Wide-temperature-range high-damping blended rubber material and preparation method therefor

A rubber material and high damping technology, applied in the field of rubber damping materials, can solve the problems that it is difficult to fully meet the requirements of practical application of ambient temperature, only -25.4 ~ 26.6 ℃, difficult to meet the requirements of practical application, etc., to achieve the purpose of broadening the effective damping temperature range, broaden the damping temperature range, and the effect of economical price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

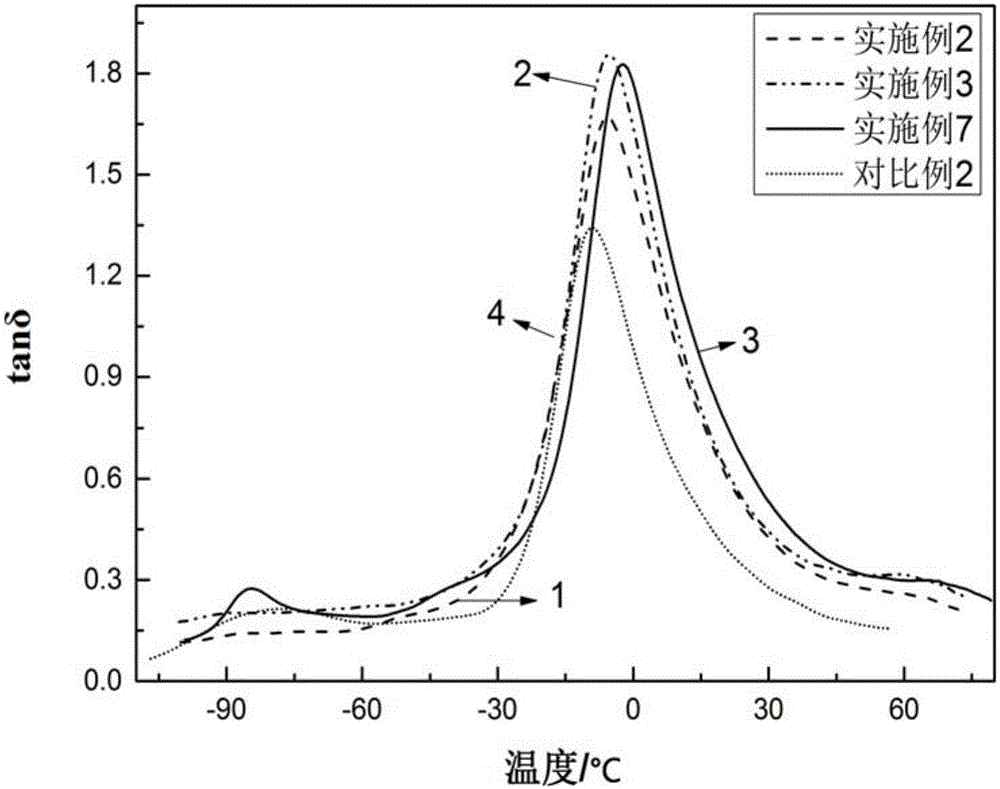

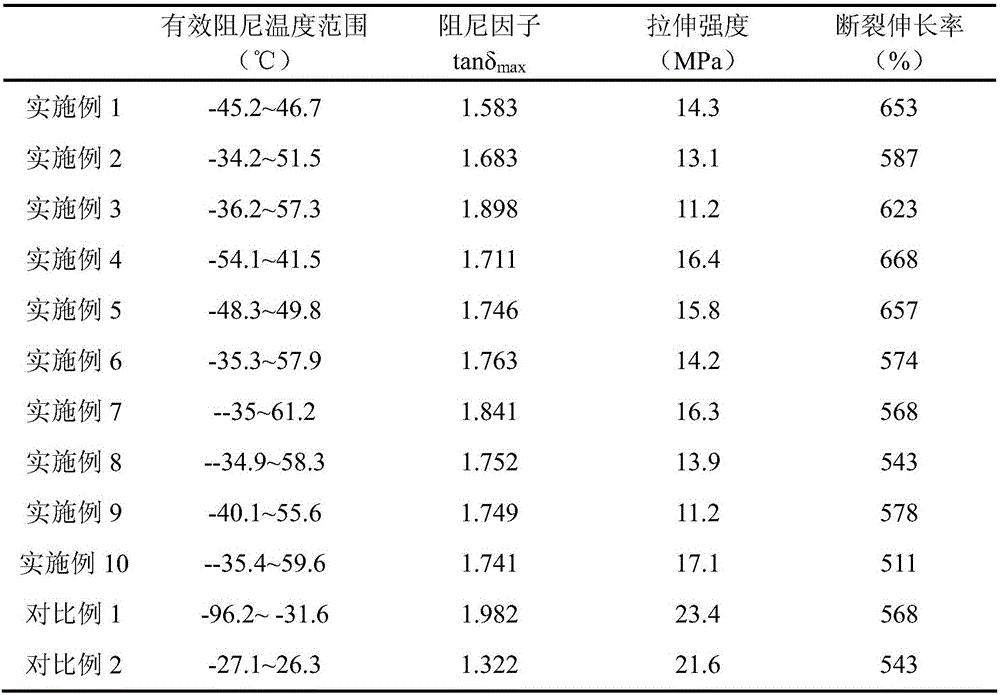

Examples

Embodiment 1

[0065] (1) At 50°C, masticate 50 parts of 3L-type natural rubber standard rubber on the open mill for 5 minutes, then cover the rolls, add 2.5 parts of zinc oxide, 1 part of stearic acid, 0.25 parts of benzothiazole disulfide, N - 0.75 parts of cyclohexyl-2-benzothiazole sulfenamide, 1.3 parts of sulfur, mixed evenly to obtain natural rubber rubber compound;

[0066] (2) At 50°C, put 50 parts each of ENR-50, ENR-40 and ENR-25 epoxidized natural rubber into the open mixer for 3 minutes, and then add 2.5 parts of zinc oxide , 1 part of stearic acid, 1 part of basic magnesium carbonate, 0.25 parts of benzothiazole disulfide, 0.75 parts of N-cyclohexyl-2-benzothiazole sulfenamide, 5 parts of 2402 tert-butylphenol formaldehyde resin, mixed Mix evenly to obtain respective rubber mixes (i.e. ENR-50 type rubber mixes, ENR-40 type rubber mixes, and ENR-25 type rubber mixes);

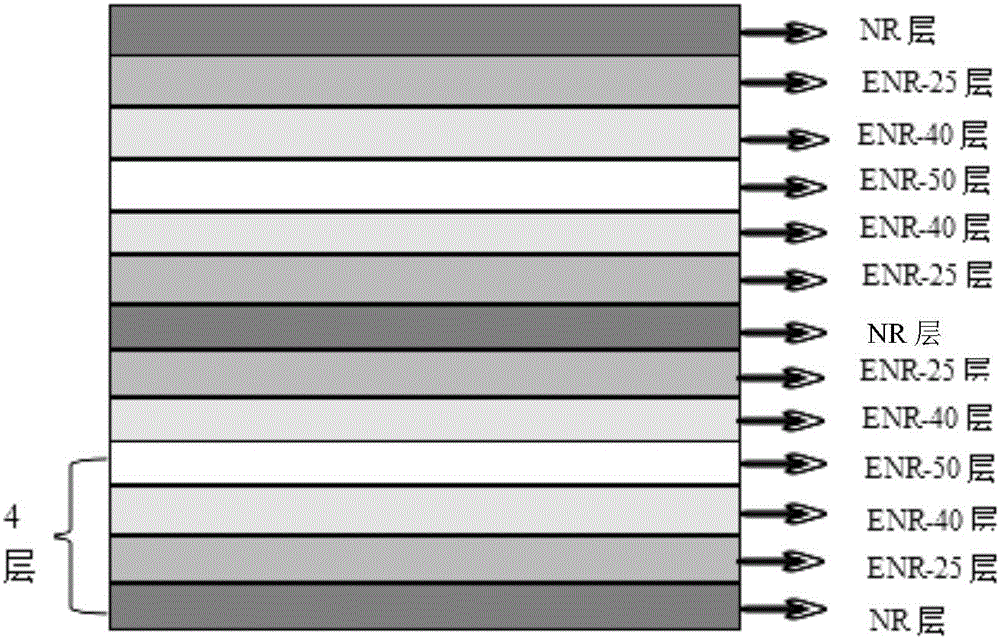

[0067] (3) After the mixed rubbers in steps (1) and (2) were left to stand for 12 hours, the four mixed rubbe...

Embodiment 2

[0069] (1) At 50°C, masticate 50 parts of 3L-type natural rubber standard rubber on the open mill for 5 minutes, then cover the rolls, add 2.5 parts of zinc oxide, 1 part of stearic acid, 0.25 parts of benzothiazole disulfide, N - 0.75 parts of cyclohexyl-2-benzothiazole sulfenamide, 1.3 parts of sulfur, mixed evenly to obtain natural rubber rubber compound;

[0070] (2) At 50°C, put 50 parts each of ENR-50 type, ENR-40 type, and ENR-25 type epoxidized natural rubber into an open mixer for 3 minutes and then add 2.5 parts of zinc oxide. 1 part of stearic acid, 1 part of basic magnesium carbonate, 0.25 part of benzothiazole disulfide, 0.75 part of N-cyclohexyl-2-benzothiazole sulfenamide, and 5 parts of 2402 tert-butylphenol formaldehyde resin were mixed separately Evenly, to obtain respective rubber compounds (i.e. ENR-50 type rubber compounds, ENR-40 type rubber compounds, ENR-25 type rubber compounds);

[0071] (3) Let the rubber mixes in steps (1) and (2) stand for 12 hour...

Embodiment 3

[0073] (1) At 50°C, masticate 50 parts of 3L-type natural rubber standard rubber on the open mill for 5 minutes, then cover the rolls, add 2.5 parts of zinc oxide, 1 part of stearic acid, 0.25 parts of benzothiazole disulfide, N - 0.75 parts of cyclohexyl-2-benzothiazole sulfenamide, 1.3 parts of sulfur, mixed evenly to obtain natural rubber rubber compound;

[0074] (2) At 50°C, put 50 parts each of ENR-50 type, ENR-40 type, and ENR-25 type epoxidized natural rubber into an open mixer for 3 minutes and then add 2.5 parts of zinc oxide. 1 part of stearic acid, 1 part of basic magnesium carbonate, 0.25 part of benzothiazole disulfide, 0.75 part of N-cyclohexyl-2-benzothiazole sulfenamide, and 5 parts of 2402 tert-butylphenol formaldehyde resin were mixed separately Evenly, to obtain respective rubber compounds (i.e. ENR-50 type rubber compounds, ENR-40 type rubber compounds, ENR-25 type rubber compounds);

[0075](3) Leave the mixed rubbers in steps (1) and (2) to stand for 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com