A kind of preparation method of metal substrate

A metal substrate and metal layer technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as surface roughness of metal substrates and achieve cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Please refer to Figure 1-Figure 4 , an embodiment of the present invention provides a method for preparing a metal substrate, including:

[0029] Disposing a sacrificial layer 2 on the mother board 1 with an atomically smooth surface;

[0030] A metal layer 3 is provided on the side of the sacrificial layer 2 away from the motherboard 1;

[0031] The metal layer 3 is separated from the sacrificial layer 2, and the separated metal layer 3 is the obtained metal substrate.

[0032] The motherboard can be an existing conventional substrate, such as a sapphire substrate, a Si substrate, a GaAs substrate, an InP substrate, a GaP substrate or a quartz substrate. It should be understood that the motherboard is not limited to those listed above. substrate.

[0033] The above-mentioned way of setting the sacrificial layer can use PECVD to grow a layer of SiO2 or SiNx layer, or use evaporation or sputtering equipment to deposit a layer of Ti layer, Al layer, Ni layer, etc., or ...

Embodiment 1

[0049] A preparation method of a metal substrate, comprising the following steps:

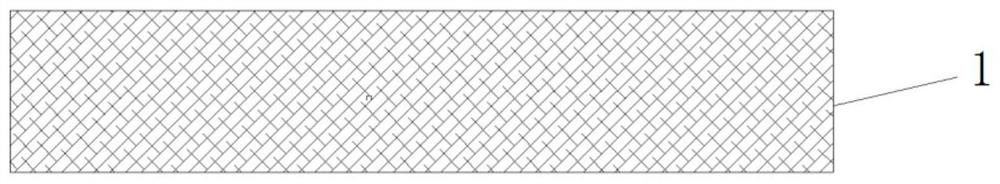

[0050] S11. Provide a motherboard 1 with an atomically smooth upper surface, such as figure 1 shown;

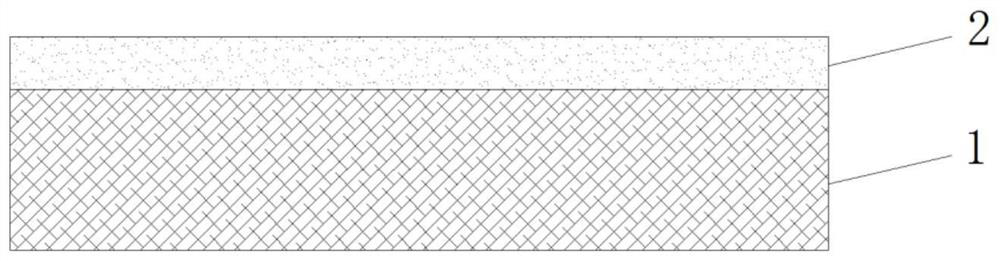

[0051] S12, disposing a sacrificial layer 2 on the upper surface of the motherboard 1, such as figure 2 shown;

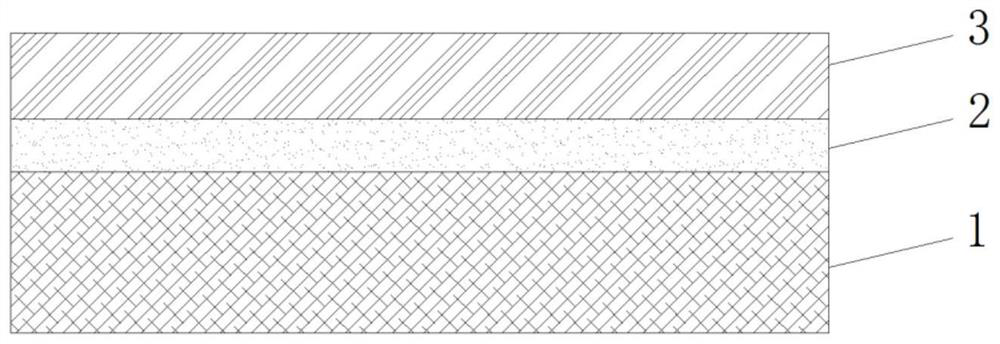

[0052] S13, disposing the metal layer 3 of the multi-layer stack structure on the upper surface of the sacrificial layer 2, such as image 3 shown;

[0053] S14, peeling off the metal layer 3 from the sacrificial layer 1 to obtain a metal layer 3 with a smooth surface, and the metal layer 3 obtained by peeling off is the prepared metal substrate, such as Figure 4 shown.

Embodiment 2

[0055] A preparation method of a metal substrate, comprising the following steps:

[0056] S21. Provide a mother board 1 with an atomically smooth surface, adjust the mother board 1 to a target shape and target size, and then make a graphic structure 11 on the upper surface of the mother board 1, such as Figure 5 shown;

[0057] S22, disposing a sacrificial layer 2 on the upper surface of the motherboard 1, such as Image 6 shown;

[0058] S23, disposing a metal layer 3 on the upper surface of the sacrificial layer 2, such as Figure 7 shown;

[0059] S24, peeling off the metal layer 3 from the sacrificial layer 2 to obtain a metal substrate with a smooth surface, the metal substrate having a pattern structure complementary to the pattern structure on the motherboard 1, such as Figure 8 shown.

[0060] In the above embodiments 1 and 2, the selection and setting of the motherboard, the setting of the sacrificial layer, the setting of the metal layer, and the method of se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com