Graphene oxide preparation method based on secondary controllable electrochemical technology

An electrochemical and graphene technology, applied in the field of graphene oxide preparation based on secondary controllable electrochemical technology, can solve the problem that the electrochemical oxidation stripping method cannot realize graphene oxide, and cannot control the composition and structure of graphene oxide. and other problems, to achieve the effect of low cost, reduced preparation cost and single component

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

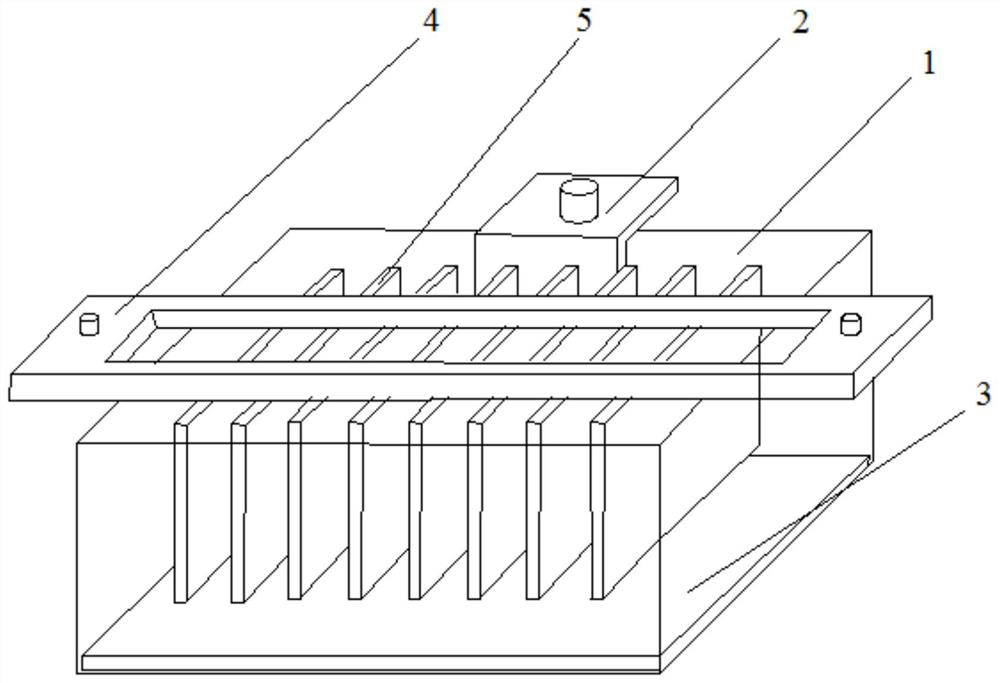

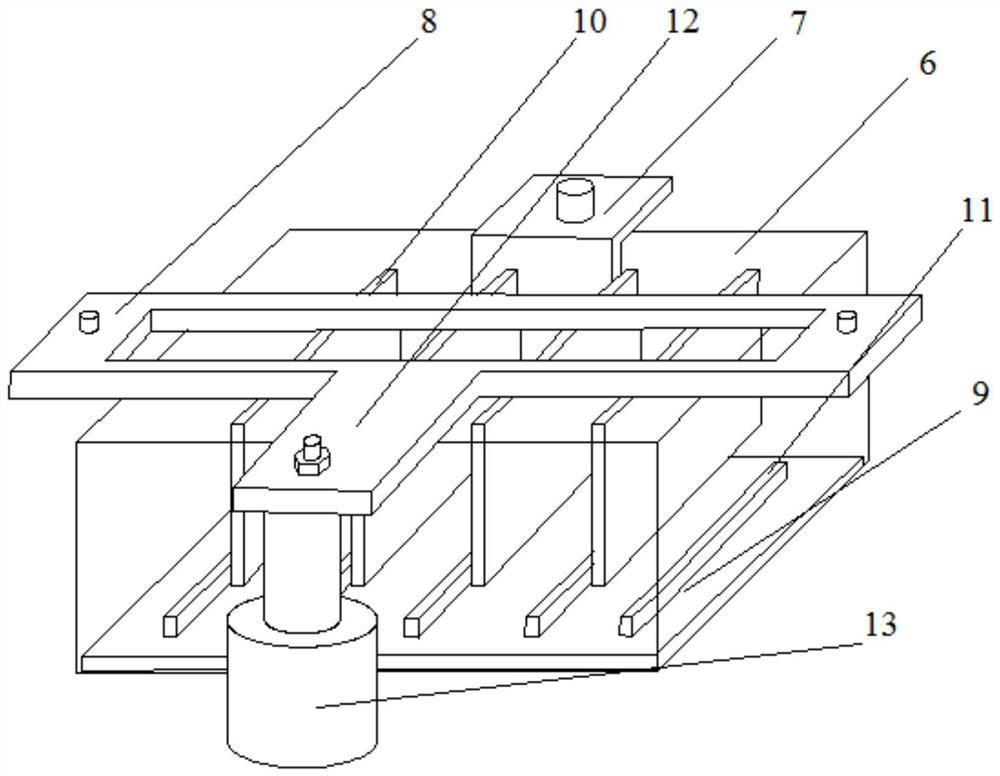

[0096] 1. Electrochemical intercalation reaction process of graphite interlayer compounds

[0097] The first analysis of the influence of electrolyte concentration on graphite intercalation compounds:

[0098] The electrochemical oxidation intercalation reaction of graphite was carried out with the intercalation agent concentrated sulfuric acid as the electrolyte. The material ratio is: m 石墨 (g): V 浓硫酸 (mL)=1:1.1. At a current density of 30mA / cm 2 1. Under the condition that the reaction time is 120min, the electrochemical oxidation intercalation reaction is carried out by changing the concentration of sulfuric acid to 90%, 93%, 95% and 98%, respectively. Under the action of constant current, as the electrochemical intercalation reaction proceeds, the material layer reaction zone gradually turns blue from the bottom to the top. Studies have shown that as the concentration of sulfuric acid electrolyte increases, the blue first-order graphite intercalation compound appears ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com