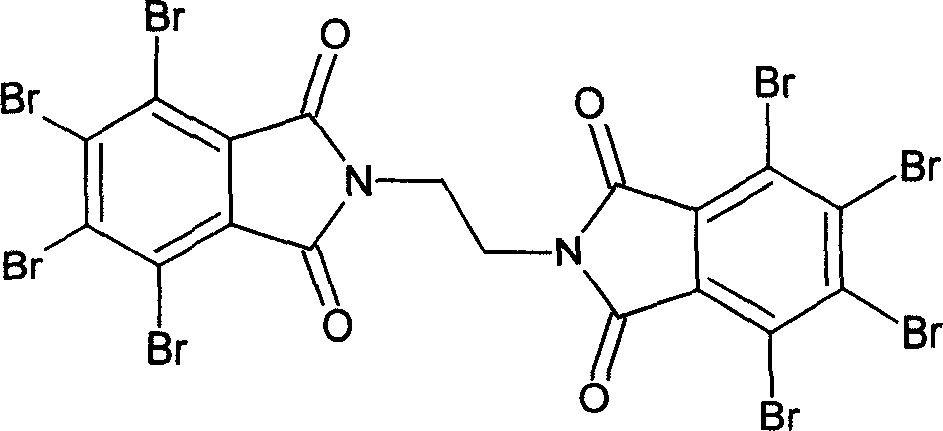

Synthetic method of fire-retardant N,N'-ethylene bis-tetrabromo phthalimide and screw thrust tubular reactor

A technology of tetrabromophthalimide and tubular reactor, which is applied in the field of flame retardant N, can solve the problems of insufficient fineness, excessive bromine content, long reaction time, etc., and achieve stable product quality , low residual bromine content and high bromination degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

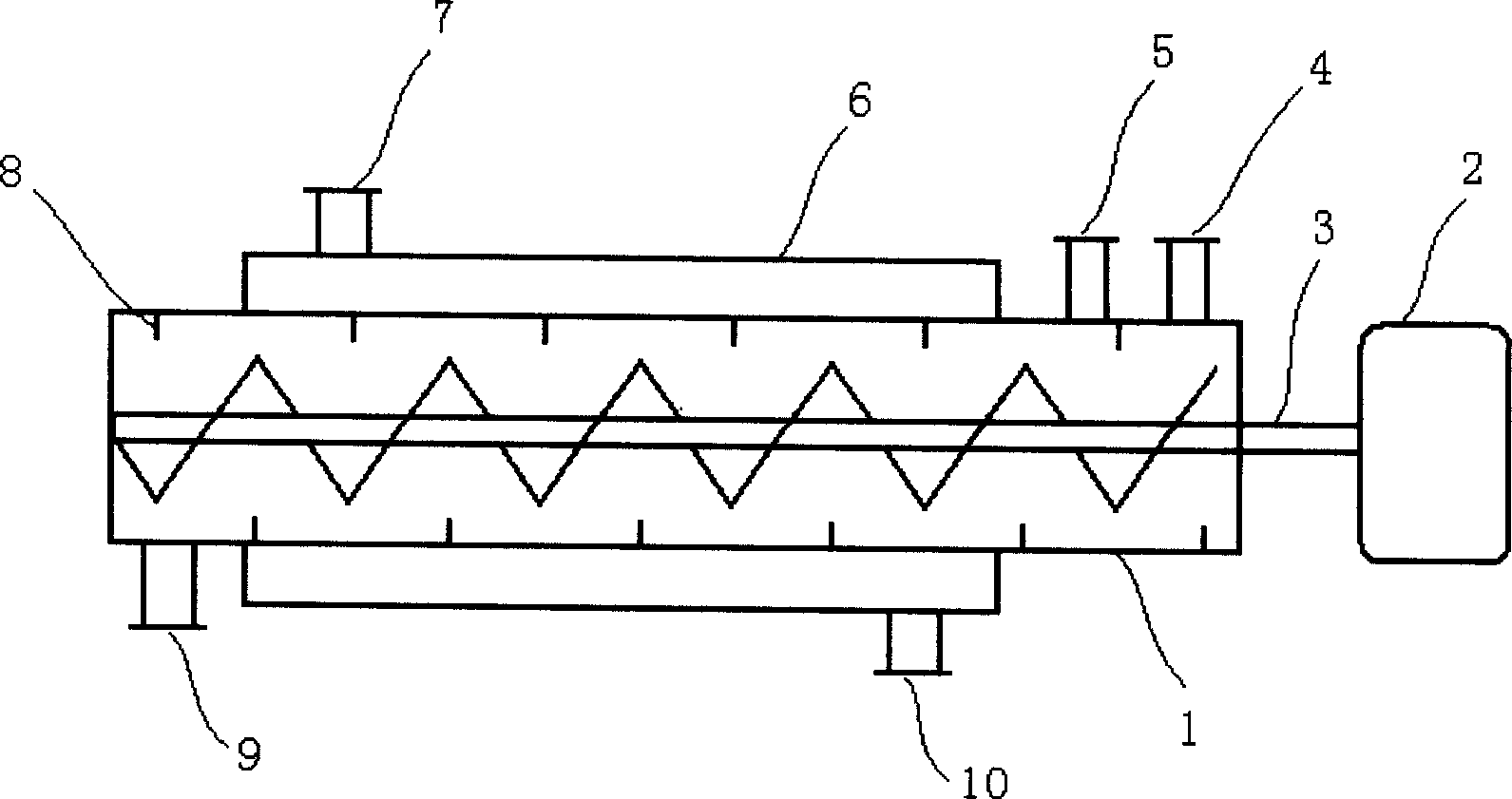

[0024] 200Kg of phthalic anhydride and 43.5Kg of ethylenediamine are simultaneously injected into the screw-propelled tubular reactor, and the temperature is gradually raised to react at 60-100°C for 4 hours, 100-160°C for 4 hours, and 240-260°C for 2 hours , In N, N'-ethylene bisphthalimide. After the reaction, the collected reaction solution was cooled to room temperature and sectioned.

[0025] Gained chip load is dropped in the reactor again, add 4.2Kg heterogeneous aluminum vanadium iron catalyst and 2500Kg 60% fuming sulfuric acid, drop the bromine of 600Kg, reaction temperature is controlled at 50~100 ℃ and reacts 14 hours, 125~ React at 135°C for 4 hours. After the reaction, cool, wash and filter (pressure) to obtain light yellow N, N'-ethylene bis-tetrabromophthalimide. The filtrate is recycled to the next use.

[0026] Add N, N`-ethylene bis-tetrabromophthalimide into 5000Kg water, use wet sanding method, sanding for 5-20 hours, check the fineness and whiteness, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com