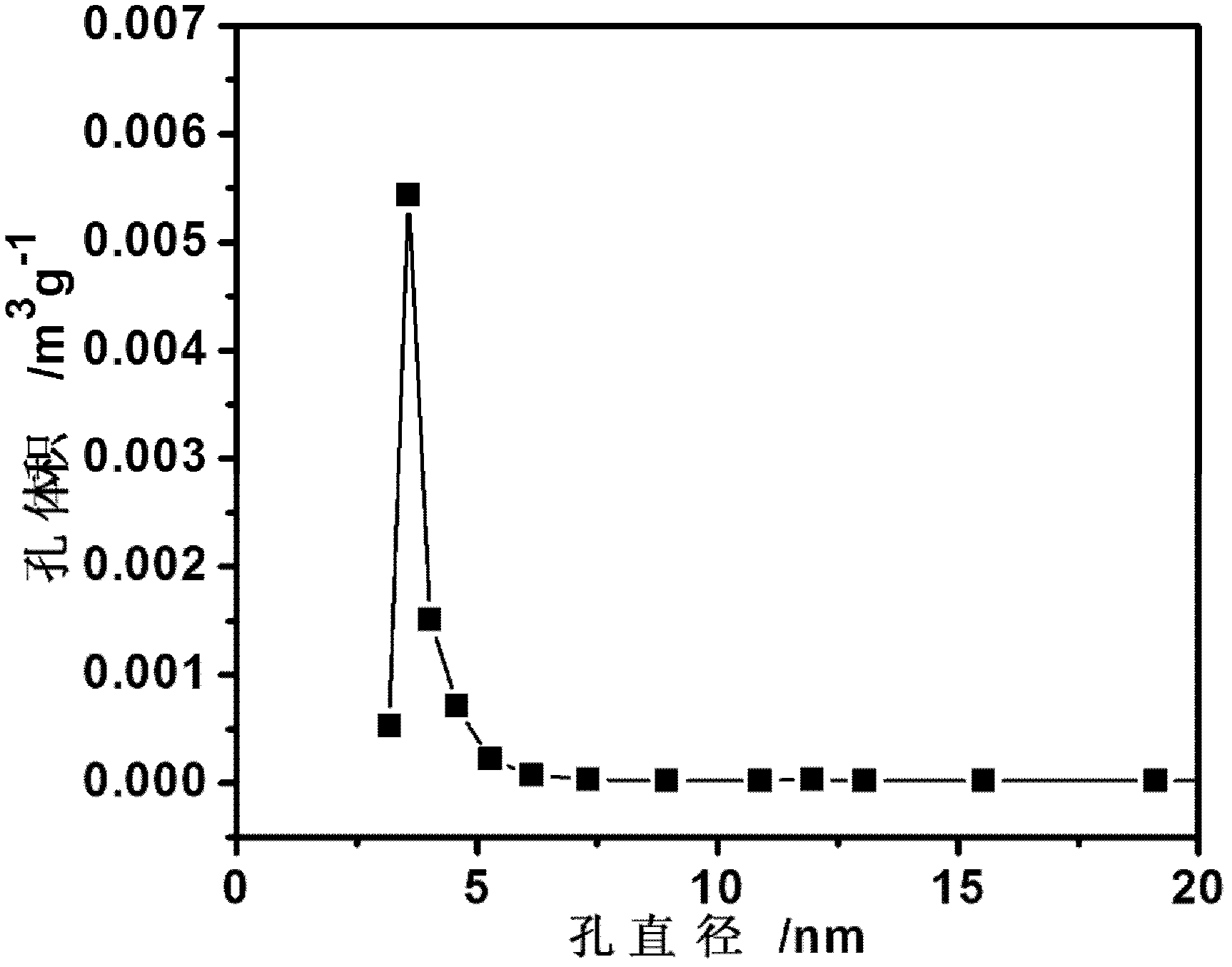

ActiveCN102544468APromote hydrolysisPromote migrationCell electrodesTitanium compoundsElectrical batteryPhysical chemistry

The invention discloses a carbon-coated mesoporous lithium titanate anode material of a lithium ion battery and a method for preparing the carbon-coated mesoporous lithium titanate anode material. A particle aggregate with the diameter of 0.1 to 10 mu m is formed by self-assembling nano-crystals with the diameter of 5 to 150 nm. The material has a mesoporous structure, the average pore diameter of the material is 2 to 6 nm, and the carbon content of the material is 0.5 to 5 percent. A lithium titanate sample can serve as an anode material of the lithium ion battery.

Owner:重庆中纳科技有限公司

Graphene oxide preparation method based on secondary controllable electrochemical technology

ActiveCN112573514AAdjust the number of layersStable and controllable qualityGrapheneElectrolytic agentPhysical chemistry

The invention discloses a graphene oxide preparation method based on a secondary controllable electrochemical technology, belonging to the field of graphene oxide preparation. The invention aims to solve the problem that the composition and the structure of graphene oxide cannot be regulated and controlled by controlling reaction parameters in a conventional chemical oxidation method, and he problem that an electrochemical oxidation stripping method cannot realize controllable preparation of graphene oxide by directly taking natural crystalline flake graphite as a raw material. The graphene oxide preparation method based on the secondary controllable electrochemical technology in the invention comprises the following steps: carrying out an electrochemical oxidation intercalation reaction on natural flake graphite to obtain a graphite intercalation compound; then carrying out an electrochemical oxidation stripping reaction on the graphite intercalation compound to obtain electrochemicalgraphene oxide; and carrying out ultrasonic dispersion on an electrochemical graphene oxide electrolyte to obtain a stable graphene oxide dispersion liquid. The method is mainly used for preparing graphene oxide.

Owner:HEILONGJIANG HEIKE TECH CO LTD

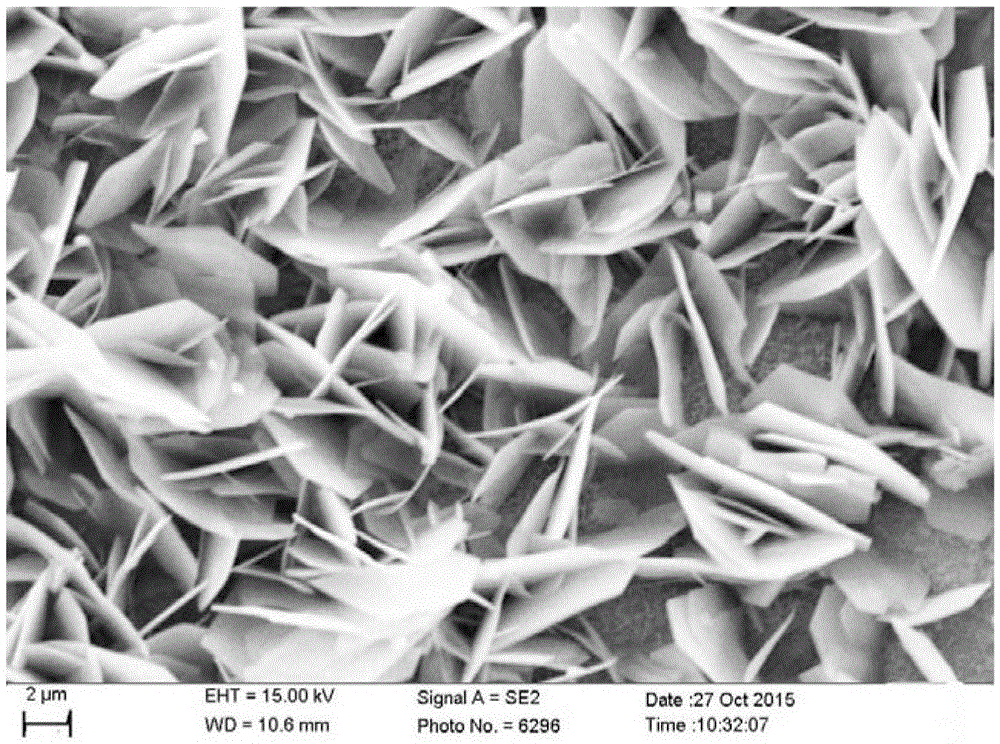

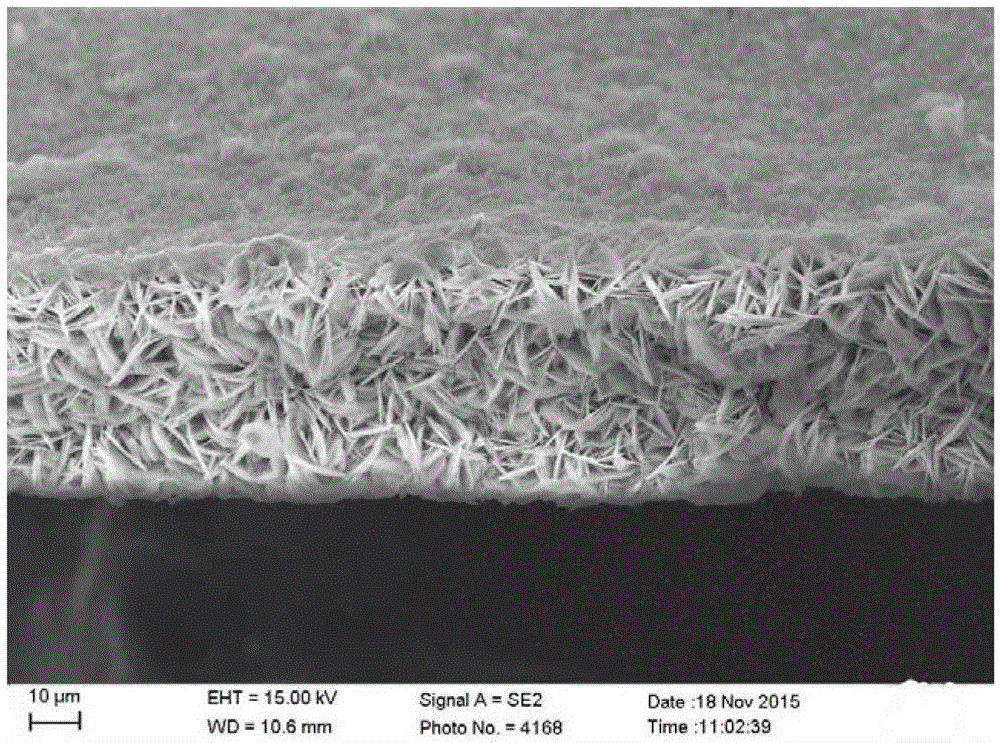

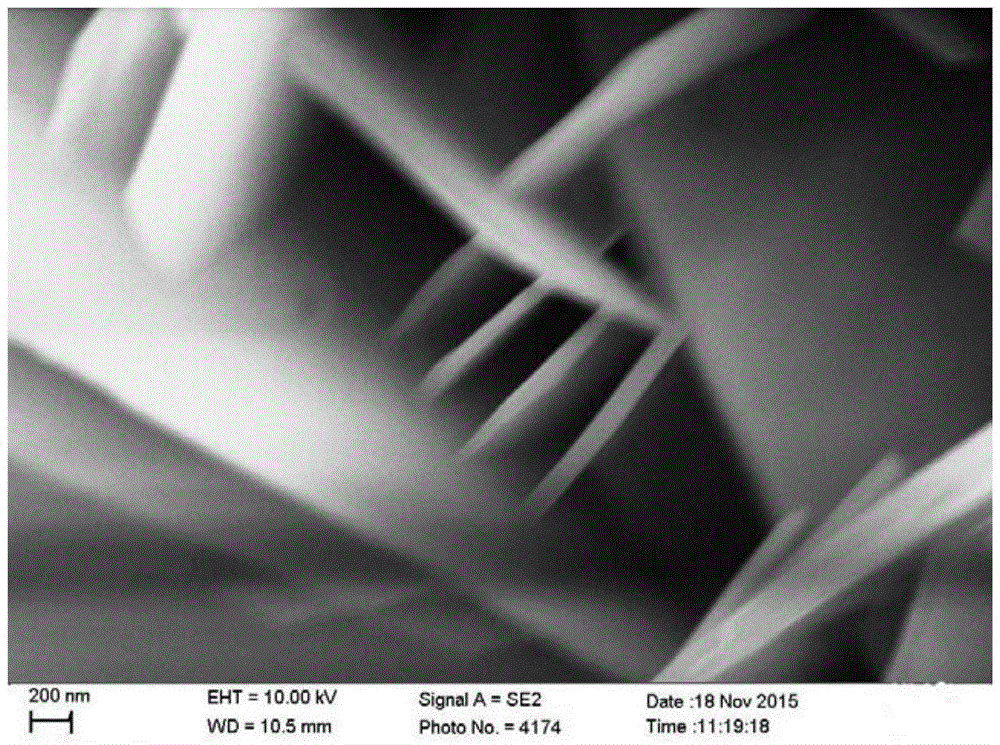

Preparation process of two-dimensional Al-O-Cu-Fe single-crystalline-layer flaky material

InactiveCN105568389AEasy to makeLow costPolycrystalline material growthSingle crystal growth detailsMaterials preparationMicrometer

The invention discloses a preparation process of a two-dimensional Al-O-Cu-Fe single-crystalline-layer flaky material, and belongs to the field of preparation of two-dimensional flaky and catalytic materials. The preparation process includes the steps of conducting alloy material preparation according to the alloy atom ratio AlxCuyFez, wherein the sum of x, y and z is equal to 100, x is larger than or equal to 60 and smaller than or equal to 70, y is larger than or equal to 13 and smaller than or equal to 30, and z is larger than or equal to 10 and smaller than or equal to 17; preparing Al-Cu-Fe alloy strips through a vacuum rapid quenching melt-spinning method; preparing the two-dimensional Al-O-Cu-Fe single-crystalline-layer flaky material through the method of NaOH room-temperature chemical dealloying. The thickness of each flake layer is 30-50 nm, and the diameter of a single crystal wafer is between 2 micrometers and 6 micrometers. The flake layers are intercrossed to form pores, the pore size is 1-10 micrometers, and a porous structure is formed. The preparation process is simple, cost is low, the yield of the generated material of the two-dimensional flaky structure is high, and a solution is provided for industrially and controllably preparing the two-dimensional Al-O-Cu-Fe single-crystalline-layer flaky catalytic material.

Owner:UNIV OF SCI & TECH BEIJING

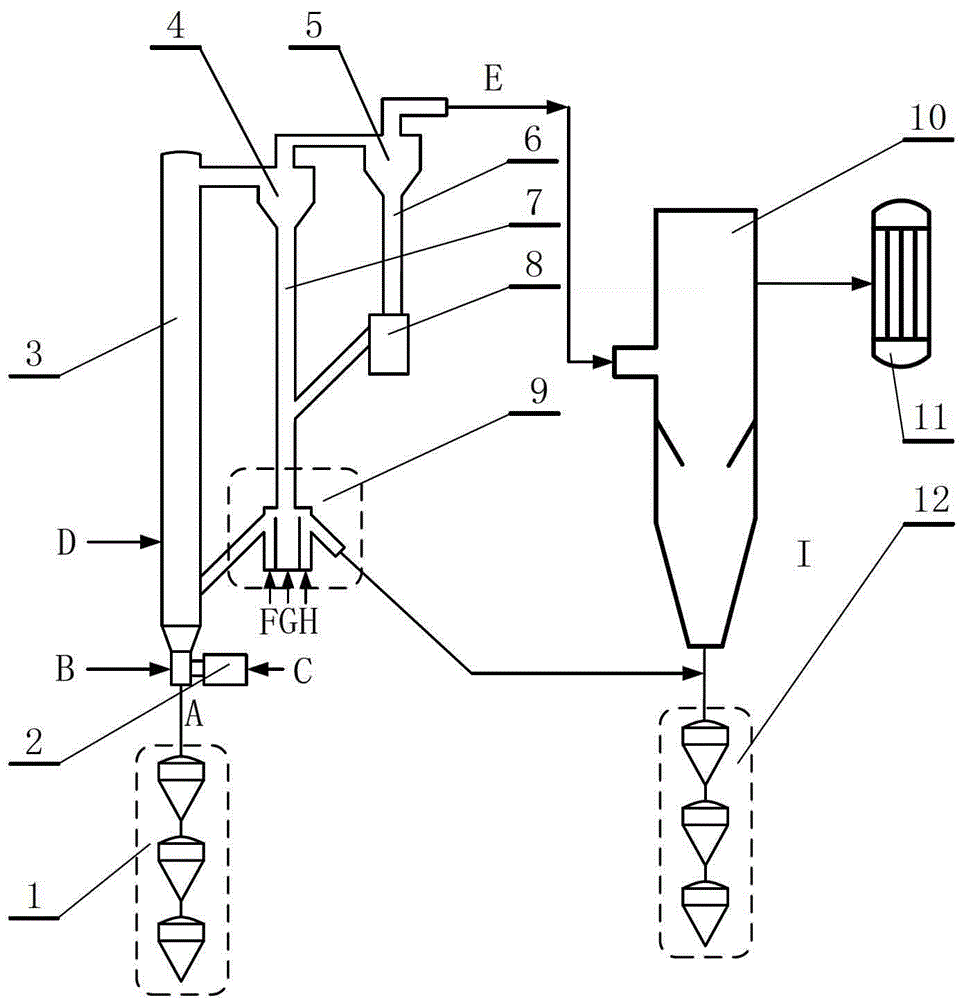

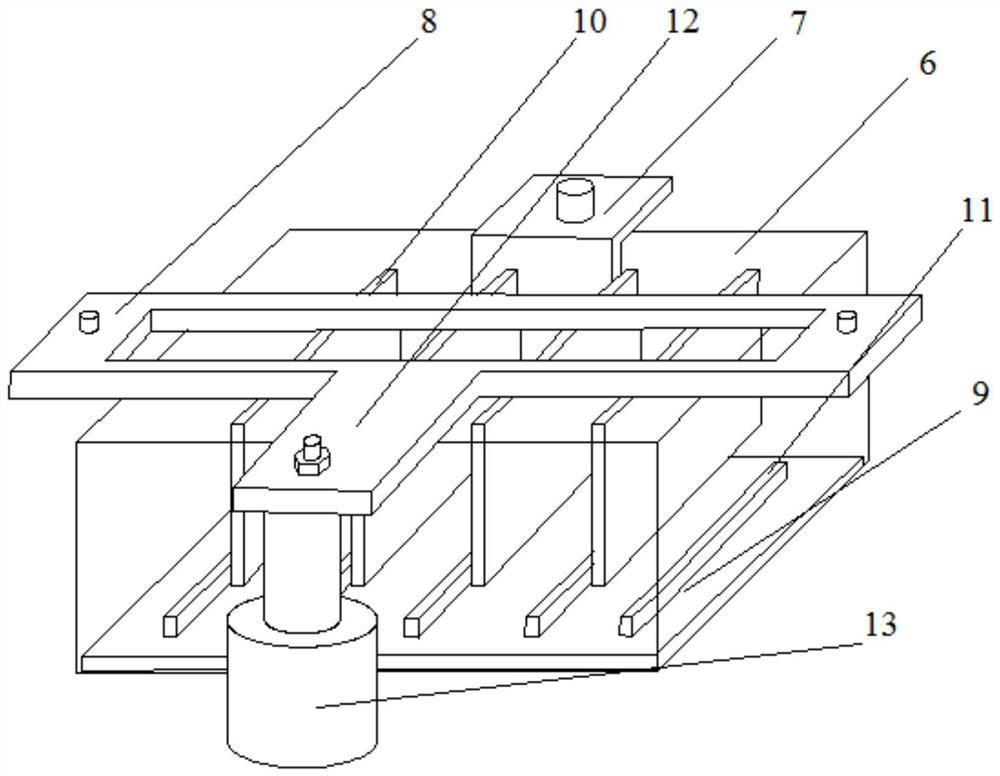

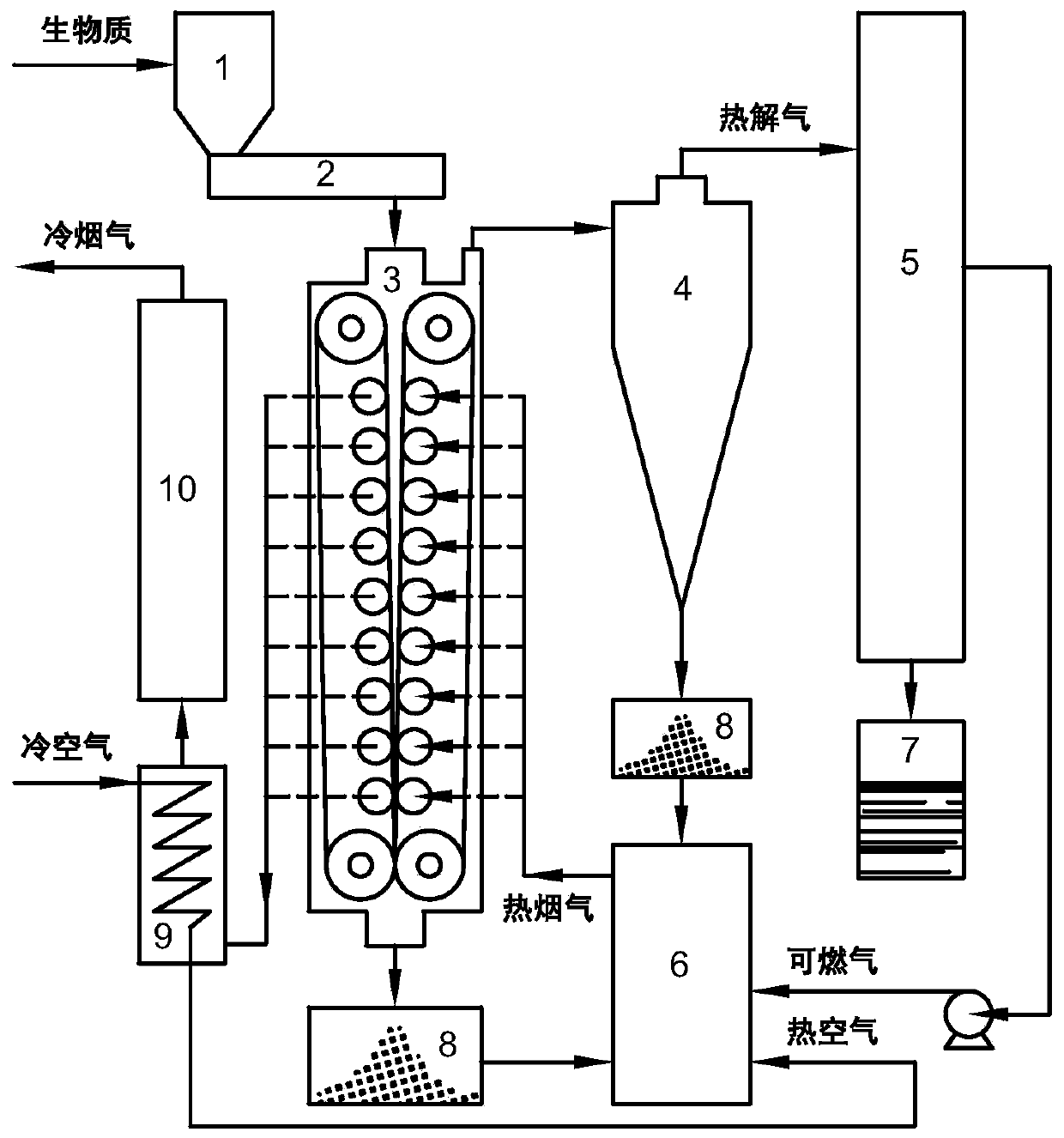

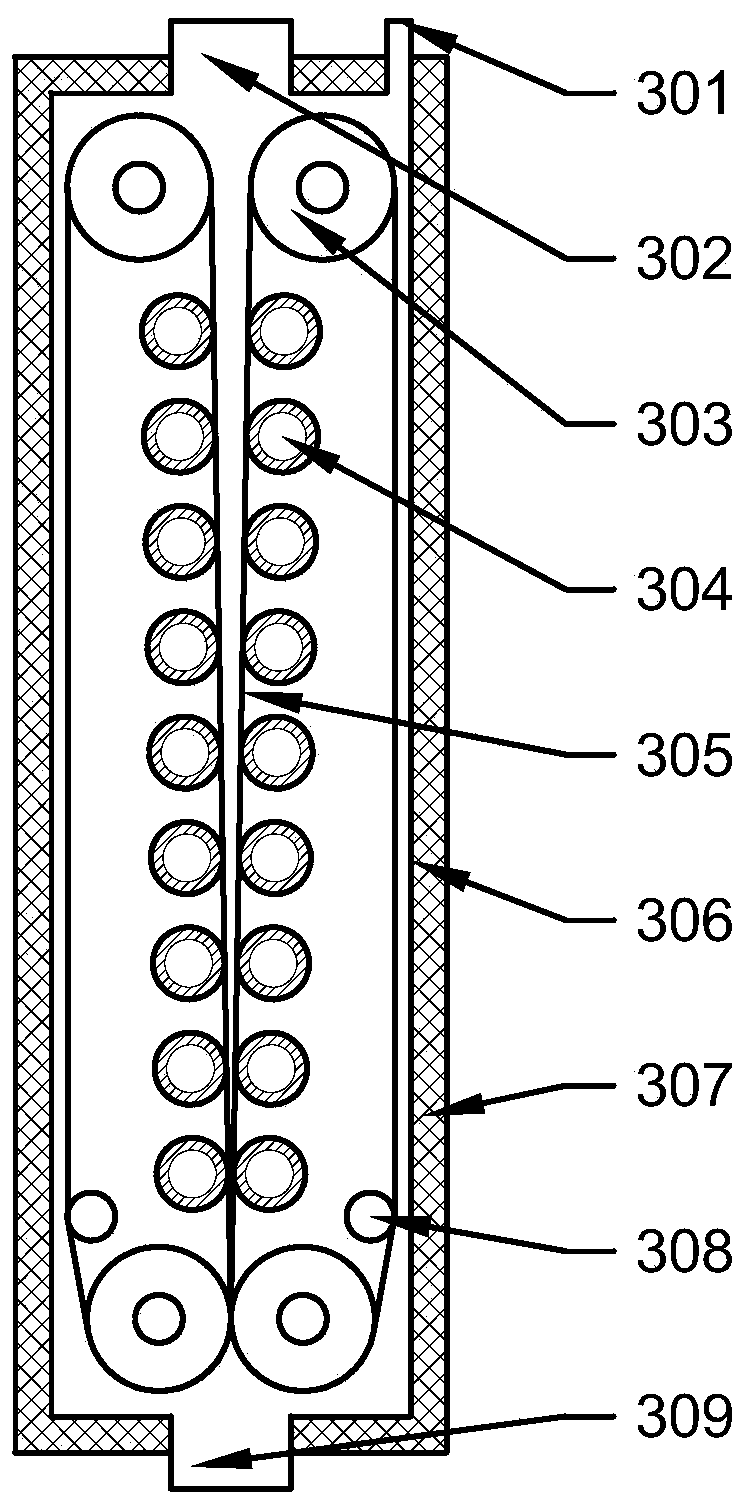

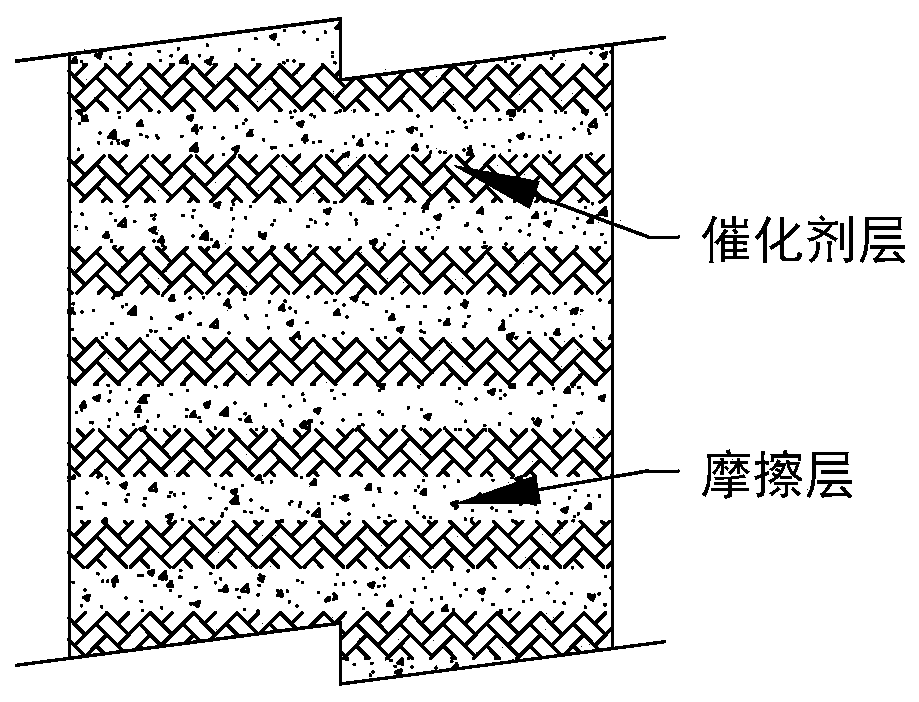

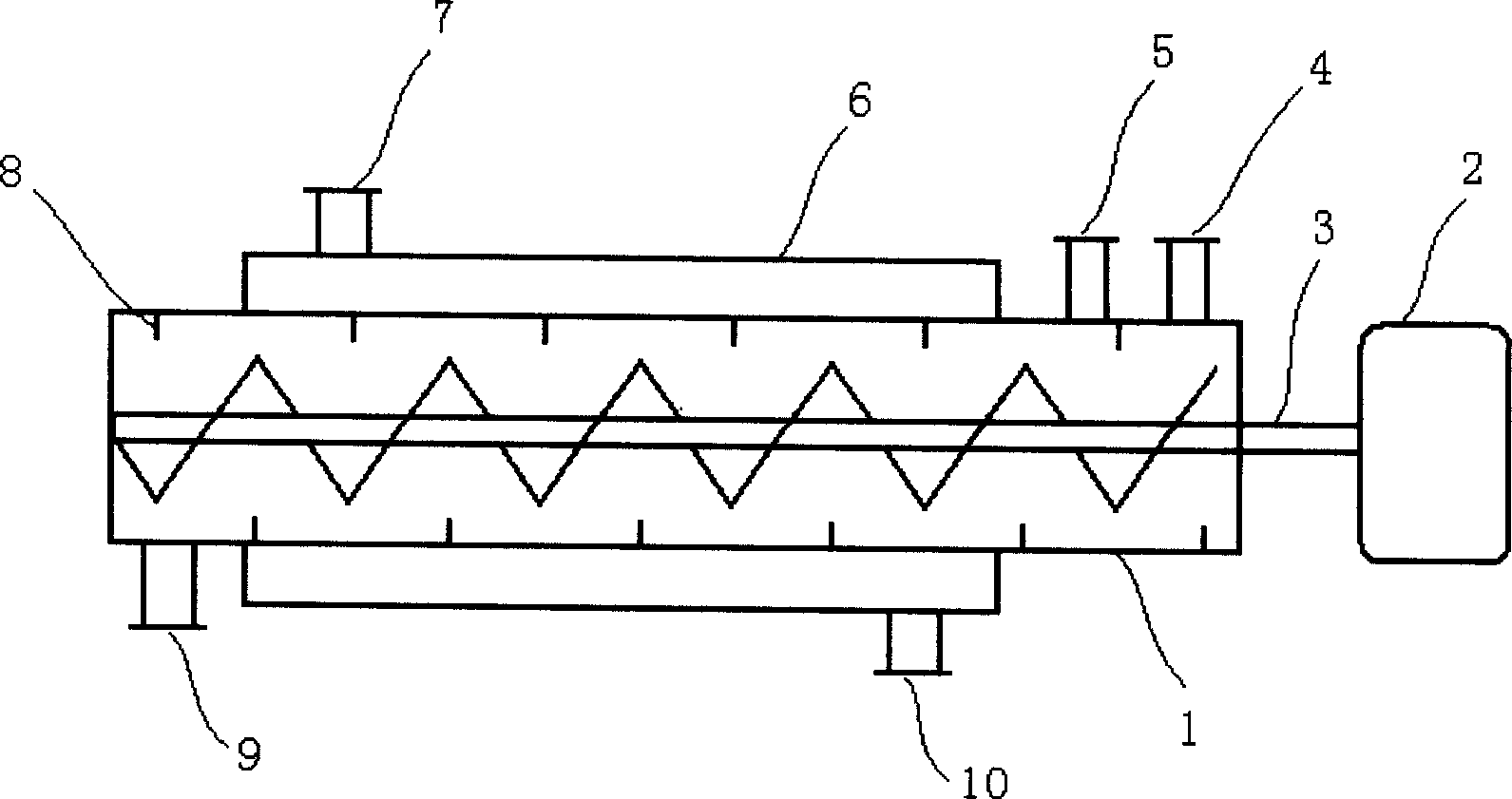

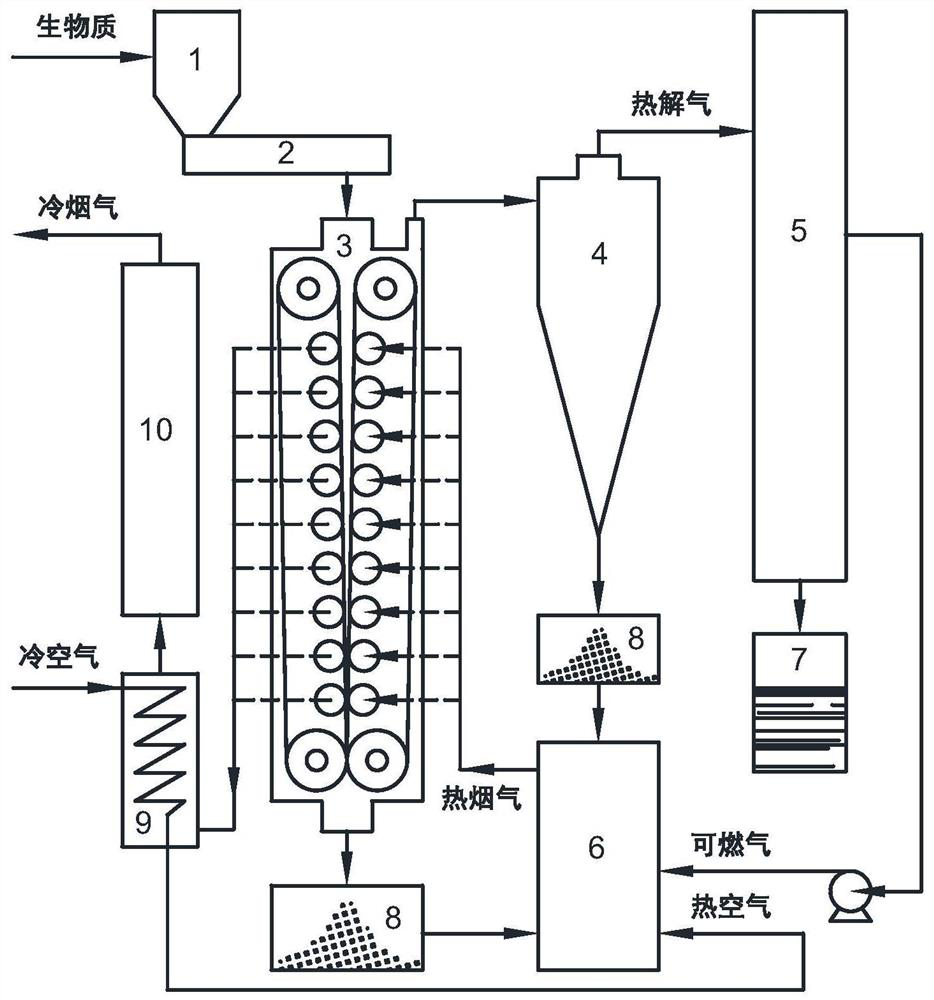

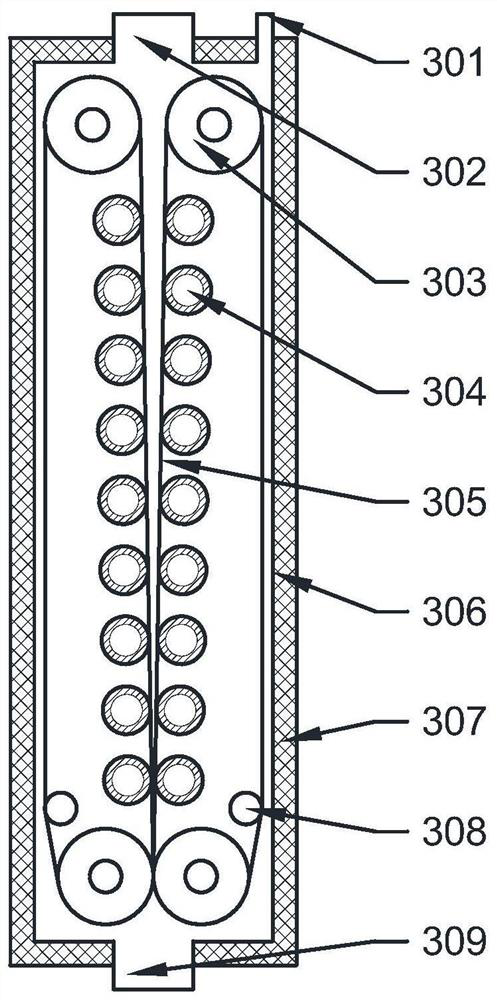

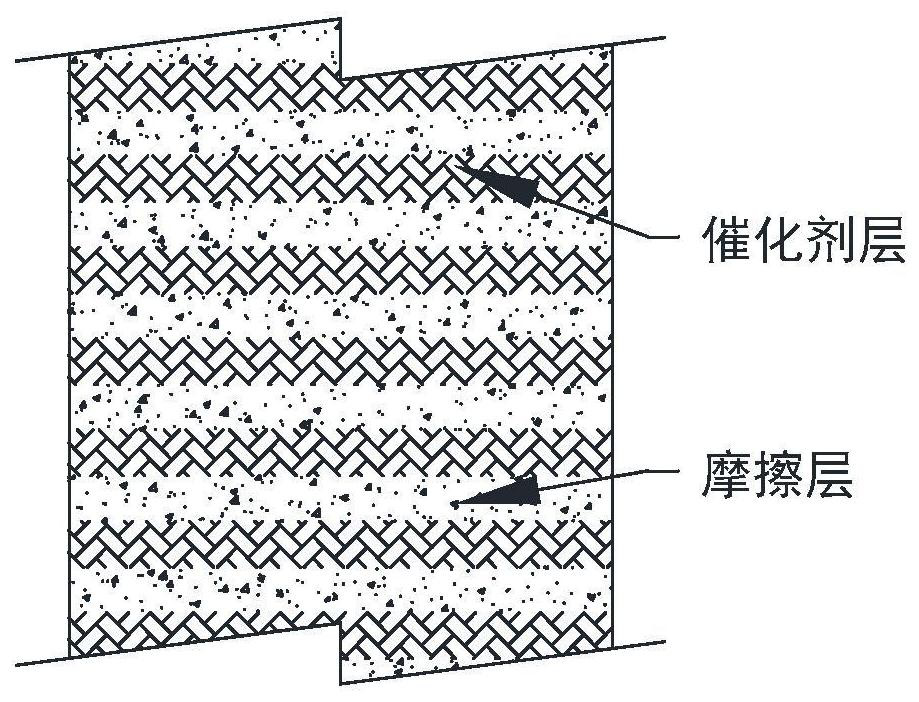

Grinding belt-type device for rapid catalytic pyrolysis of biomass and method

ActiveCN110003927ARapid condensationFully condensedBiofuelsLiquid hydrocarbon mixture productionCatalytic pyrolysisCombustion system

The invention belongs to the field of biomass energy utilization, and relates to a grinding belt-type device for rapid catalytic pyrolysis of biomass and a method. The device comprises a hopper, a feed system, a grinding belt-type pyrolysis reactor, a gas-solid separation system, a pyrolysis gas condensation system, a combustion system, a bio-oil collection tank, a charcoal collection tank, an airpreheating system and a flue gas purification system, wherein the grinding belt-type pyrolysis reactor comprises grinding belts, heating tubes, driving drums, tensioning devices, a sealed casing, a feed inlet, a discharge opening and a gas outlet. Pretreated material particles are continuously sheared and rubbed by the grinding belts with speed difference on two sides, and are heated by the multi-layer heating tubes to continuously pyrolyze on the surface while stripping the residual charcoal, so that a catalyst and heat can be fully fed inside the particles; the pyrolysis gas is rapidly condensed by gas-solid separation to obtain high-grade bio-oil fuel or bio-oil rich in specific high value-added products; combustible gas and coke produced by combustion generate high-temperature flue gas for heating the heating tubes, so as to achieve an autothermal pyrolysis process.

Owner:北京博霖环境科技有限公司

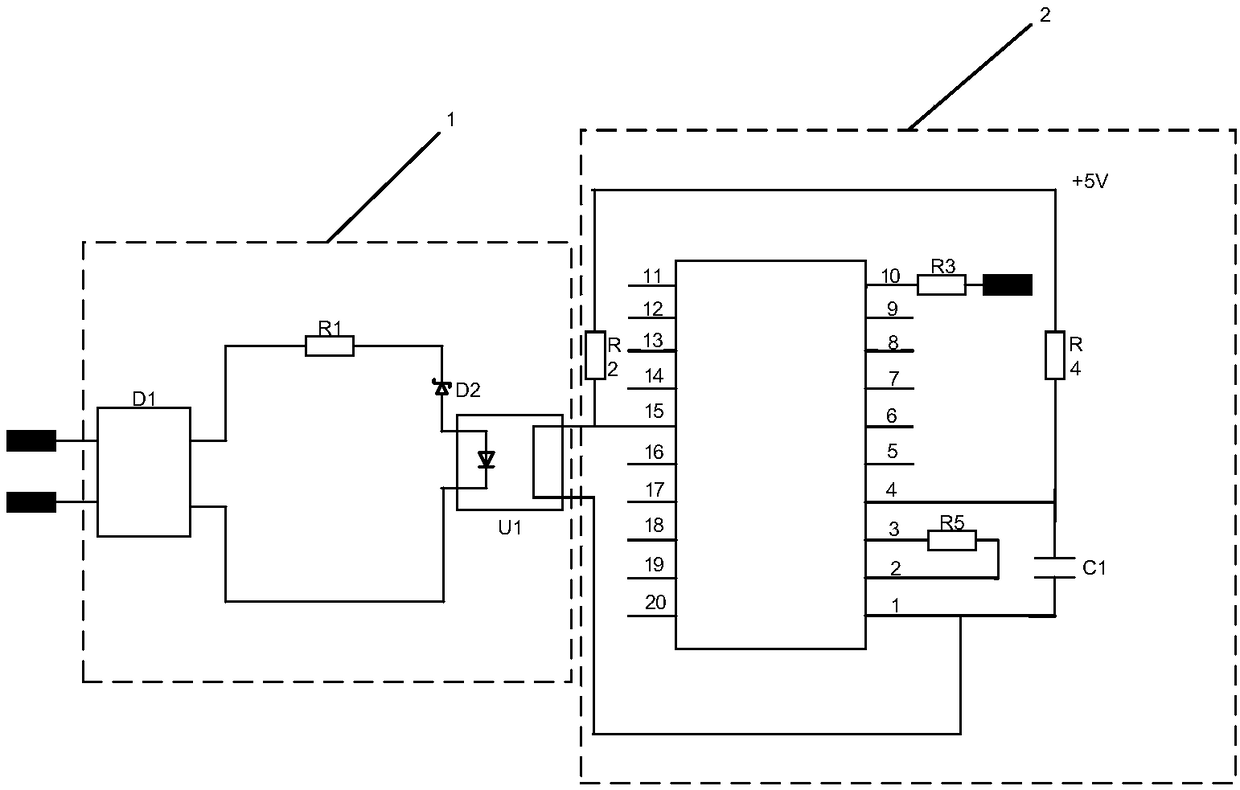

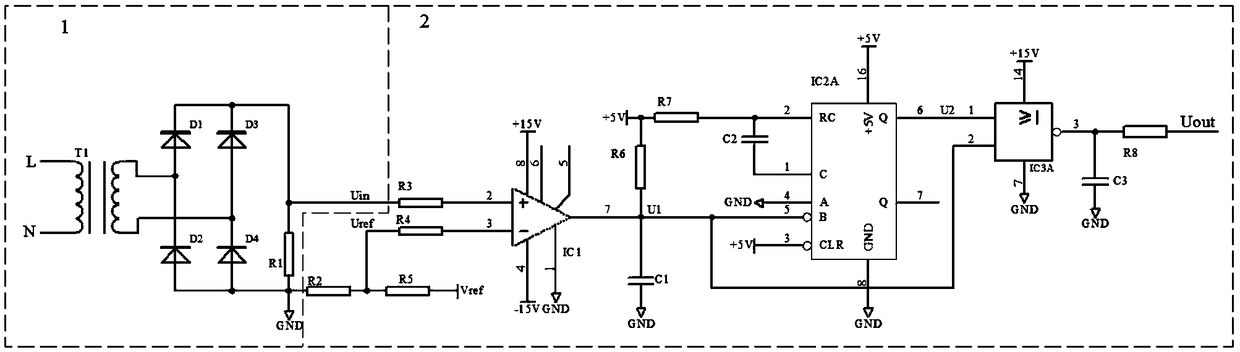

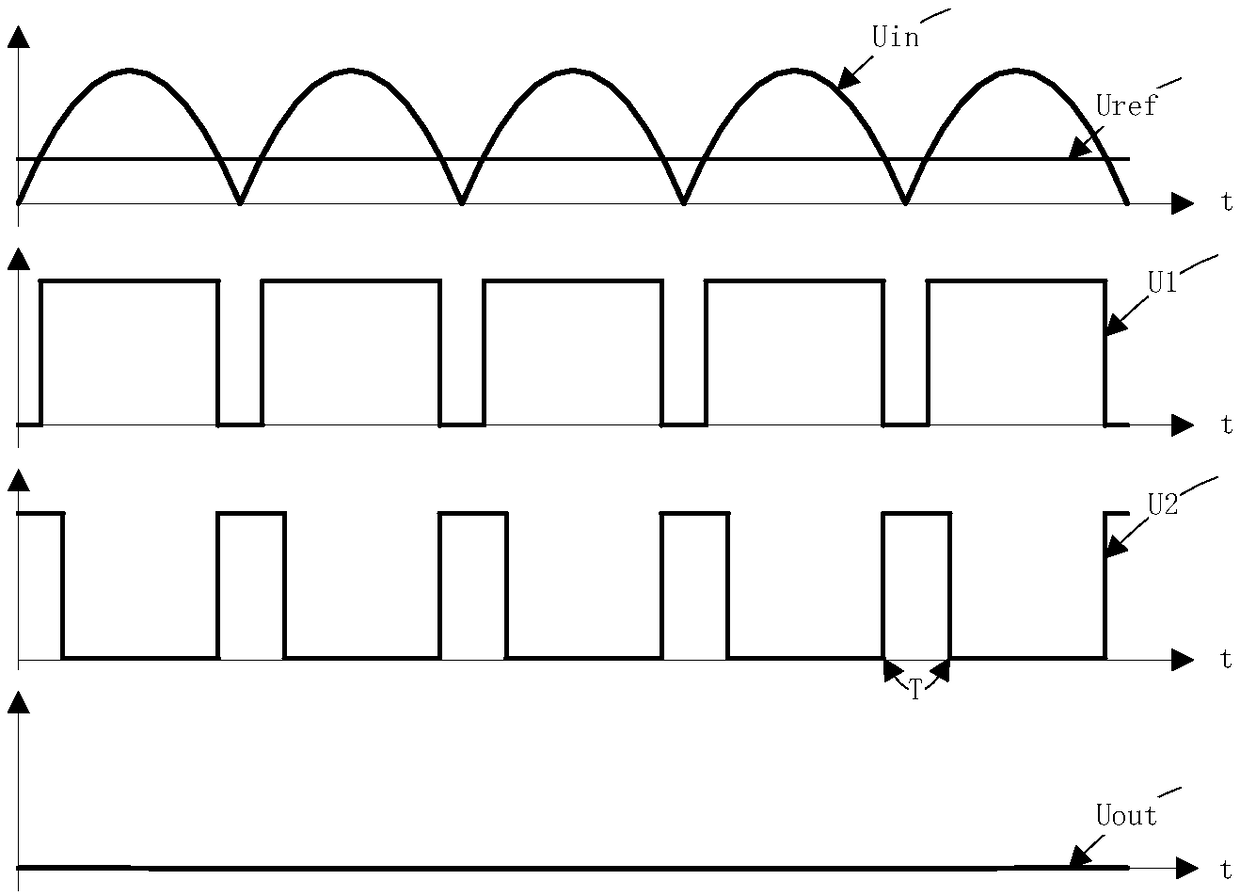

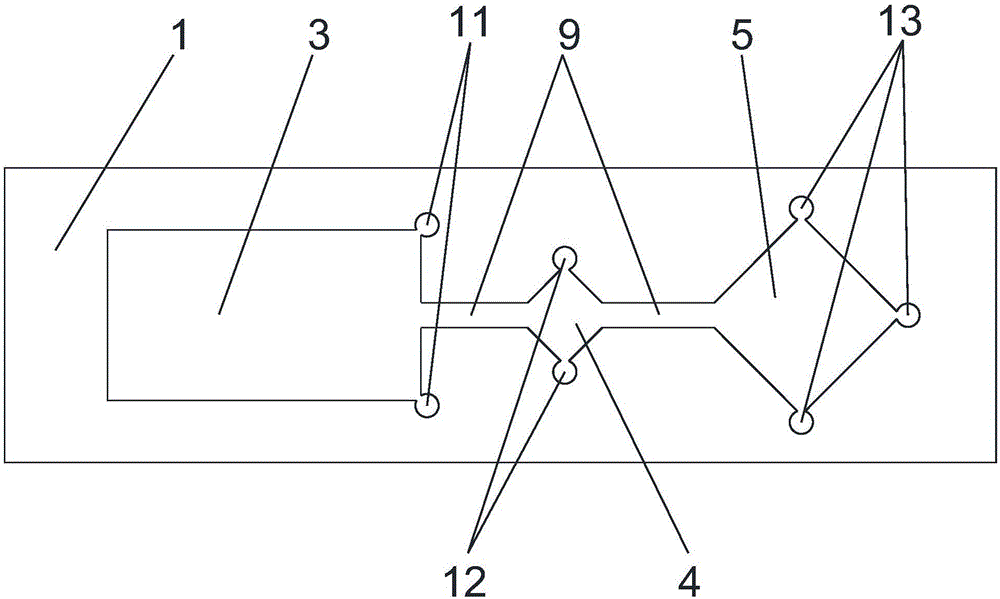

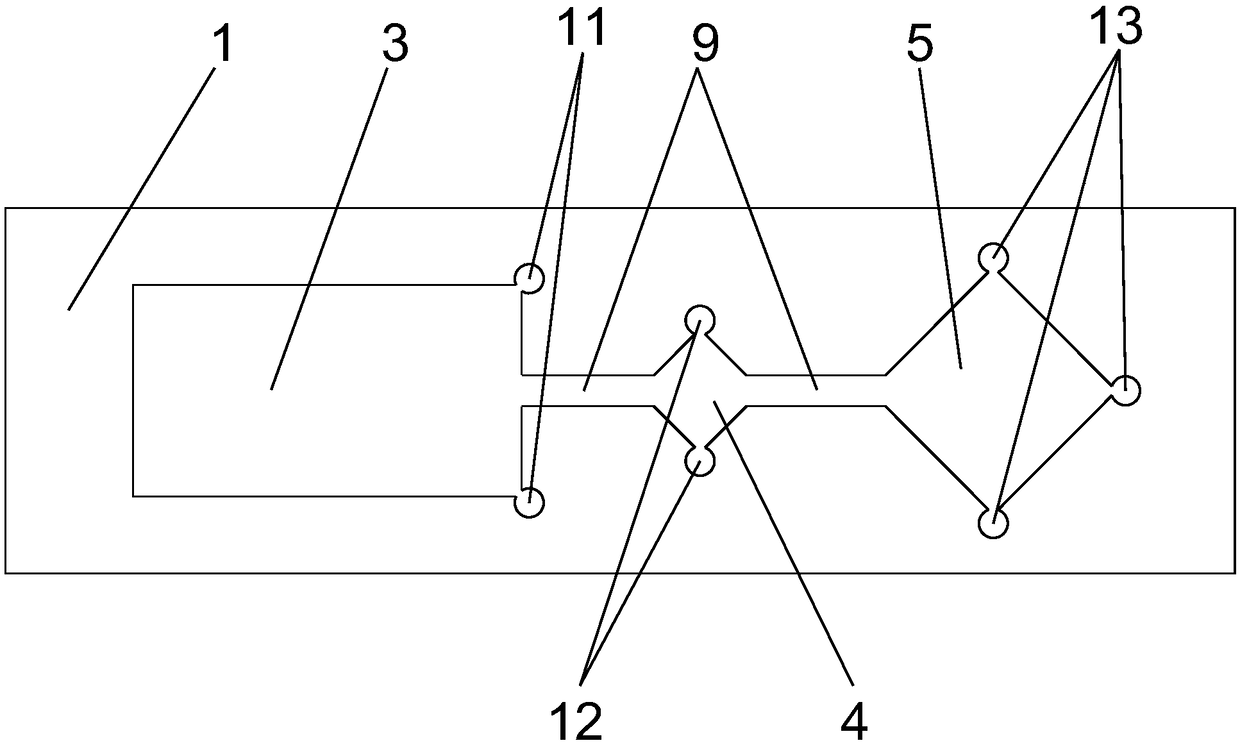

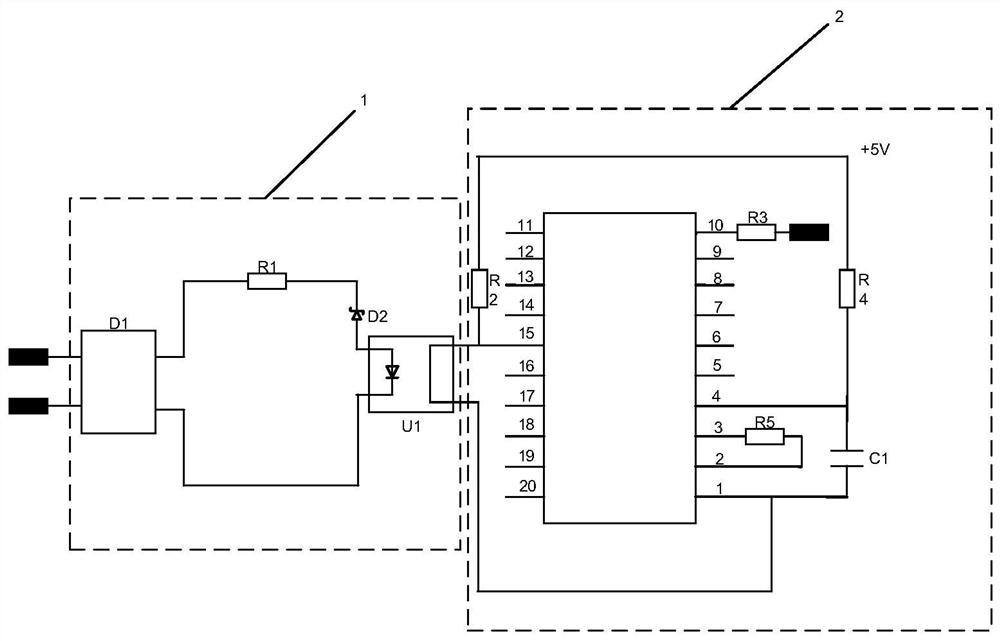

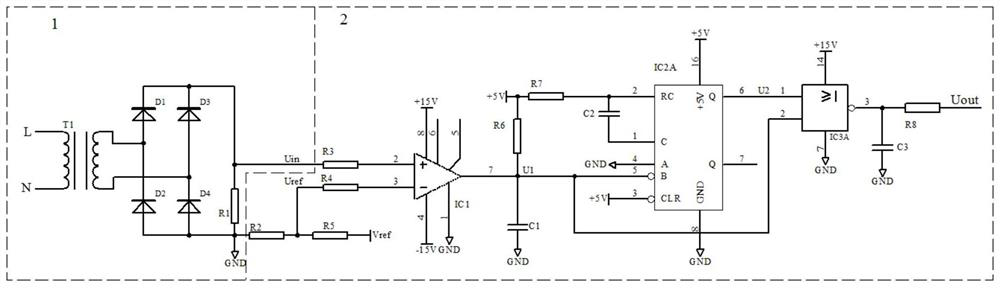

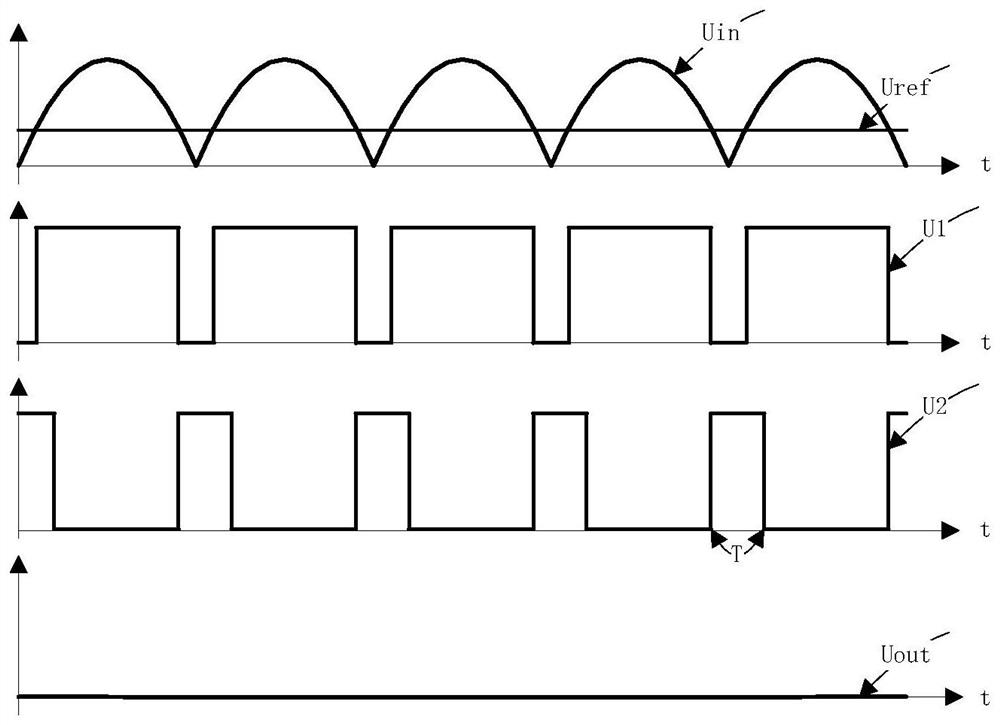

Power grid power failure detection circuit

ActiveCN109061362AAdjust reaction timeEliminate the effects ofFault location by conductor typesInformation technology support systemVoltage referenceZero crossing

The invention relates to the technical field of power grid detection, in particular to a power grid power failure detection circuit. According to key points of the scheme, a voltage detection unit reduces and rectifies a power grid voltage and transmits rectified signals to a judgment unit; the judgment unit compares output signals of the detection unit with the reference voltage, and at the sametime uses a monostable trigger to prevent the judgment error caused by the zero-crossing of a power grid voltage cycle, and outputs the state after comparison in the form of level; a traditional powergrid power failure detection circuit uses an energy storage device or a single chip microcomputer to calculate the waveform, the response time of the circuit is too long, the calculation is complex and the cost of the circuit is high. The power grid power failure detection circuit is realized entirely by discrete devices and does not need programming control over the single chip microcomputer, circuit components are few, the reaction speed is high and the reaction time of the circuit can be adjusted according to the actual situation, and the influence of the zero-crossing of the power grid voltage on the circuit can be eliminated.

Owner:XJ POWER CO LTD +2

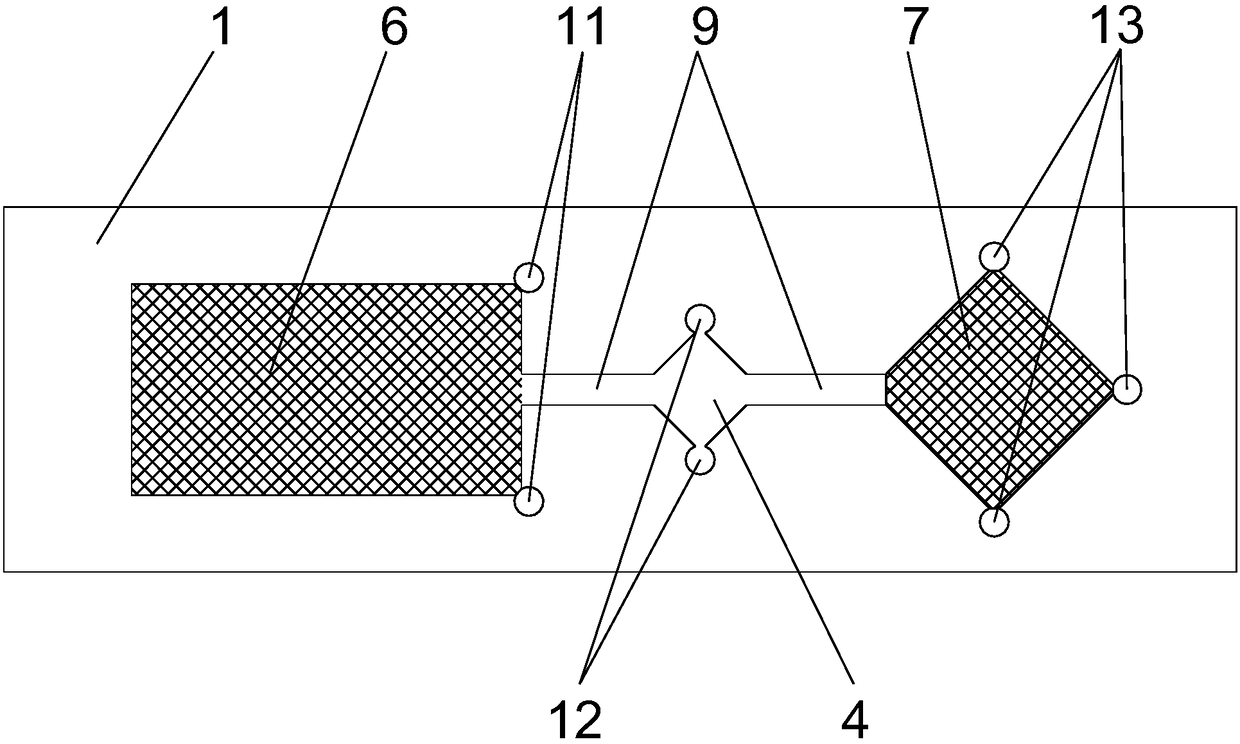

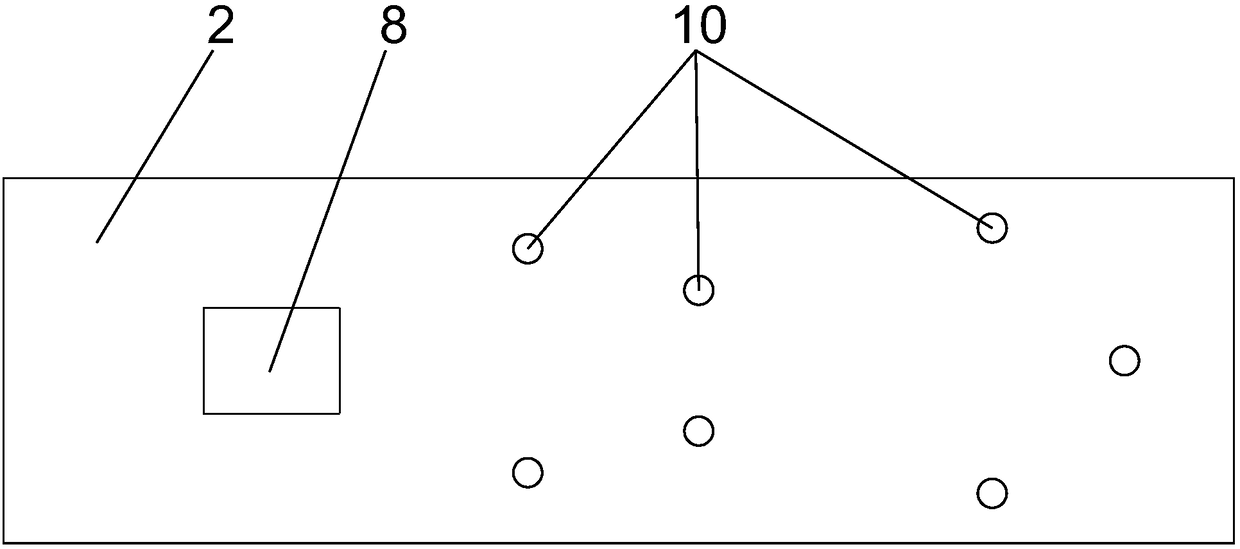

Kit for rapidly detecting ischemia modified albumin in blood

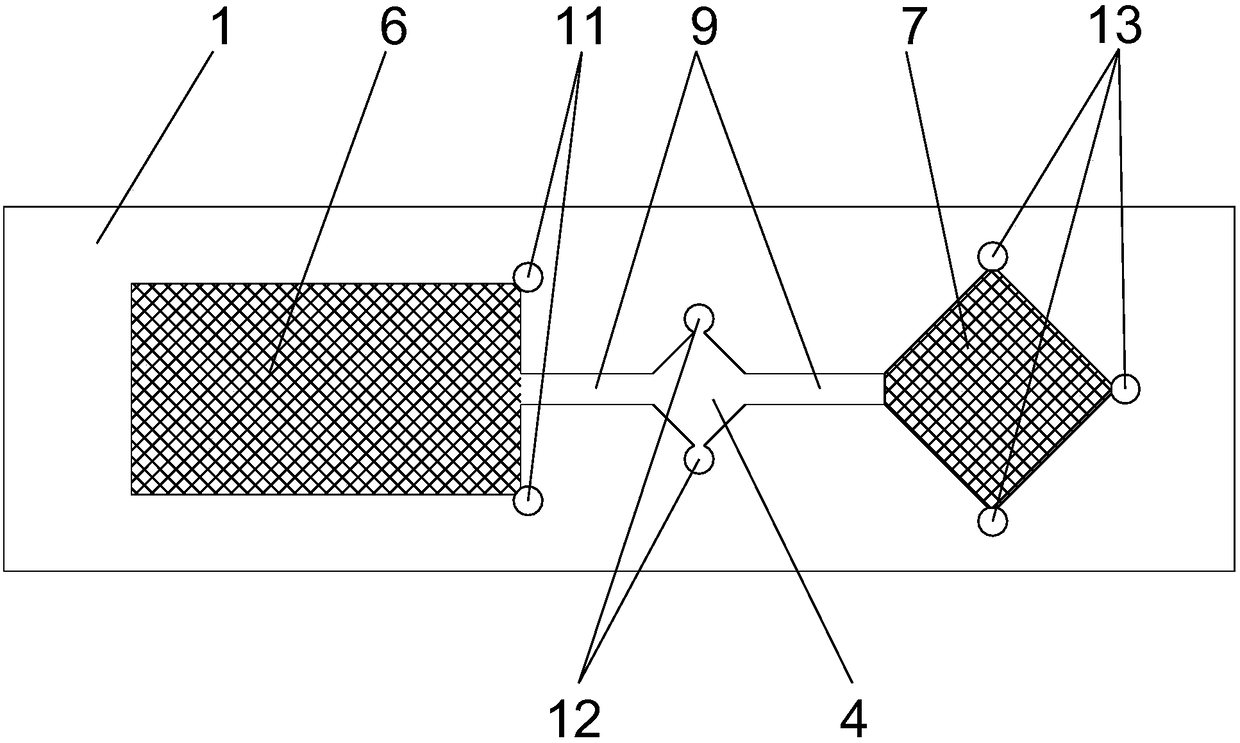

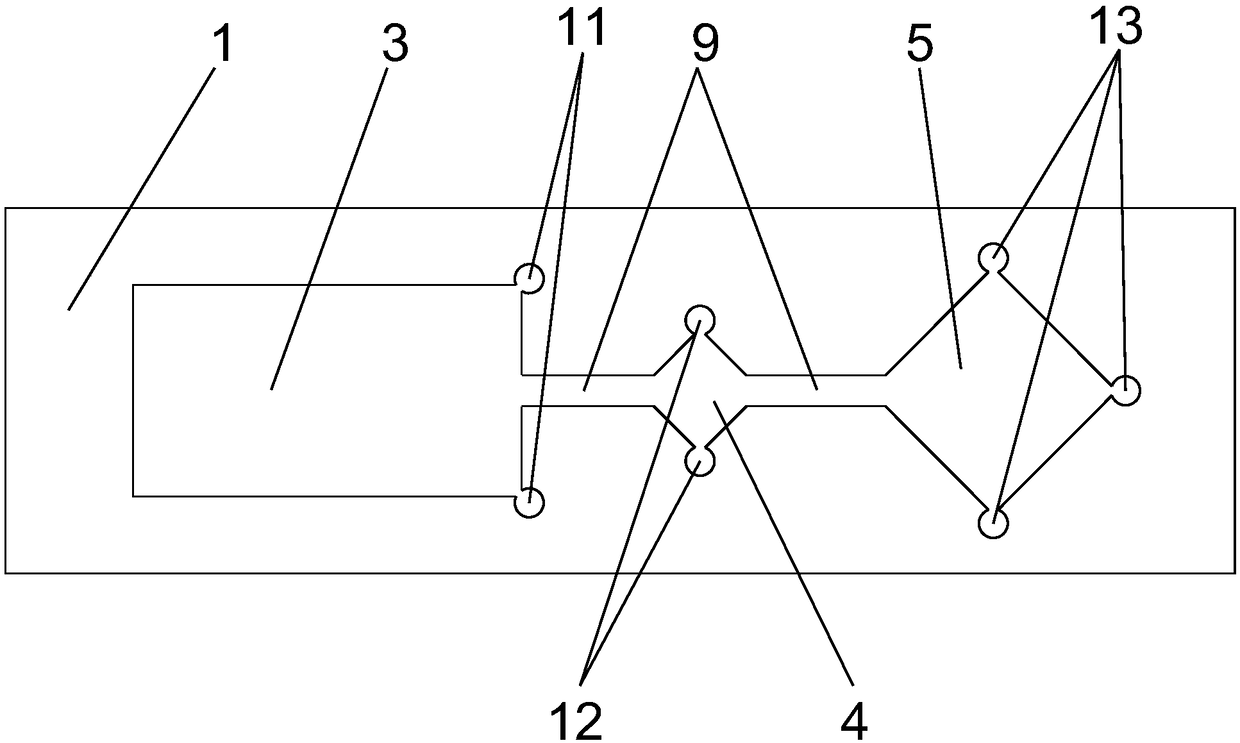

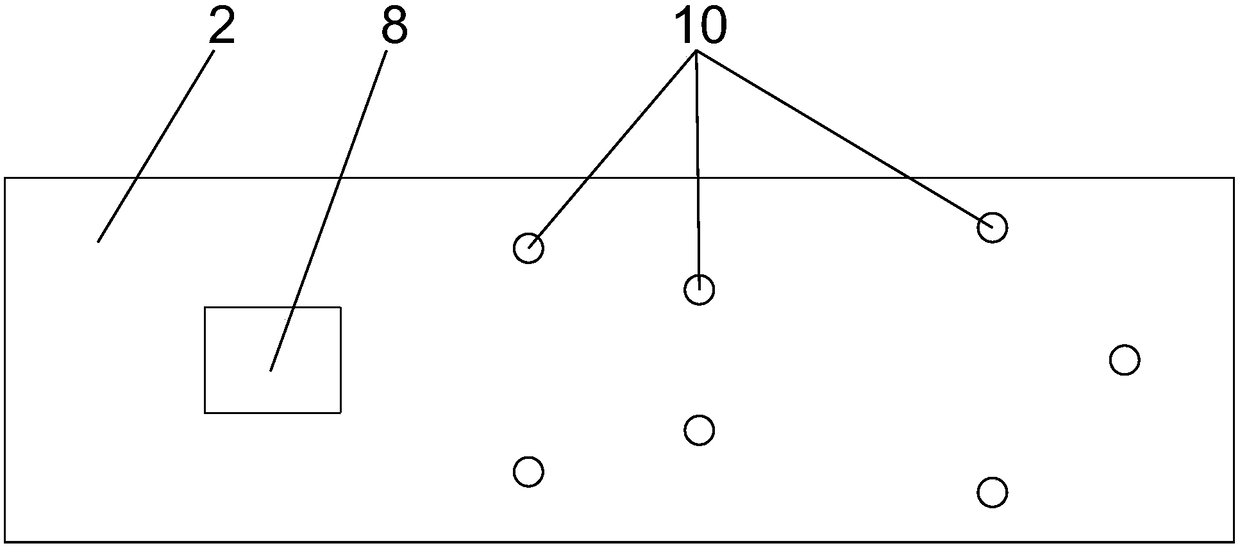

ActiveCN105973888AUniform physical and chemical propertiesMulti-buffer mixing spaceMaterial analysis by observing effect on chemical indicatorBORATE BUFFERCobalt

The invention discloses a kit for rapidly detecting ischemia modified albumin in blood. The kit comprises a detection chip and a reagent bottle filled with detection reagents, wherein the detection chip comprises a non-absorbent bottom plate and a non-absorbent cover plate; a sample cell, a mixing cell and a detection cell are sequentially arranged on the bottom plate; micro pipelines are formed between the sample cell and the mixing cell and between the mixing cell and the detection cell; a sample pad is filled in the sample cell; a cobalt standard substance is coated on the sample pad; a detection pad is filled in the detection cell; a cobalt indicator is coated on the detection pad; the cover plate is fixedly arranged above the bottom plate; a sample injection hole is formed in a position, which is positioned above the sample cell, of the cover plate; and the detection reagents refer to phosphate buffer, borate buffer or Tris-HCl buffer. According to the kit disclosed by the invention, based on the principle of an albumin cobalt binding test, sample separation and detection analysis processes are integrated into a device, so that IMA detection is more convenient.

Owner:西安良升生物科技有限公司

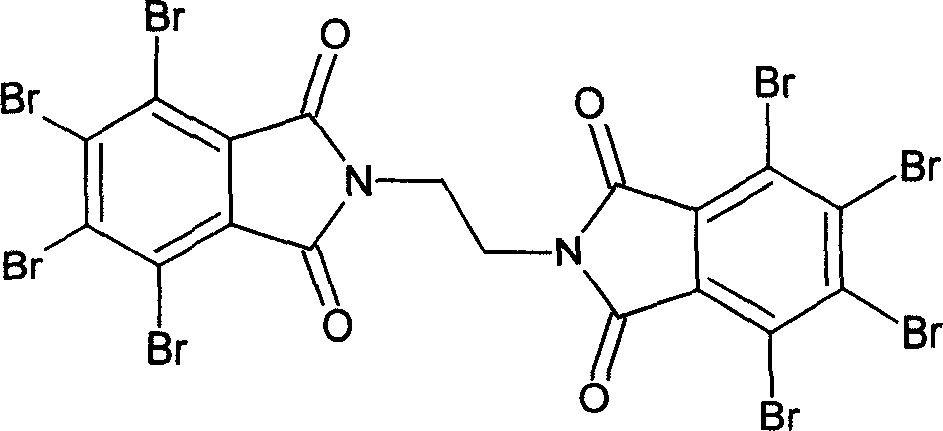

Synthetic method of fire-retardant N,N'-ethylene bis-tetrabromo phthalimide and screw thrust tubular reactor

The present invention discloses the synthesis process of fire retardant Nú¼Níõ-ethylene bis-tetrabromo phthalimide and its screw thrust tubular reactor. Inside the screw thrust tubular reactor, phthalic anhydride and ethylene diamine are first condensated under no water condition to synthesize Nú¼Níõ-ethylene bis-phthalimide, and bromine is then dropped to produce bromination in fuming sulfuric acid as solvent and in the presence of multiple phase catalyst so as to produce Nú¼Níõ-ethylene bis-tetrabromo phthalimide. The process may include post-treatment steps of water washing, sand grinding, pressure filtering, stoving, etc. to obtain the target product fine white Nú¼Níõ-ethylene bis-tetrabromo phthalimide powder. It has no color change in high temperature roasting, and may be used in product with high color requirement.

Owner:蔡晨波

Preparation method of structured lipid with long carbon chain and low calorie

The invention relates to a preparation method of a structured lipid with a long carbon chain and low calorie. The preparation method is mainly characterized by comprising the steps of dissolving glycerin and rice bran wax (of which the mol ratio is (2:1)-(7:1)) into isooctane and tert-amyl alcohol solvents (of which the volume ratio is 7:3) in a concentration of 10%; placing on a magnetic stirrer with a speed of 200rpm / min; heating at 50-70 DEG C, and stirring until substrates are uniformly mixed; adding 4-10% of lipase in percentage by weight, and reacting for 6-36 hours; after completing reaction, removing lipase in a product by virtue of filtration, removing organic solvents by virtue of rotary evaporation, then removing unreacted glycerin by virtue of water washing, and performing vacuum drying to obtain a powdered solid product. The preparation method disclosed by the invention is low in cost and simple in experimental operation, can be used for respectively obtaining triglyceride, diglyceride and monoglyceride by controlling different reaction conditions, and can be used for determining applications of the product according to the characteristics of melting points.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Hot-aerosol fire-extinguishing agent

The invention relates to a hot-aerosol fire-extinguishing agent. The hot-aerosol fire-extinguishing agent comprises the following raw materials in percentage by weight: 10-30% of potassium nitrate, 10-30% of zinc nitrate, 10-30% of magnesium nitrate, 10-30% of guanidine nitrate, 6-10% of manganese dioxide, 0.2-0.8% of bamboo charcoal, 0.2-0.8% of azodicarbonamide, 0.5-1% of metallic magnesium, 0.2-0.8% of adhesive and 0.2-0.8% of thermite. The formula of the materials is improved, the ideal state of efficient fire extinguishment of potassium salt in an oxidizing agent is exerted, and the reaction time of the materials is adjusted, thus the concentration of the solid particles of the potassium salt after reaction in the oxidizing agent in a hot-aerosol fire-extinguishing gas is lowered to achieve no corrosion. The hot-aerosol fire-extinguishing agent is suitable for fire extinguishment for a generator room with a high accuracy requirement.

Owner:ANHUI NEWT FIRE EQUIP

Hot aerosol fire extinguishing agent

The invention discloses a hot aerosol fire extinguishing agent which is prepared by an oxidant, a reductant, a performance modifying agent, and an adhesive. The invention not only has good fire extinguishing effect, but also is energy-saving, environment-friendly, and low in cost; meanwhile, the invention does not cause corrosion or damage of equipment after utilization, and can effectively prevent secondary combustion of files and equipment.

Owner:浙江华神消防科技有限公司

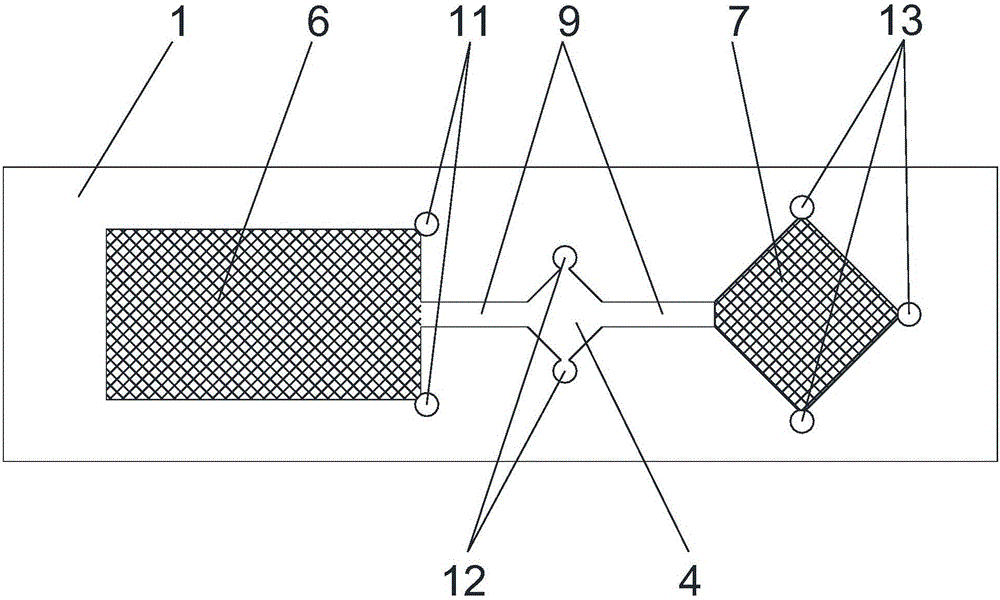

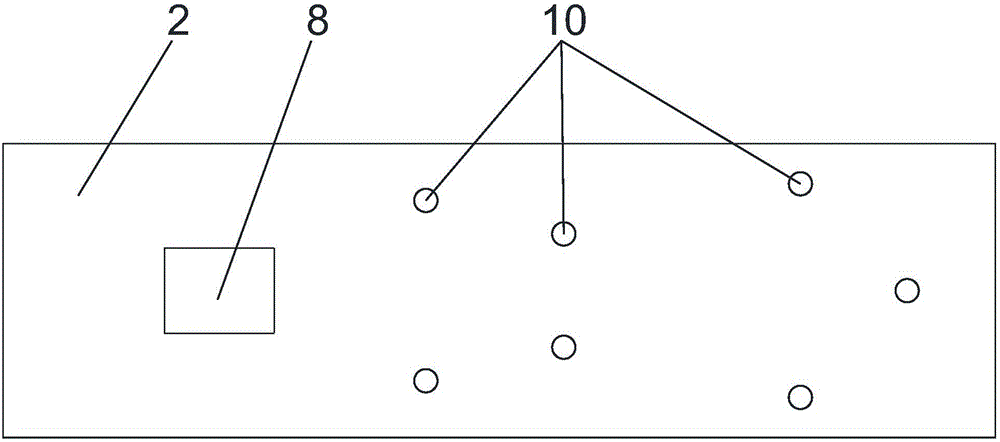

A chip for rapid detection of ischemia-modified albumin in blood

ActiveCN105973887BUniform physical and chemical propertiesMulti-buffer mixing spaceMaterial analysis by observing effect on chemical indicatorMedical unitHospitalized patients

The invention discloses a chip for rapidly detecting ischemia modified albumin in blood. The chip comprises a non-absorbent bottom plate and a non-absorbent cover plate, wherein a sample tank, a mixing tank and a detection tank are arranged on the bottom plate in sequence; micro-pipelines are arranged between the sample tank and the mixing tank and between the mixing tank and the detection tank; the sample tank is internally filled with a sample pad; the sample pad is coated with a cobalt standard product; the detection tank is internally filled with a detection pad; the detection pad is coated with a cobalt indicator; the cover plate is fixedly arranged above the bottom plate; and the cover plate is located above the sample tank and is provided with a sample feeding hole. The chip disclosed by the invention is simple in detection method, and a result is easy to judge; and the chip is suitable for being used in medical units including primary-level hospitals, emergency departments and the like or on bedsides of hospitalized patients, so that medical workers can rapidly judge dangers of the patients by layers and medical resources and health cost are saved.

Owner:西安良升生物科技有限公司

Coal gasification device for circulating fluidized bed

InactiveCN102911741BReduce carbon contentAdjust cycle ratioGranular/pulverulent flues gasificationCycloneCombustion chamber

The invention discloses a coal gasification device for a circulating fluidized bed. The coal gasification device comprises a start combustion chamber, a raising pipe and a primary cyclone separator, wherein the start combustion chamber is arranged at the lower end of the raising pipe; a slag discharge opening and a fuel inlet are further arranged in the lower end of the raising pipe; a pulverized coal inlet is arranged in the middle part of the raising pipe; a smoke outlet is arranged in the upper end of the raising pipe; the primary cyclone separator is connected with the smoke outlet of the raising pipe; an M-shaped material returner is arranged at the lower end of the primary cyclone separator; a material returning tuyere, a loosening tuyere and an ash discharge tuyere are respectively arranged at the bottom of the M-shaped material returner; a material returning pipe is arranged at the upper end of the material returning tuyere; an ash discharge pipe is arranged at the upper end of the ash discharge tuyere; and the material returning pipe is connected to the middle part of the raising pipe. According to the coal gasification device disclosed by the invention, ash discharge operations are carried out at the bottom of the raising pipe and inside the M-shaped material returner respectively. Compared with the situation of singly discharging slag at the bottom of the raising pipe in the prior art, the M-shaped material returner obviously has a lower carbon content.

Owner:SOUTHEAST UNIV

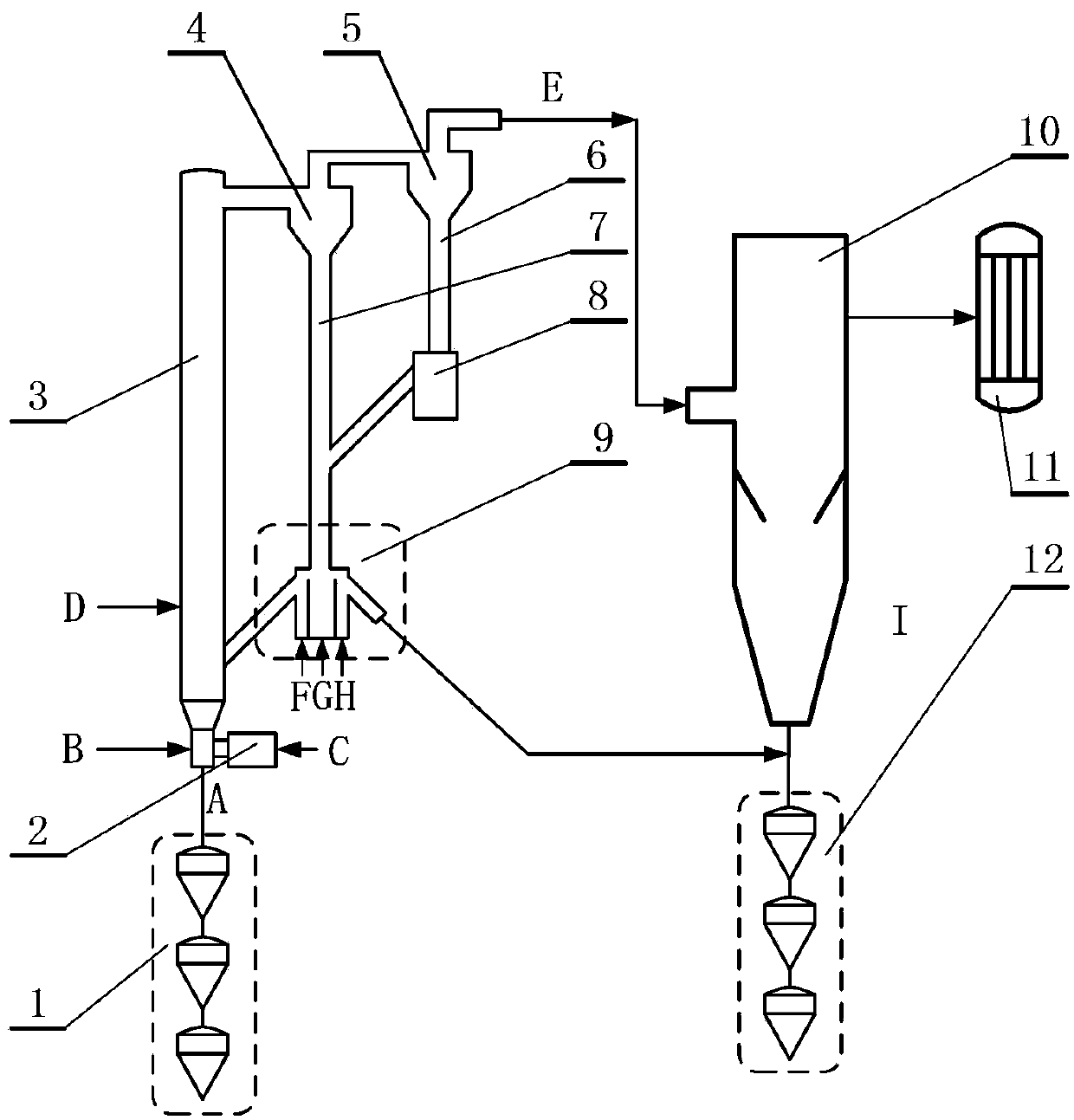

Reaction device capable of realizing continuous preparation of colloidal gold

The invention discloses a reaction device capable of realizing continuous preparation of colloidal gold. The reaction device comprises a raw material mixing vessel, a reaction vessel and a heating device used for heating the reaction vessel, wherein a raw material inlet, a mixed liquor outlet and a stirring device are arranged on the raw material mixing vessel; the inlet end of the reaction vessel is communicated with the mixed liquor outlet; a colloidal gold collecting vessel is arranged at the outlet end of the reaction vessel; the stirring device is used for stirring liquid in the raw material mixing vessel to form the mixed liquor; the duration during which the mixed liquor enters the reaction vessel through the inlet end and the duration during which the mixed liquor flows out of the reaction vessel through the outlet end are matched with the set duration. The overall reaction device provided by the invention adopts a continuous production design on feeding, mixing, reacting and colloidal gold collecting, so that the structure is simple, a complex pipe spraying device is avoided, the production time consumed is short, colloidal gold is produced not only in batches but also on a small scale, and the preparation quantity can be adjusted through an opening and closing valve.

Owner:WUHAN J H BIO TECH

Device for purifying vinosity

InactiveCN101948732BImprove inner qualityReduce flow rateAlcoholic beverage preparationUltraviolet lightsSolid particle

Owner:李建东

Chip for rapidly detecting ischemia modified albumin in blood

ActiveCN105973887AUniform physical and chemical propertiesMulti-buffer mixing spaceMaterial analysis by observing effect on chemical indicatorMedical unitHospitalized patients

The invention discloses a chip for rapidly detecting ischemia modified albumin in blood. The chip comprises a non-absorbent bottom plate and a non-absorbent cover plate, wherein a sample tank, a mixing tank and a detection tank are arranged on the bottom plate in sequence; micro-pipelines are arranged between the sample tank and the mixing tank and between the mixing tank and the detection tank; the sample tank is internally filled with a sample pad; the sample pad is coated with a cobalt standard product; the detection tank is internally filled with a detection pad; the detection pad is coated with a cobalt indicator; the cover plate is fixedly arranged above the bottom plate; and the cover plate is located above the sample tank and is provided with a sample feeding hole. The chip disclosed by the invention is simple in detection method, and a result is easy to judge; and the chip is suitable for being used in medical units including primary-level hospitals, emergency departments and the like or on bedsides of hospitalized patients, so that medical workers can rapidly judge dangers of the patients by layers and medical resources and health cost are saved.

Owner:西安良升生物科技有限公司

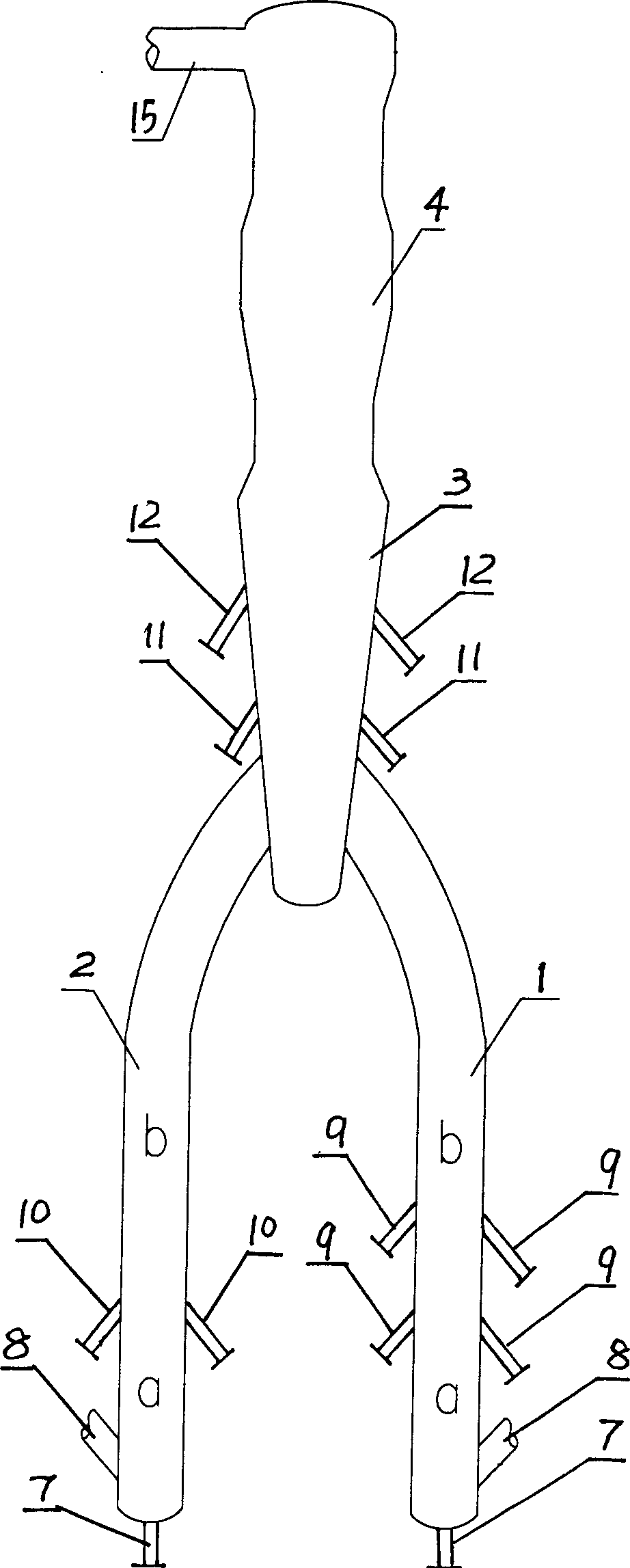

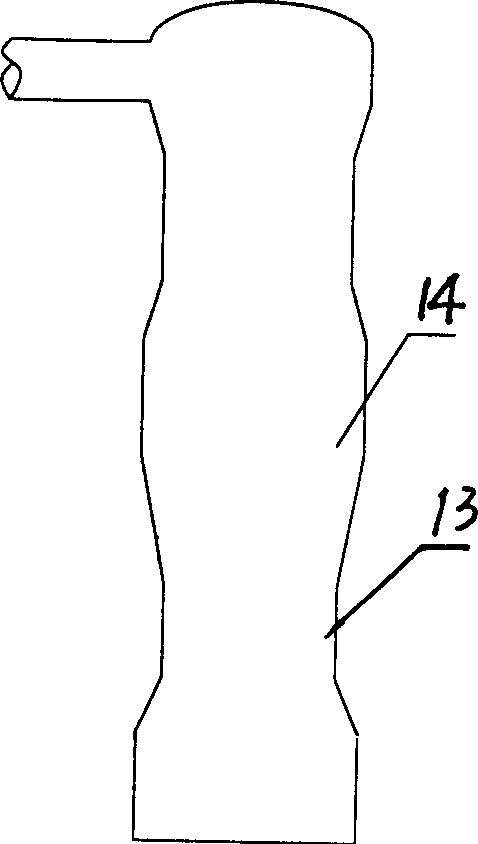

Hydrocarbon material catalytic cracking lift pipe reactor

InactiveCN1640538ASpeed up the flowAvoid damageCatalytic naphtha reformingChemical/physical processesGasolineEngineering

The present invention relates to a catalytic cracking lift pipe reactor for hydrocarbon raw material. It comprises parallelly-arranged first reactor and second reactor and coaxially series-connected third reactor and fourth reactor, the upper ends of first and second reactors are serial-connected with lower end of third reactor, and is formed from prelift stage of lower portion and cracking reaction stage of upper portion, the bottom portion of its prelift stage is equipped with prelift gas inlet pipe, its lower portion is equipped with a catalyst inlet pipe, and the lower portion of its craking stage respectively is equipped with raw material oil inlet pipe nozzle, recycle oil and slurry oil inlet pipe nozzle. Said invention also provides the concrete structure of third and fourth reactors. Said invention can raise gasoline yield by 1%, and the olefin content in the produced gasoline can be reduced by 10-15%.

Owner:石宝珍

Heat exchange type ventilator

ActiveCN101317041BGood construction performanceAdjust the sensitivityLighting and heating apparatusVentilation systemsEngineeringType ventilator

The present invention provides a heat exchange type ventilator in which the size of a flow passage changing unit provided with a damper can be reduced. The ventilator includes a partition plate (211) partitioning an exhaust flow passage (209) from an intake flow passage (210), an exhaust damper receiver (213) having an exhaust opening (212), and an intake opening (214). The ventilator further includes a flow passage changing unit (222) having an intake damper receiver (215), an exhaust damper (216) opening and closing the exhaust opening (212), and an intake damper (217) opening and closing the intake opening (214). A damper side bent part (224) is provided in the exhaust damper (216) and the intake damper (217), and a receiving side bent part (223) is provided near the end parts of the exhaust damper receiver (213) and the intake damper receiver (215) along the damper side bent part (224).

Owner:PANASONIC CORP

A kit for rapidly detecting ischemia-modified albumin in blood

ActiveCN105973888BUniform physical and chemical propertiesMulti-buffer mixing spaceMaterial analysis by observing effect on chemical indicatorCobaltBORATE BUFFER

The invention discloses a kit for rapidly detecting ischemia modified albumin in blood. The kit comprises a detection chip and a reagent bottle filled with detection reagents, wherein the detection chip comprises a non-absorbent bottom plate and a non-absorbent cover plate; a sample cell, a mixing cell and a detection cell are sequentially arranged on the bottom plate; micro pipelines are formed between the sample cell and the mixing cell and between the mixing cell and the detection cell; a sample pad is filled in the sample cell; a cobalt standard substance is coated on the sample pad; a detection pad is filled in the detection cell; a cobalt indicator is coated on the detection pad; the cover plate is fixedly arranged above the bottom plate; a sample injection hole is formed in a position, which is positioned above the sample cell, of the cover plate; and the detection reagents refer to phosphate buffer, borate buffer or Tris-HCl buffer. According to the kit disclosed by the invention, based on the principle of an albumin cobalt binding test, sample separation and detection analysis processes are integrated into a device, so that IMA detection is more convenient.

Owner:西安良升生物科技有限公司

Heat exchange type ventilator

ActiveCN102661621BAchieve purificationGood construction performanceEnergy recovery in ventilation and heatingMechanical apparatusPath switchingType ventilator

Owner:PANASONIC CORP

A power grid power failure detection circuit

ActiveCN109061362BAdjust reaction timeEliminate the effects ofFault location by conductor typesContinuity testingHemt circuitsPower grid

The invention relates to the technical field of power grid detection, in particular to a power grid power failure detection circuit. According to key points of the scheme, a voltage detection unit reduces and rectifies a power grid voltage and transmits rectified signals to a judgment unit; the judgment unit compares output signals of the detection unit with the reference voltage, and at the sametime uses a monostable trigger to prevent the judgment error caused by the zero-crossing of a power grid voltage cycle, and outputs the state after comparison in the form of level; a traditional powergrid power failure detection circuit uses an energy storage device or a single chip microcomputer to calculate the waveform, the response time of the circuit is too long, the calculation is complex and the cost of the circuit is high. The power grid power failure detection circuit is realized entirely by discrete devices and does not need programming control over the single chip microcomputer, circuit components are few, the reaction speed is high and the reaction time of the circuit can be adjusted according to the actual situation, and the influence of the zero-crossing of the power grid voltage on the circuit can be eliminated.

Owner:XJ POWER CO LTD +2

Method for preparing semiconductor quantum-point material by low-temperature solvent method

InactiveCN1288716CModulate FluorescenceHigh boiling pointLaser detailsNanostructure manufacturePolyvinyl alcoholReaction temperature

Owner:SHANGHAI JIAOTONG UNIV

Apparatus and method for rapid catalytic pyrolysis of milled-belt biomass

ActiveCN110003927BRapid condensationFully condensedBiofuelsLiquid hydrocarbon mixture productionCatalytic pyrolysisPtru catalyst

The invention belongs to the field of biomass energy utilization, and relates to a grinding belt-type device for rapid catalytic pyrolysis of biomass and a method. The device comprises a hopper, a feed system, a grinding belt-type pyrolysis reactor, a gas-solid separation system, a pyrolysis gas condensation system, a combustion system, a bio-oil collection tank, a charcoal collection tank, an airpreheating system and a flue gas purification system, wherein the grinding belt-type pyrolysis reactor comprises grinding belts, heating tubes, driving drums, tensioning devices, a sealed casing, a feed inlet, a discharge opening and a gas outlet. Pretreated material particles are continuously sheared and rubbed by the grinding belts with speed difference on two sides, and are heated by the multi-layer heating tubes to continuously pyrolyze on the surface while stripping the residual charcoal, so that a catalyst and heat can be fully fed inside the particles; the pyrolysis gas is rapidly condensed by gas-solid separation to obtain high-grade bio-oil fuel or bio-oil rich in specific high value-added products; combustible gas and coke produced by combustion generate high-temperature flue gas for heating the heating tubes, so as to achieve an autothermal pyrolysis process.

Owner:北京博霖环境科技有限公司

Low-residue and high-insulation-strength aerosol fire extinguishing composition

InactiveCN111821642AReduced dielectric strengthLess corrosiveFire extinguisherCombustionOxidizing agent

The invention provides a low-residue and high-insulation-strength aerosol fire extinguishing composition, which comprises the following material components by mass: 30%-60% of an oxidant, 20%-40% of areducing agent, 2%-10% of a performance regulator, 5%-10% of an adhesive and 10%-30% of a coating agent. According to the invention, the aerosol fire extinguishing composition is good in fire extinguishing effect and less in residue; the hot aerosol fire extinguishing agent particles are subjected to coating treatment, so that the aerosol fire extinguishing agent particles have high insulating strength, namely, the condition that conductive substances form on the surface of a sprayed object to corrode and damage equipment can be avoided; and the flame temperature is reduced, the combustion reaction is inhibited, and after-combustion is effectively prevented.

Owner:深圳市源烯科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com