Patents

Literature

149results about How to "Affordable price" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

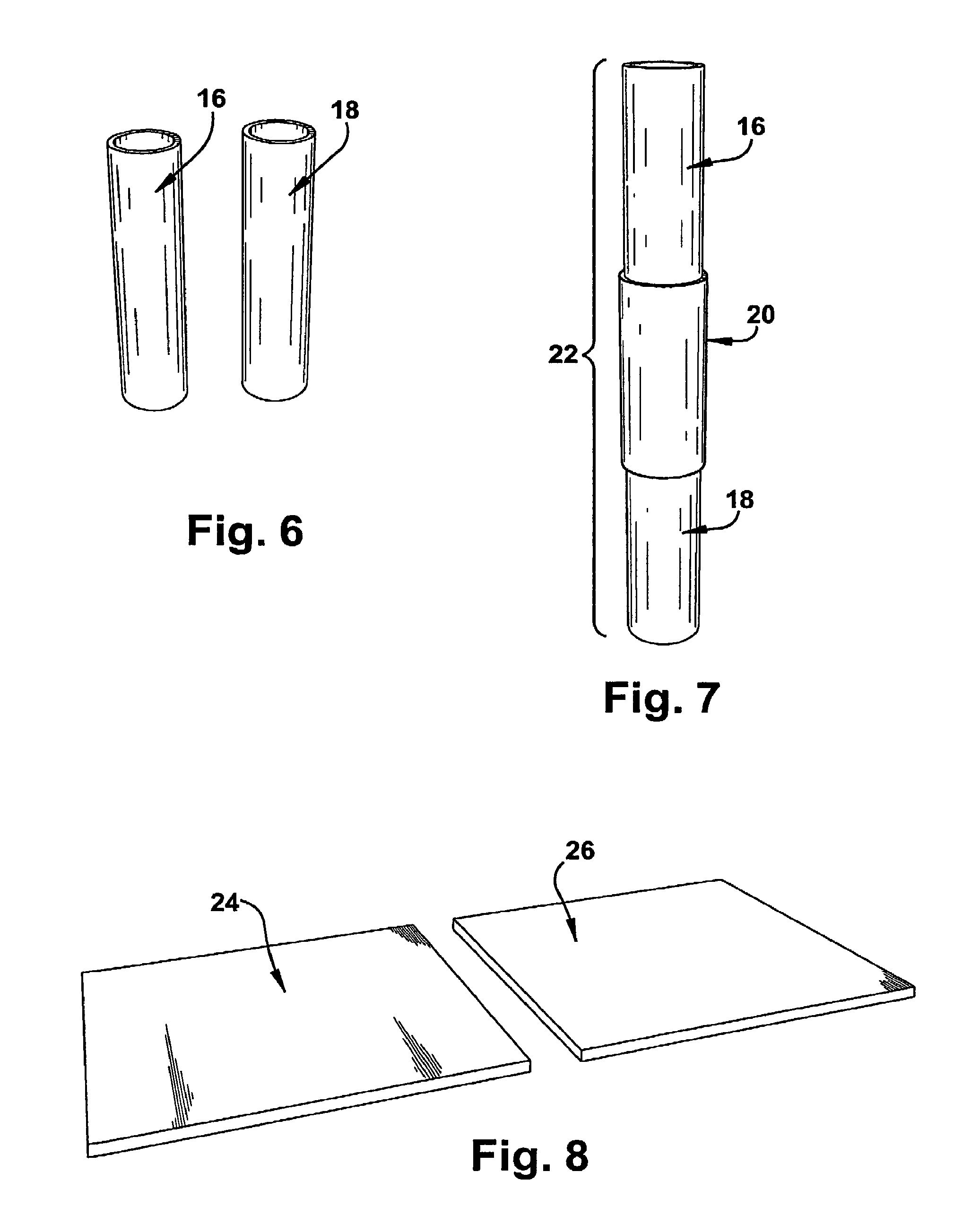

Integrated electromechanical arrangement and method of production

ActiveUS20050002168A1Improve customizabilityFacilitates upgradabilityInput/output for user-computer interactionContact surface shape/structureEngineeringInjection moulding

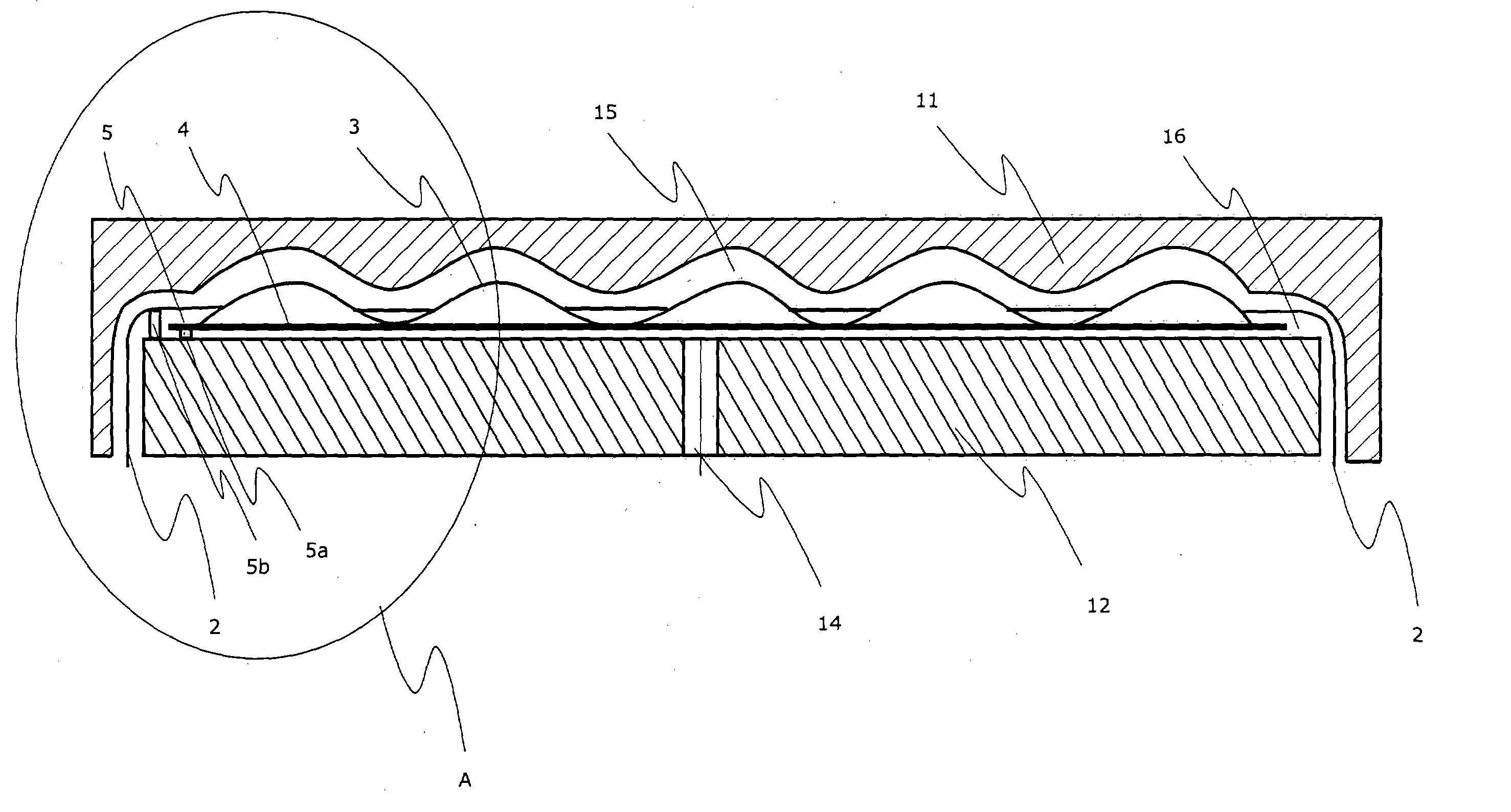

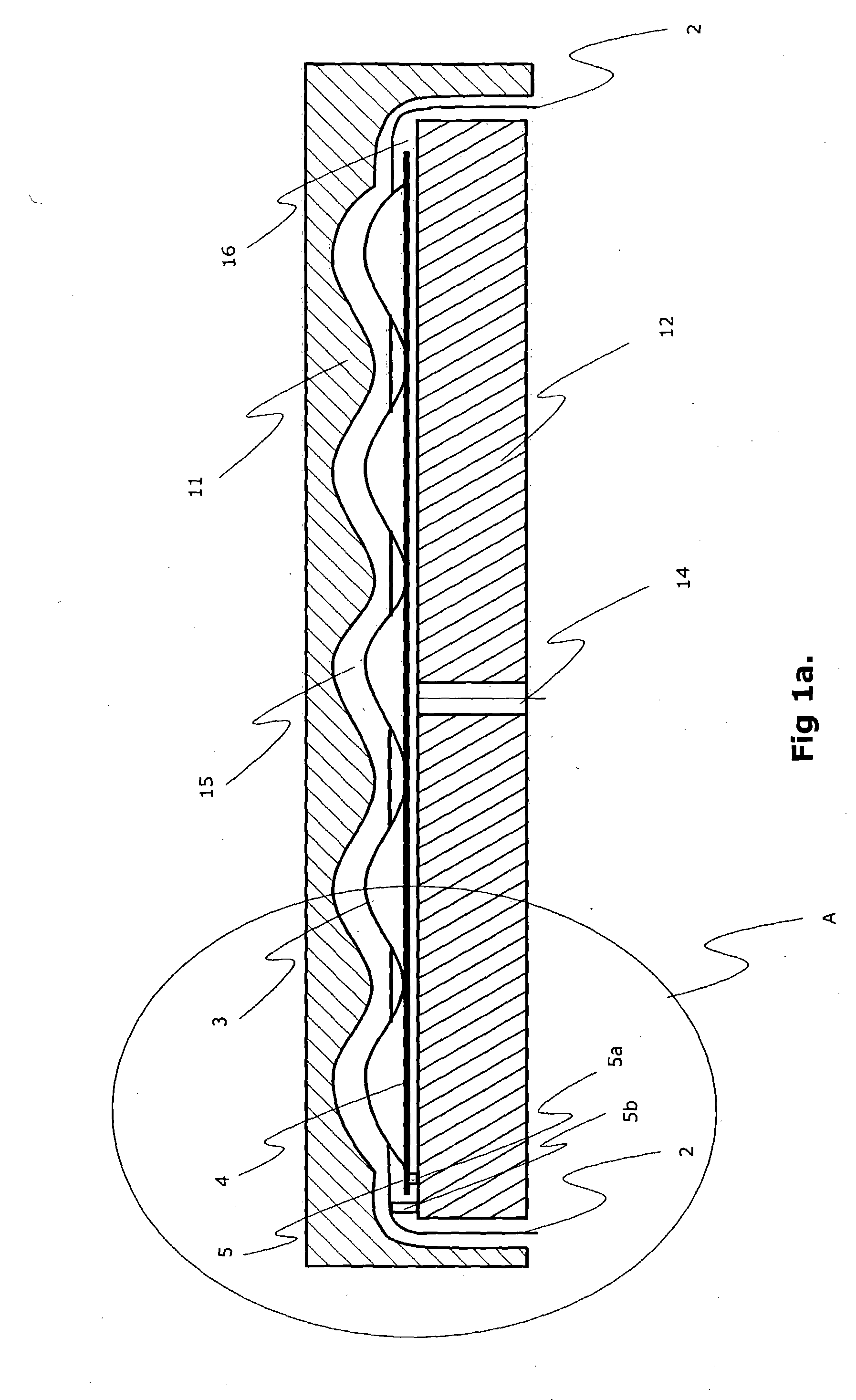

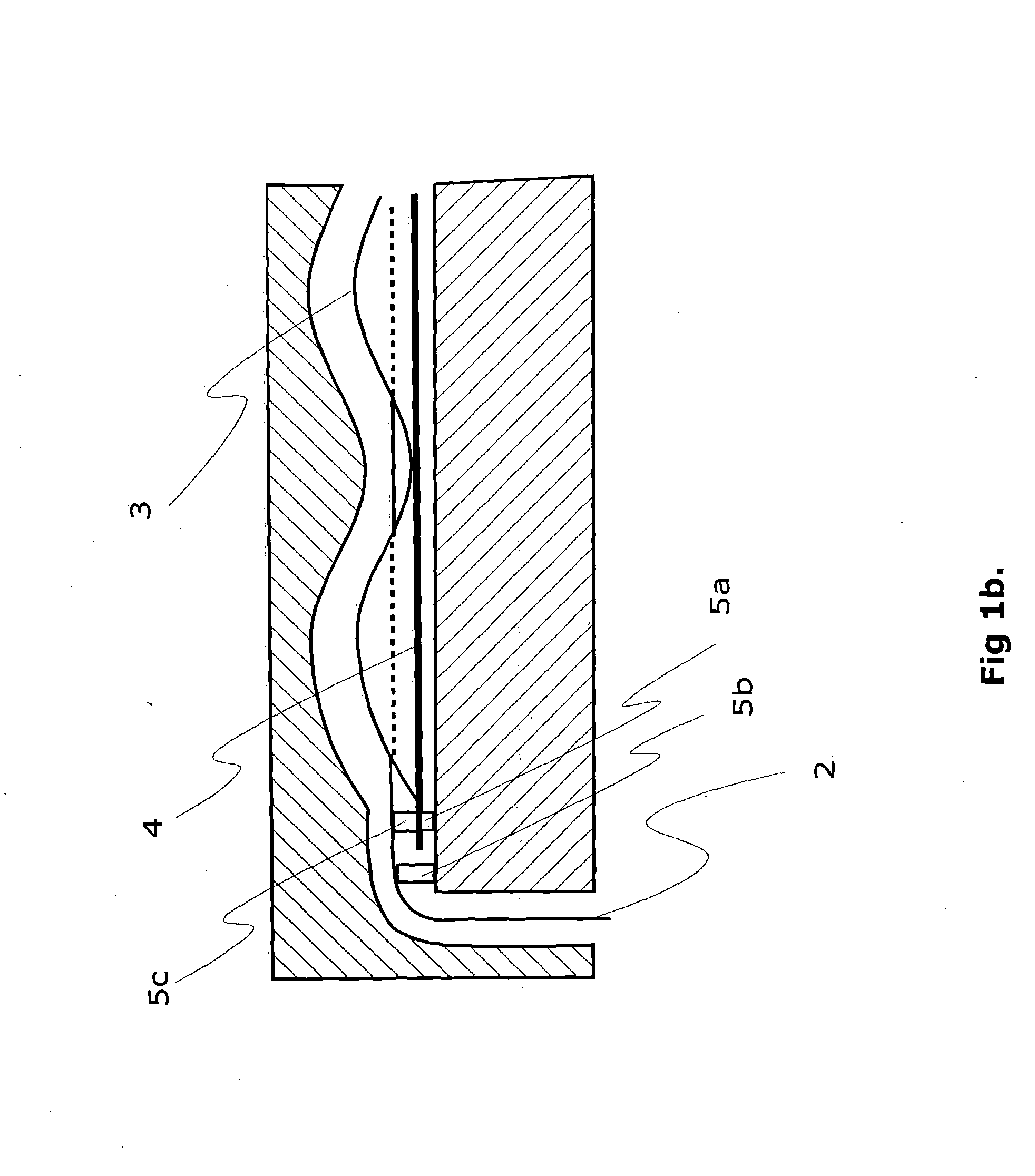

It is an object of the invention to provide a electromechanical structure comprising an input device and a printed wired board (3, 4), which structure is advantages in terms of manufacturing and offers freedom to the layout design of the printed wired board, the user interface as well as the appearance of the device itself. It is also an object of the invention to provide a electromechanical structure that is compact and facilitates the customizability and upgradability with a new electronic functionality without any need for modifications to the main electronics of the device. This is achieved by integrating the electromechanical assembly with the mechanical cover part of the electronic device by using an injection moulding process to compose an integrated combination (113) which is detachable from the electronic device. More precisely the objects of the invention are achieved by combining the injection mould technologies with the printing of electronic wired boards.

Owner:NOKIA TECHNOLOGLES OY

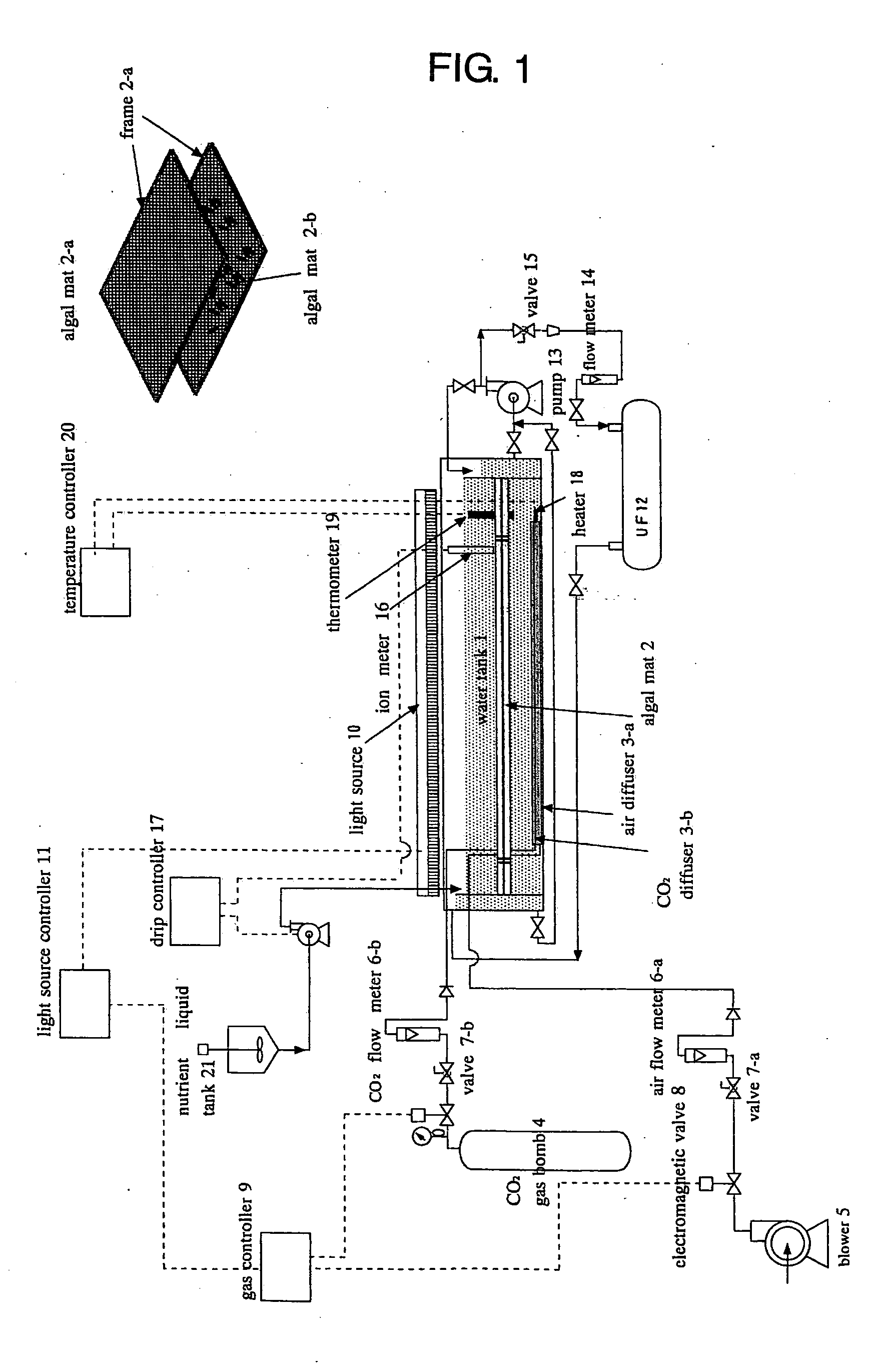

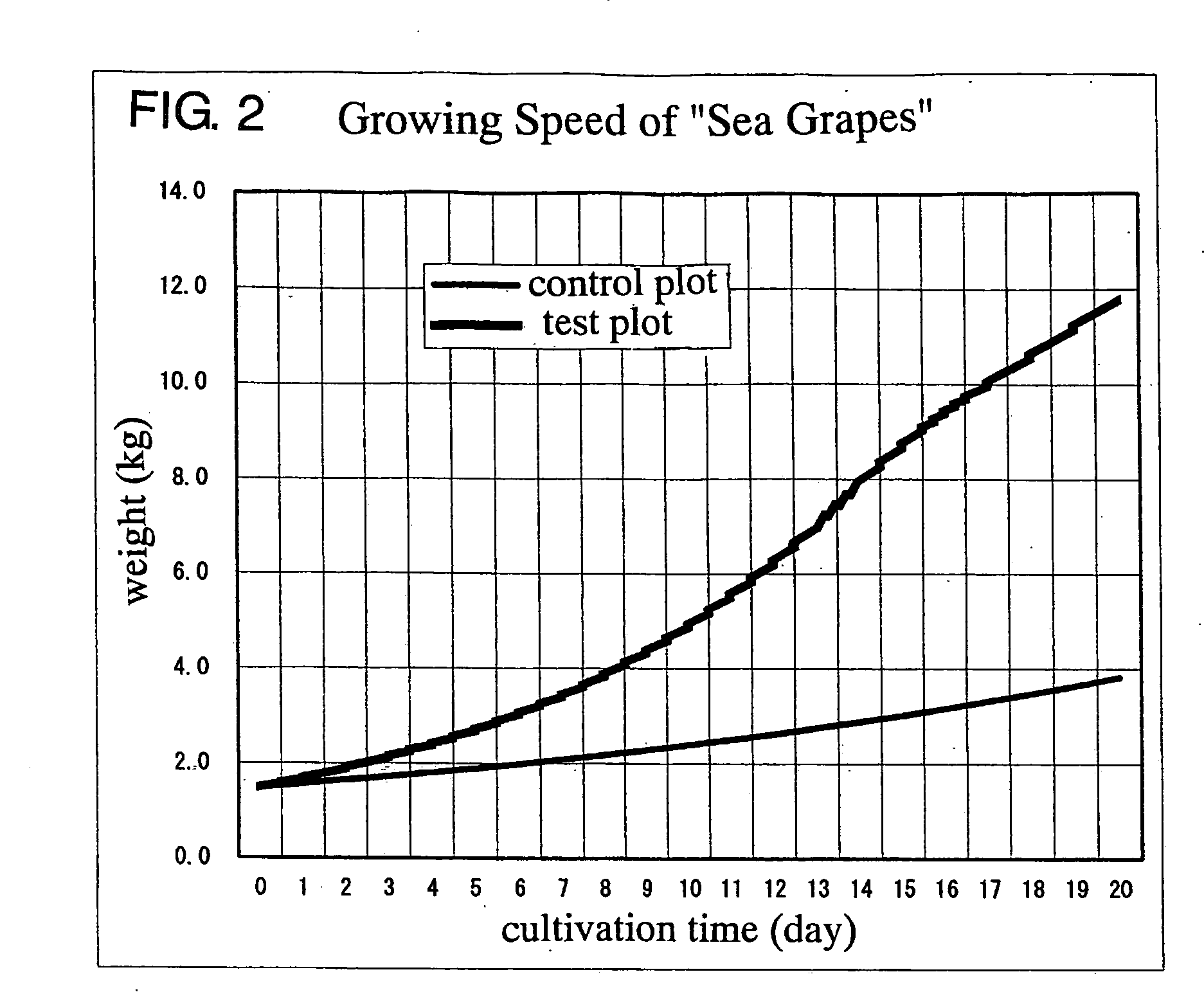

Algae intensive cultivation apparatus and cultivation method

InactiveUS20090151240A1Quality improvementDifficult to achieveAlgae productsUnicellular algaeLight irradiationIlluminance

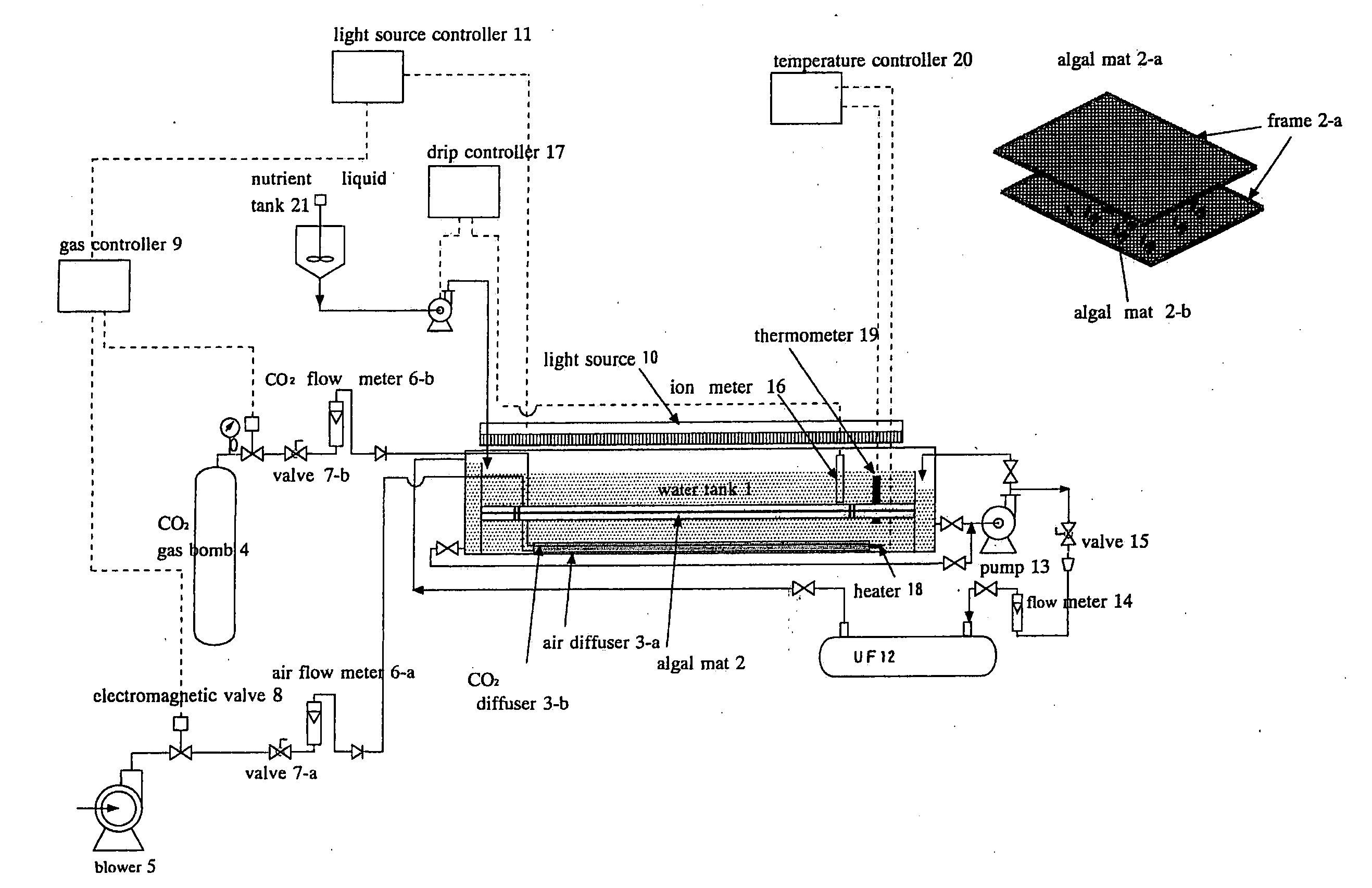

An apparatus for carrying out algae intensive-cultivation while conducting an environmental control most suitable for growth of algae in an artificial environment including dissolved gas, light, temperature, nutrient source and sanitary atmosphere; and a method of intensive cultivation therewith. There is provided an apparatus comprising water tank (1) for cultivating unialgae as seedling; gas dissolution diffusion units (3-a, 3-b) for achieving dissolution of a gas in a culture water of the water tank; light irradiation units (10, 11) for irradiating the water tank with light whose wavelength and illuminance are controlled; temperature control unit (20) for controlling the temperature of the culture water of the water tank so as to fall within a given range; nutrient salts adding unit (17) for adding to the water tank a nutrient liquid containing an essential nutrient source vital to the growth of algae; purification unit (12) for carrying out bacterial eradication and filtration of the culture water of the water tank; and meters for control of the above units.

Owner:KAGOSHIMA UNIV

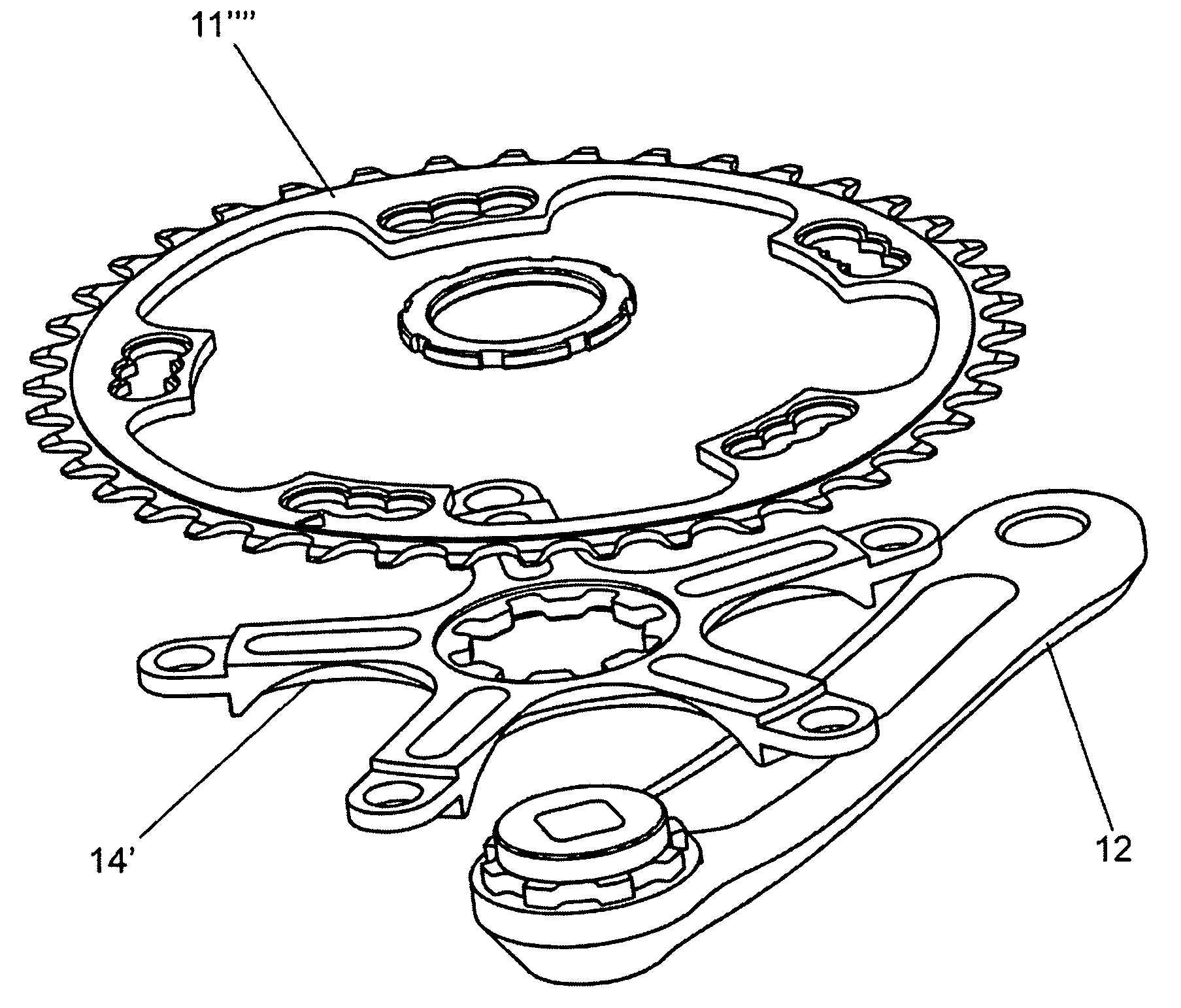

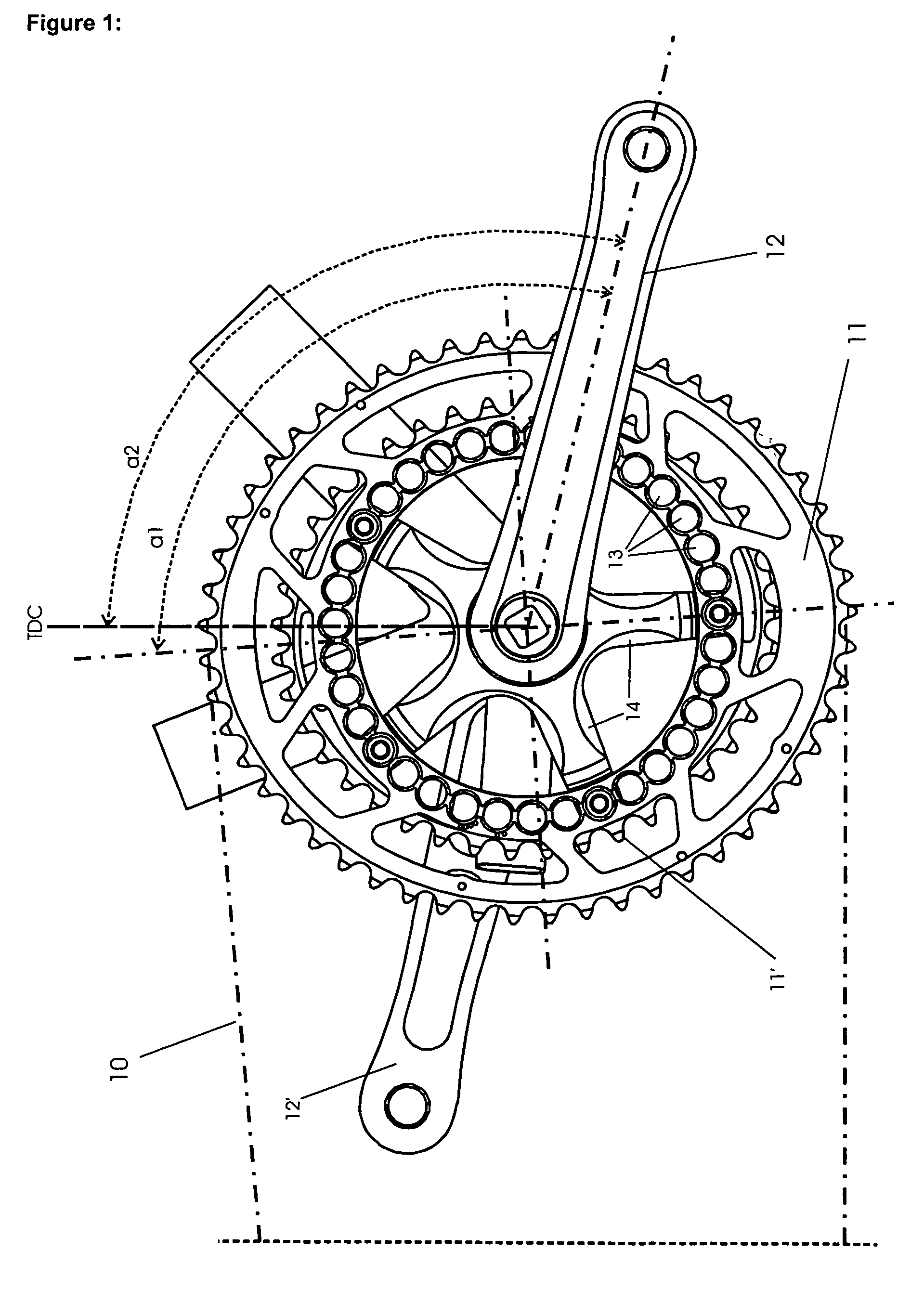

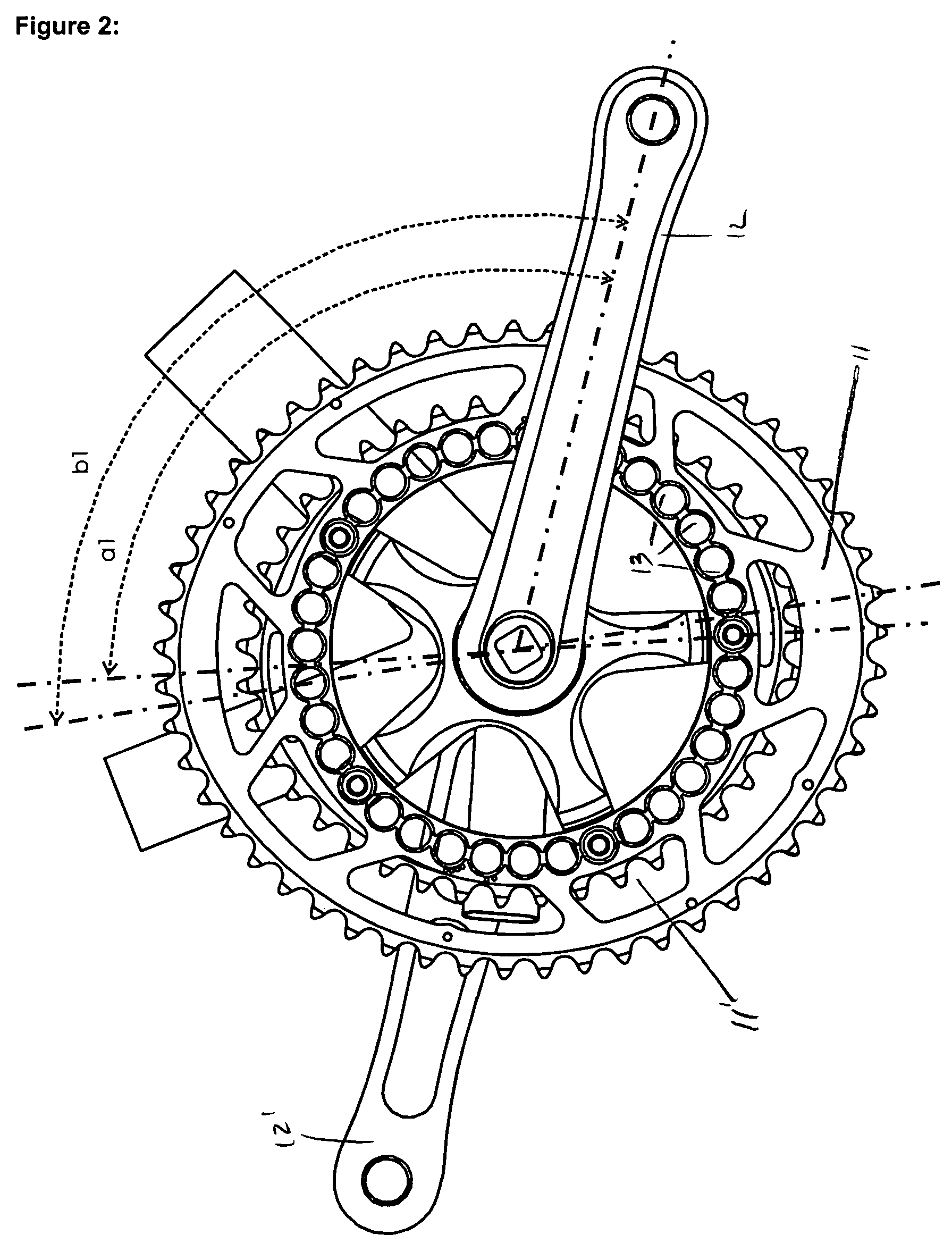

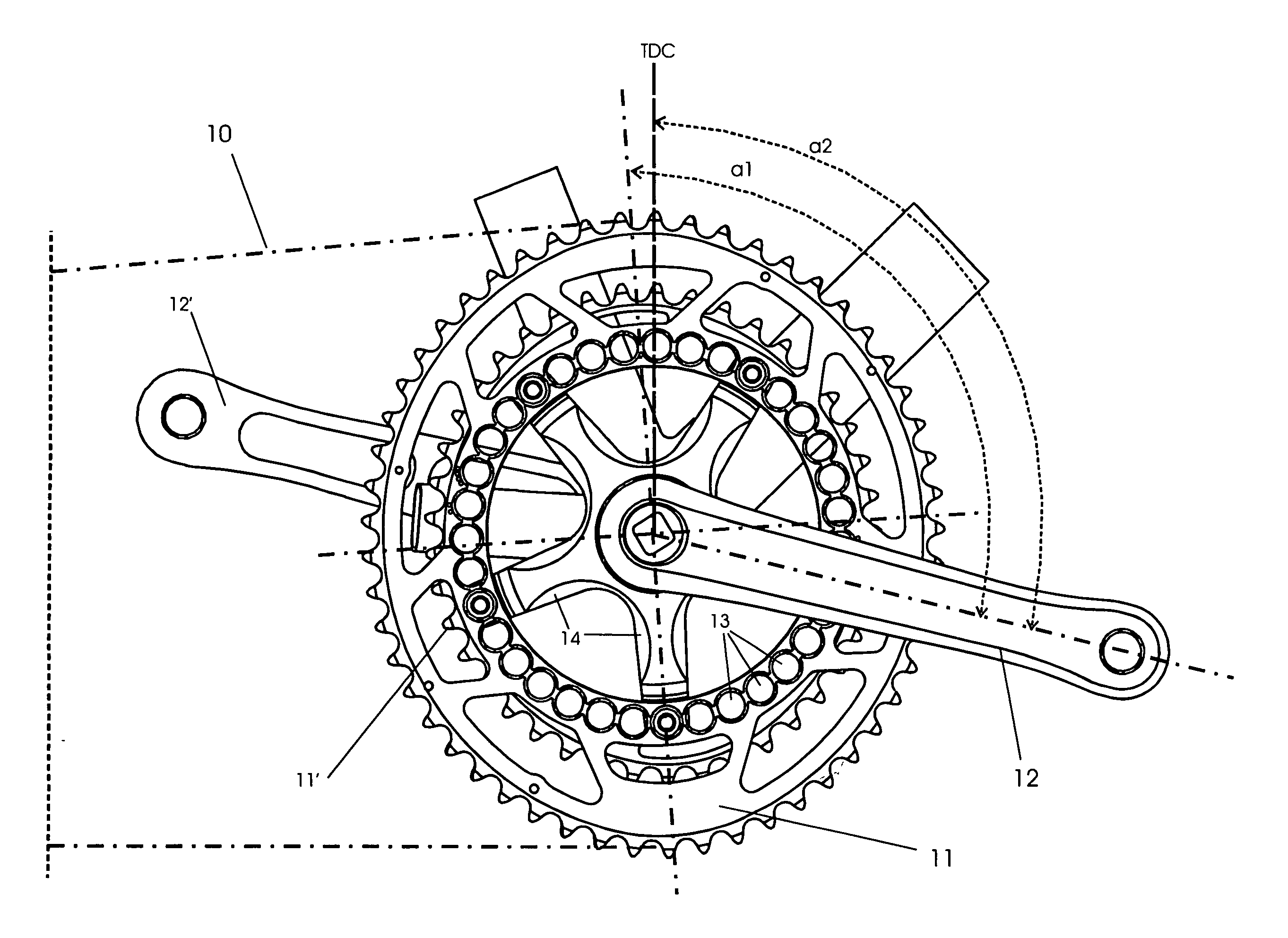

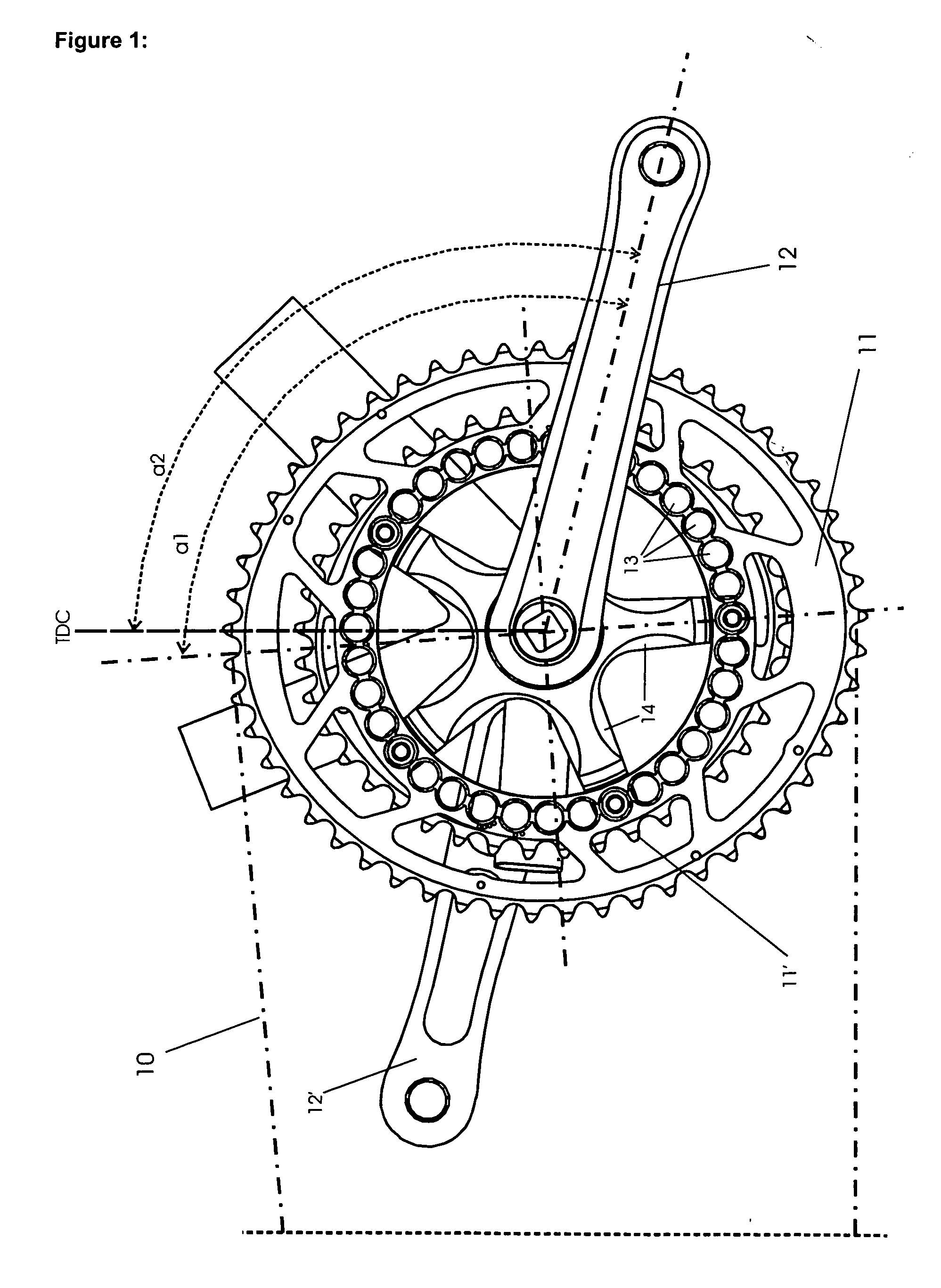

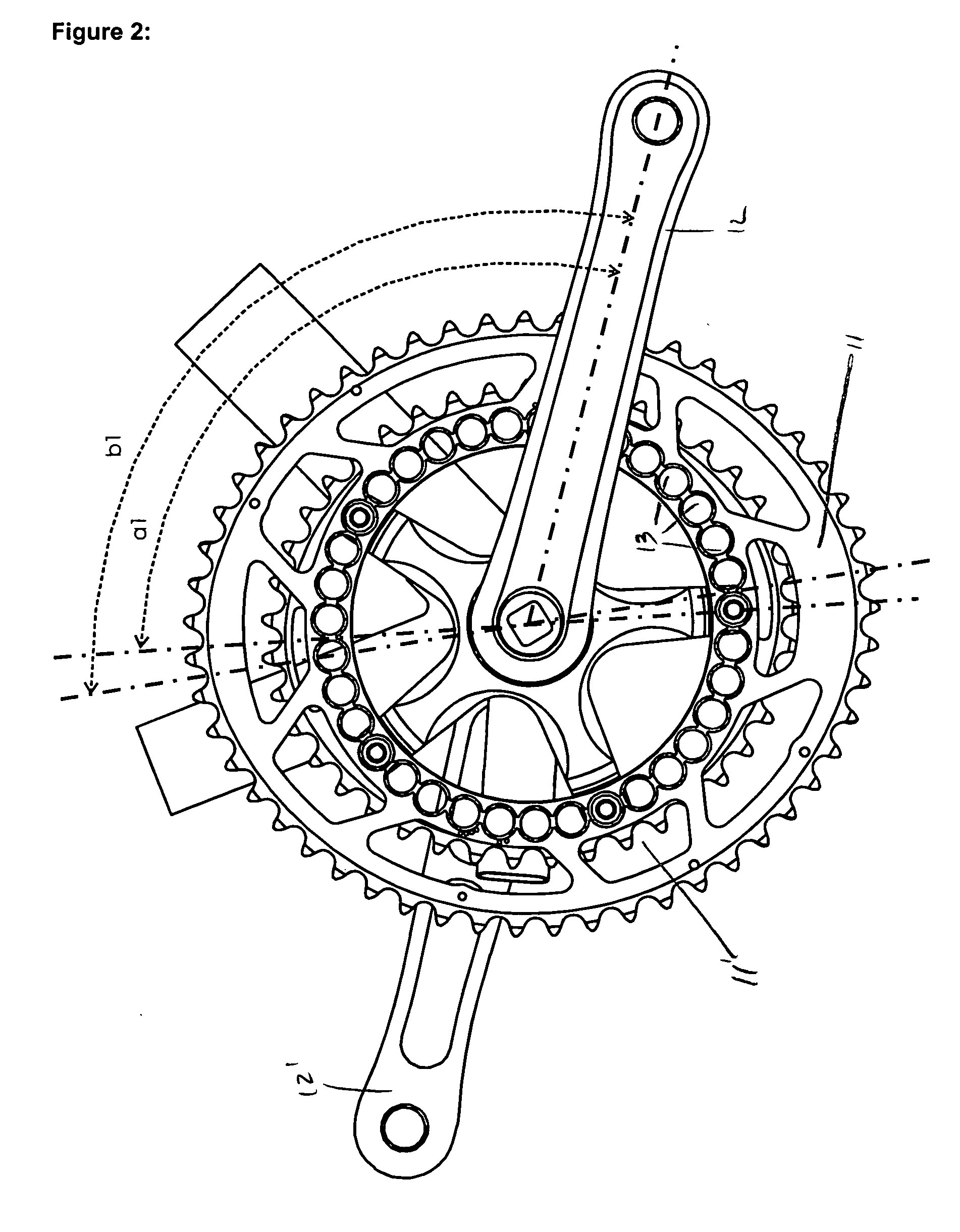

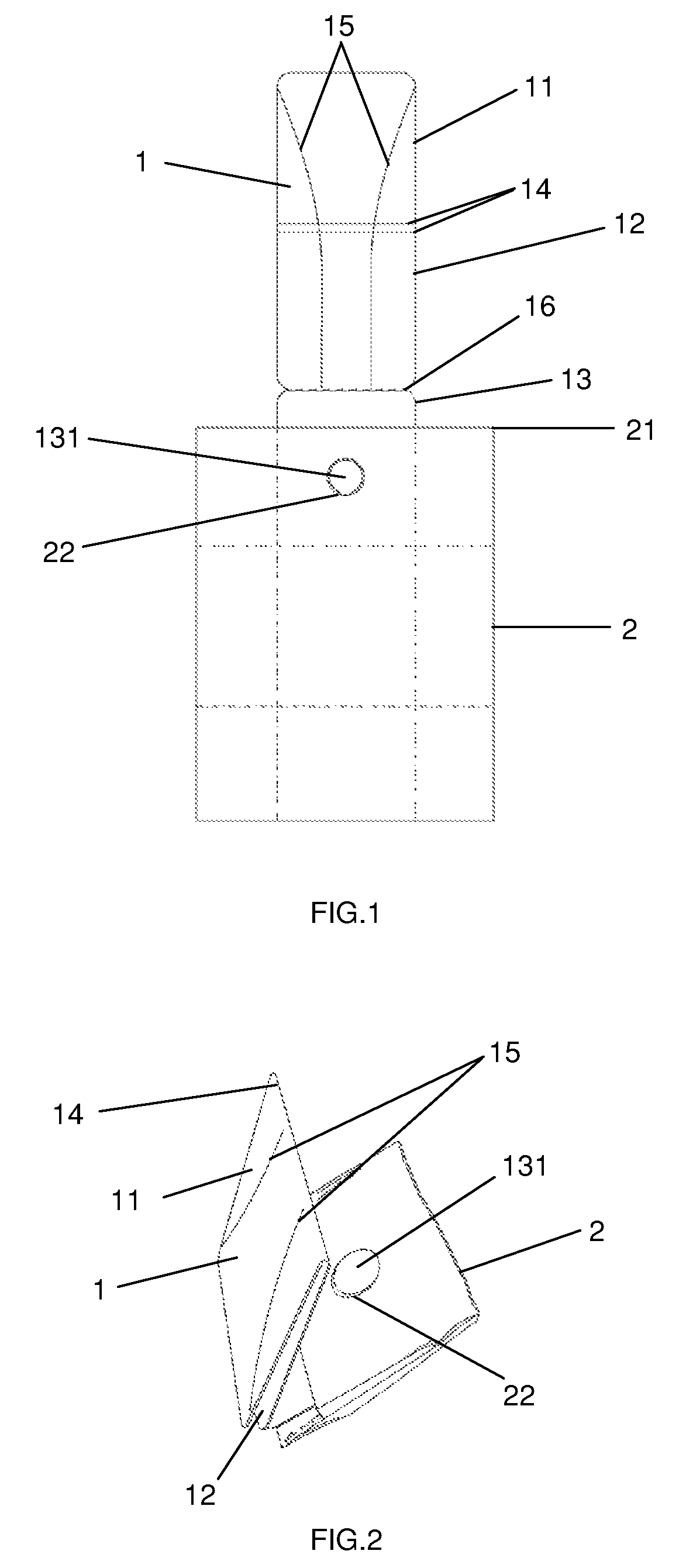

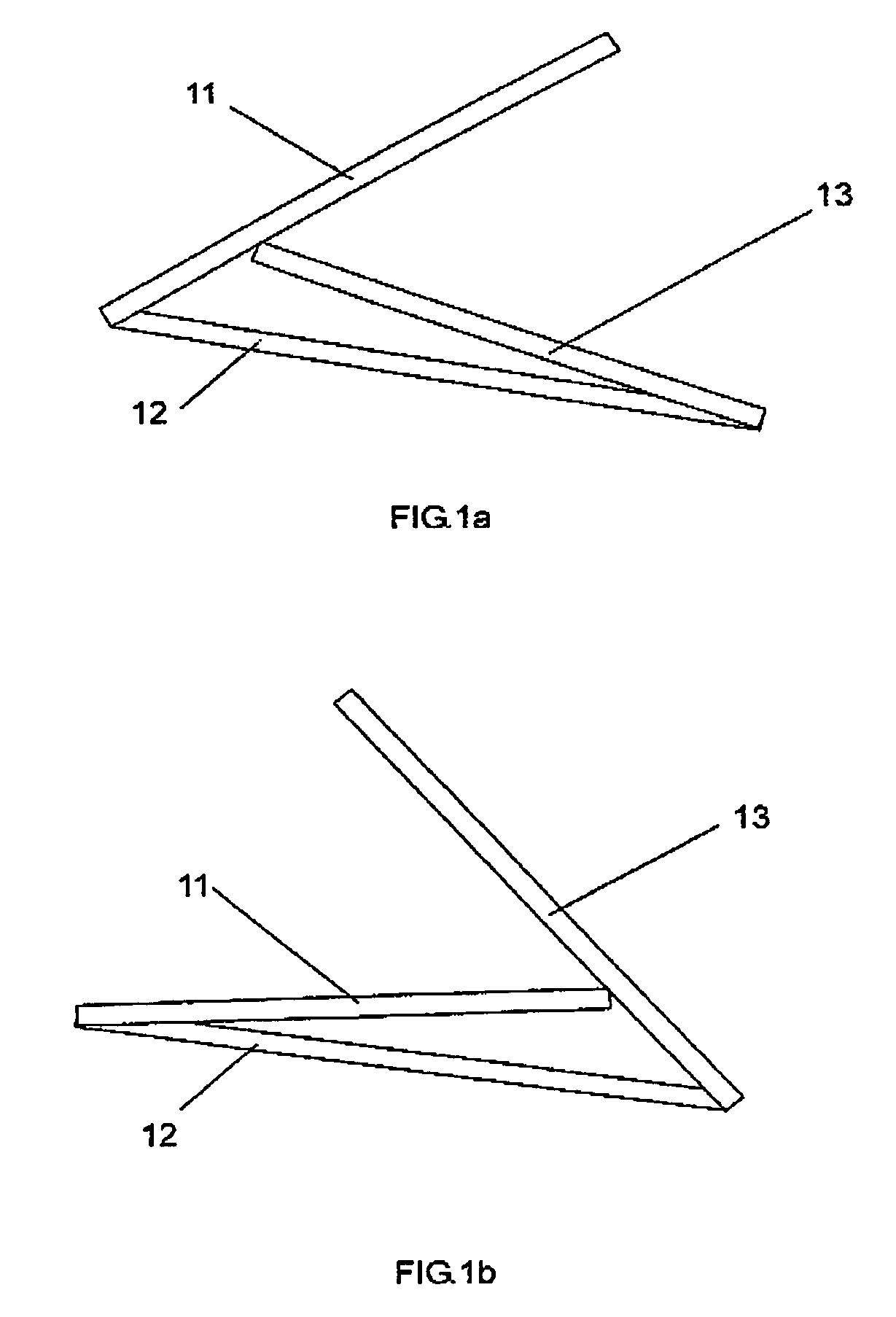

Ovoid chainrings for optimising conventional pedaling

ActiveUS7749117B2Abate chanceSimple stepsChain/belt transmissionPortable liftingBiomechanicsEngineering

Improvement in the design of variable original radius chainrings for coupling to conventional bicycle cranks in order to apply traction, which primarily consists of its being provided with a plurality of possible anchorages to the crank, so that the user may adjust the relative position between the crank and the major radius of the chainring, and thus optimize the biomechanics of his own pedalling; furthermore, other design parameters are offered to endow this non-circular pedalling with leg speeds optimized within the limitation of pedalling with cranks at 180 degrees and therefore with a dead spot.

Owner:ROTOR COMPONENTES TECHCOS

Ovoid chainrings for optimising conventional pedaling

ActiveUS20060211529A1Abate chanceSimple stepsChain/belt transmissionPortable liftingSprocketEngineering

Improvement in the design of variable original radius chainrings for coupling to conventional bicycle cranks in order to apply traction, which primarily consists of its being provided with a plurality of possible anchorages to the crank, so that the user may adjust the relative position between the crank and the major radius of the chainring, and thus optimise the biomechanics of his own pedalling; furthermore, other design parameters are offered to endow this non-circular pedalling with leg speeds optimised within the limitation of pedalling with cranks at 180 degrees and therefore with a dead spot.

Owner:ROTOR COMPONENTES TECHCOS

Integrated electromechanical arrangement and method of production

ActiveUS7200009B2Improve customizabilityFacilitates upgradabilityInput/output for user-computer interactionContact surface shape/structureEngineeringInjection moulding

It is an object of the invention to provide a electromechanical structure comprising an input device and a printed wired board (3, 4), which structure is advantageous in terms of manufacturing and offers freedom to the layout design of the printed wired board, the user interface as well as the appearance of the device itself. It is also an object of the invention to provide a electromechanical structure that is compact and facilitates the customizability and upgradability with a new electronic functionality without any need for modifications to the main electronics of the device. This is achieved by integrating the electromechanical assembly with the mechanical cover part of the electronic device by using an injection moulding process to compose an integrated combination (113) which is detachable from the electronic device. More precisely the objects of the invention are achieved by combining the injection mould technologies with the printing of electronic wired boards.

Owner:NOKIA TECHNOLOGLES OY

Preparation method of emulsified stable type soy isolate protein

InactiveCN102578365AImprove emulsion stabilityHigh activityVegetable proteins working-upProtein solutionFreeze-drying

The invention relates to a preparation method of emulsified stable type soy isolate protein and belongs to the field of process technology of soy protein. The preparation method comprises the main steps as follows: preparing a soy isolate protein solution with the ratio of deionized water to soy isolate protein used as a raw material being (5-25):1 w / w; fully hydrating, and then stirring and preheating at 40-60 DEG C; regulating pH to be 6.5-7.5; adding papain for enzymolysis to obtain a sample of different hydrolysis degrees; then killing enzyme for 5 min at 90 DEG C; cooling to room temperature; regulating pH to be neutral; centrifuging; taking supernate to carry out freeze drying or spray drying; preparing a sample solution with the ratio of deionized water to the sample of different hydrolysis degrees being (5-25):1 w / w; preheating at 30-50 DEG C; regulating pH to be 7.0; adding transglutaminase to start crosslinking; after 1h, heating for 5 min at 80 DEG C to inactivate the enzyme; cooling to room temperature; then regulating pH to be neutral; centrifuging; taking supernate; and performing freeze drying or spray drying to obtain the highly emulsified stable type soy isolate protein. The preparation method for the emulsified stable type soy isolate protein is economic and effective; and the emulsion stability of the soy protein is remarkably improved.

Owner:JIANGNAN UNIV

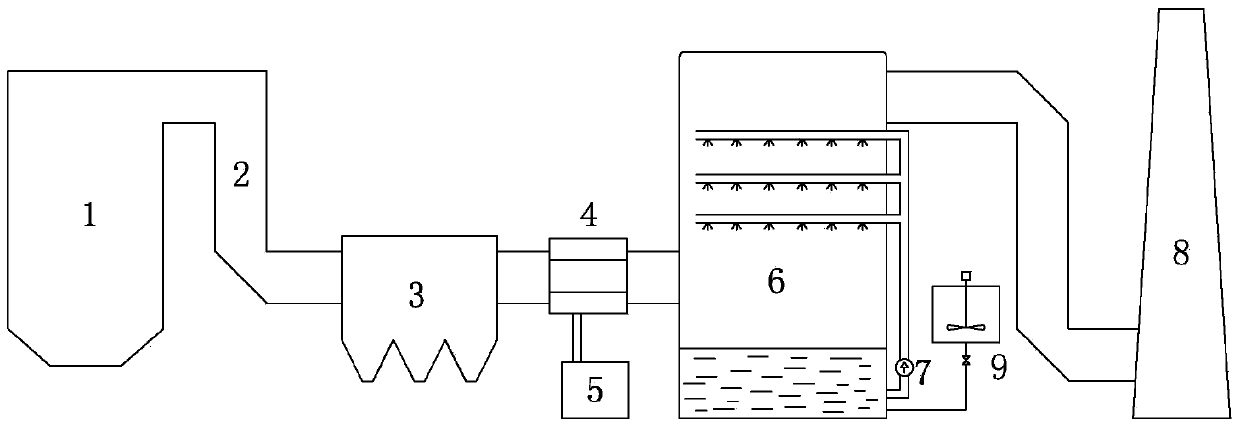

Flue gas treatment method and flue gas treatment device capable of simultaneous desulfurization, de-nitration and mercury removal through magnesium oxide

InactiveCN103736373AFully oxidizedPrevent oxidationDispersed particle separationFlue gasDust control

The invention discloses a flue gas treatment method and a flue gas treatment device for simultaneous desulfurization, de-nitration and mercury removal through magnesium oxide. The flue gas treatment method comprises the following steps: (1) removing dust from boiler flue gas and then transmitting the boiler flue gas into a static mixer, spaying ozone into the static mixer at the same time, mixing and oxidizing the boiler flue gas with the ozone; (2) transmitting the mixed and oxidized mixture gas into an absorbing tower from the bottom part of the absorbing tower, circularly spraying magnesium oxide solution in the absorbing tower; and (3) exhausting the sprayed-absorbed flue gas from the top of the absorbing tower through a chimney. Due to the adoption of combination of oxidization with a gaseous oxidizing agent and absorbing with magnesium oxide solution, the effect of simultaneous desulfurization, de-nitration and mercury removal in one tower is realized, and furthermore, the effects of simultaneous desulfurization, de-nitration and mercury removal are all good.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

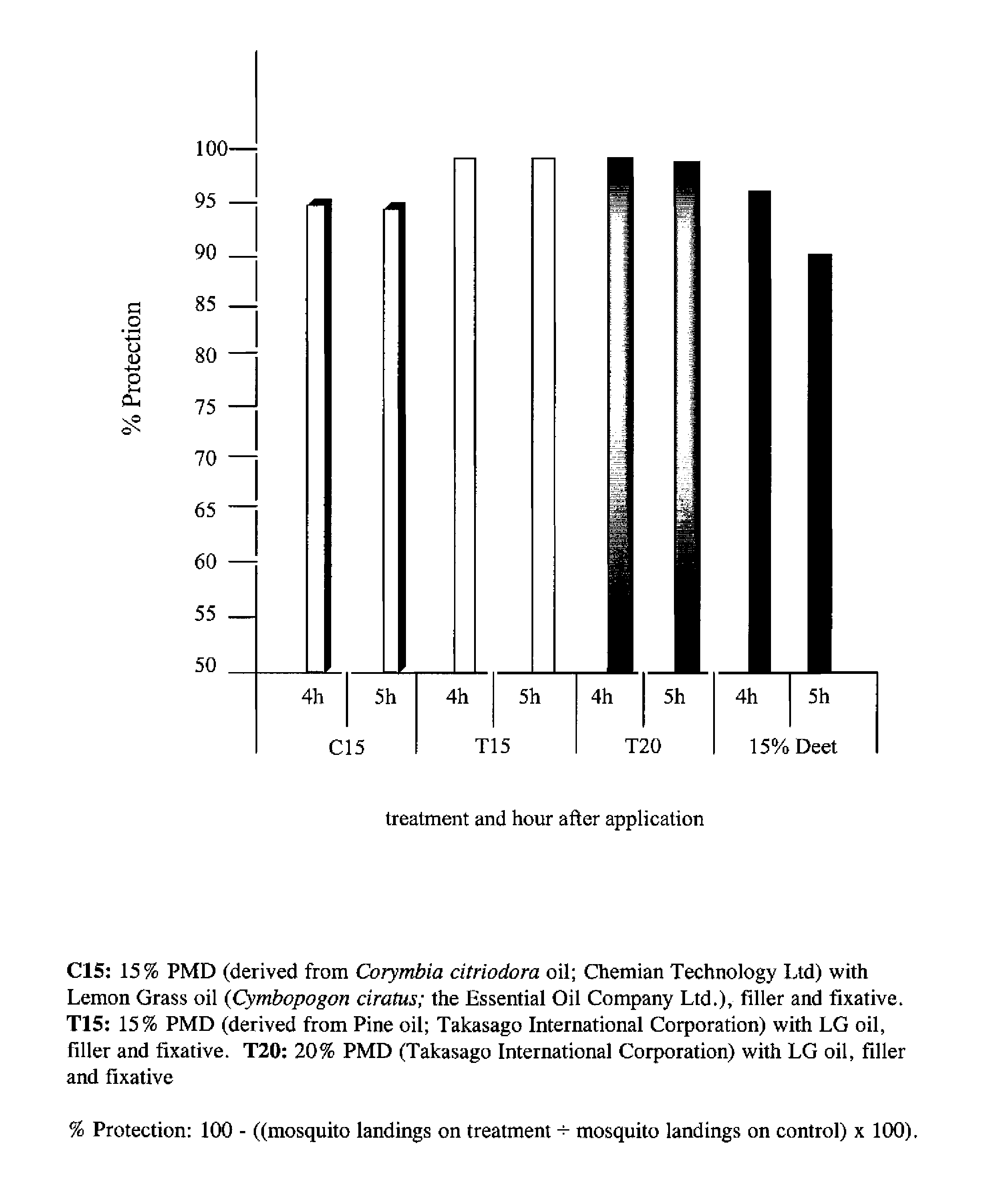

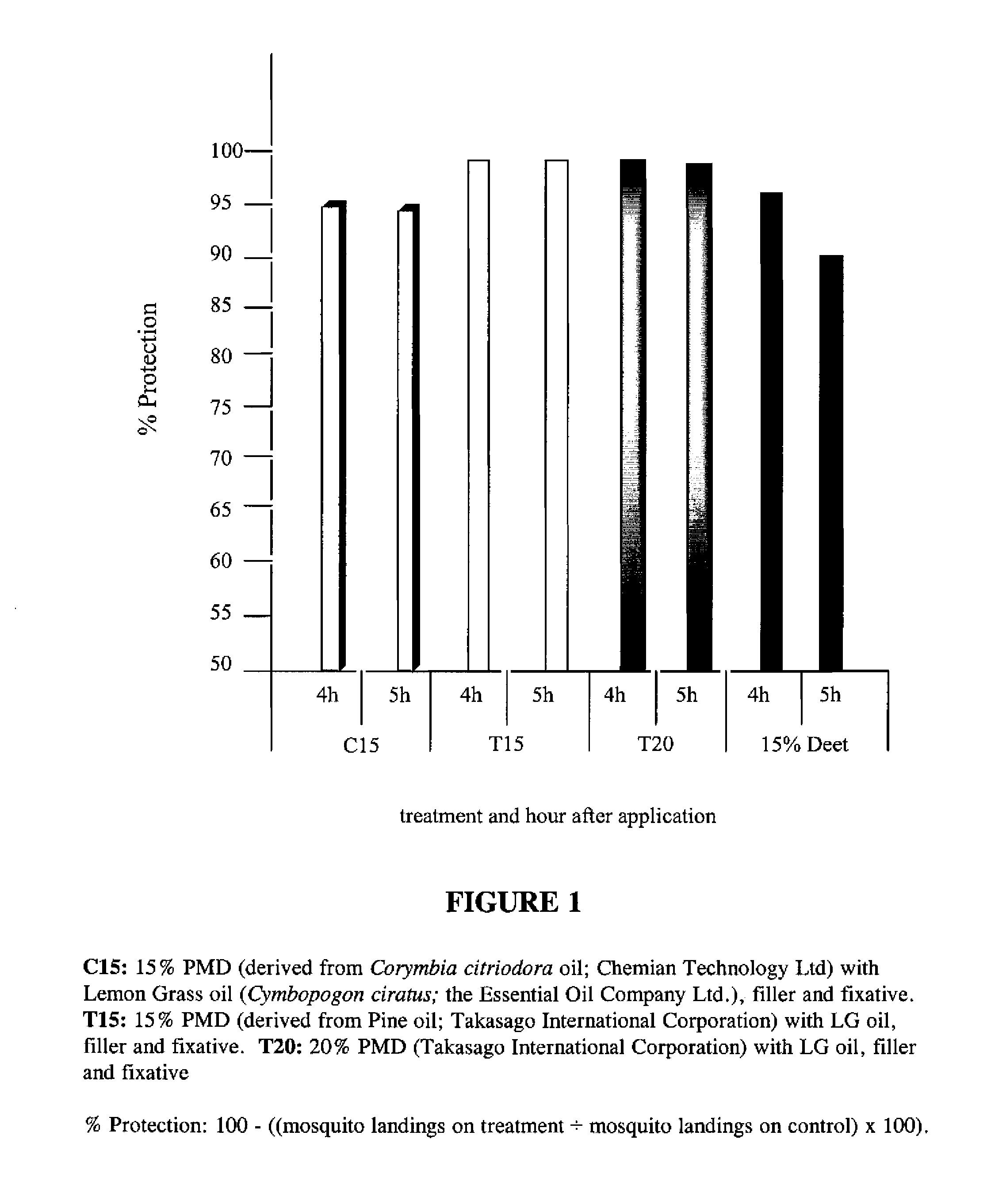

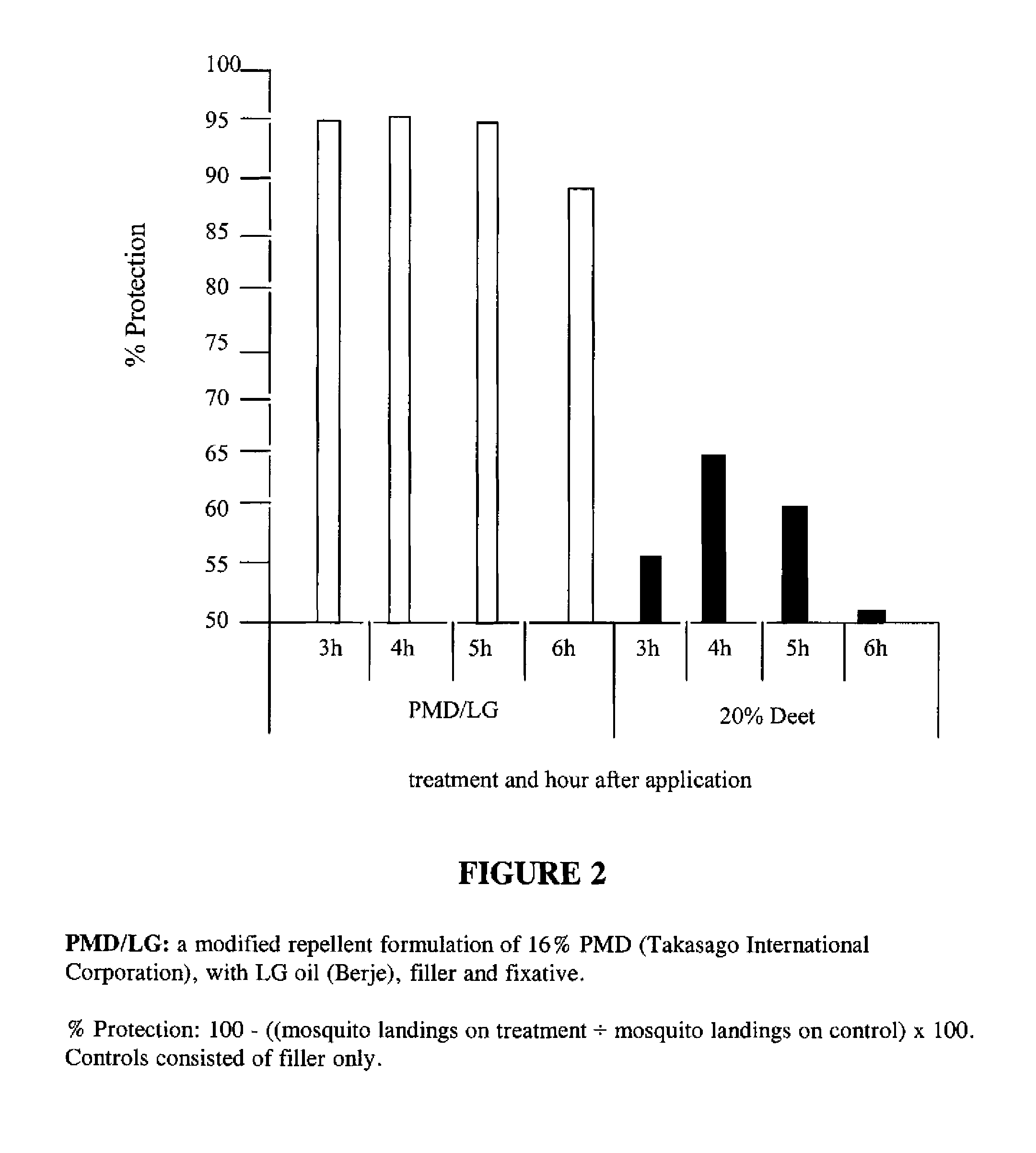

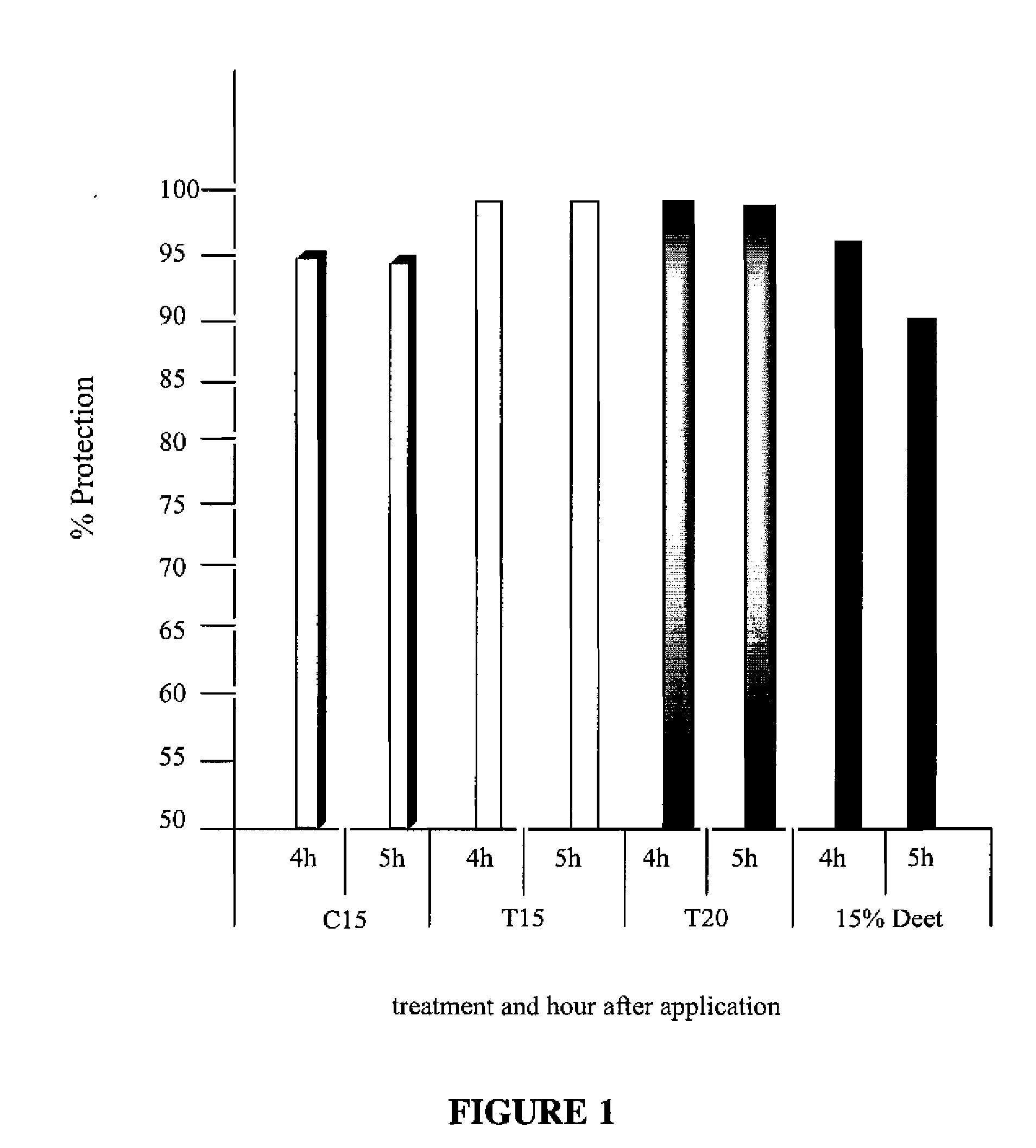

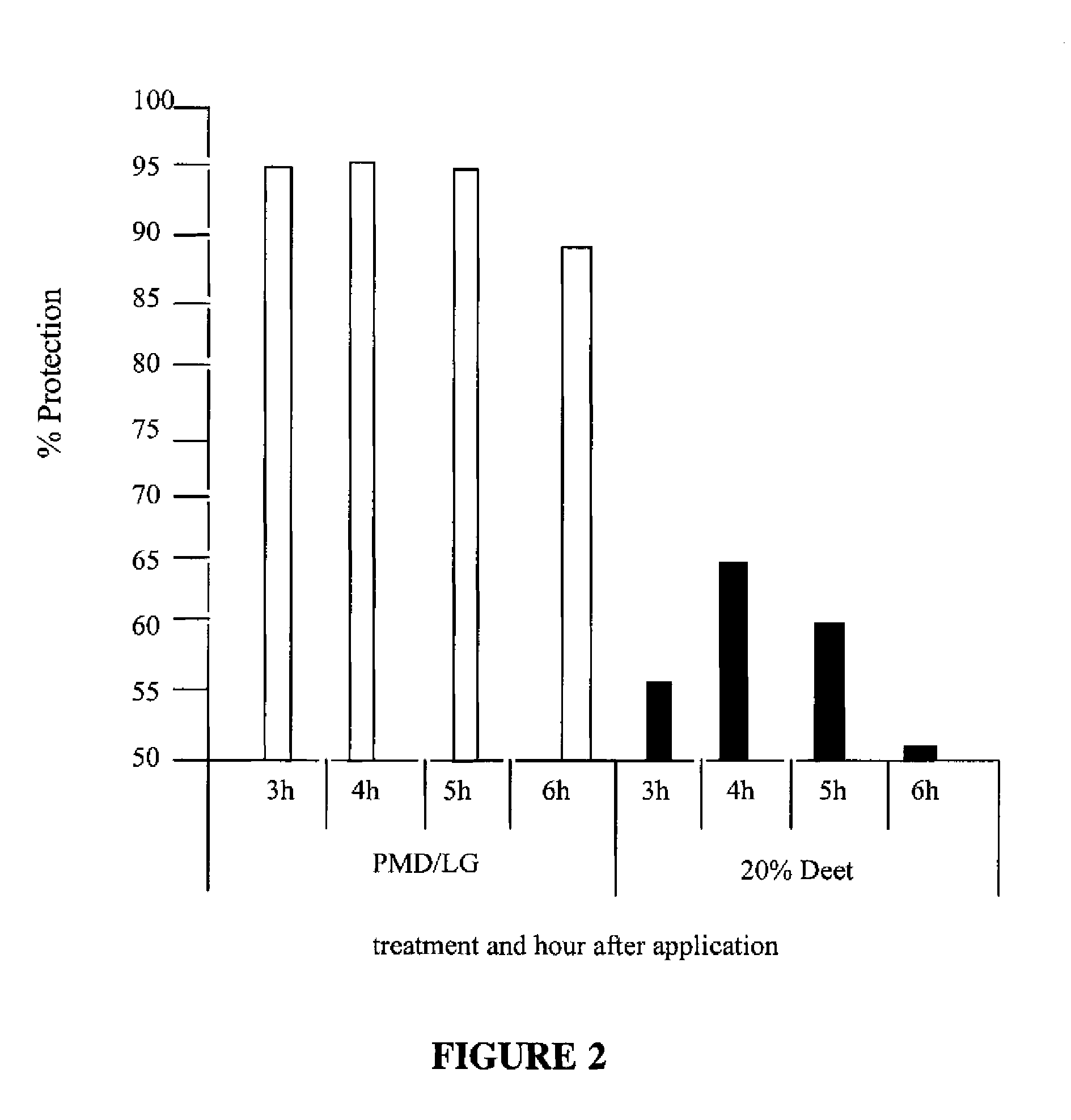

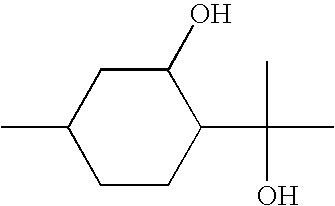

Insect repellent composition

ActiveUS7846464B2Superior efficacy and attributeGood effectBiocideDead animal preservationPaleontologyDiol

Owner:DARLING & CO

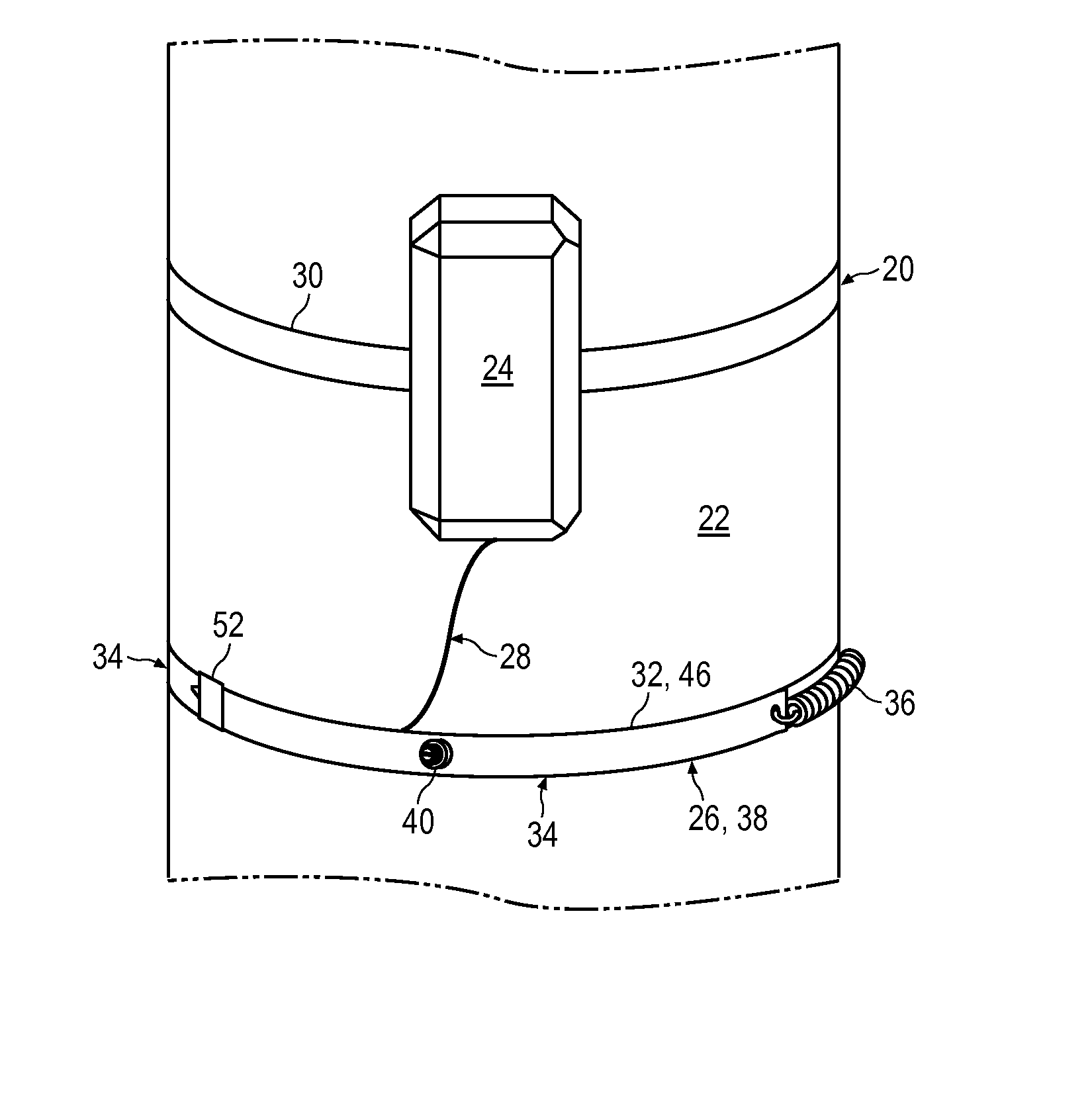

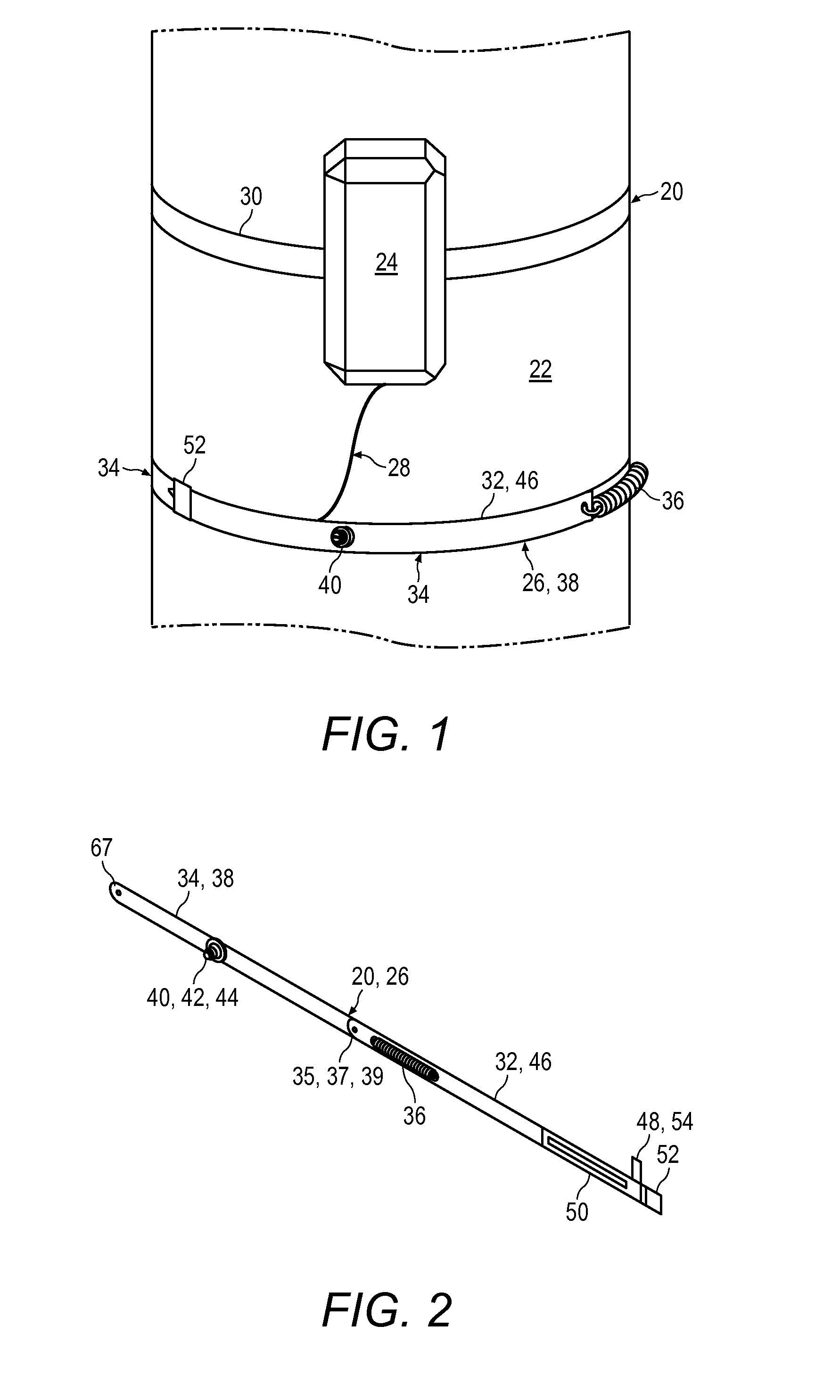

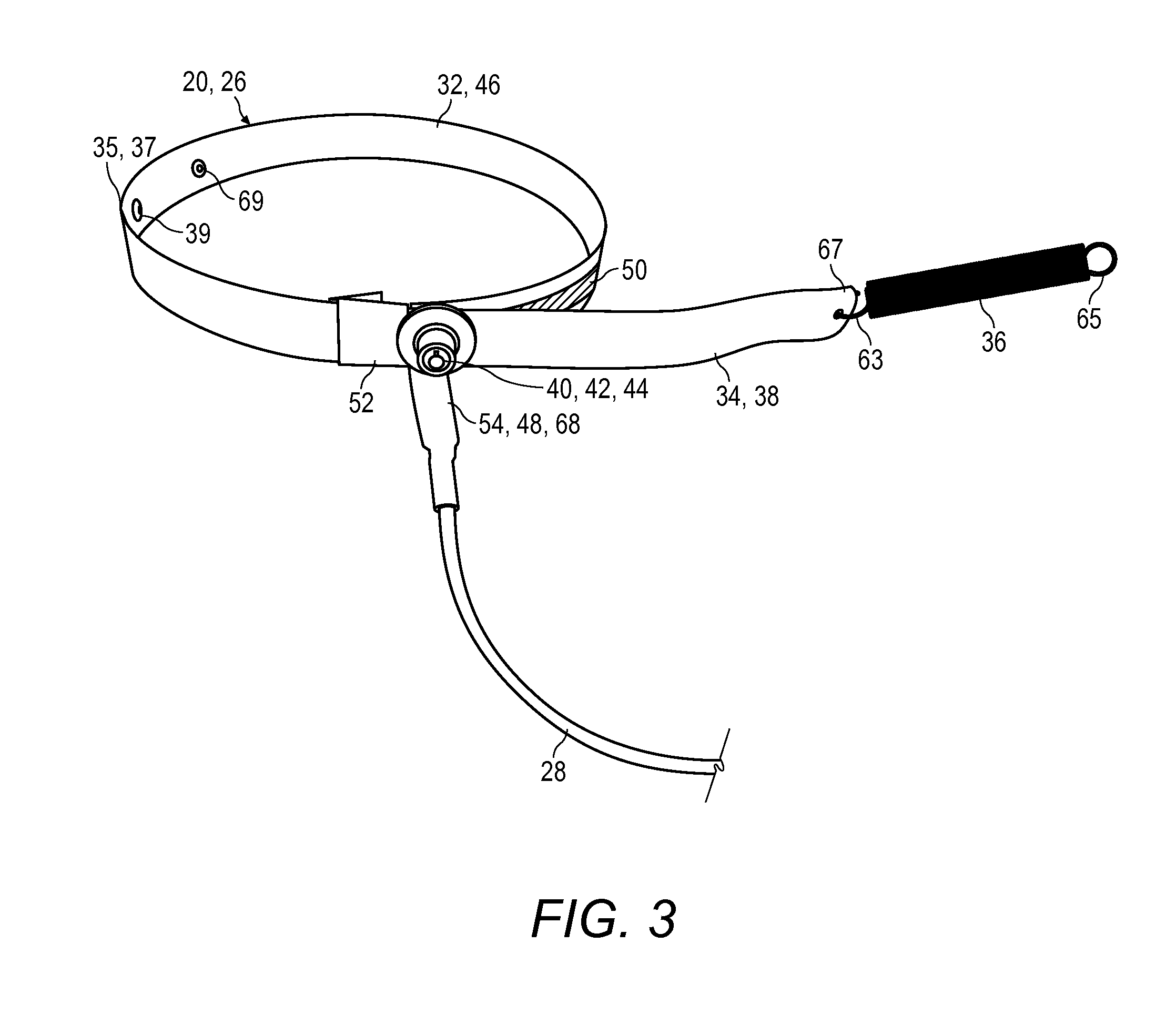

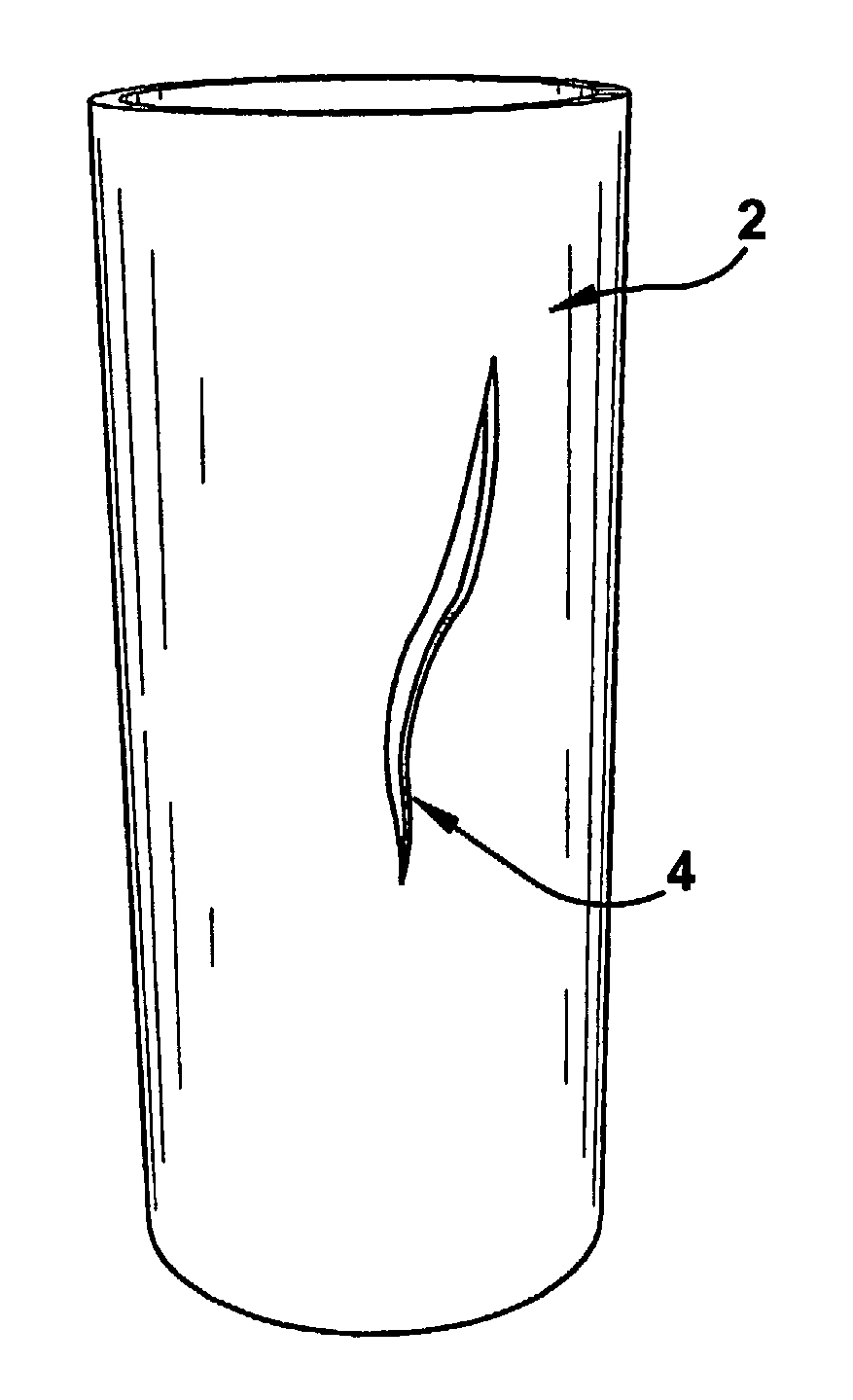

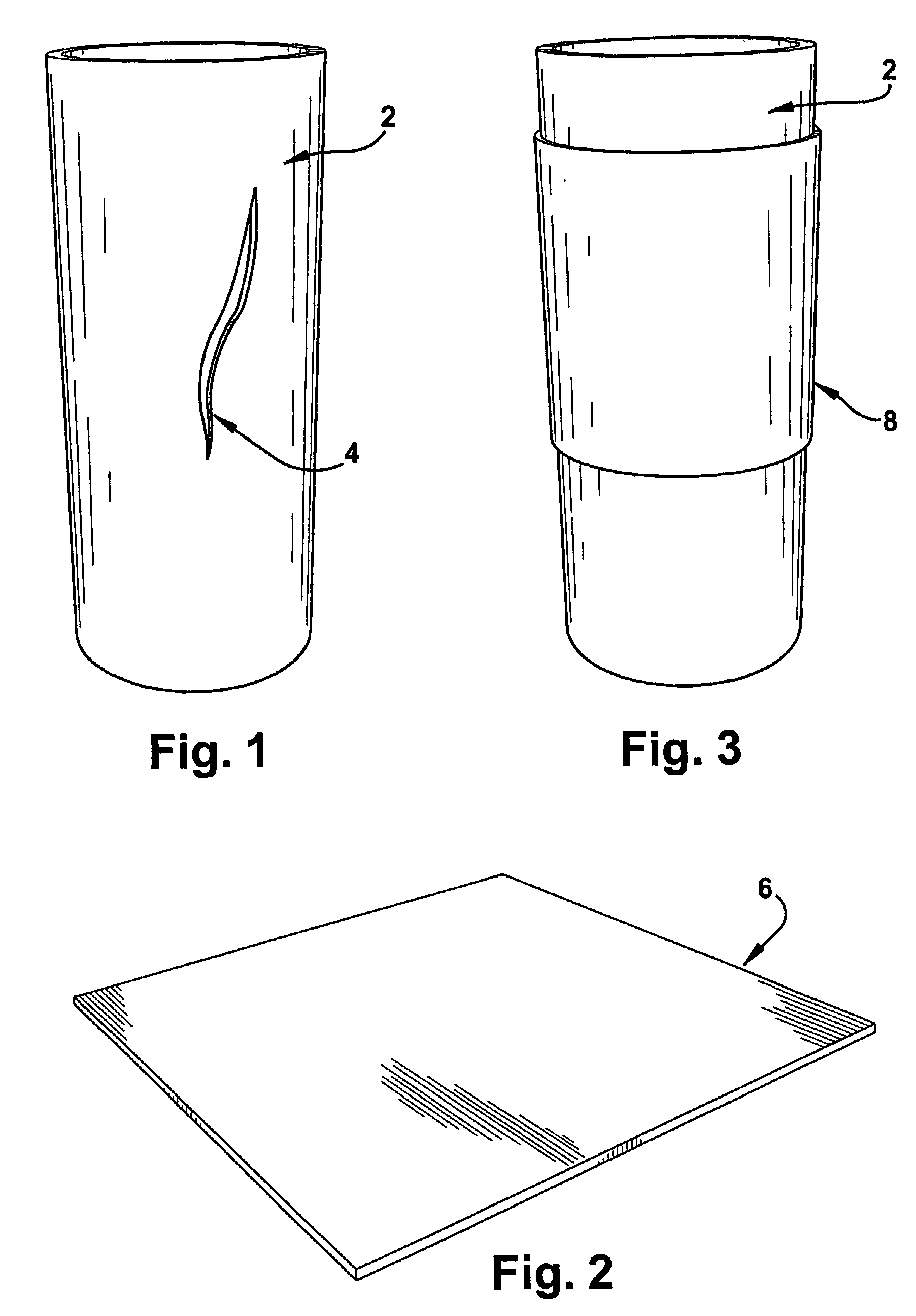

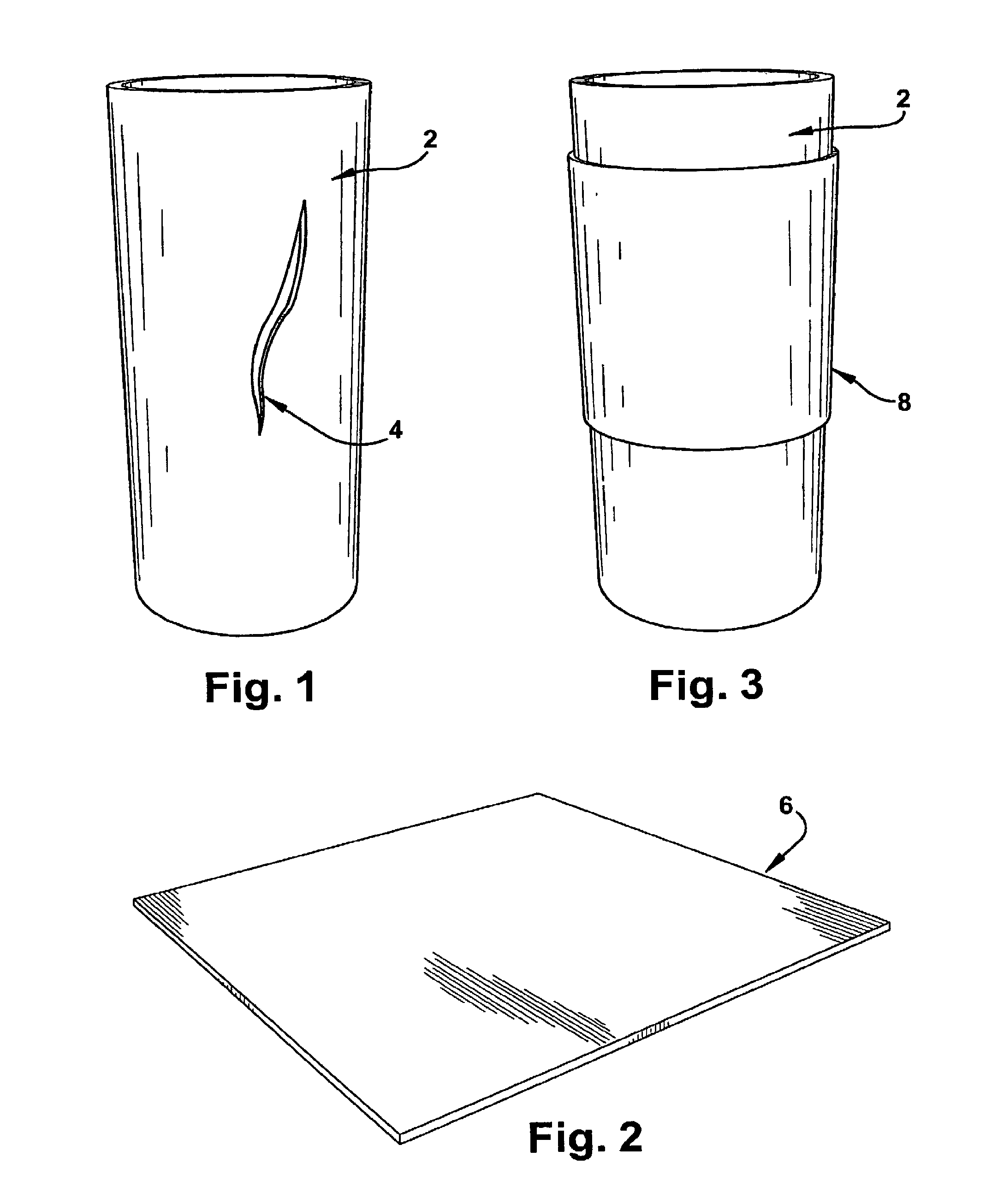

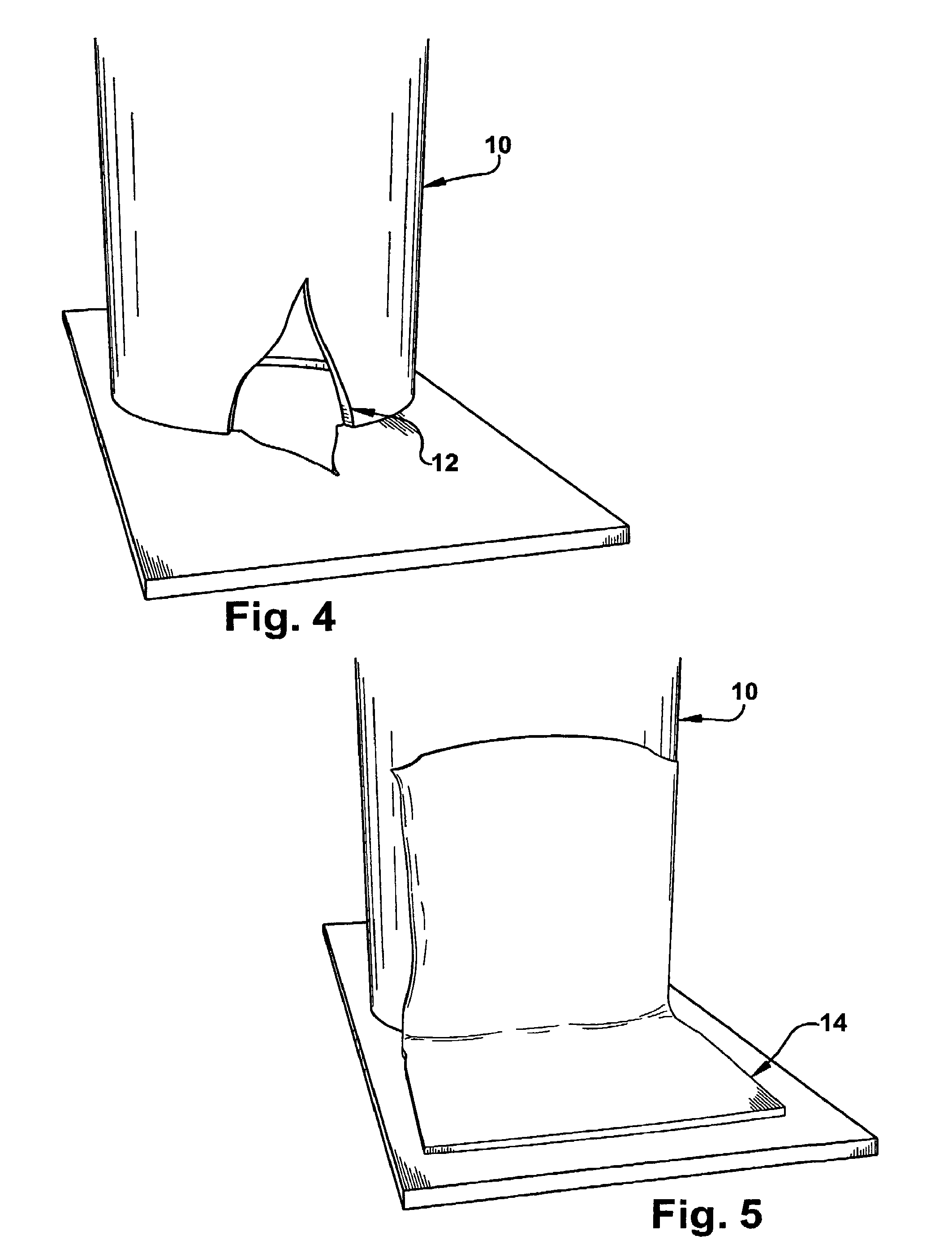

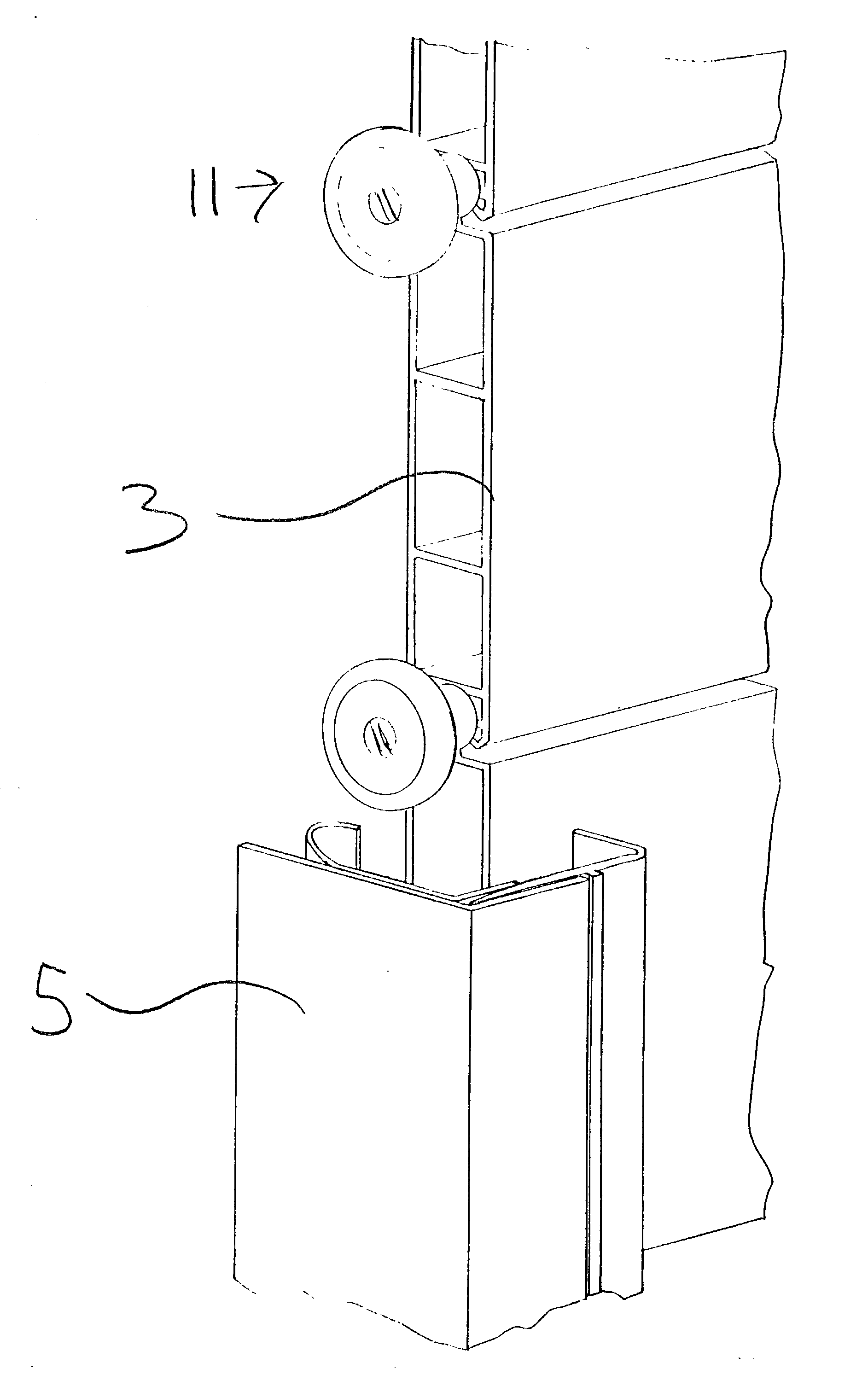

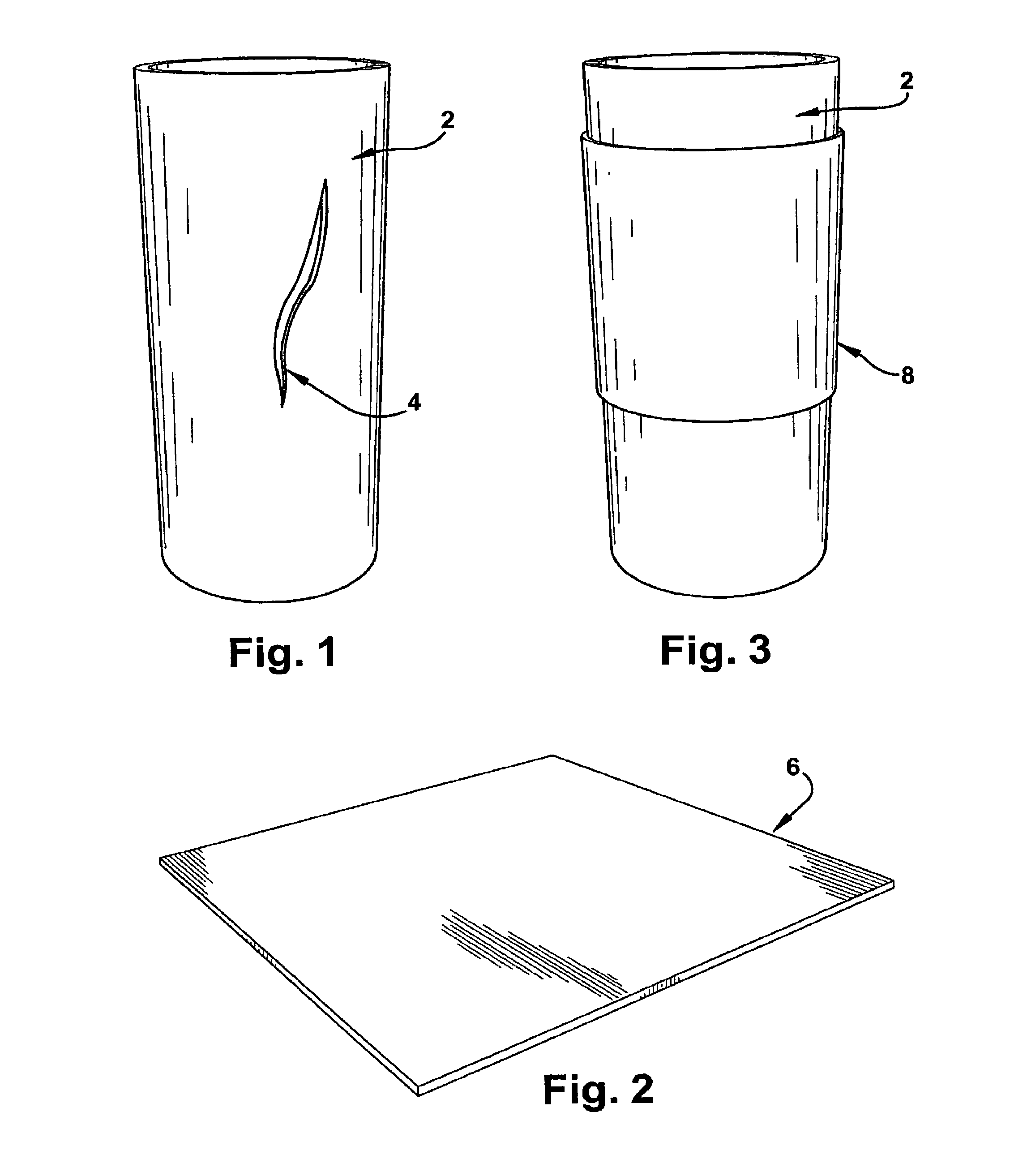

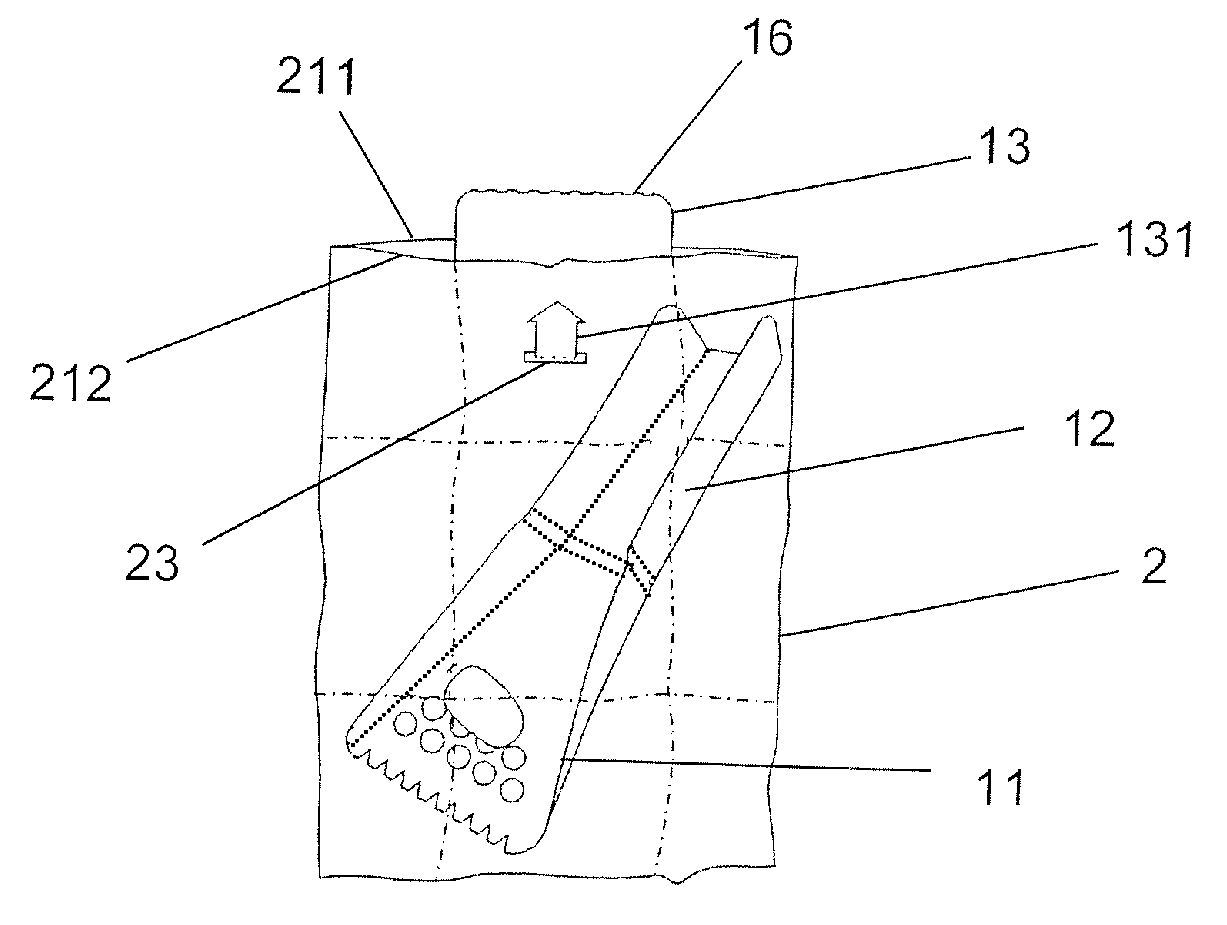

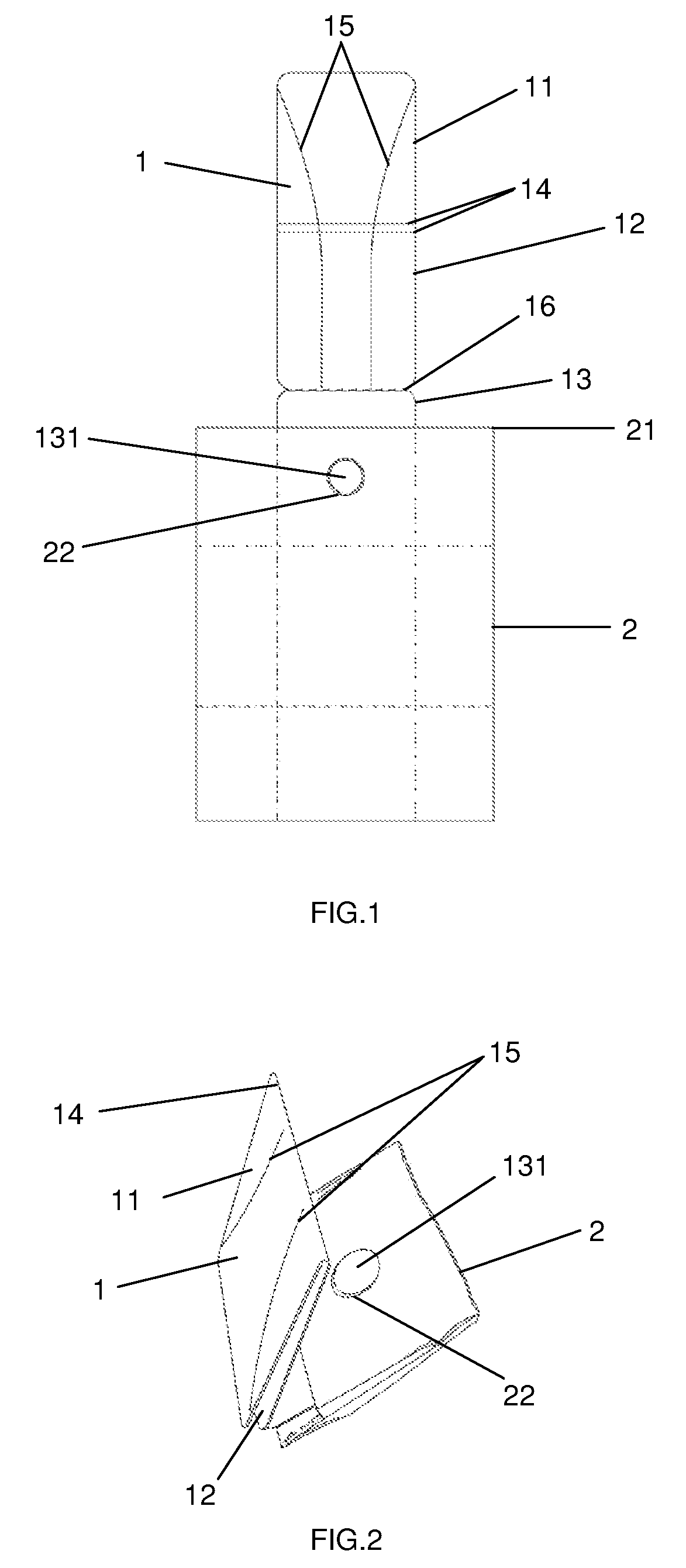

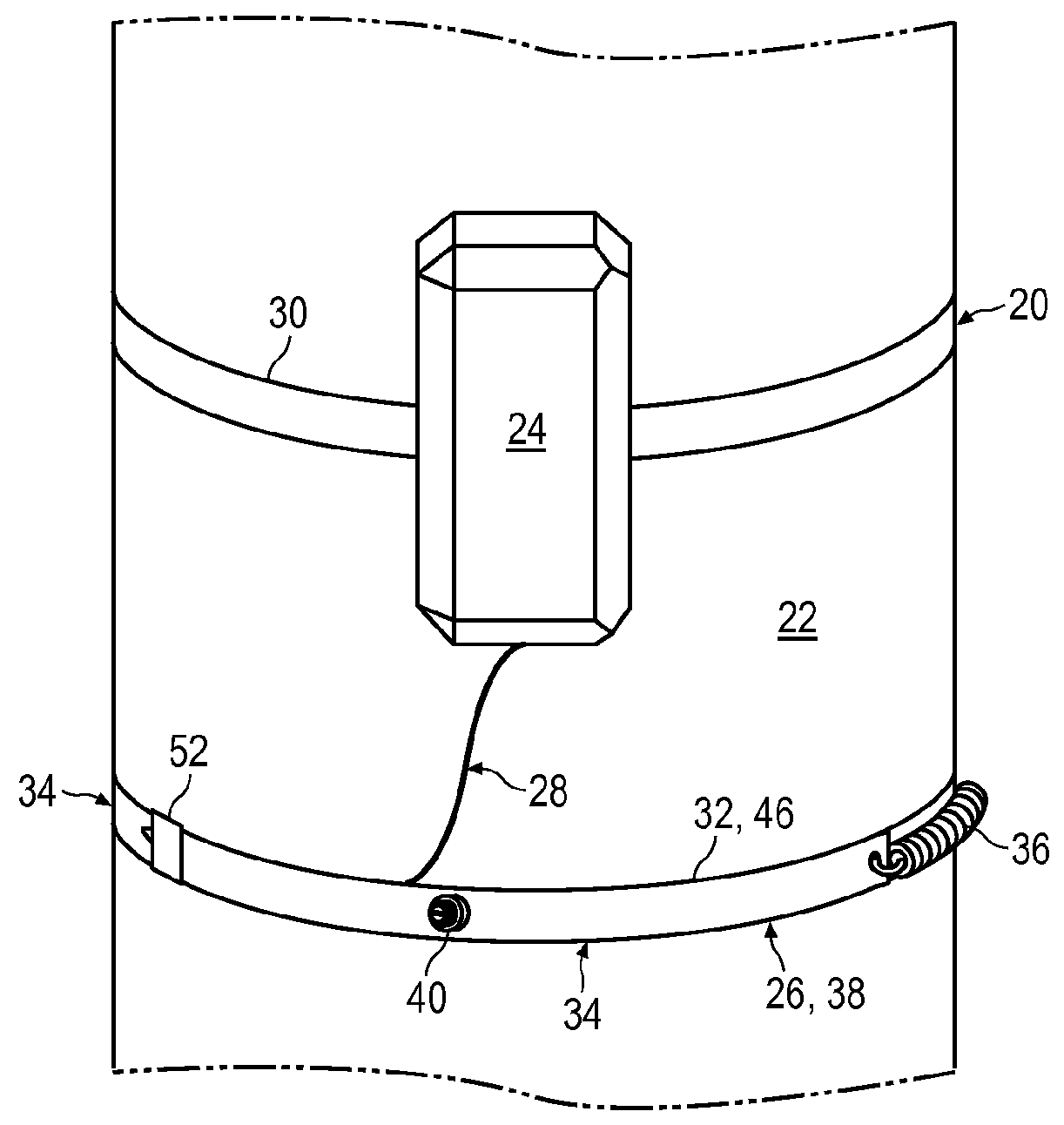

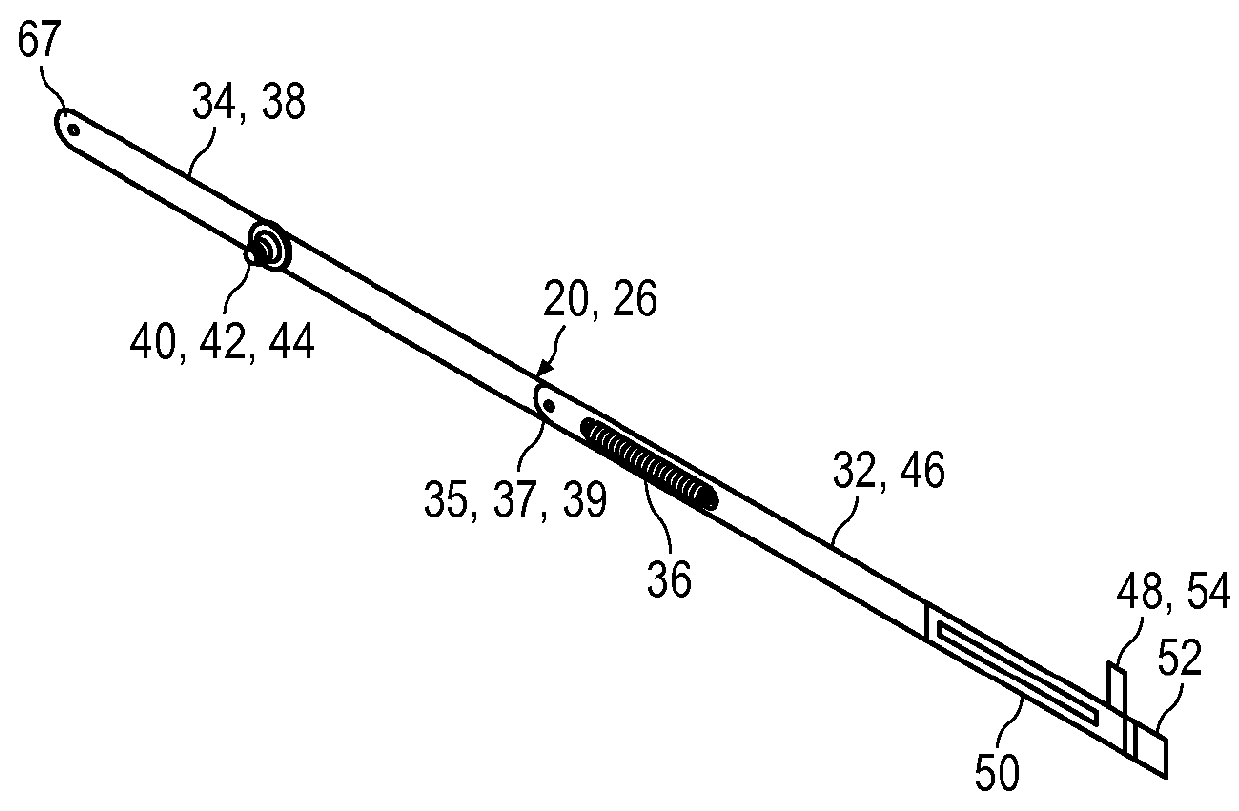

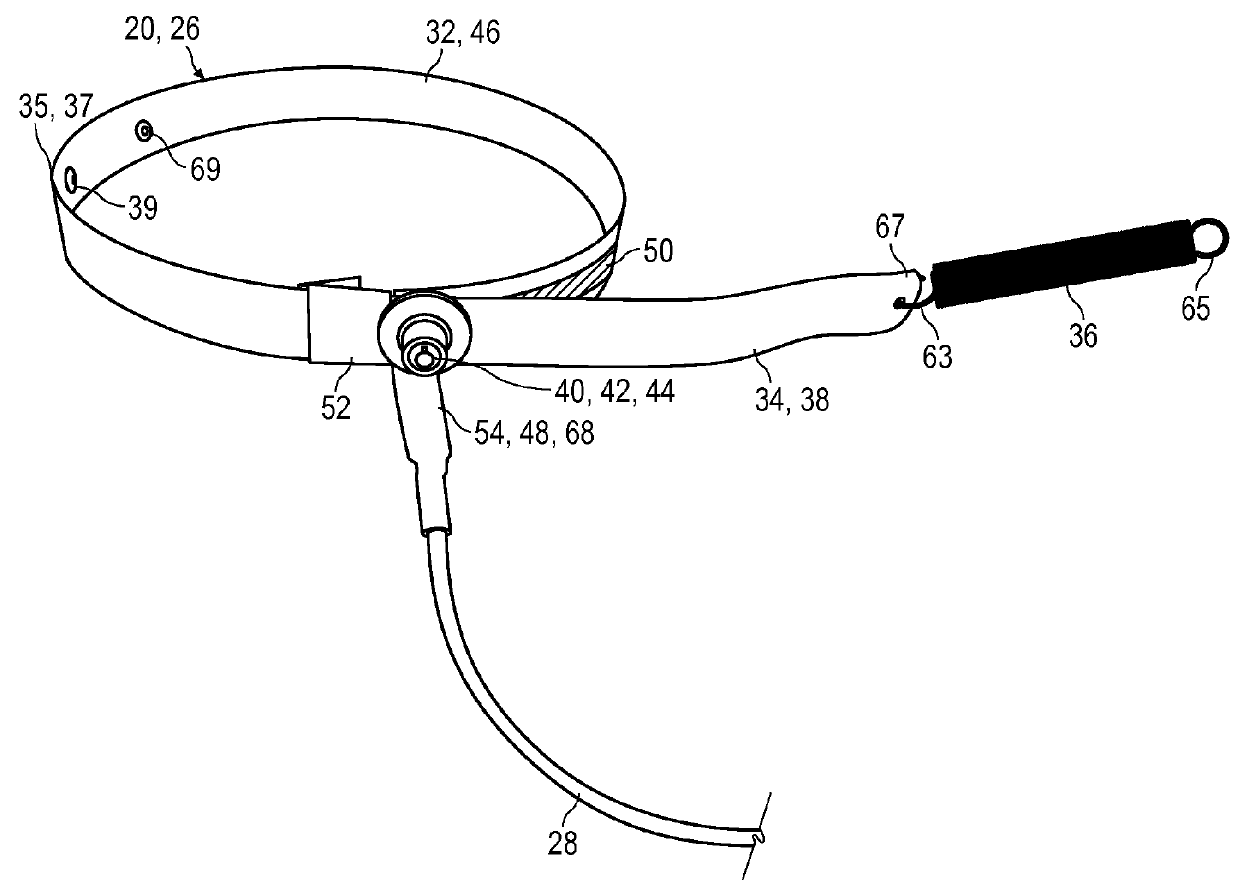

dendrometer

ActiveUS20140360037A1Easy constructionGuaranteed uptimeElectrical/magnetic solid deformation measurementTesting plants/treesLength variationTree trunk

A dendrometer comprises a dendrometer band whose length is extendable for encircling a tree trunk. The dendrometer further comprises an elongated electronic component that is closely or contiguously attached to the dendrometer band for moving along with the dendrometer band in order to follow length extension of the dendrometer band. Length variation of the dendrometer band is configured to be converted to electronic signals by the electronic component.

Owner:GLOBAL CHANGE SOLUTIONS

Insect repellent composition

ActiveUS20070166342A1Good effectEffectiveBiocideDead animal preservationMentha x gracilisInsect repellent

Owner:DARLING & CO

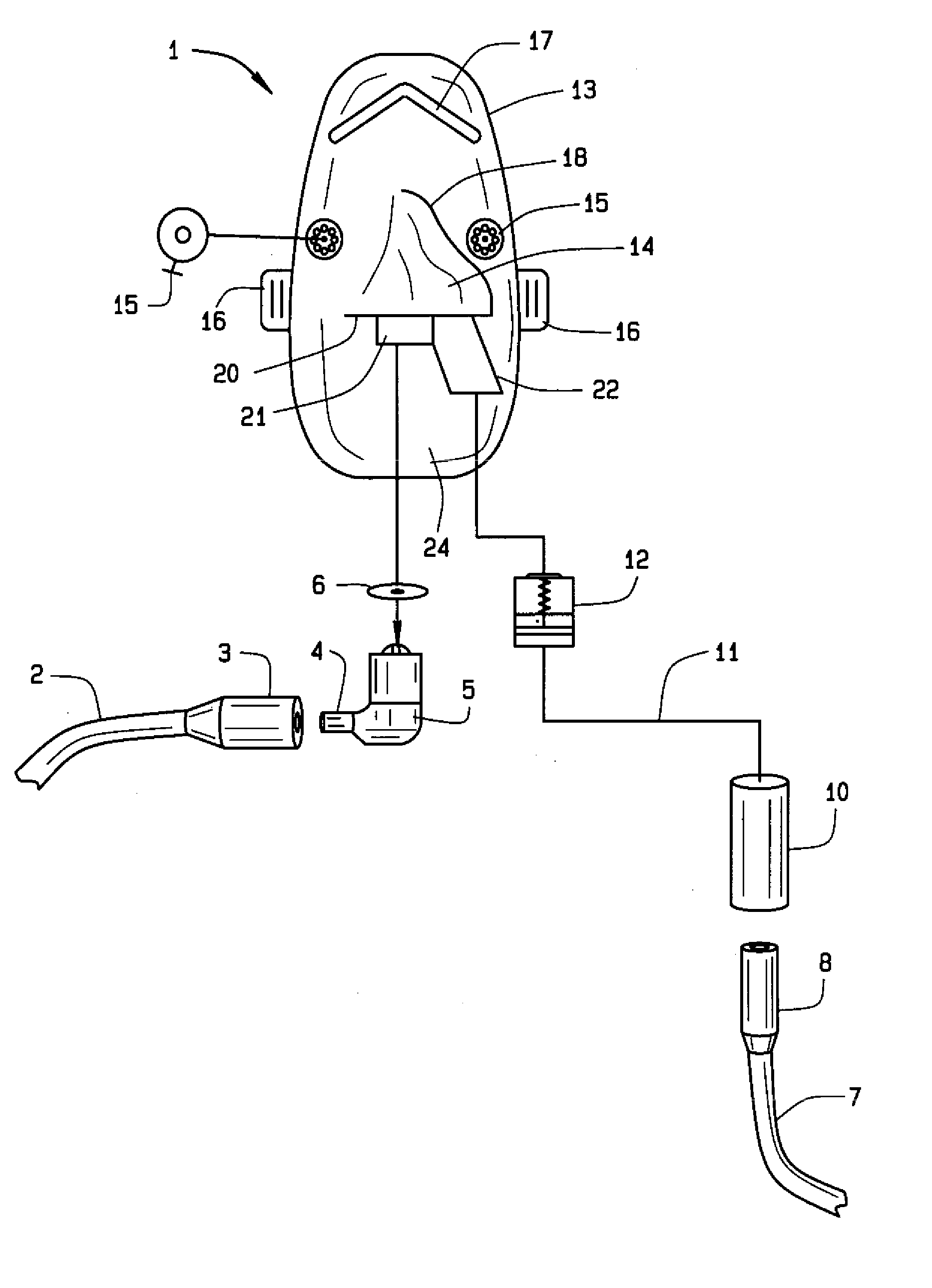

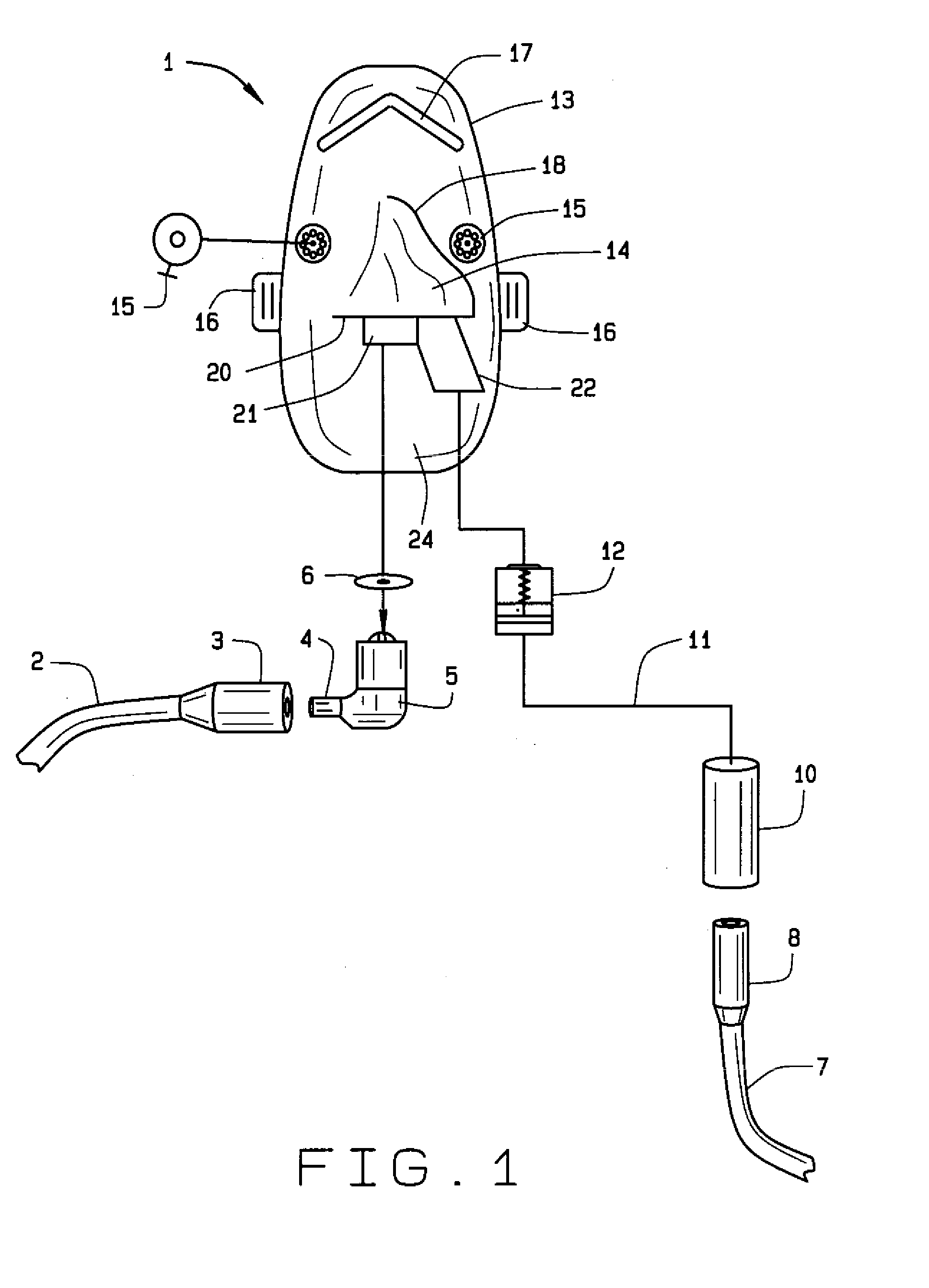

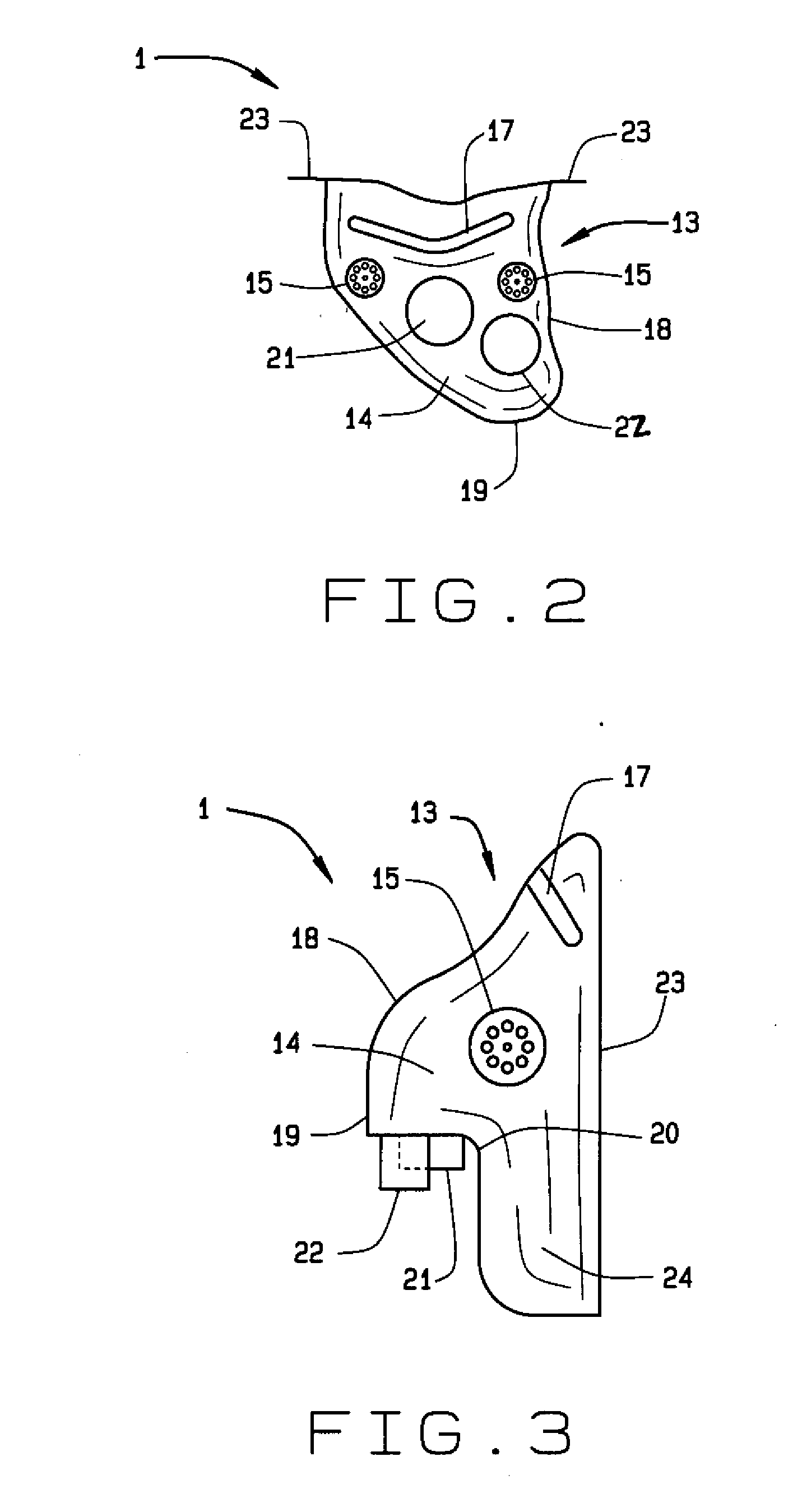

Mask for oxygen delivery with medication inlet

InactiveUS20090293881A1Minimal disruptionReduce usageRespiratory masksBreathing masksProximateInhalation

A mask delivers oxygen and medication to a patient simultaneously without lifting and inserting a second line beneath the mask. This mask has an extension with fittings for at least two functions, including oxygen delivery and medication delivery through a medication supply device. The extension has the fittings mutually proximate and generally adjacent in a compact space for minimal disruption to the patient and ease of inspection by the medical staff. The mask also includes check valves for inhalation regulation of the patient. Regarding placement upon a patient's face, the mask has a perimeter flange and a strap for securement upon the head of a patient.

Owner:GRAHAM WILLIAM B

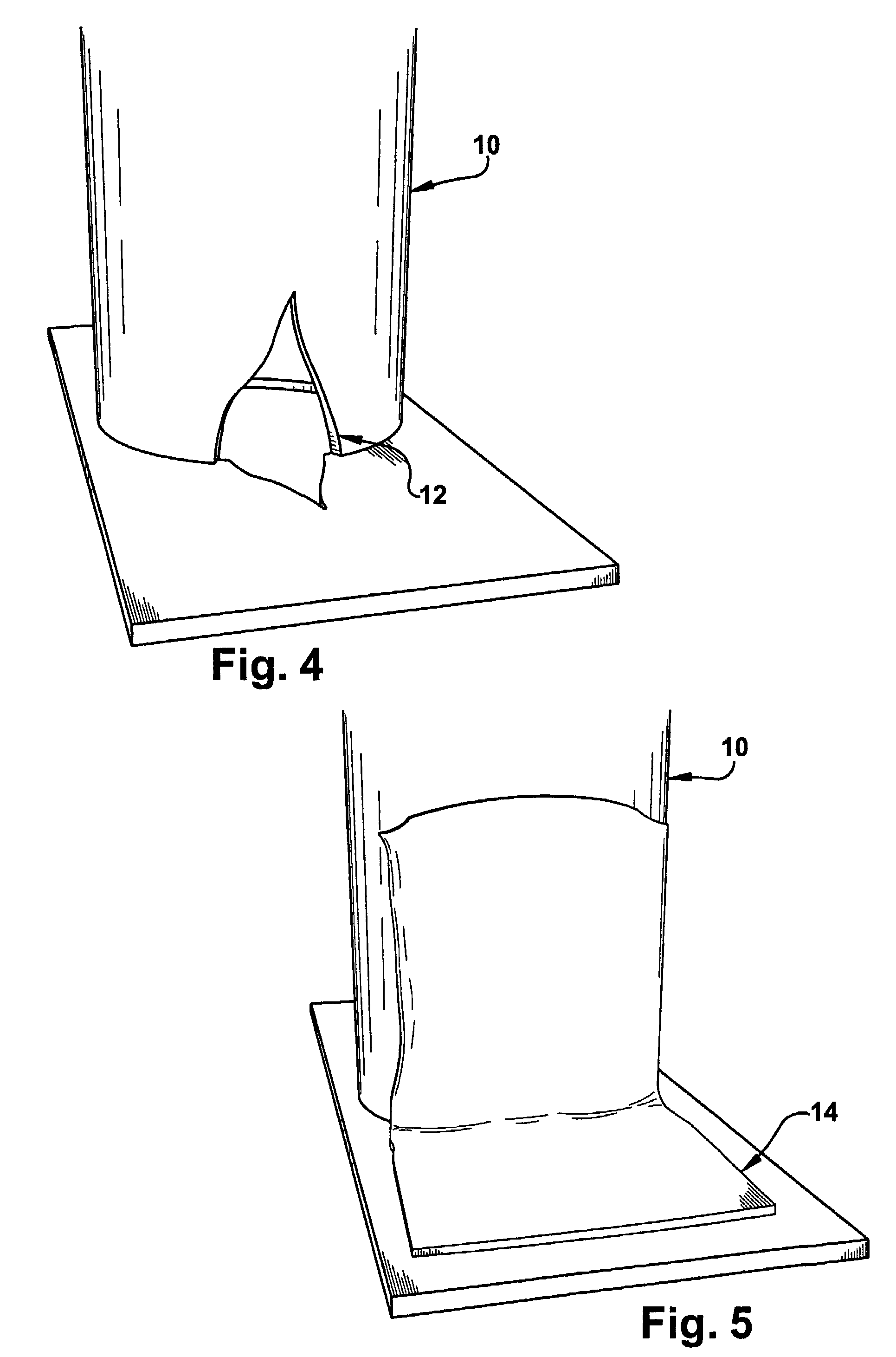

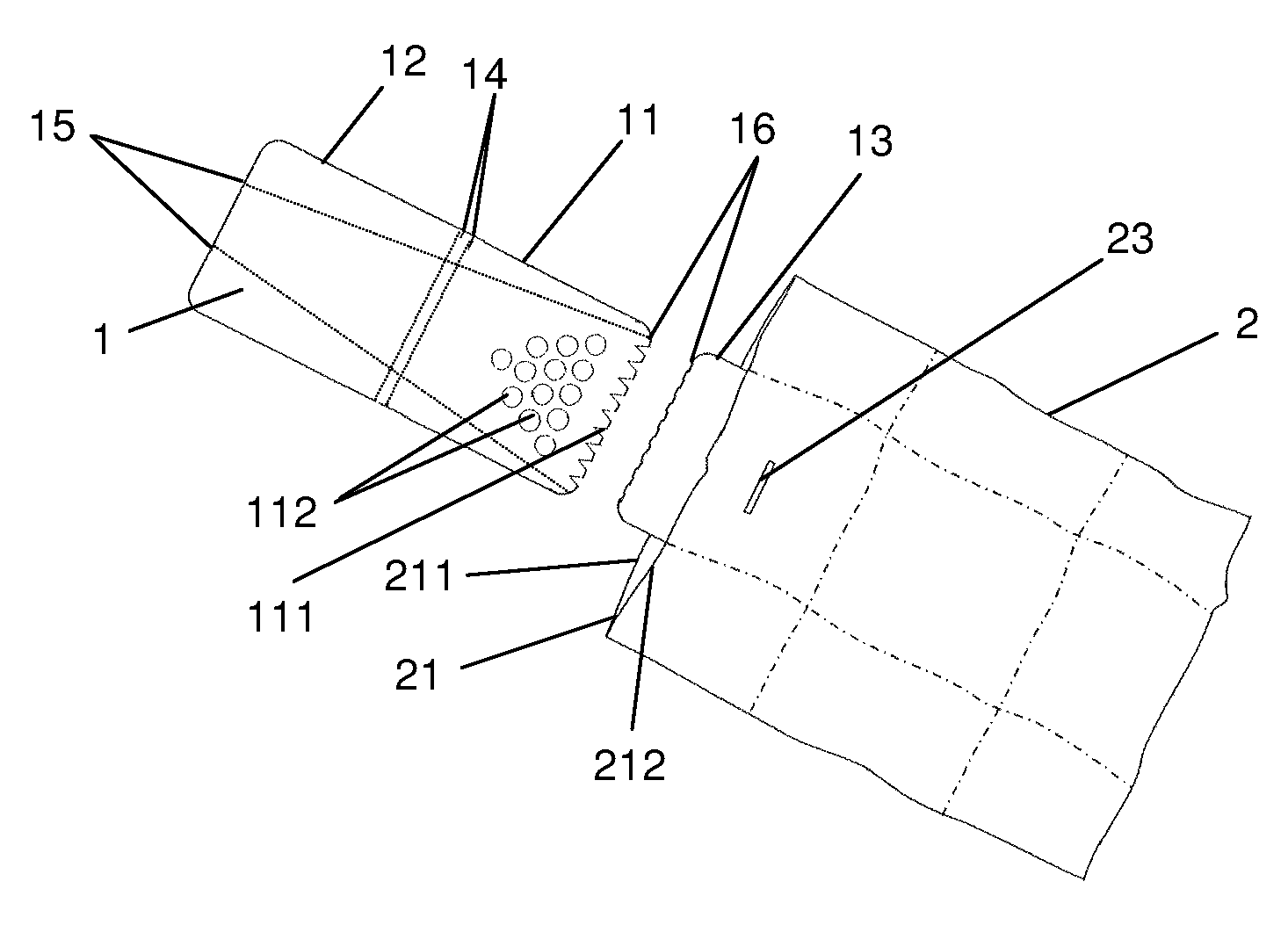

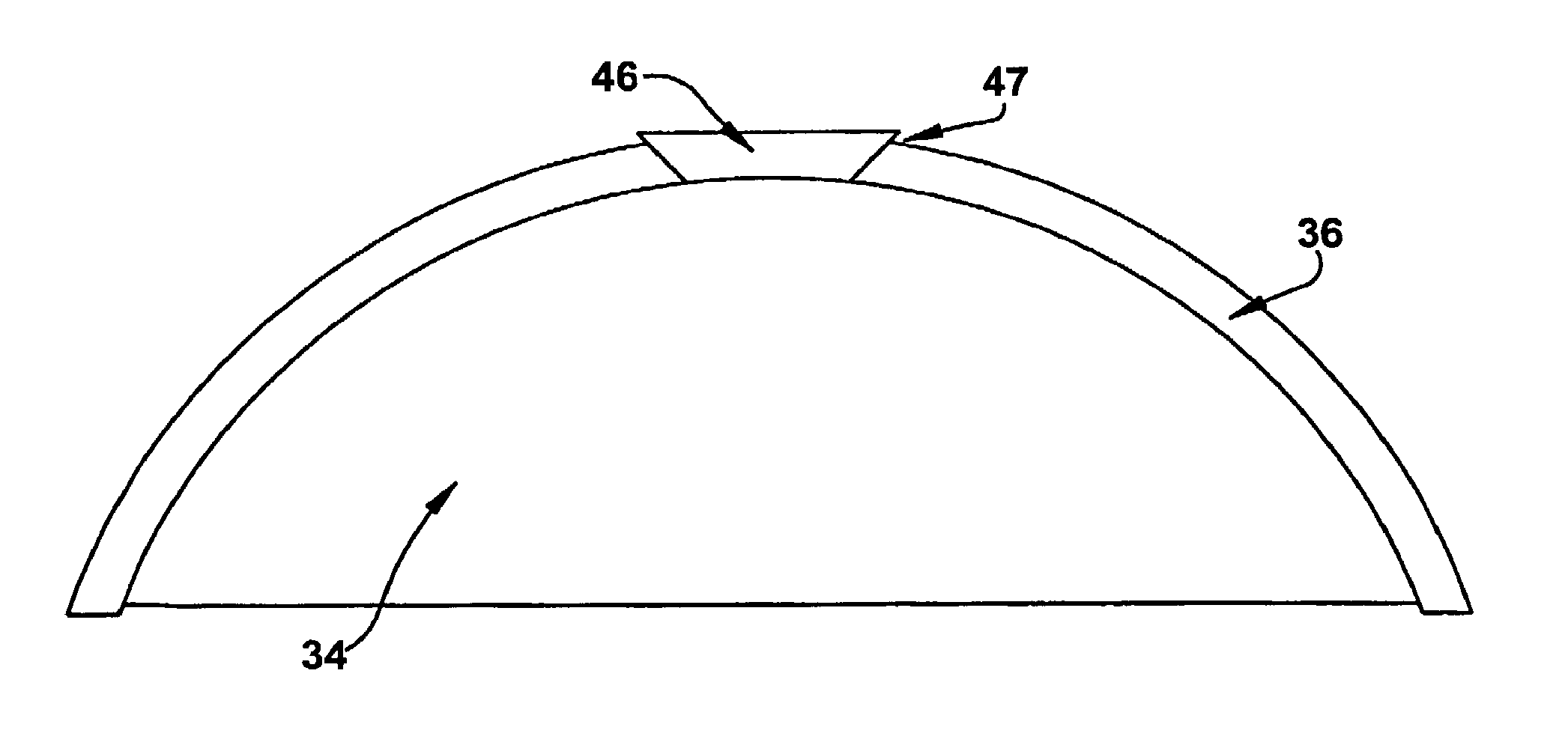

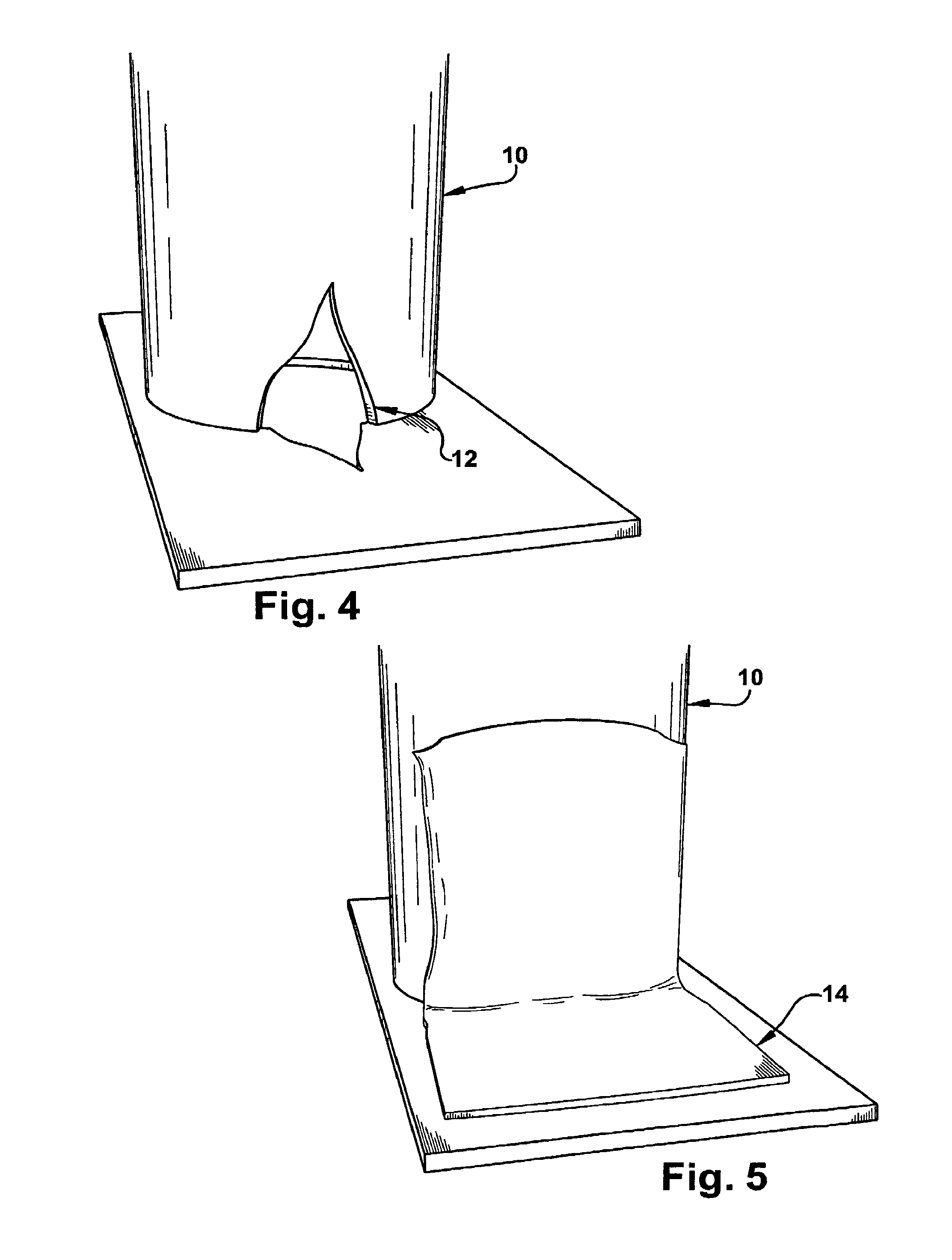

Method of making and using shape memory polymer composite patches

ActiveUS7938923B2Shorten the timeAffordable priceLayered productsLaminationMaterials scienceShape-memory polymer

A method of repairing a composite component having a damaged area including: laying a composite patch over the damaged area; activating the shape memory polymer resin to easily and quickly mold said patch to said damaged area; deactivating said shape memory polymer so that said composite patch retains the molded shape; and bonding said composite patch to said damaged part.

Owner:SPINTECH LLC

Method of making and using shape memory polymer composite patches

InactiveUS20100196705A1Shorten the timeAffordable priceWoven fabricsCoatingsMaterials scienceShape-memory polymer

A method of repairing a composite component having a damaged area including: laying a composite patch over the damaged area; activating the shape memory polymer resin to easily and quickly mold said patch to said damaged area; deactivating said shape memory polymer so that said composite patch retains the molded shape; and bonding said composite patch to said damaged part.

Owner:CORNERSTONE RES GROUP

Animal litter collector

InactiveUS7625026B2Reduce manufacturing costAffordable priceCarpet cleanersFloor cleanersFecesLitter

Owner:DESIGN MFG

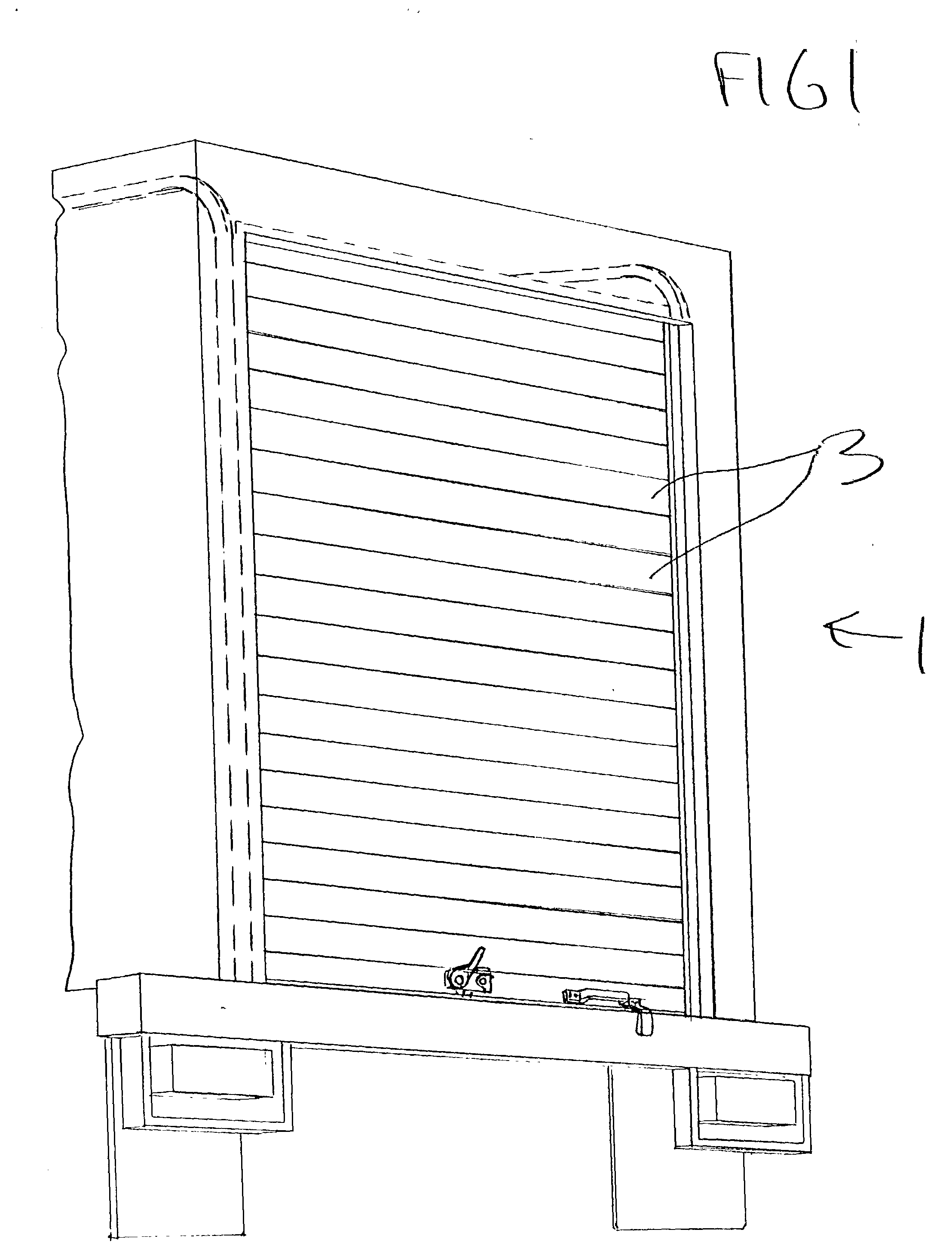

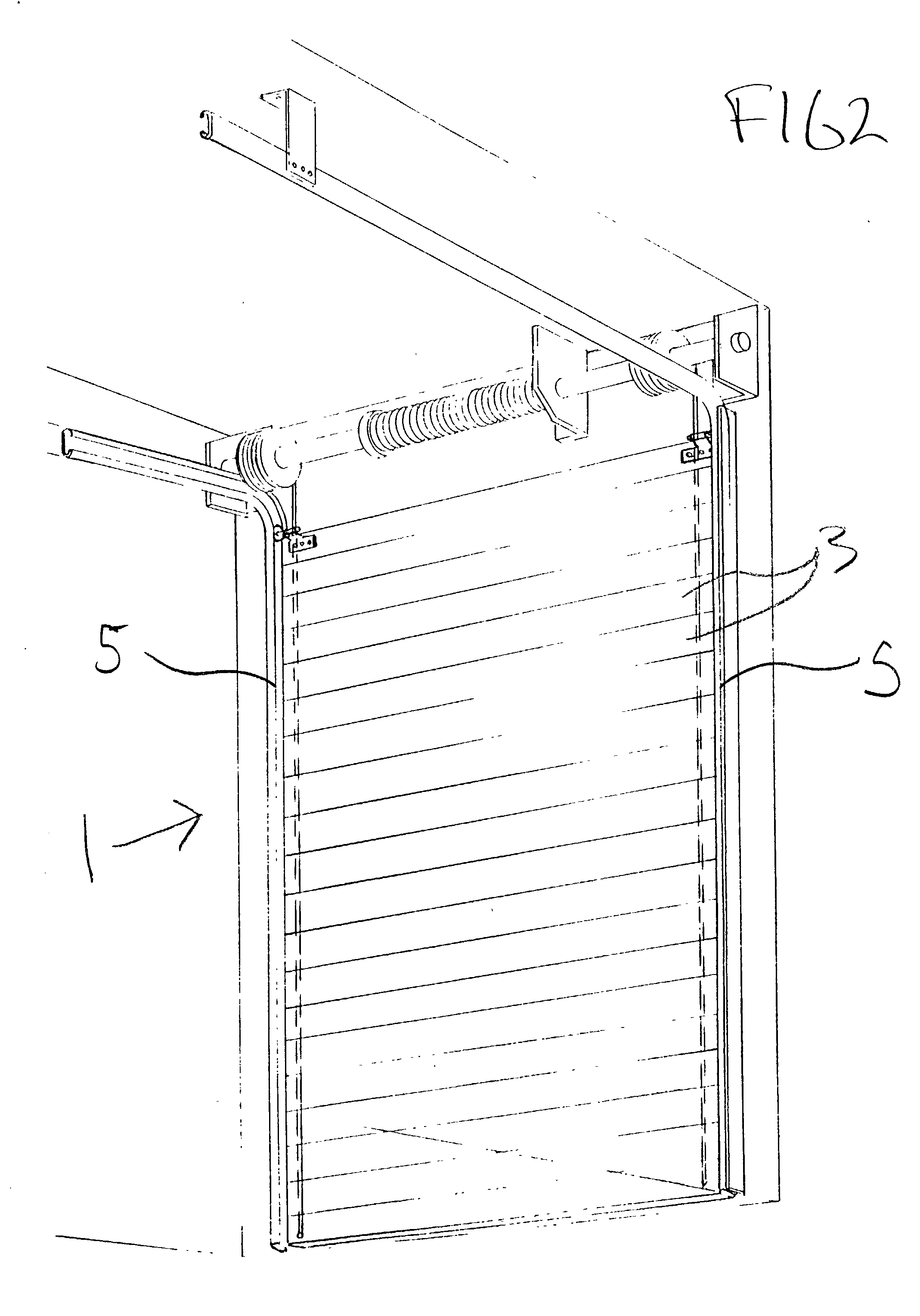

Panel roller

InactiveUS20030213093A1Light weightEasy to assembleCurtain accessoriesDoor/window protective devicesFastenerEngineering

Owner:PROPLAS

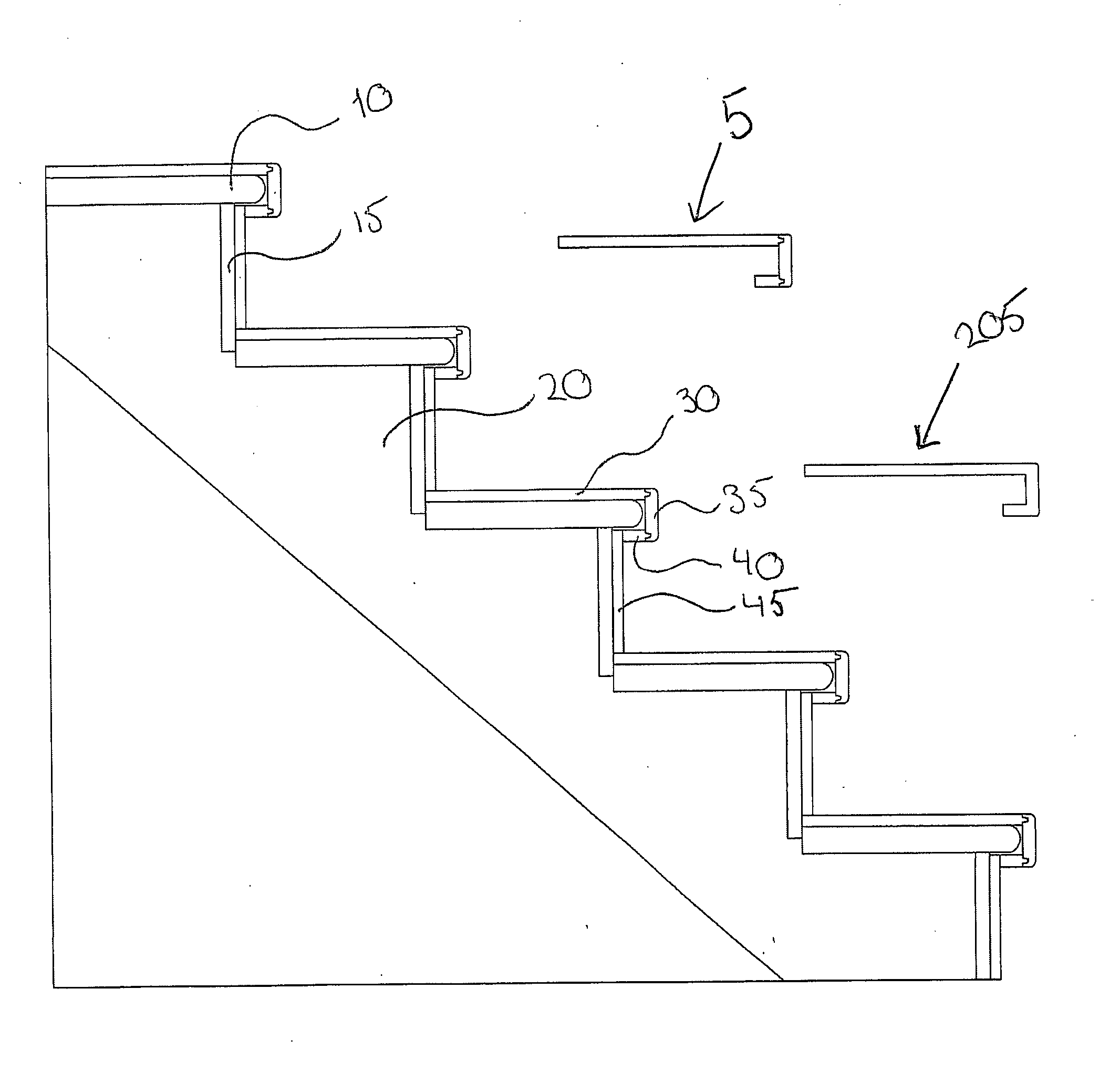

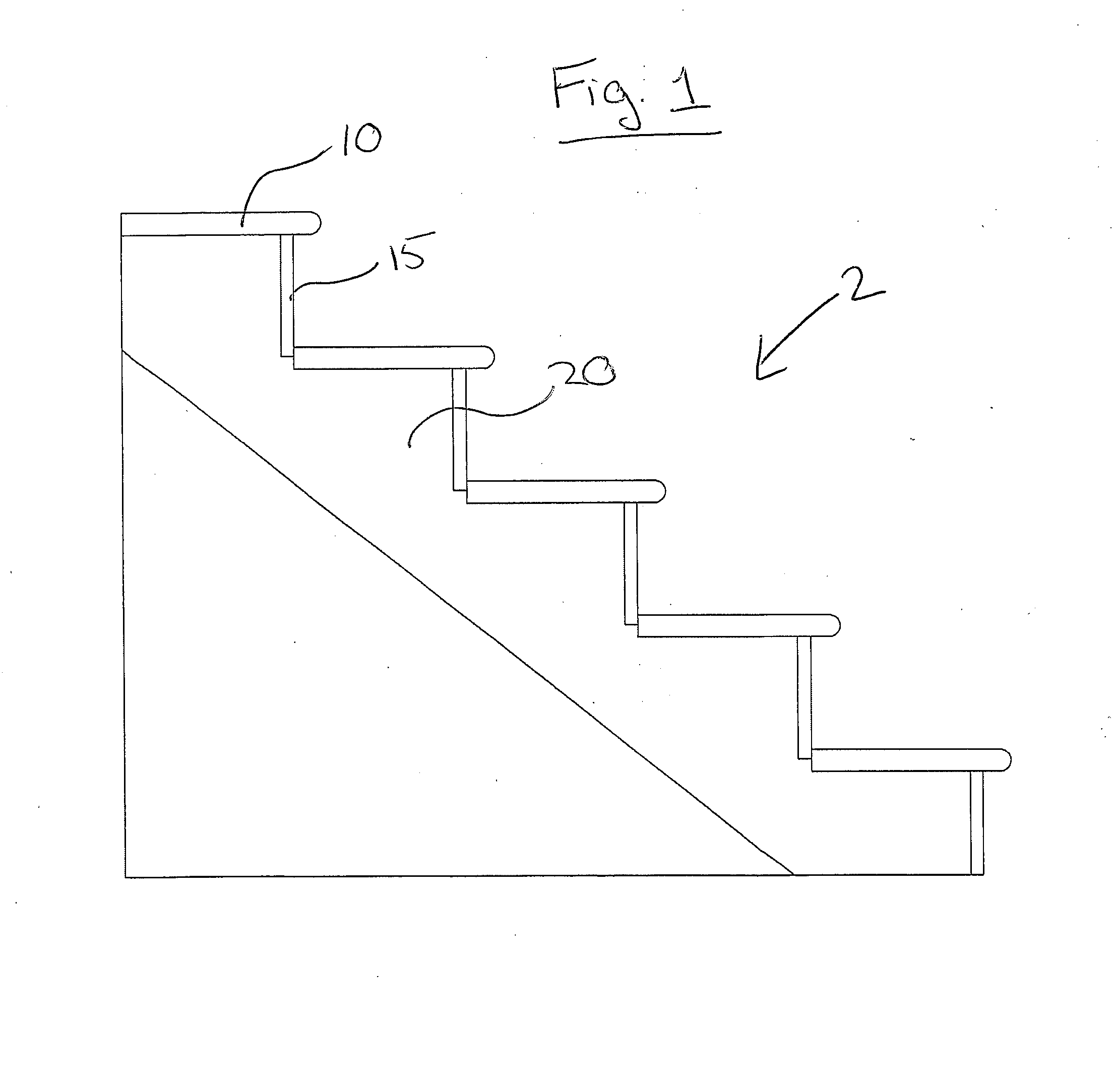

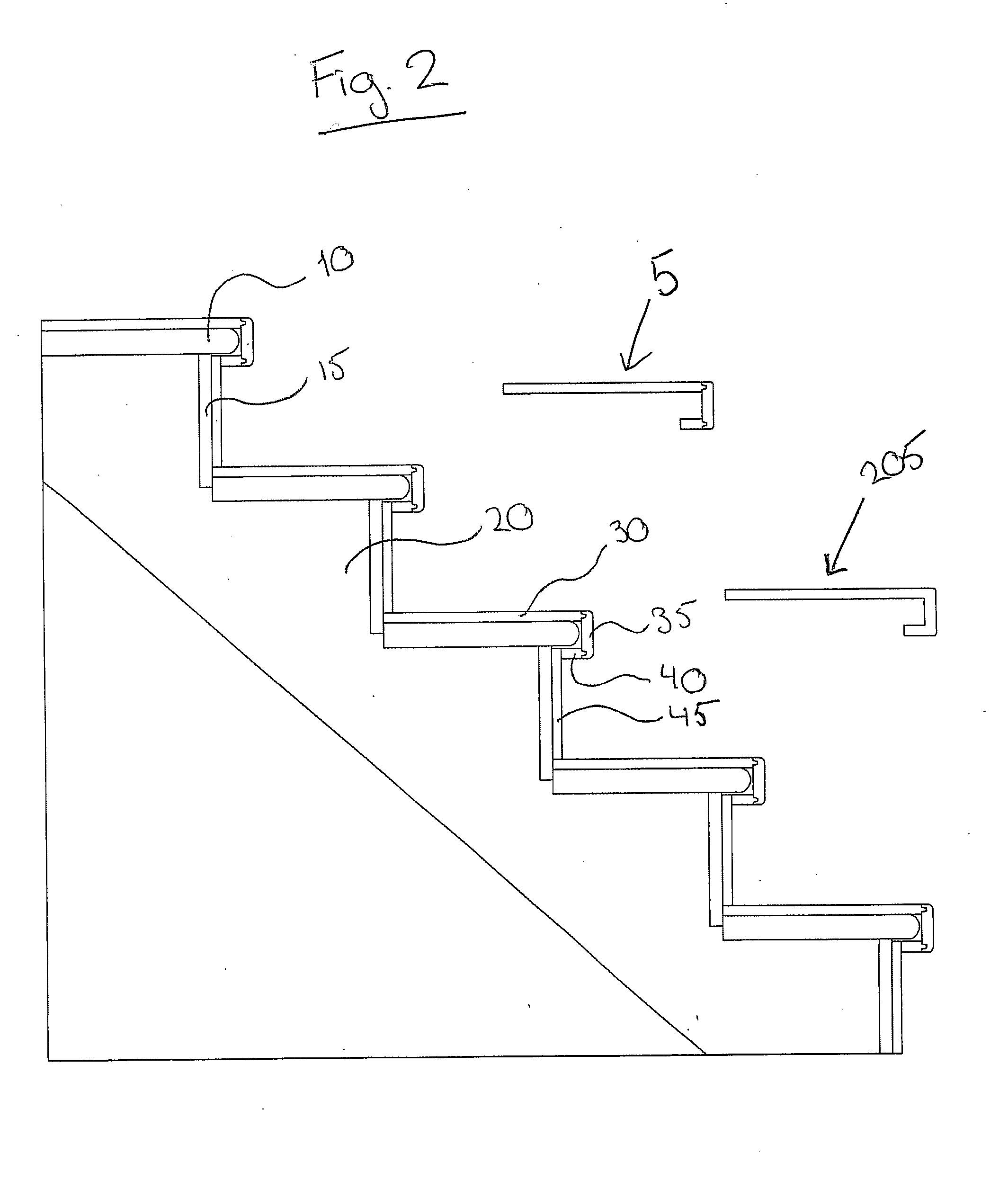

Modular Stair Tread Overlay

InactiveUS20140174005A1Mitigate some of the short comingsImprove usabilityTreadsBuilding repairsAdhesiveEngineering

A modular stair tread overlay including a tread and a front nosing attached to a front edge of the tread cover is disclosed. The front nosing is attached to a front edge by a securing means such as a tongue and groove joint to providing a strong mechanical joint between the nosing portions and the tread cover. Adhesive may be applied at the tongue and groove joint to enhance the strength of the joint. The front nosing of the modular stair tread is hollow thereby allowing the installation of the stair tread overlay over the original stairs without the requirement of removing or trimming the nose of the original stair treads. The stair tread and the nosing can also be unitary and be made of material such as metal, plastic or composite. A method for remodeling stair sets is also disclosed.

Owner:RICHARD JEAN MARC +1

Method of making and using shape memory polymer composite patches

ActiveUS20110265936A1Quickly and cheaply permanently repairQuickly and cheaply joiningLayered productsLaminationMaterials scienceShape-memory polymer

A method of repairing a composite component having a damaged area including: laying a composite patch over the damaged area; activating the shape memory polymer resin to easily and quickly mold said patch to said damaged area; deactivating said shape memory polymer so that said composite patch retains the molded shape; and bonding said composite patch to said damaged part.

Owner:SPINTECH LLC

Chinese herbal medicine galactogogue for sow and its preparing method

InactiveCN1813853AGood lactation effectGood curative effectAnthropod material medical ingredientsAluminium/calcium/magnesium active ingredientsStalactiteCurative effect

The present invention discloses a Chinese medicine galactagogue for sow. It is made up by using (by weight portion) 30-48 portions of stalactite, 20-35 portions of batryticated silkworm, 100-130 portions of Chinese angelica root, 120-160 portions of rice-paper plant pith, 85-150 portions of vaccaria seed, 10-20 portions of pangolin scales and 55-110 portions of lettuce seed through a certain preparation process. Besides, said invention also provides the concrete steps of said preparation process.

Owner:四川绿欣养殖科技有限公司

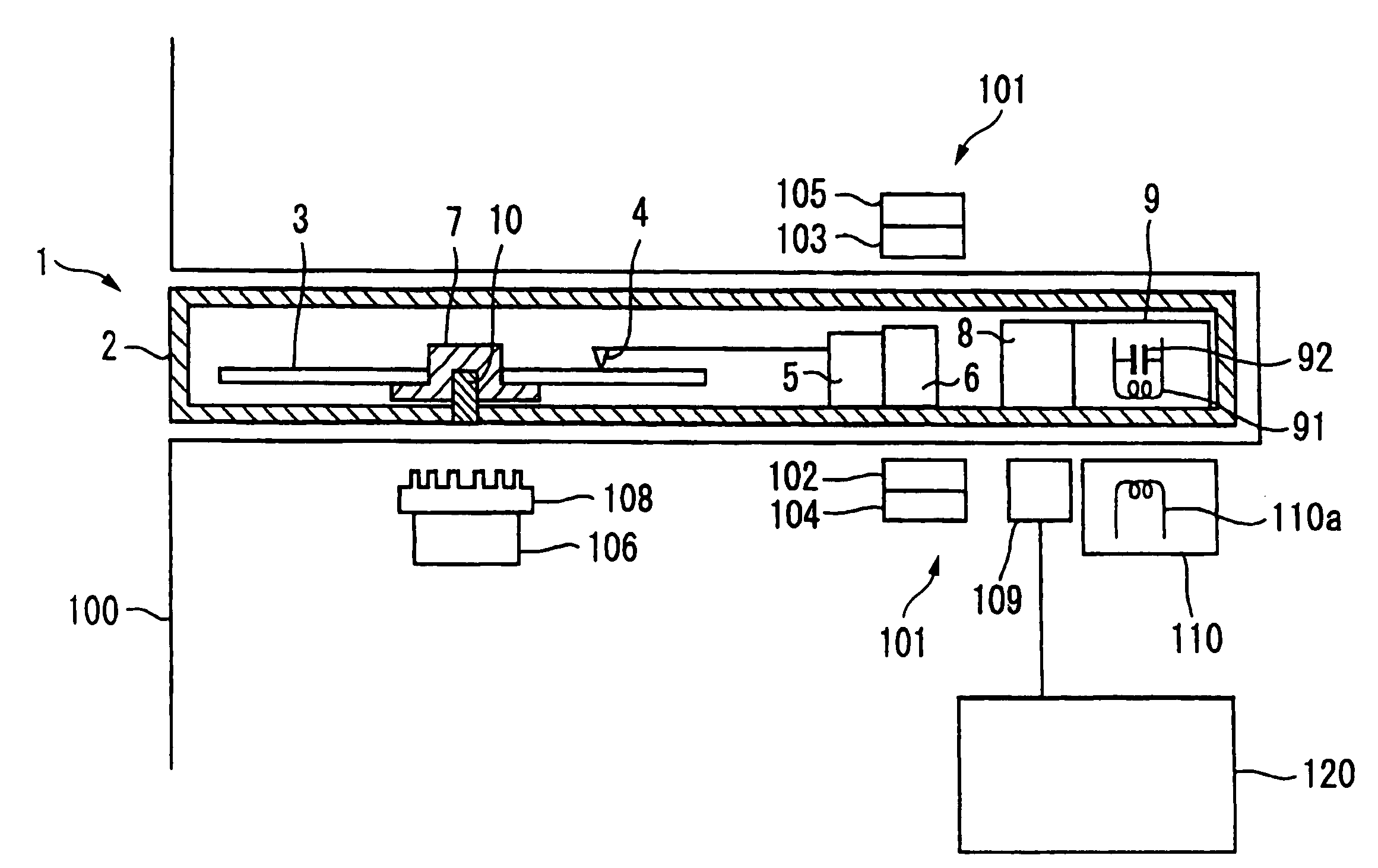

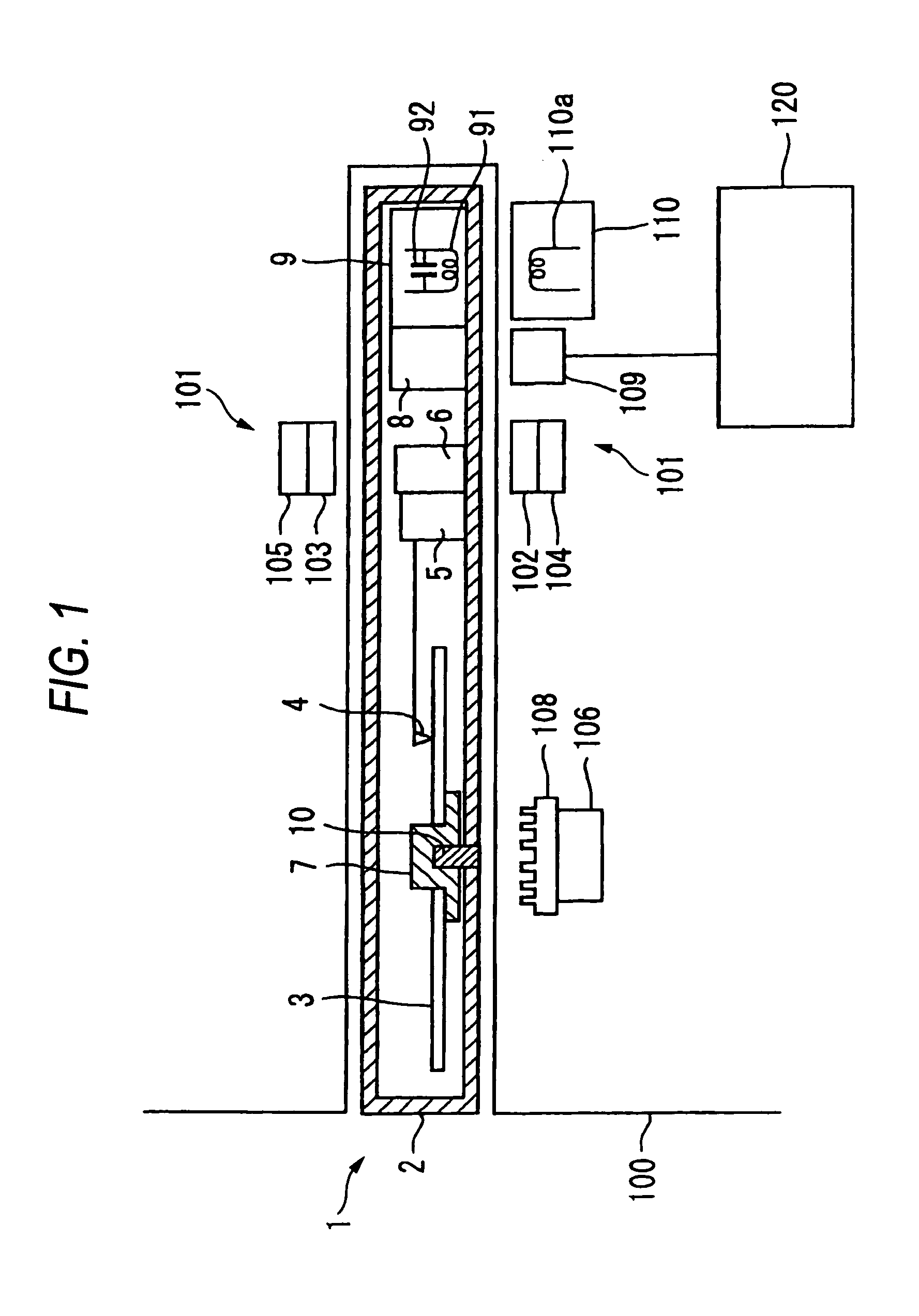

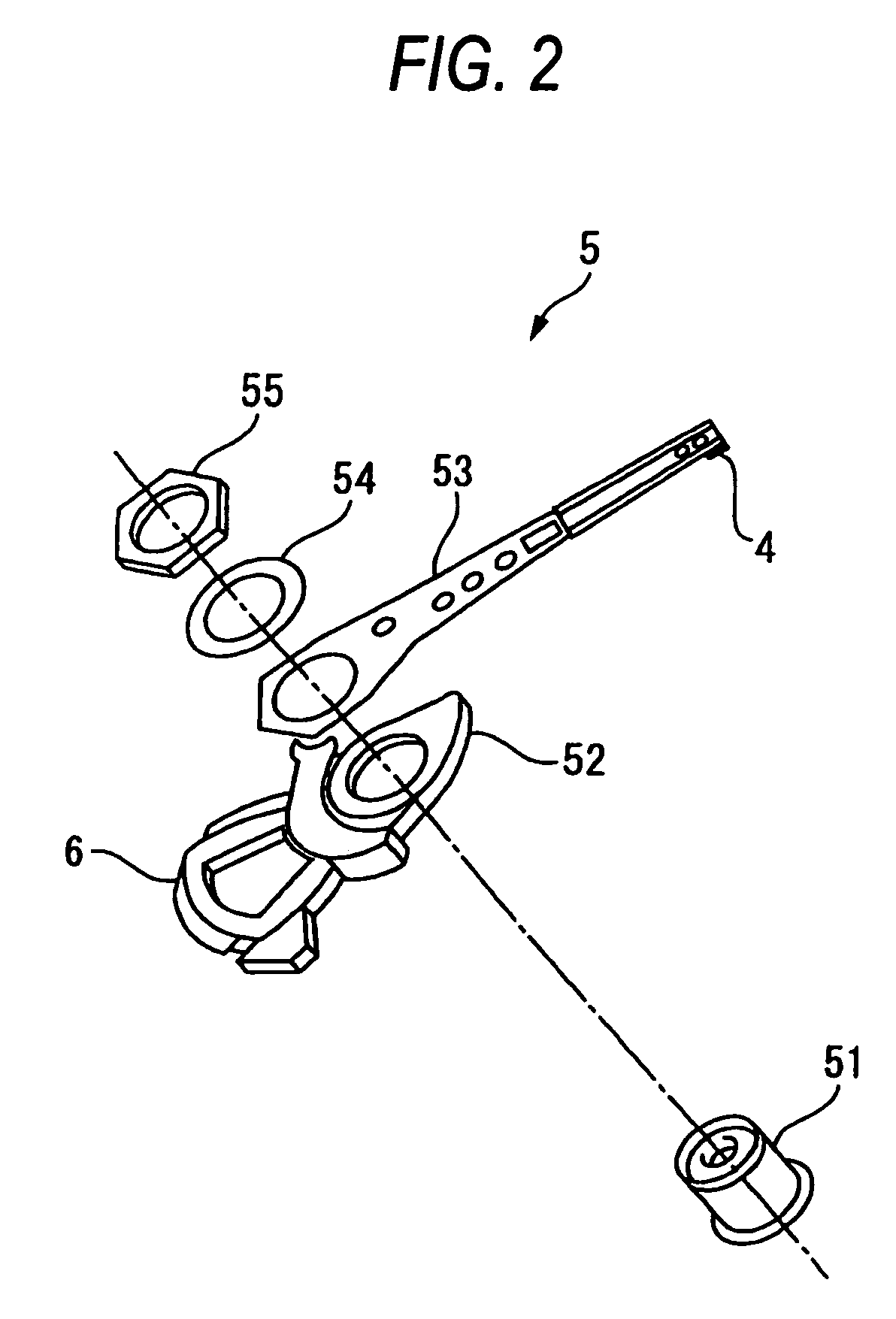

Hard disc device

InactiveUS7251088B2Improve portabilityAffordable priceFilamentary/web record carriersRecord information storageHard disc driveEngineering

A portable hard disc device which is read by a recording and / or reproducing apparatus, including: a disc for recording and / or reproducing; a head slider for recording and / or reproducing the disc; an arm mechanism for moving the head slider to a predetermined position; a voice coil motor type coil for driving the arm mechanism by being driven by an external magnetic field generated by magnets provided in the recording and / or reproducing apparatus and a current supplied from a power circuit; a spindle for rotating the disc after the disc is fixed; and a power circuit for supplying a current to the voice coil motor type coil.

Owner:FUNAI ELECTRIC CO LTD

Animal litter collector

An animal litter collector, comprising a foldable board and a foldable bag having an opening, wherein the foldable board is thin, flat and elongated having a receptacle portion at one end for receiving animal litter, a handle portion in the middle for holding with the human hand and a fastening portion at the other end with a fastener for closing the opening of the foldable bag by fixing it in place; one side of the opening of the foldable bag is fixed onto the fastening portion of the board, and the fastener of the fastening portion is in shape and position that can engage with the other side of the opening to fix it in place and keep the opening closed after animal litter is disposed inside the foldable bag. The present invention is to provide an animal litter collector which is portable, simple and easy to use, and is susceptible of a low cost of manufacture and an affordable price of sale, and can effectively pick up and hold the litter for disposal.

Owner:DESIGN MFG

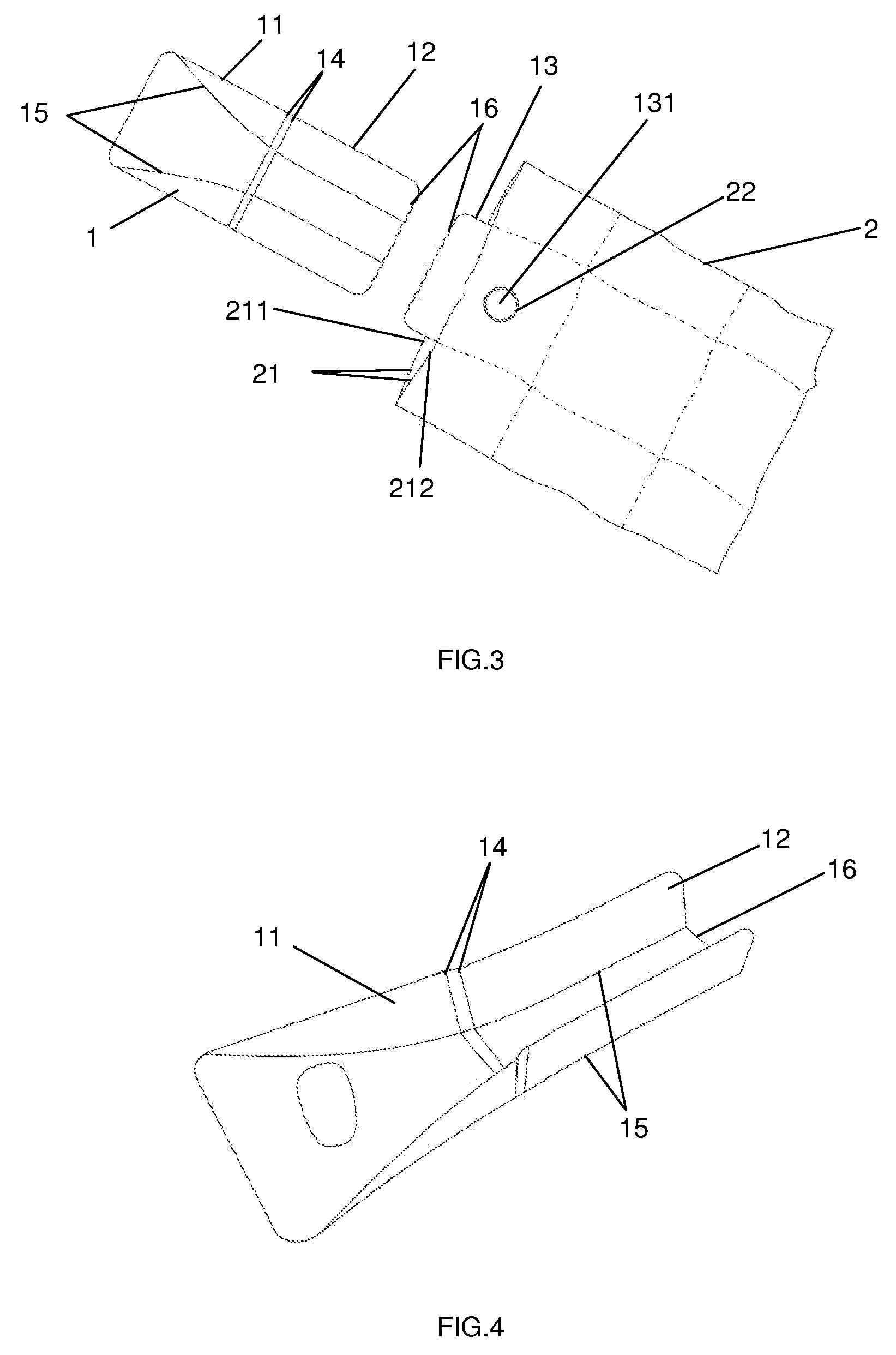

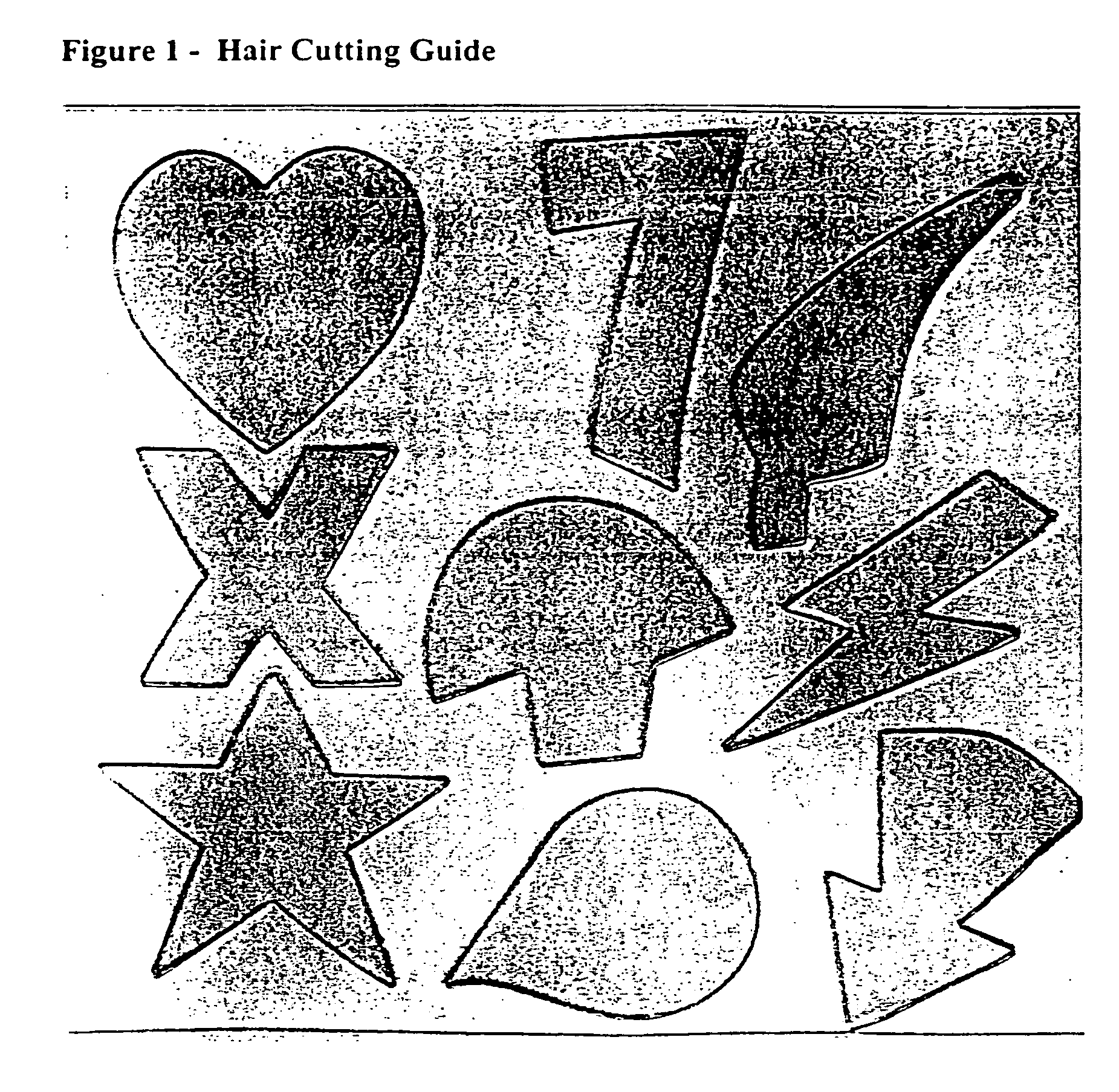

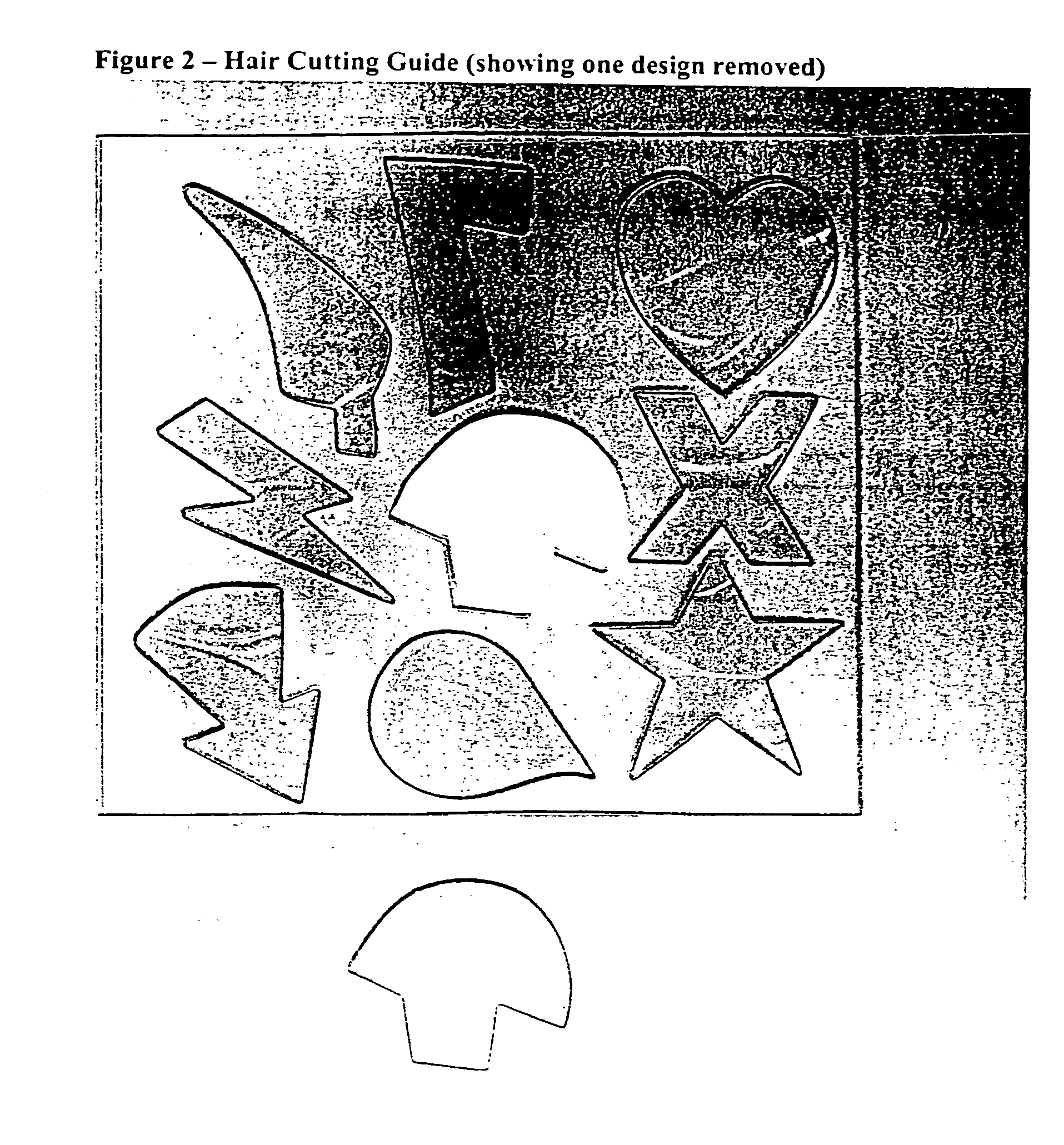

Notorious hair designs

InactiveUS20050000536A1Simple designEasy to implementHair combsMetal working apparatusEngineeringBody hair

Notorious Hair Designs is a series of templates and / or guides used in conjunction with an electrical or battery powered hair trimmer to produce specific designs in body hair. One of the templates / guides is placed over an area of body hair and the hair trimmer is used to remove all hair surrounding the template and not covered by the guide. Thereby producing the design of the template in the form of the remaining body hair.

Owner:NOTORIO FREDERICK JAMES

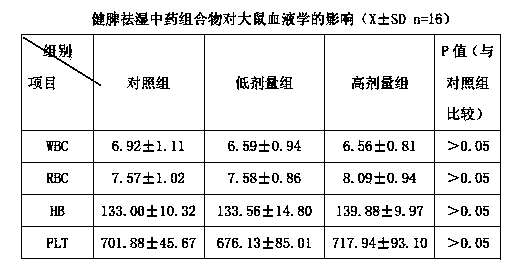

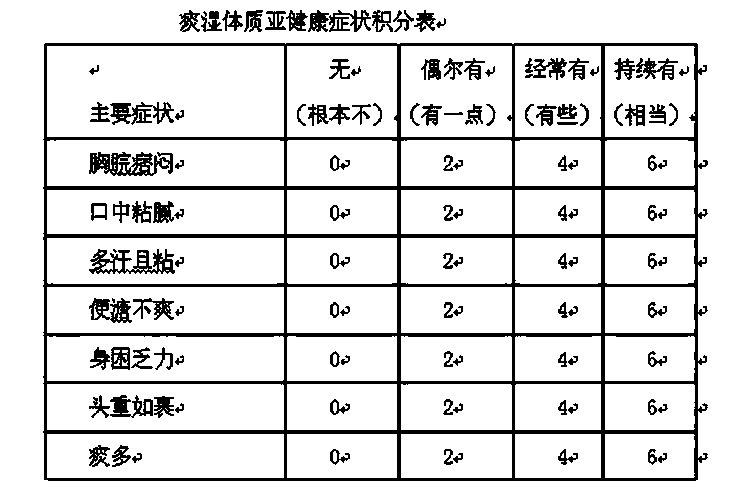

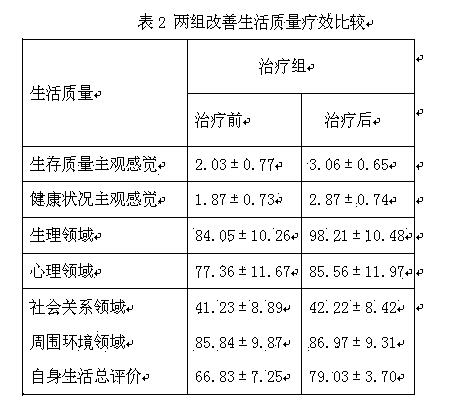

Spleen-strengthening dampness-removing traditional Chinese medicine composition and preparation method thereof

InactiveCN103816519AAffordable priceLow cost of treatmentDigestive systemPill deliveryBULK ACTIVE INGREDIENTBeta-Cyclodextrins

The invention provides a technical scheme of spleen-strengthening dampness-removing traditional Chinese medicine composition and a preparation method thereof. The traditional Chinese medicine composition is prepared from active ingredients in parts by weight as follows: 250-350 parts of stir-fried largehead atractylodes rhizome, 250-350 parts of dried ginger, 80-120 parts of stir-fried rhizoma atractylodis, 80-120 parts of officinal magnolia bark, 80-120 parts of tangerine peel, 80-120 parts of rhizoma pinelliae preparata, 120-180 parts of coix seeds, 120-180 parts of poria, 80-120 parts of purified fructus amomi, 120-180 parts of raw hawthorn, 120-180 parts of raw malt and 80-120 parts of raw licorice. The preparation method comprises the steps as follows: extracting volatile oil from five medicines, namely, the stir-fried largehead atractylodes rhizome, the dried ginger, the stir-fried rhizoma atractylodis, the tangerine peel and the purified fructus amomi, and including the volatile oil with beta-cyclodextrin; adding water into decoction dregs and the rest seven medicines for decoction for two times, merging, filtering and concentrating decoction liquids, adding a volatile oil inclusion compound, dextrin and xylitol, evenly mixing the mixture, adding 70% of ethyl alcohol to produce softwood, and producing the softwood into a needed dosage form.

Owner:冯程

Compound thermal insulation material eiderdown flocculus and making process thereof

InactiveCN102720002ACost-effectiveAffordable priceNon-woven fabricsAdhesivesThermal insulationChemistry

The invention relates to a compound thermal insulation material eiderdown flocculus taking eiderdown, mainly duck down and goose down as the main materials and the making process thereof. The compound thermal insulation material eiderdown flocculus is made by the eiderdown, mainly the duck down and the goose down as well as synthetic fabric, wherein the synthetic fabric is made by meldable fiber and tencel fiber in the weight ratio of 13 to 18:6-15; the mixing ratio of the eiderdown and the synthetic fabric is set by the contents required by the finished eiderdown product; and during making, the animal eiderdown is the main material and the meldable fiber and tencel fiber are the auxiliary materials, and the materials are made into the compound thermal insulation material with 65% content of eiderdown according to different ratios. The compound thermal insulation material eiderdown flocculus not only has the thermal insulation characteristic of the eiderdown and cashmere products, but also is environment-friendly, has spinnability and cuttability, rather lower cost, simple and mature process, easiness for operation and big market potential.

Owner:河北兴瑞羽绒制品有限公司

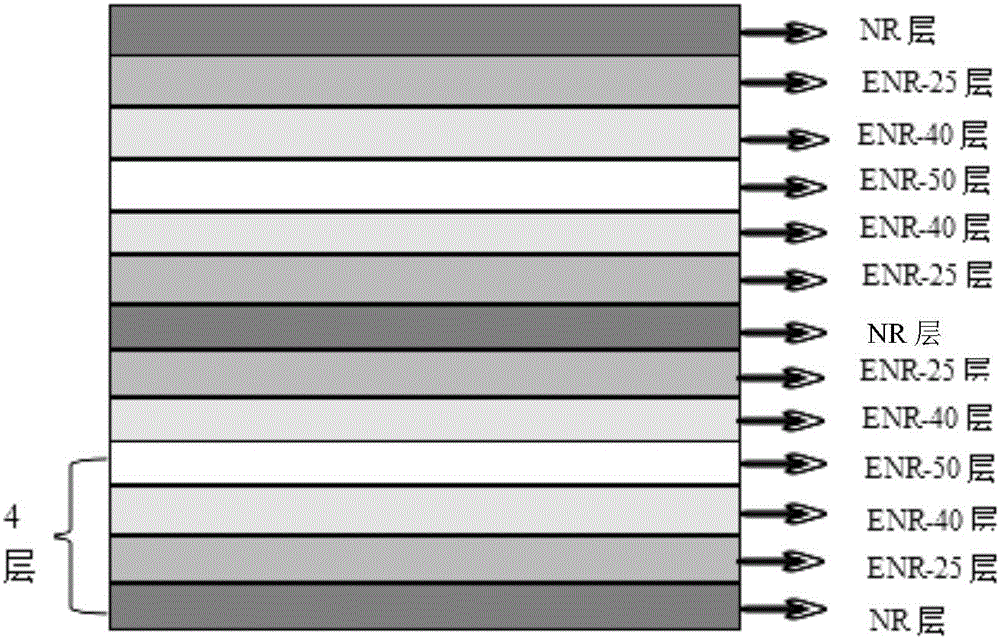

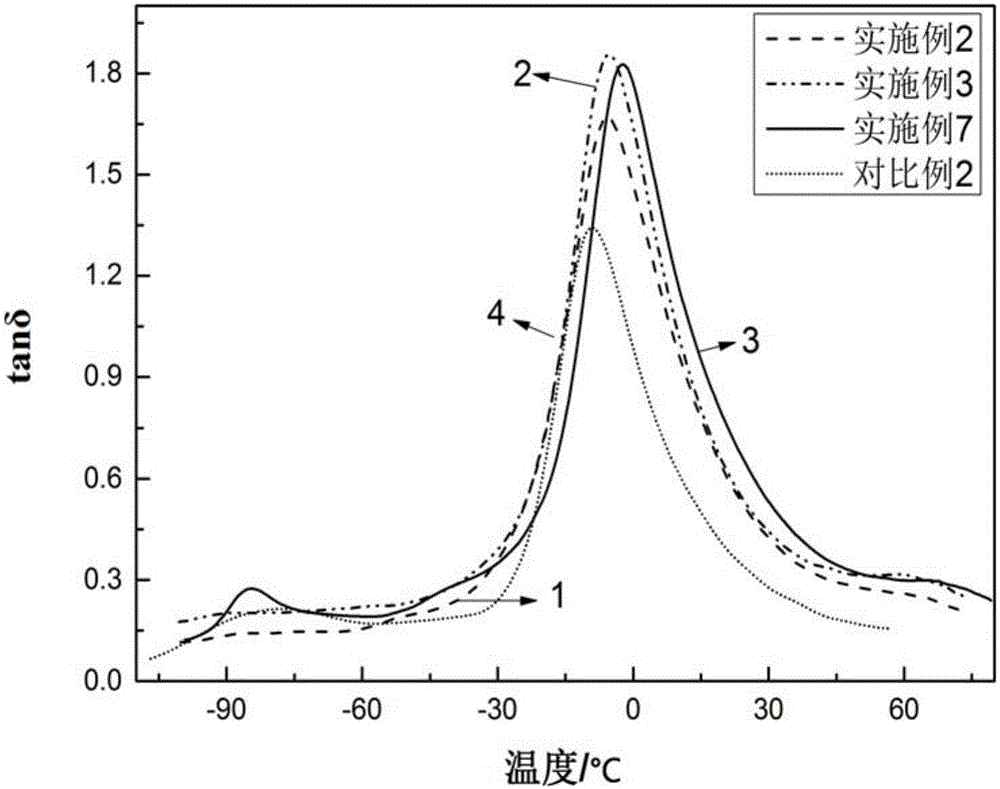

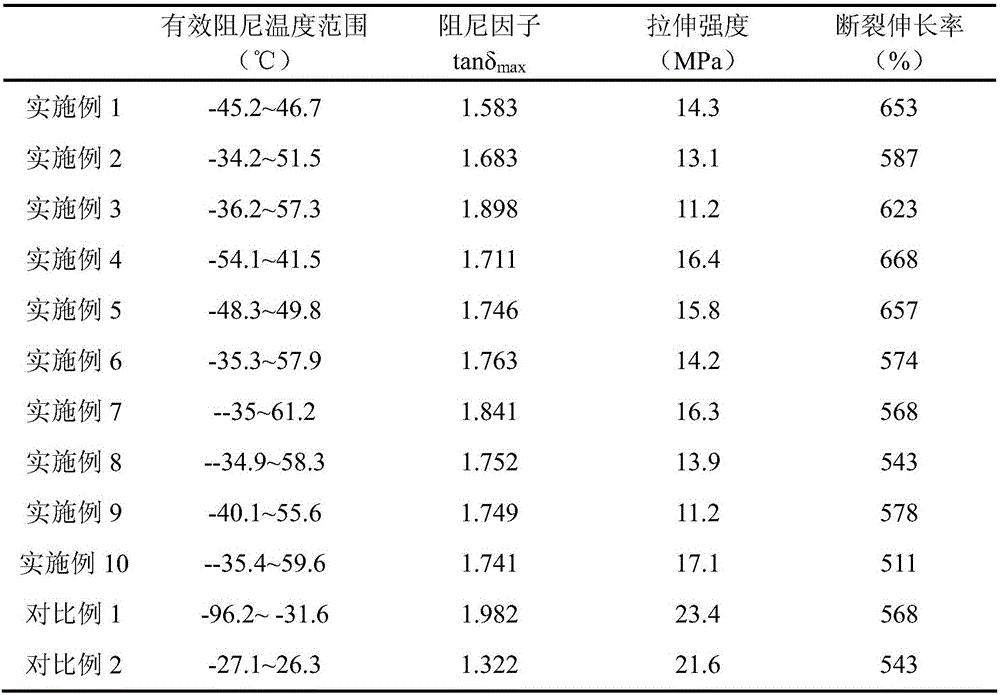

Wide-temperature-range high-damping blended rubber material and preparation method therefor

ActiveCN106633216AWide variety of sourcesAffordable priceLaminationLamination apparatusRubber materialPolymer science

The invention belongs to the technical field of rubber damping materials and discloses a wide-temperature-range high-damping blended rubber material and a preparation method therefor. The blended rubber material is prepared through alternately superimposing natural rubber layers and epoxidized natural rubber layers of n kinds of epoxidation degrees, wherein each kind of epoxidation degree corresponds to one epoxidized natural rubber layer; a gradient of the epoxidation degrees is formed through alternately superimposing the natural rubber layers and the epoxidized natural rubber layers of n kinds of epoxidation degrees; n is an integer and is not smaller than 1; the natural rubber layers employ natural rubber as a main raw material; and each of the epoxidized natural rubber layers of n kinds of epoxidation degrees employs epoxidized natural rubber as a main raw material. The prepared rubber material has the characteristics of wide temperature range and high damping, and meanwhile, the mechanical properties of the rubber material are relatively good.

Owner:SOUTH CHINA UNIV OF TECH

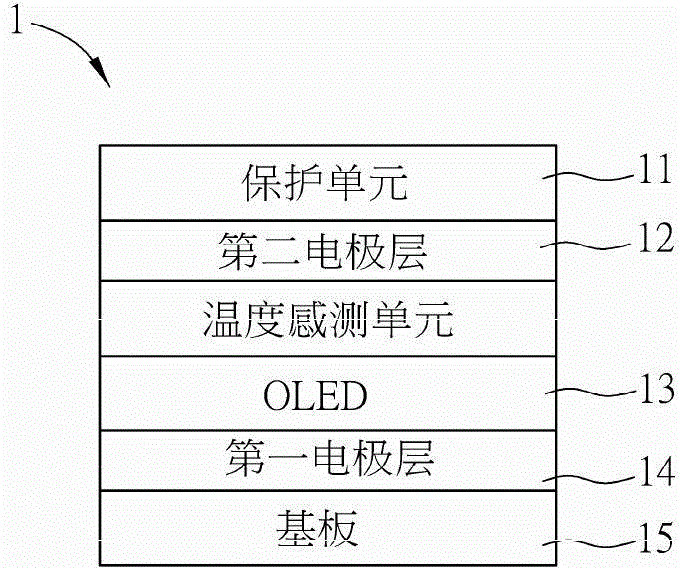

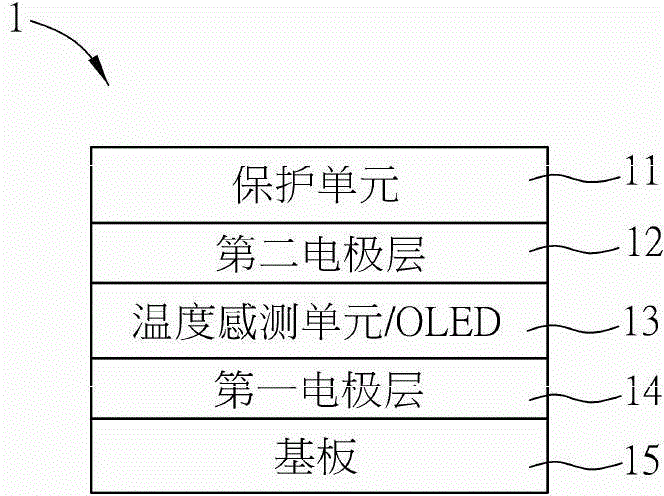

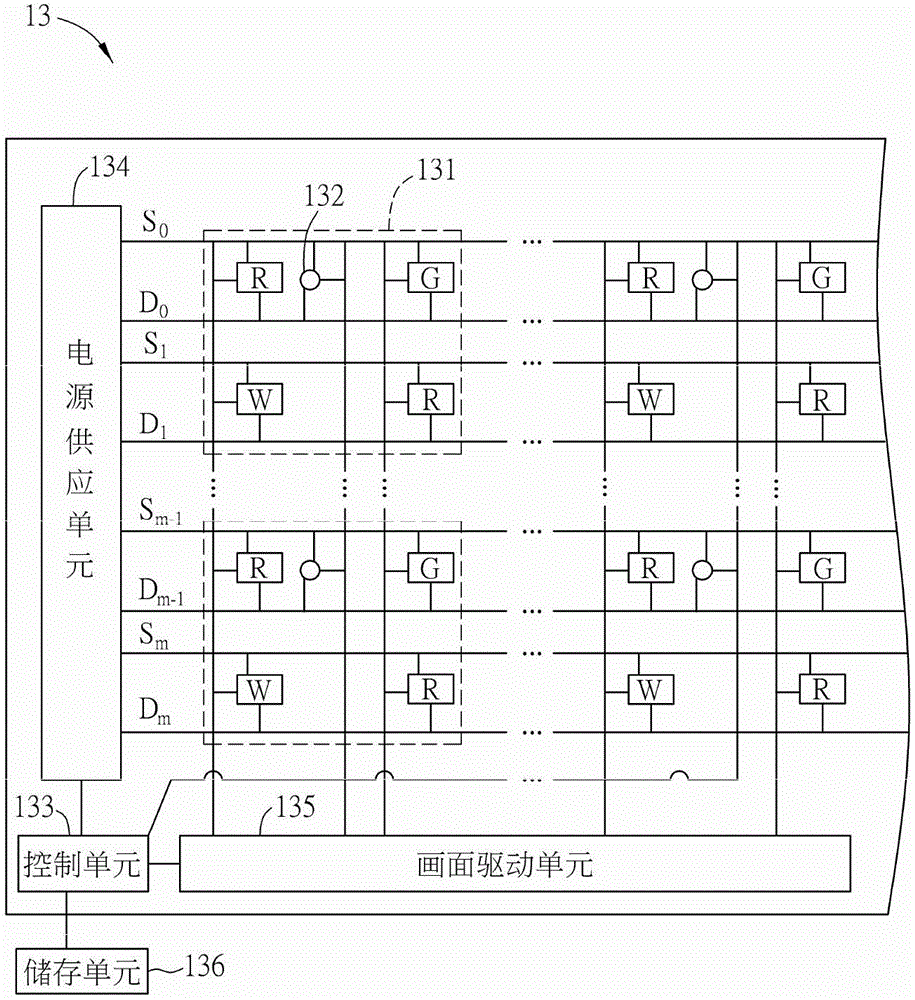

Organic light-emitting diode display panel and organic light-emitting diode display apparatus

InactiveCN105321977AAffordable priceImprove the level of manufacturing technologySolid-state devicesInput/output processes for data processingEngineeringLight-emitting diode

The invention discloses an organic light-emitting diode display panel. The organic light-emitting diode display panel comprises a plurality of pixel units, a plurality of temperature sensing units and a control unit; the multiple pixel units are arranged in a matrix manner; the multiple temperature sensing units are arranged corresponding to the multiple pixel units; the control unit is electrically connected with the multiple temperature sensing units; the organic light-emitting diode display panel receives input; the control unit receives at least one temperature signal transmitted by the multiple temperature sensing units, and a control position or instruction corresponding to the input is calculated based on multiple temperature signals.

Owner:HANNSTAR DISPLAY NANJING +1

Dendrometer

ActiveUS9377288B2Easy constructionGuaranteed uptimeElectrical/magnetic solid deformation measurementTesting plants/treesLength variationTree trunk

A dendrometer comprises a dendrometer band whose length is extendable for encircling a tree trunk. The dendrometer further comprises an elongated electronic component that is closely or contiguously attached to the dendrometer band for moving along with the dendrometer band in order to follow length extension of the dendrometer band. Length variation of the dendrometer band is configured to be converted to electronic signals by the electronic component.

Owner:GLOBAL CHANGE SOLUTIONS

Dehumidifying colorless PET (polyethylene Terephthalate) color master batch

InactiveCN103172985AReduce manufacturing costReduce dosagePolyethylene terephthalate glycolPolyethylene terephthalate

The invention discloses a dehumidifying colorless PET (polyethylene Terephthalate) color master batch which is prepared from the components in percentage by weight as follows: 40-60% of carrier, 1-3% of coloring agent, 1-3% of dispersant, 5-15% of dehumidifying additive and 15-25% of nucleating agent. The invention further discloses a preparation method of the dehumidifying colorless PET color master batch. According to the dehumidifying colorless PET color master batch provided by the invention compared with color master batches marketed with similar functions, the price is more economical, and the production cost of a plastic process is reduced. With the adoption of an integral production mode, the production process is reduced and the energy resources are saved. According to the invention, the structure of PET grains is further changed, so that the crystallizing efficiency is improved, the mechanical performance is increased, the forming period is shortened and the economic benefit of enterprises is improved. According to the invention, novel components are adopted, and the use level of harmful substances is reduced, so that the harmful substances are substantially not volatilized without affecting the health of a human body. The color master batch is suitable for application and use in the manufacturing industry.

Owner:胡君

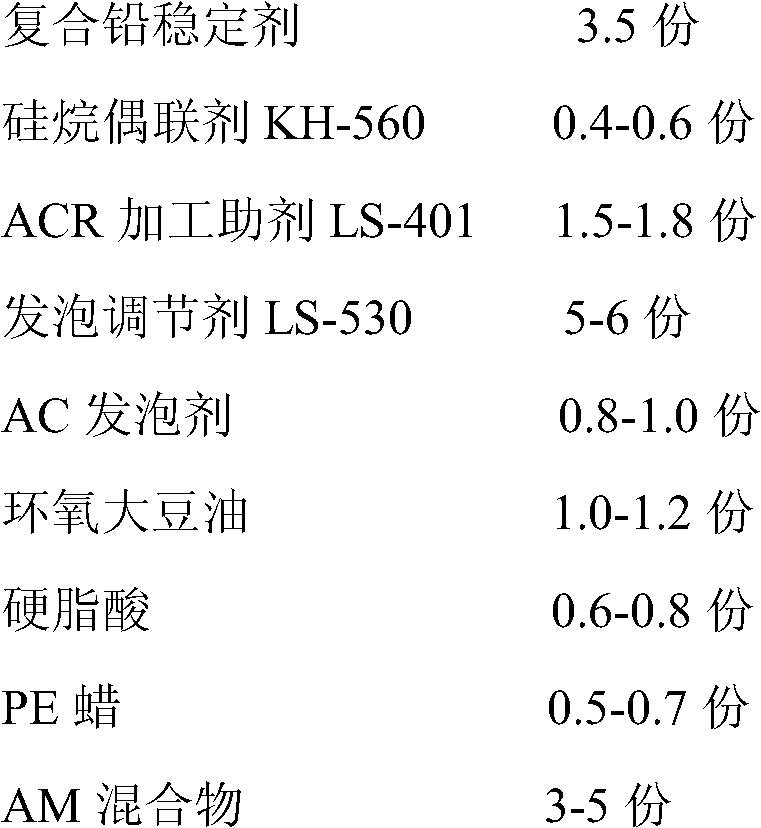

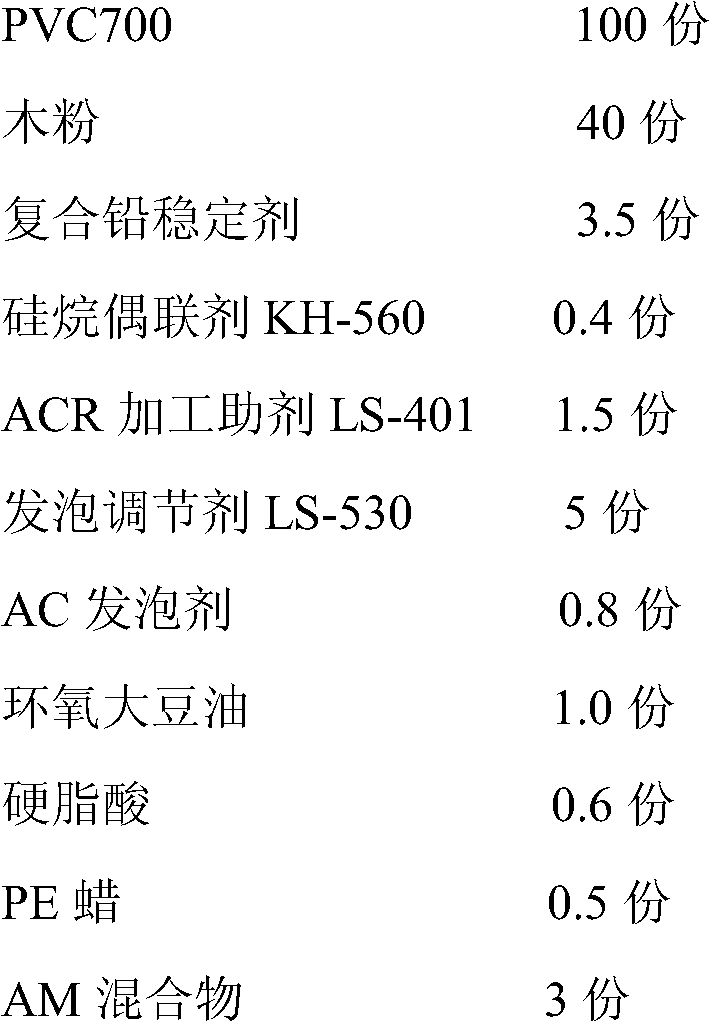

AM mixture used for wood plastic products, and preparation and application methods thereof

Owner:SHANDONG RUIFENG CHEM

Mung bean ice sucker and preparation method thereof

InactiveCN102008002ASimple preparation processAffordable priceFrozen sweetsGeneral familyLemon juice

The invention discloses a mung bean ice sucker and a preparation method thereof. The invention contains the following components by weight percent: mung bean: 4 to 8, starch: 2 to 5, white sugar: 1 to 5, saccharin sodium: 1 to 3, vanilline: 1 to 2, lemon juice: 1 to 3 and water as the balance in 100 parts. The preparation method of the mung bean ice sucker comprises the following steps of: (1) adding the starch into water the amount of which accounts for 20% of formula, mixing until pasty to obtain a filtrate A; (2) adding the white sugar and the saccharin sodium into water the amount of which accounts for 20% of formula, evenly stirring, and filtering with a gauge to obtain a filtrate B; (3) mixing the filtrate A with the filtrate B, sterilizing the mixed filtrate by boiling, adding the vanilline, the lemon juice and the rest water to the mixed filtrate, and uniformly stirring; and (4) cooling and then filling the product resulted from the step (3) in an ice sucker mold, inserting a bamboo stick and freezing. The ice sucker of the invention is convenient for preparation, suitable for ordinary families, low in price and good in taste, and becomes an preferred choice of heatstroke prevention, heat reduction and physical refreshment.

Owner:朱丽华

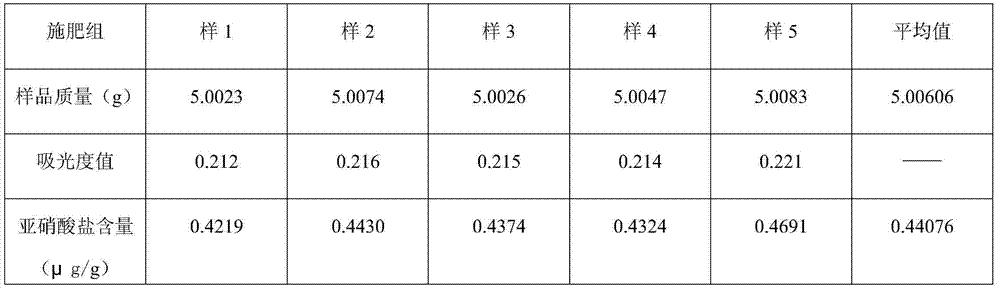

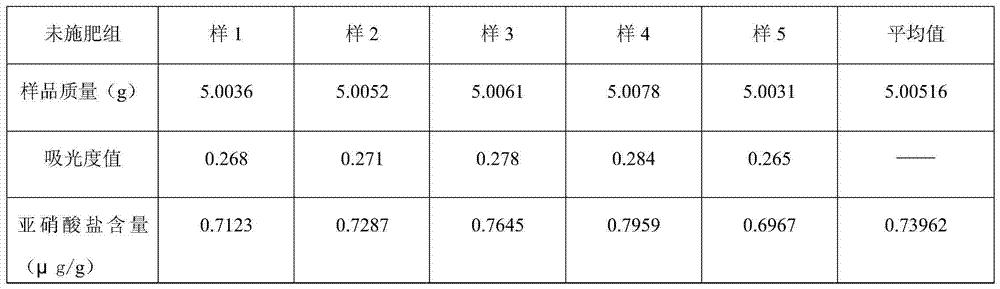

Compound fertilizer

InactiveCN103588557AHigh activityImprove long-term effectFertilizer mixturesManganeseDipotassium phosphate

The invention relates to a fertilizer and particularly relates to a compound fertilizer. The compound fertilizer disclosed by the invention consists of beer residue, urea, dipotassium phosphate, potassium sulphate, median nutrient elements, borax, manganese sulfate, molybdenum ammoniate heptahydrate and compound strains. The compound fertilizer disclosed by the invention is fast, long-term and comprehensive in fertilizer efficiency, not only has high activity and long residual action of an organic fertilizer and a biological fertilizer, but also has the specificity of a micro element fertilizer and a bacterial fertilizer. The compound fertilizer contains full-value nutrient elements required by plants and scientific in matching, and the utilization rate and fertilizer efficiency of the compound fertilizer can be greatly improved.

Owner:何建波

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com