Hot aerosol fire extinguishing agent

A technology of fire extinguishing agent and sol, which is applied in the direction of fire prevention equipment, etc., can solve the problems of particle settlement, small amount of gas, and ineffective fire extinguishing effect, and achieve the effect of large specific surface area and surface area energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

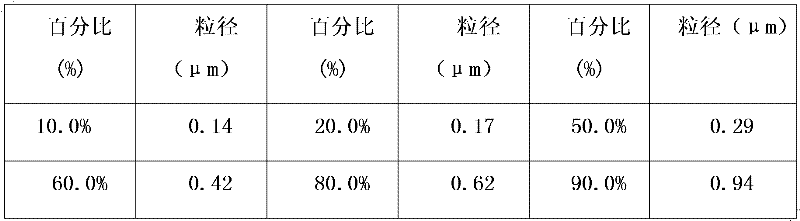

Embodiment 1

[0025] Embodiment 1: hot aerosol fire extinguishing agent, the fire extinguishing agent adopts 40 parts of oxidizing agent, 50 parts of reducing agent, 7 parts of performance modifier and 3 parts of adhesive in parts by mass. The oxidant can choose nitrates such as potassium nitrate and strontium nitrate and a small amount of carbonate. The oxidant is oxidizing, and it is reduced by itself. The nitrate is reduced in the chemical reaction to NO, NO 2 , N 2 . The pyrolysis products of solid particles exist in the form of steam or ions, and instantly adsorb and react with active groups such as H, OH, and O, thereby consuming fuel active groups and inhibiting the chain reaction of combustion. Among them, the metal oxide produced by the oxidation-reduction reaction reacts with the combustion substance carbon at high temperature, absorbs part of the heat of the combustion fire source, and reduces the flame temperature, so the combustion reaction is inhibited to a certain extent. C...

Embodiment 2

[0027] Embodiment 2: hot aerosol fire extinguishing agent, the fire extinguishing agent adopts 50 parts of oxidizing agent, 40 parts of reducing agent, 5 parts of performance modifier and 5 parts of adhesive in parts by mass. Adhesive can adopt resin type adhesive. The preparation process of the hot aerosol fire extinguishing agent can be made according to the conventional preparation process in the field, that is, the prepared oxidant, reducing agent, performance modifier and binder are mixed and stirred to form.

Embodiment 3

[0028] Embodiment 3: hot aerosol fire extinguishing agent, this fire extinguishing agent adopts 40~75 parts of oxidant, 15~50 parts of reductant, 1~7 parts of performance regulator and 1~5 parts of binding agent to make by mass parts; Parts include 10-15 parts of potassium nitrate, 20-25 parts of strontium nitrate, 3-5 parts of zinc nitrate, 3-5 parts of magnesium nitrate and 1-5 parts of calcium nitrate; 20-38 parts of amide; the performance modifier includes 1-2 parts of aluminum carbonate, 1-3 parts of magnesium carbonate and 1-3 parts of carbon powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com