Self-adhesive gradient damping material and preparation method thereof

A damping material and self-adhesive technology, applied in the field of self-viscous gradient damping materials and their preparation, can solve the problems of high cost, complex synthesis process, difficult solvent removal, etc., and achieve the improvement of compatibility, dispersion and uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

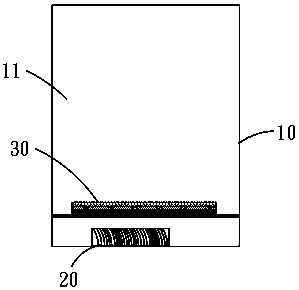

Image

Examples

Embodiment Construction

[0015] In order to further understand the features, technical means and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

[0016] A self-adhesive gradient damping material of the present invention comprises, in parts by weight: 90-110 parts of butyl rubber, 50-100 parts of first reinforcing filler, 100-150 parts of liquid tackifier and 50-150 parts of wrapped magnetic filler , the wrapped magnetic filler is composed of a magnetic material, carboxylated styrene-butadiene latex, a second reinforcing filler and a vulcanization aid, wherein the weight ratio of the magnetic material to carboxylated styrene-butadiene latex is 1:1.5~2.0, and the second reinforcing filler It accounts for 2-5wt% of the total weight of the wrapped magnetic filler, and the vulcanization aid accounts for 1-3wt% of the total weight of the wrapped magnetic filler.

[0017] In one of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com