Abab-type multilayer lithium-ion battery separator with thermal shutdown function and preparation method thereof

A lithium-ion battery, thermal shutdown technology, applied to battery components, separators/films/diaphragms/spacers, circuits, etc., can solve the residual stress of porous films, poor thermal dimensional stability, and reduce the diaphragm Thermal shrinkage and other issues, to achieve effective thermal shutdown function, improve thermal stability, uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

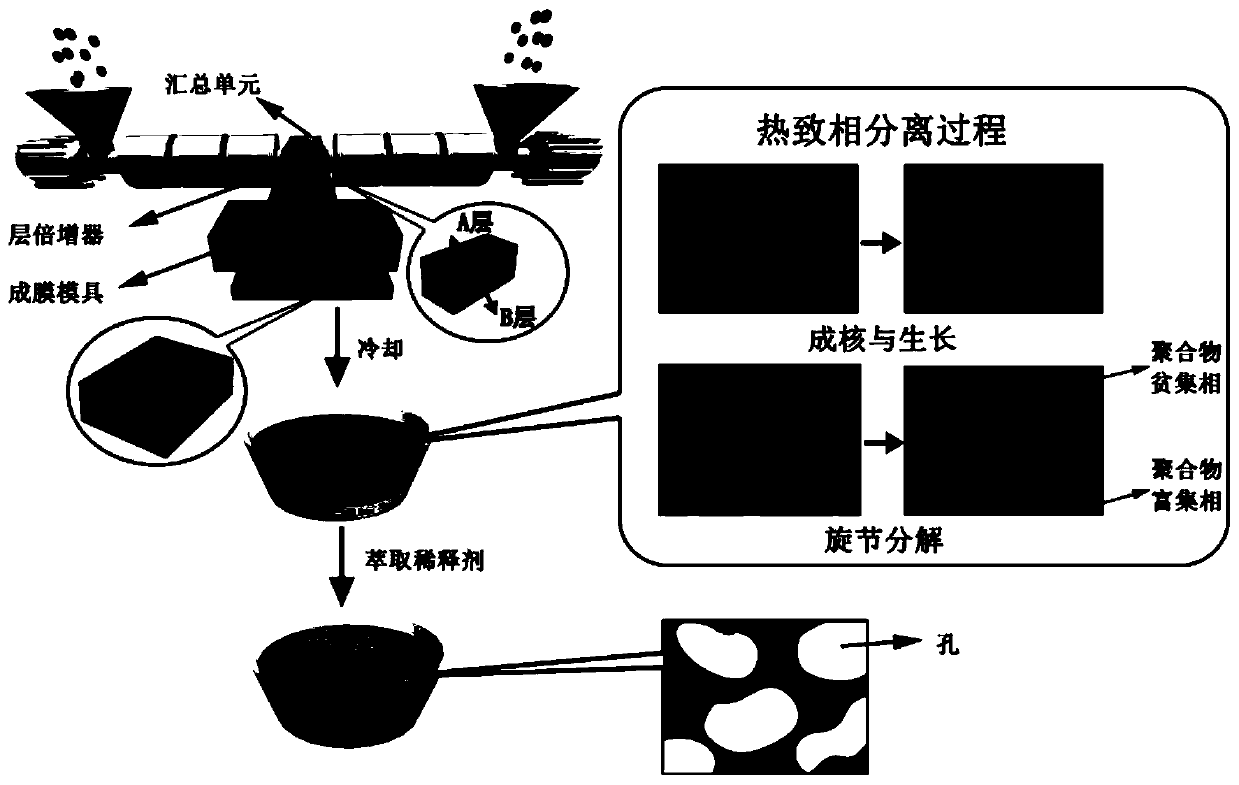

[0051] Example 1: Using solid paraffin as diluent and n-hexane as extractant, microlayer co-extrusion technology and thermal phase separation method were used to prepare a polypropylene / polyethylene multilayer porous diaphragm with uniform layer thickness.

[0052] Specific steps are as follows:

[0053] (1) Preparation of polypropylene / polyethylene masterbatch

[0054] Before micro-layer co-extrusion, solid paraffin is pre-dispersed in polypropylene resin and polyethylene resin, and the above components are pre-mixed, and put into a twin-screw extruder to prepare a masterbatch of polypropylene resin and polyethylene resin ;

[0055] Its raw material composition is counted as in parts by mass:

[0056] 45 parts of polypropylene resin,

[0057] 45 parts of polyethylene resin,

[0058] 110 parts of solid paraffin,

[0059] 180 parts of n-hexane;

[0060] (2) Preparation of polypropylene resin / polyethylene resin multilayer porous separator

[0061] Two-component micro-laye...

Embodiment 2

[0072] Example 2: Polypropylene / polyethylene multilayer porous diaphragms with different layer thicknesses were prepared by using solid paraffin as diluent and petroleum ether as extractant by microlayer coextrusion technology and thermal phase separation method.

[0073] Specific steps are as follows:

[0074] (1) Preparation of polypropylene resin / polyethylene resin masterbatch

[0075] Before the micro-layer co-extrusion, the diluent is pre-dispersed in the polypropylene resin and polyethylene resin, and the above components are pre-mixed, and put into the twin-screw extruder to prepare the masterbatch of polypropylene resin and polyethylene resin ;

[0076] Its raw material composition is counted as in parts by mass:

[0077] 45 parts of polypropylene resin,

[0078] 70 parts of polyethylene resin,

[0079] 150 parts of solid paraffin

[0080] 190 parts of petroleum ether;

[0081] (2) Preparation of polypropylene resin / polyethylene resin multilayer porous separator ...

Embodiment 3

[0083] Example 3: Using liquid paraffin as diluent and chloroform as extractant, microlayer co-extrusion technology and heat-induced phase separation method were used to prepare ethylene-propylene copolymer / polyethylene oxide multilayer porous diaphragm.

[0084] Specific steps are as follows:

[0085] (1) Preparation of ethylene-propylene copolymer / polyethylene oxide masterbatch

[0086] Before micro-layer co-extrusion, the diluent is pre-dispersed in polyethylene oxide and ethylene-propylene copolymer, and the above components are pre-mixed, and then put into a twin-screw extruder to prepare polyethylene oxide and ethylene-propylene copolymer material masterbatch;

[0087] Its raw material composition is counted as in parts by mass:

[0088] 80 parts of ethylene-propylene copolymer,

[0089] 80 parts of polyethylene oxide,

[0090] 80 parts of liquid paraffin,

[0091] 130 parts of chloroform;

[0092] (2) Preparation of ethylene-propylene copolymer / polyethylene oxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com