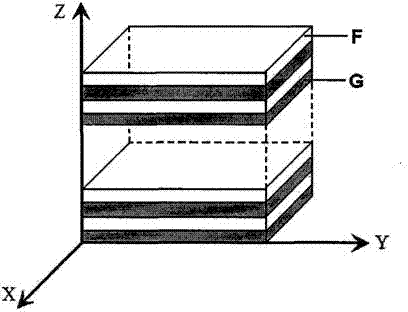

A polymer-based wide temperature range damping composite material and its preparation method

A damping composite material and polymer-based technology, which is applied to the composite material of the wide-temperature-domain constrained damping structure, and the polymer-based wide-temperature-domain damping composite material field, can solve the problems of low number of layers, complicated process, inconvenient use, etc. Achieve the effect of improving damping performance, increasing interfacial friction and slip, and increasing loss factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

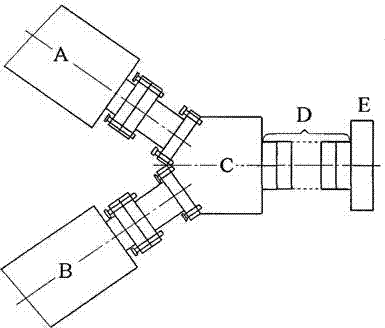

[0032](1) Select 100 parts of chlorinated butyl rubber (by weight) with damping properties as the matrix of the polymer-based rubber damping layer, add 30 parts of carbon black (filler), 35 parts of petroleum resin (tackifying resin), 10 parts of white oil (operation oil), 1 part of stearic acid (lubricant), and 1 part of p-phenylenediamine anti-aging agent were kneaded on a double-roller mill at room temperature for 8 minutes to produce a damping rubber compound. The glass transition temperature of the compound is -15°C, that is, between -60°C and 10°C, the maximum loss factor is 1.20, that is, greater than 0.75, and the effective damping temperature range (Tanδ>0.5) is -36°C to 21°C, that is, the width of the effective damping temperature range is greater than 40°C, which meets the requirements for the performance of the polymer-based rubber damping layer material in the claims.

[0033] (2) Select fully dry polyvinyl acetate plastic as the matrix of the polymer-based plasti...

Embodiment 2

[0039] (1) Select 100 parts of fully dry nitrile rubber (by weight) as the matrix of the polymer-based rubber damping layer, add 30 parts of carbon black (filler), 10 parts of white oil (operation oil), stearic acid ( Lubricant) 1 part, hindered phenol (AO-60) 25 parts, after stirring and mixing, add to the extruder to granulate to obtain the damping layer material. The glass transition temperature of the damping layer material is -9°C, that is, between -60°C and 10°C, the maximum loss factor is 1.2, that is, greater than 0.75, and the effective damping temperature range (Tanδ>0.5) is -29°C~ 24°C, that is, the width is greater than 40°C, which meets the requirements for the performance of the polymer-based rubber damping layer material in the claims.

[0040] (2) Select 100 parts of fully dry polyvinyl acetate (by weight), add 12 parts of benzyl alcohol (plasticizer), stir and mix, then add to an extruder to mix and granulate to obtain a plastic constrained layer material. Af...

Embodiment 3

[0046] (1) Select 100 parts of chlorinated butyl rubber (by weight) as the matrix of the polymer-based rubber damping layer, add 35 parts of carbon black (filler), 20 parts of petroleum resin (tackifying resin), white oil (operation Oil) 10 parts, stearic acid (lubricant) 1 part, p-phenylenediamine anti-aging agent 1 part, and kneaded on a double-roll mill at room temperature for 8 minutes to produce a damping rubber compound. The glass transition temperature of the damping layer material is -10°C, that is, between -60°C and 10°C, the maximum loss factor is 1.25, that is, greater than 0.75, and the effective damping temperature range (Tanδ>0.5) is -33°C to 25°C, that is, the width of the effective damping temperature range is greater than 40°C, which meets the requirements for the performance of the polymer-based rubber damping layer material in the claims.

[0047] (2) Select 100 parts of polymethyl methacrylate (by weight) as the matrix of the polymer-based plastic constrain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com