Wide temperature range acrylate rubber-based nano-silica damping material and preparation method thereof

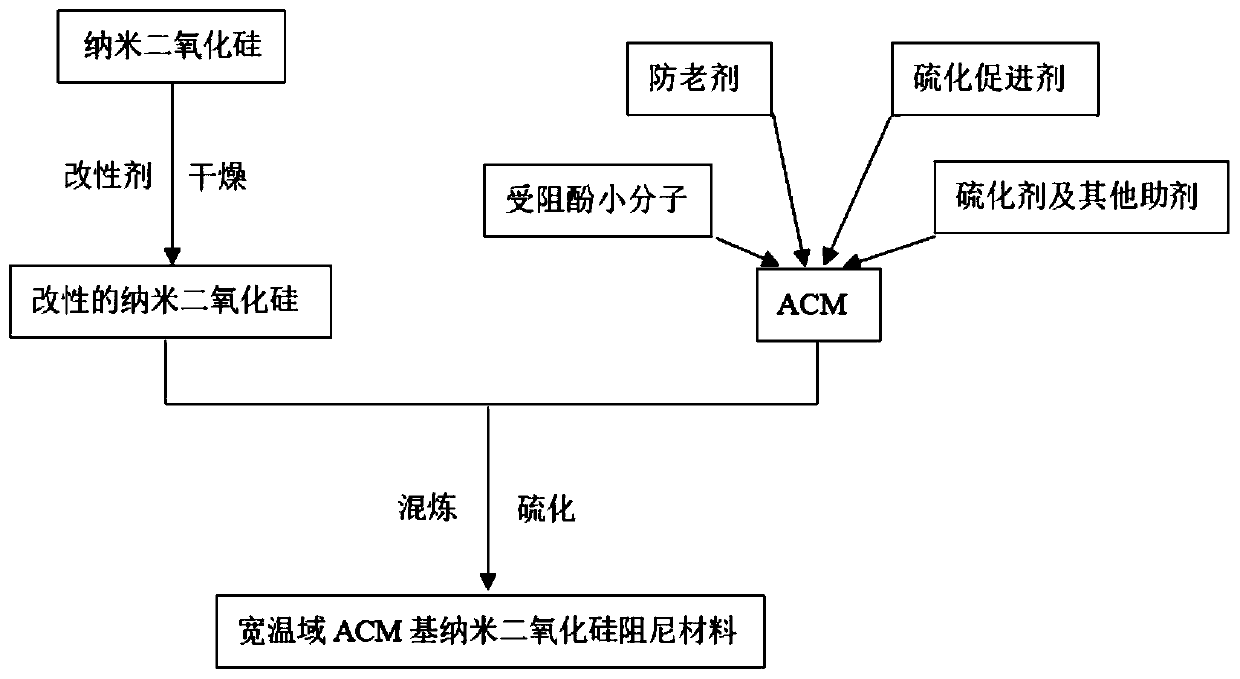

A technology of nano-silica and acrylate, which is applied in the field of damping material preparation, can solve the problems of low application value, failure to take into account high damping performance, and deterioration of material mechanical properties, so as to improve mechanical properties, improve damping performance, and expand The effect of effectively damping the temperature domain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1: Put 60g of nano-silica in a beaker, add ethanol, ultrasonically disperse at 40°C for 1 hour, then transfer to a three-necked flask, mechanically stir at 55°C and slowly add 10g of dodecyltrimethoxysilane, in the reflux state After stirring for 6 hours, the mixture was cooled and filtered, and the filter cake was rinsed with ethanol, and vacuum-dried at 60° C. to obtain modified nano-silica;

[0027] Step 2: Mix 100 parts of ACM rubber, 60 parts of hindered phenol small molecule AO-80, 60 parts of modified nano silicon dioxide, 1 part of stearic acid, 1 part of vulcanization accelerator D, 2 parts of antioxidant 4010NA, 2 parts The processing aid RL210 and 1 part of sulfur were mixed, and then thinned out, and the positive vulcanization time was measured with a vulcanization meter, and the wide temperature range ACM-based nano-silica damping material was obtained by vulcanization according to the positive vulcanization time.

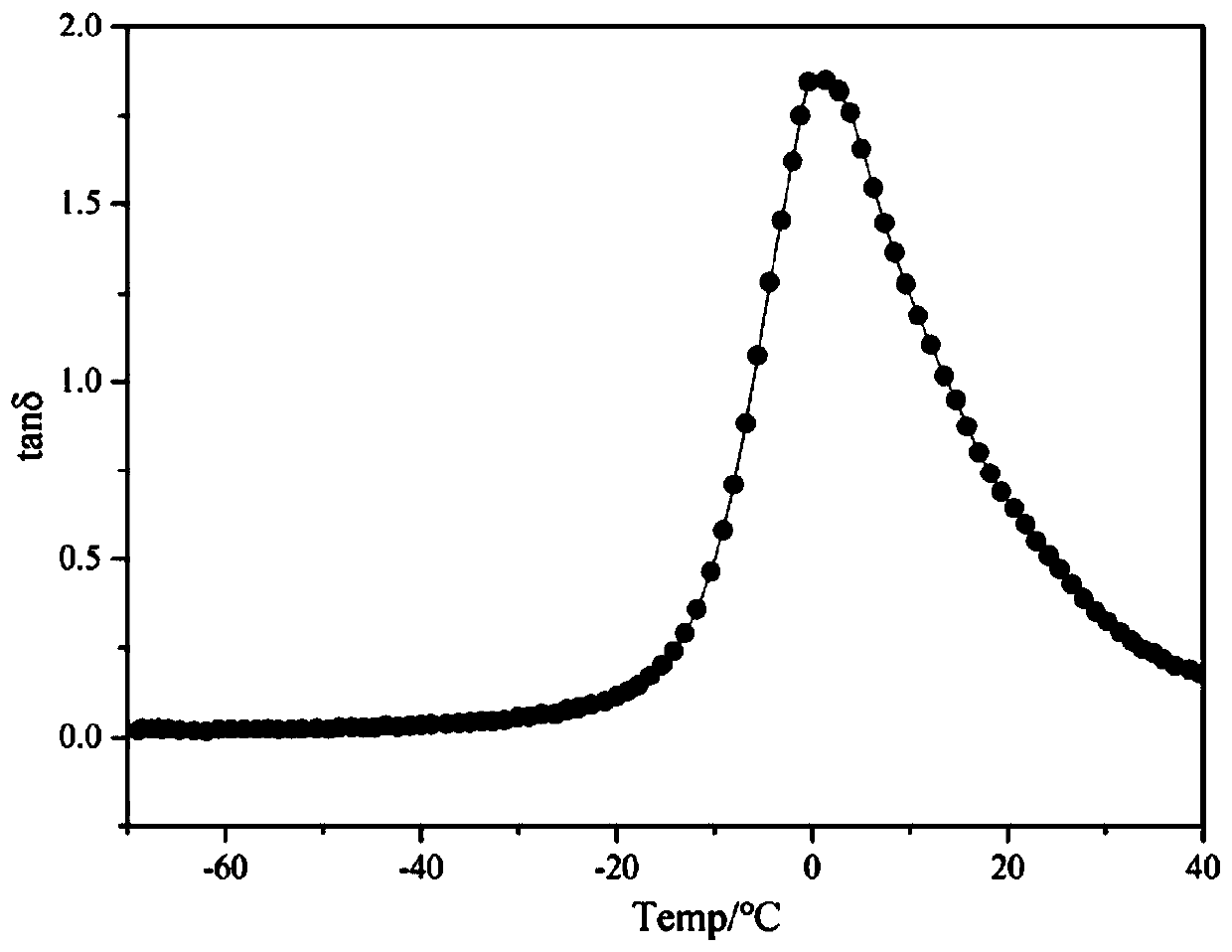

[0028] The DMA diagram of the wide t...

Embodiment 2

[0030] Repeat embodiment 1 method, in step one, 40g nano silicon dioxide, modifier is 5g dodecyltrimethoxysilane and 5g gamma-aminopropyl triethoxysilane; In step two, mixing formula is 100 parts of ACM rubber, 50 parts of hindered phenol small molecule AO-80, 40 parts of modified nano silica, 3 parts of stearic acid, 2 parts of vulcanization accelerator D, 4 parts of vulcanization accelerator DOTG, 2 parts of antioxidant 4010NA , 3 parts of anti-aging agent RD, 1 part of processing aid RL210, 3 parts of processing aid WS280, 4 parts of sulfur. The effective damping temperature range of the obtained damping material is -11.2°C to 32.3°C, and the width of the temperature range reaches 43.5°C. The tensile strength is 8.87MPa, and the tear strength is 24.52kN / m.

Embodiment 3

[0032] Repeat Example 1 method, in step one, 40g nano silicon dioxide, modifying agent is 7g octadecyltrimethoxysilane and 5g gamma-methacryloxypropyl trimethoxysilane; In step two, The mixing formula is 100 parts of ACM rubber, 30 parts of hindered phenol small molecule AO-60, 40 parts of modified nano silicon dioxide, 2 parts of stearic acid, 2 parts of vulcanization accelerator DOTG, 3 parts of antioxidant RD, 2 parts of processing Auxiliary WB222, 1 part of processing aid WS280, 3 parts of sulfur. The effective damping temperature range of the obtained damping material is -10.6°C to 31.8°C, and the width of the temperature range reaches 42.4°C. The tensile strength is 8.54MPa, and the tear strength is 24.09kN / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Damping temperature range | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com