Hydrocarbon material catalytic cracking lift pipe reactor

A catalytic cracking and reactor technology, applied in chemical instruments and methods, naphtha catalytic reforming, chemical/physical processes, etc., can solve the problems of poor versatility of equipment and complex engineering, and achieve simple structure, high catalyst density, Reduces the effect of catalyst backmixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

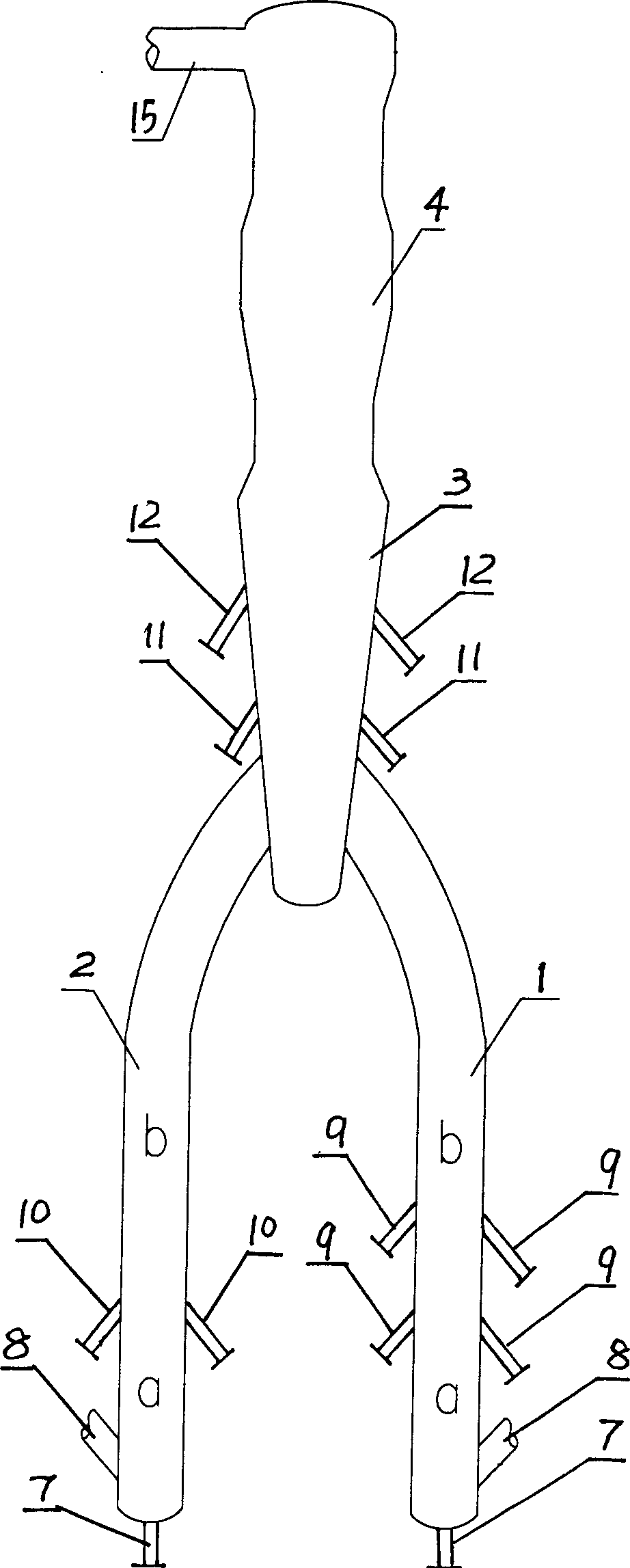

Method used

Image

Examples

Embodiment 2

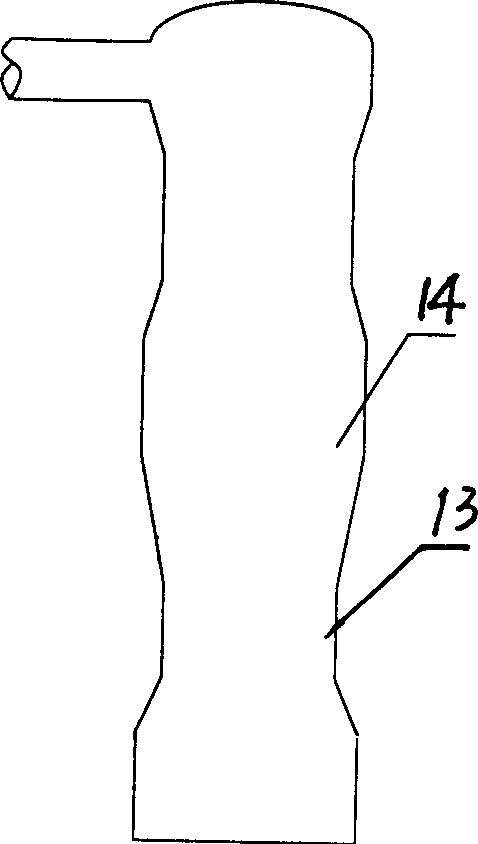

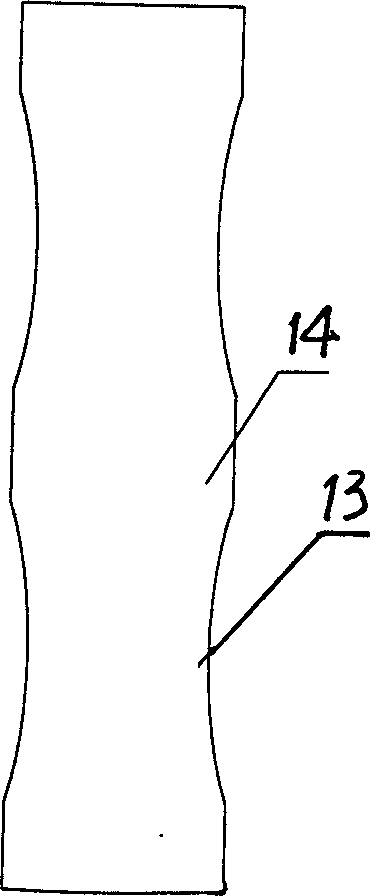

[0014] Embodiment 2. In this embodiment, the height of the first and second reactors 1 and 2 is 5 meters, and the height of the cracking section b is 15 meters. The third reactor 3 has an inverted conical structure with a cone angle of 20 degrees, and its height is 4 meters. The fourth reactor 4 is a zoom-shaped structure, and the longitudinal section structure of the diameter-reducing zone 13 is as follows: image 3 As shown, the diameter of the reduced-diameter zone 13 is 0.7-1 times of the diameter of the non-diameter-reduced zone 14, and the height is 10 meters. Others are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com