A kind of multi-layer lithium-ion battery diaphragm material and preparation method thereof

A technology of multi-layer film and hybrid material, applied in the field of lithium-ion battery separator material and its preparation, can solve the problems of inability to exert the nanometer properties of attapulgite, and achieve excellent thermal dimensional stability, improved electrochemical performance, and ionic conductivity. rate increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

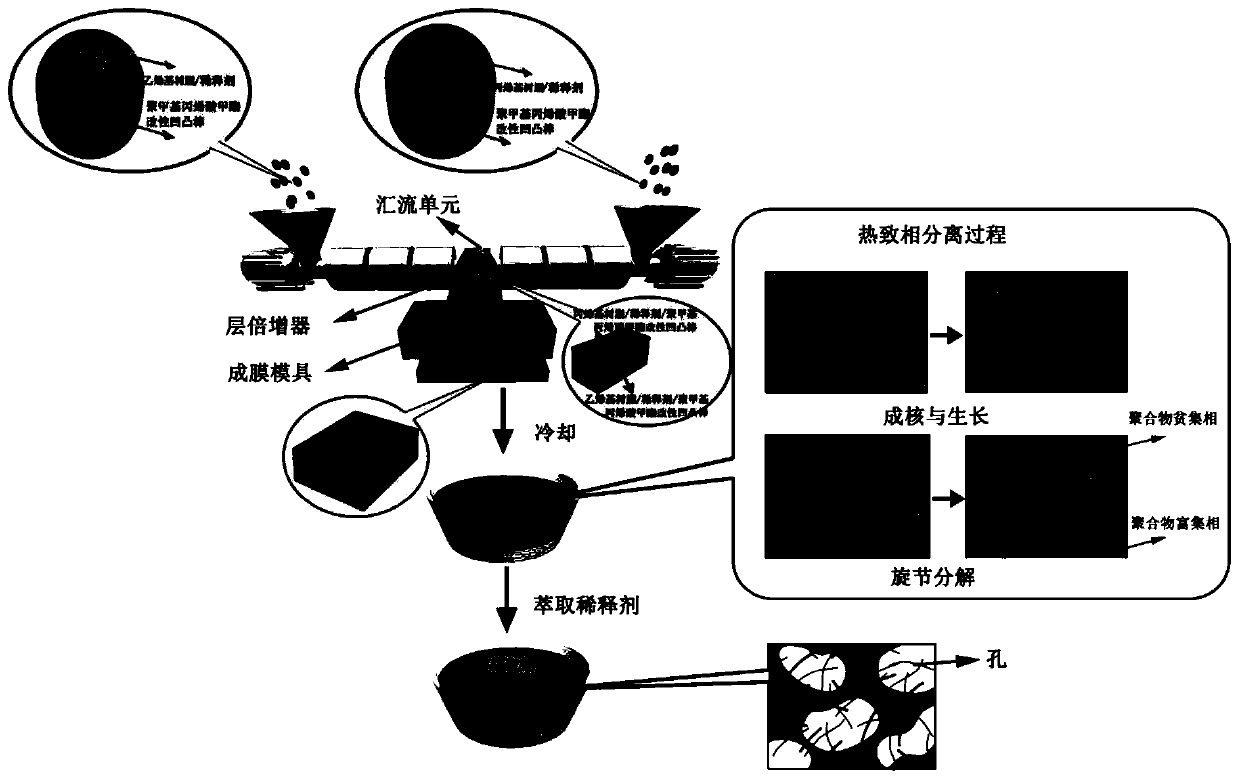

[0069] Example 1: Using solid paraffin as diluent and petroleum ether as extractant, microlayer co-extrusion technology and heat-induced phase separation method were used to prepare polyethylene / polypropylene multilayer porous diaphragm. Specific steps are as follows:

[0070] (1) Preparation of polyethylene / polypropylene masterbatch

[0071] Before micro-layer co-extrusion, the solid paraffin is pre-dispersed in polyethylene resin and polypropylene resin, and the above components are pre-mixed, and put into a twin-screw extruder to prepare a masterbatch of polyethylene resin and polypropylene resin .

[0072] The raw material composition of the masterbatch of polyethylene resin is calculated in parts by mass:

[0073] 45 parts of polyethylene resin,

[0074] 55 parts of solid paraffin.

[0075] The raw material composition of the masterbatch of polypropylene resin is calculated in parts by mass:

[0076] 45 parts of polypropylene resin,

[0077] 55 parts of solid paraff...

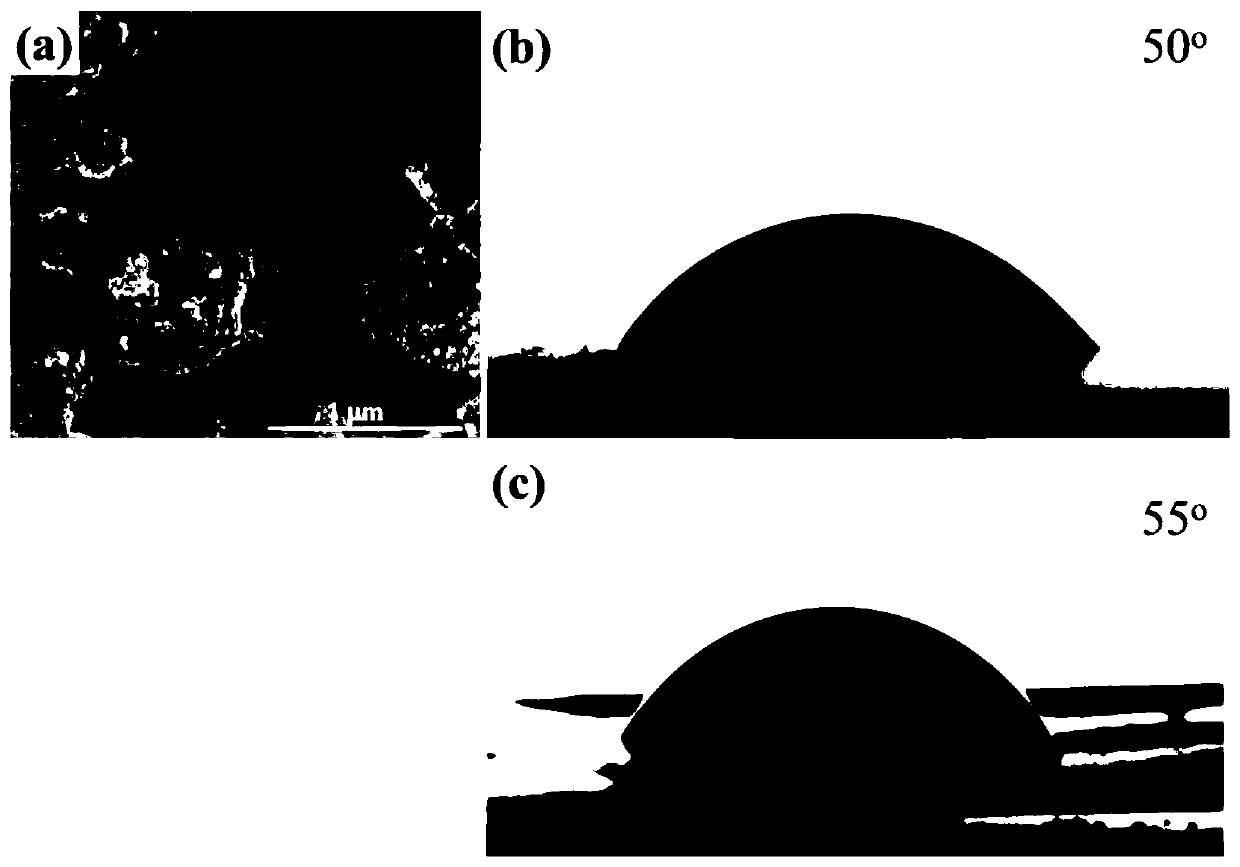

Embodiment 2

[0092] Example 2: Using solid paraffin as diluent and petroleum ether as extractant, polyethylene / polypropylene (6% polymethyl methacrylate modified attapulgite) was prepared by micro-layer co-extrusion technology and thermal phase separation method Layer porous membrane. Specific steps are as follows:

[0093] (1) Preparation of polymethyl methacrylate modified attapulgite

[0094] Attapulgite in 1 mol L -1Stir and react in hydrochloric acid for 3 h, then let stand for 12 h, filter and wash until neutral, dry and pulverize, weigh 1 part and disperse in xylene, vibrate ultrasonically for 1 h, add 1 part of 3-aminopropyl triethoxy base silane, heated to 80°C and stirred at constant temperature for 6 h, the product was filtered, washed and dried, crushed and passed through a 200-mesh sieve, and the product was designated as ATP-APTES. Weigh 1 part of ATP-APTES and disperse in ethyl acetate, and oscillate ultrasonically for 2 h; weigh 3 parts of azodicyanovaleric acid and diss...

Embodiment 3

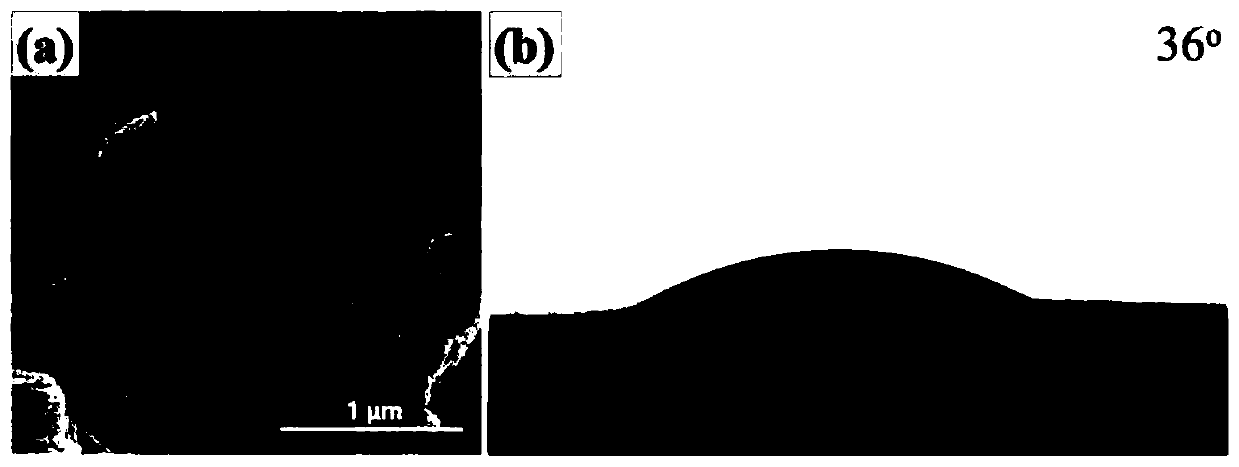

[0108] Example 3: Using solid paraffin as diluent and petroleum ether as extractant, polyethylene / polypropylene (9% polymethyl methacrylate modified attapulgite) was prepared by micro-layer co-extrusion technology and thermal phase separation method Layer porous membrane. Specific steps are as follows:

[0109] (1) Preparation of polymethyl methacrylate modified attapulgite

[0110] Attapulgite in 1 mol L -1 Stir in hydrochloric acid for 8 hours and let stand for 12 hours, filter and wash until neutral, dry and pulverize, weigh 2 parts and disperse in xylene, ultrasonically shake for 1 hour, add 2 parts of 3-aminopropyl triethoxy base silane, heated to 80°C and stirred at constant temperature for 6 h, the product was filtered, washed and dried, crushed and passed through a 200-mesh sieve, and the product was designated as ATP-APTES. Weigh 2 parts of ATP-APTES and disperse in ethyl acetate, and ultrasonically shake for 3 h; weigh 5 parts of azodicyanovaleric acid and dissolv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com