Patents

Literature

33results about How to "Uniform physical and chemical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gas-shielded flux-cored wire with recyclable welding slag

InactiveCN102139424ALow diffusible hydrogen contentReduce sensitivityWelding/cutting media/materialsSoldering mediaCrack resistanceHydrogen

A gas-shielded flux-cored wire with recyclable welding slag belongs to the welding field. In the invention, the skin of the gas-shielded flux-cored wire is made from a mild steel strip, and welding slag powder is partially or completely instead of natural rutile, thus the purposes of saving the resource and reducing the cost are achieved. The powder of the flux-cored wire comprises the following chemical components in percentage by weight: 15-35% of the welding slag powder of the flux-cored wire (including 20-65% of TiO2, 5-15% of MnO, 5-15% of MgO, 5-15% of SiO2, 1-10% of Fe2O3 and 1-10% of Al2O3), 15-35% of TiO2, 2-7% of Si, 3-8% of Mn, 0.5-5% of Al-Mg, 0-5% of Na, 0-5% of K, 1-5% of Mg and the balance of ferrous powder. When the flux-cored wire manufactured by adopting the welding slag powder is applied to welding, the gas-shielded flux-cored wire has the advantages of excellent technical performance of welding and omnibearing welding adaptability, attractive appearance good humidity resistance, low content of diffusible hydrogen in a welding seam, excellent crack resistance, high connection strength and good low-temperature impact toughness.

Owner:BEIJING UNIV OF TECH

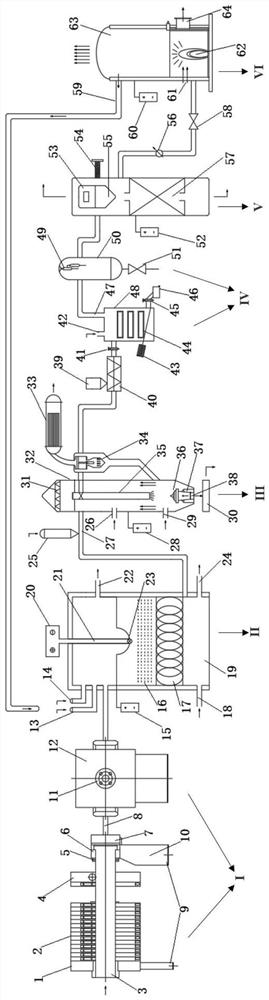

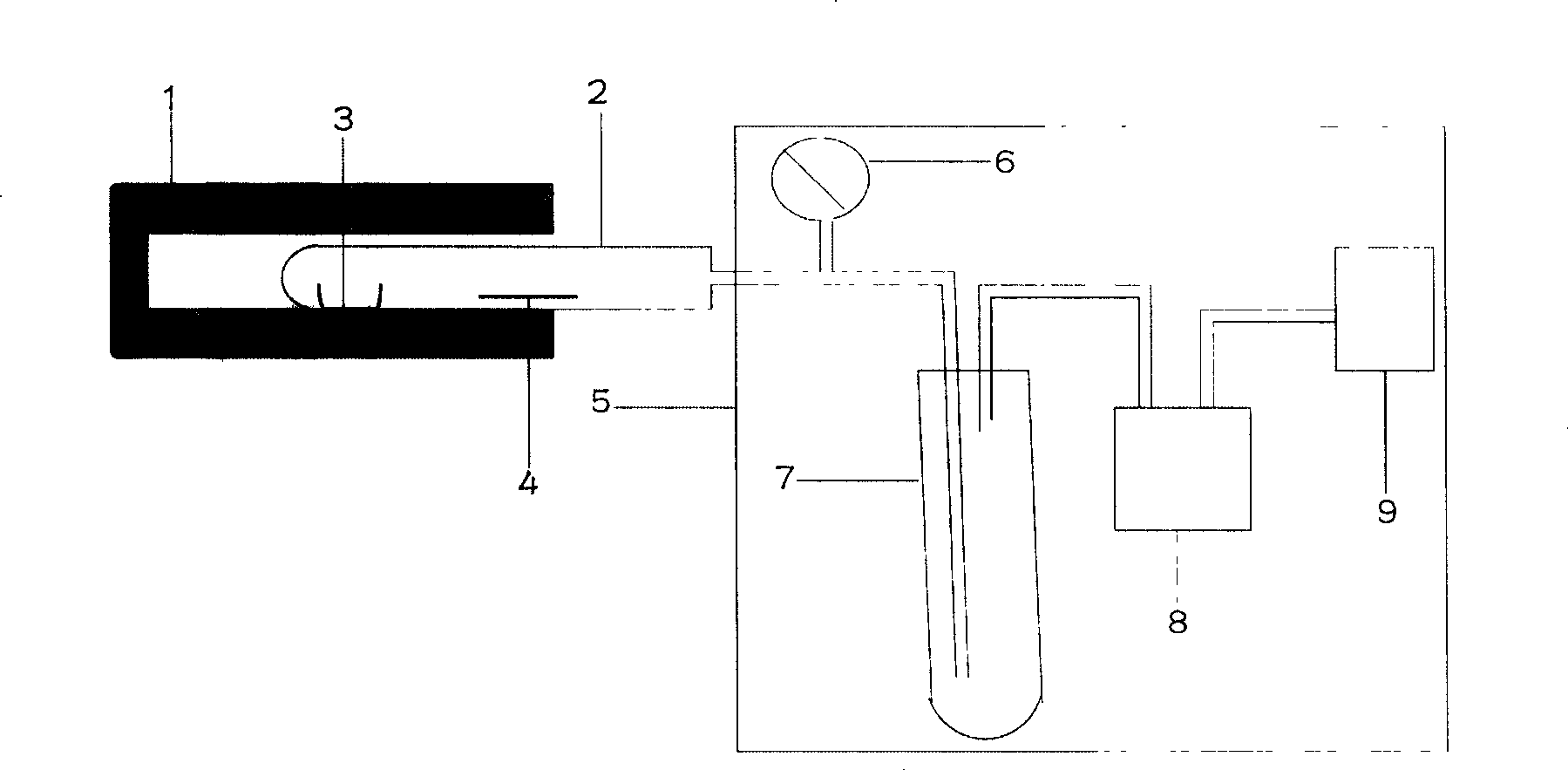

Efficient continuous water atomizing process for producing steel powder

ActiveCN104249157ARealize continuous and uninterrupted operationUniform physical and chemical propertiesProduction lineThermal insulation

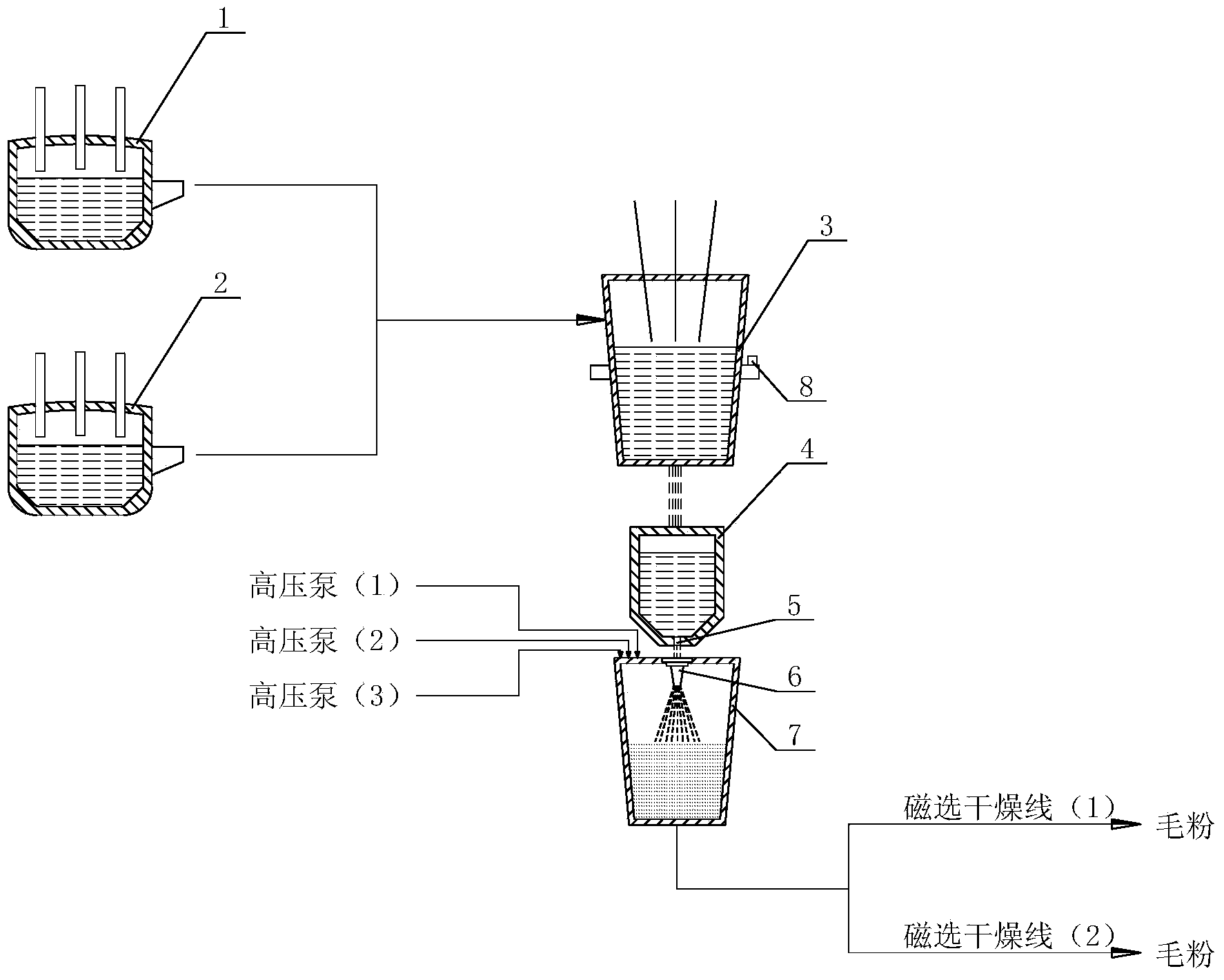

The invention relates to an efficient continuous water atomizing process for producing steel powder. The process includes: continuously injecting molten steel into an intermediate thermal insulation heating device, continuously adjusting components and temperatures, continuously providing temperature signals to a control system by a temperature measuring device during atomizing, and controlling tundish temperature to be at 1550-1580 DEG C; by a weighing system located on the tank support base of the large tank of the intermediate thermal insulation heating device. continuously displaying the weight of the residual molten steel in the large tank to guarantee that the weight of the residual molten steel in the large tank is not less than 5 tons. Compared with the prior art, the efficient continuous water atomizing process has the advantages that two magnetic separation drying production lines are used, two working high-pressure pump and a backup high-pressure pump are equipped, and continuous steel powder water atomizing is achieved; atomizing temperature is fed back and controlled through real-time temperature measuring, and the physical and chemical performance of base powder is allowed to be even and consistent; reasonable nozzle size, draining hole diameter and atomizing pressure are used, tapping temperature is lowered, atomizing efficiency is increased, and base powder quality is increased.

Owner:ANGANG (ANSHAN) METALLURGY POWDER MATERIAL CO LTD

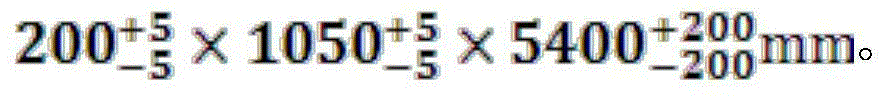

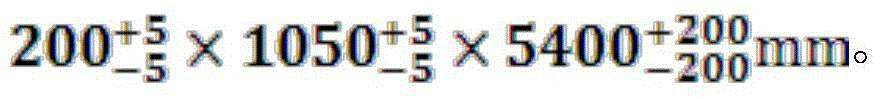

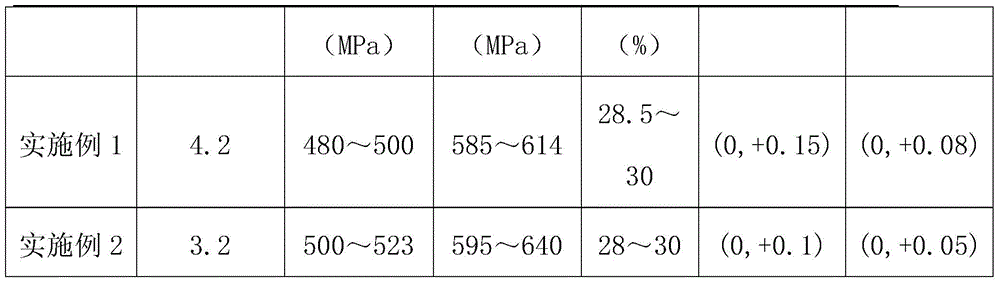

Production technology for medical TA3 sheet materials

The invention relates to a production technology for medical TA3 sheet materials. The technology comprises the following steps: slabs are subjected to production and roll type hot rolling, strip coils are subjected to annealing, shot blasting, acid pickling, cold rolling, degreasing and cutting and splitting, the sheet materials are subjected to annealing and shot blasting, and the TA3 sheet materials are obtained. According to the invention, one-chip production is replaced by a roll type production; for medical TA3 sheet materials of 4.0-6.2 mm, 2-3 heating numbers and semi-finished product processing procedures between firing can be omitted; for TA3 sheet materials of 2.0-4.0 mm, 2-3 heating numbers can be omitted, and 2-3 rolling processes and semi-finished product processing procedures can be omitted, and the total processing procedures can be reduced by more than 30%; 4-6 tons of the TA3 sheet materials can be produced for one batch; the production technology has the advantages of low cost and high efficiency.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Method for producing nano-iron powder

A process for preparing Fe nanoparticles from carbonyl iron includes such steps as heating the carbonyl iron to become vapor, mixing it with CO gas, feeding the mixture into a decomposing apparatus, and hot decomposing while controlling the internal temp and pressure to be 150-400 deg.C and 1-10 KPa.

Owner:JINCHUAN GROUP LIMITED

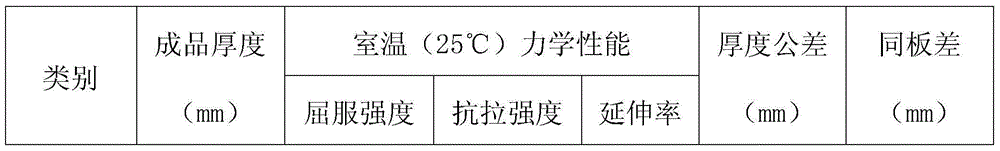

Method for preparing organic compound single-crystal nano structure

InactiveCN101210347AEconomical and simpleEasy to operatePolycrystalline material growthFrom condensed vaporsCrystal structureSingle crystal

The invention discloses a method for preparing single crystal nanostructure of an organic compound, which comprises the following steps of: (1) disposing a substrate and a quartz boat loaded with an organic compound powder into a quartz tube, connecting the quartz tube with a vacuum system and vacuuming the quartz tube to a pressure 10<-2> to -5 Pa; and (2) heating the quartz boat to the sublimation temperature of the organic compound and heating the substrate to a temperature lower than the sublimation temperature of the organic compound by 130 to 180 DEG C, keeping the vacuum degree in the quartz tube and growing the crystal nanostructure of the organic compound on the substrate. The invention is simple and easy and can obviate the use of a template and a catalyst. The obtained nanostructure has good crystallization, no defect, high purity and better test reproducibility.

Owner:INST OF CHEM CHINESE ACAD OF SCI

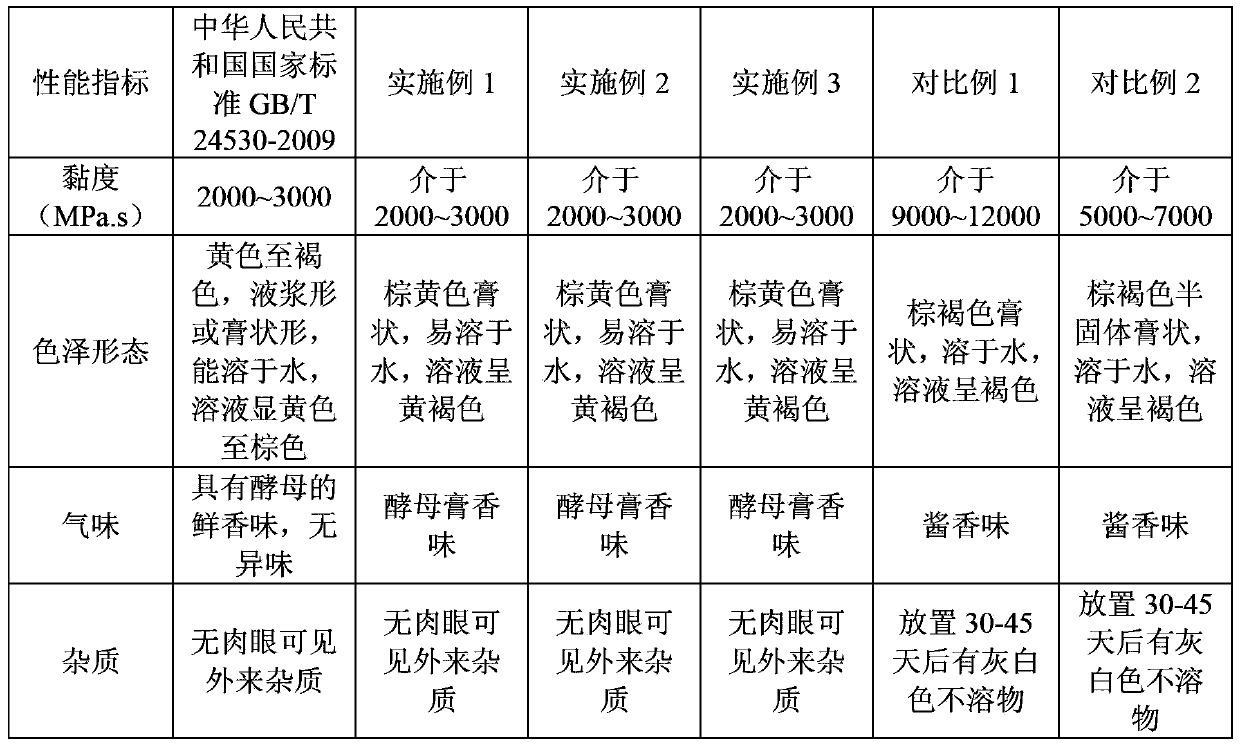

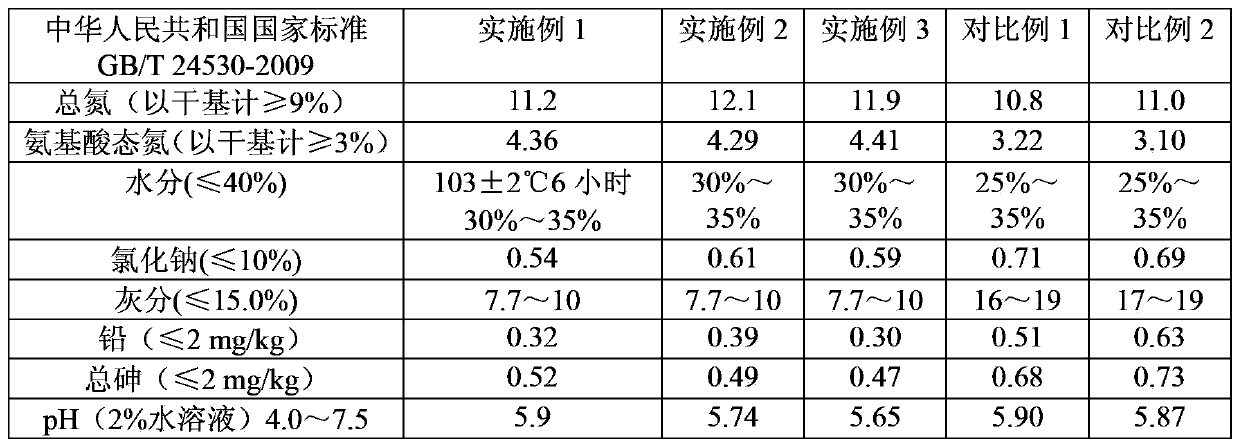

Yeast extract and method for preparing same

InactiveCN103966099AReduce viscosityImprove liquidityMicroorganism lysisMicroorganism based processesSolubilitySolid content

The invention discloses a yeast extract and a method for preparing the same. According to the method for preparing the yeast extract, a yeast fermentation broth is subjected to steps of discoloring and size-mixing, autolyzing, enzymolyzing, centrifugal precipitate removing, and concentrating successively. The step of concentrating includes primary concentrating and secondary concentrating. In the primary concentrating, a supernate obtained after the step of centrifugal precipitate removing is subjected to decompression concentrating at a temperature below 60 DEG C so that a primary concentrate liquid containing 28 % to 32% of solid matter by weight is obtained. In the secondary concentrating, the primary concentrate liquid is subjected to decompression concentrating at a temperature below 55 DEG C, and the yeast extract containing 60% to 70% of the solid matter by weight is obtained. Through the method, the yeast extract is enabled to have lowered viscosity and improved liquidity on the basis of maintaining the original solid content, and a yeast extract product having moderate viscosity and excellent liquidity is obtained. In addition, the method prevents the nutrient composition of the yeast extract from getting inactivated and lost, enables the yeast extract product to have a bright color, good dissolvability and a rich meat flavor, guarantees uniform physicochemical properties of the yeast extract product in later storage and transport processes, and thus clients' requirements are satisfied.

Owner:ANGELYEAST CO LTD

Nonluminous glaze

The invention relates to nonluminous glaze. The nonluminous glaze is prepared by adding a proper amount of aluminum powder into slaked talc, quartz and feldspar to generate metal aluminum oxide without glossiness, so that the production cost of the nonluminous glaze can be effectively reduced; the added slaked talc is subjected to high-temperature calcination, so the impurity content is low, the loss on ignition is small and new grain which people do not like is avoided; a proper amount of silicon micropowder is added into the nonluminous glaze, the temperature resistance and the acid and alkali resistance of the glaze layer can be improved and the effect of improving the mechanical strength of the glaze layer is achieved; and the nonluminous glaze is obtained by performing wet ball milling by a wet ball mill, the raw materials for forming the nonluminous glaze are stirred and mixed uniformly, slurry with the physical and chemical properties tending to be uniform and consistent can beobtained, and glazing is fertilized.

Owner:GUANGXI NANSHAN PORCELAIN

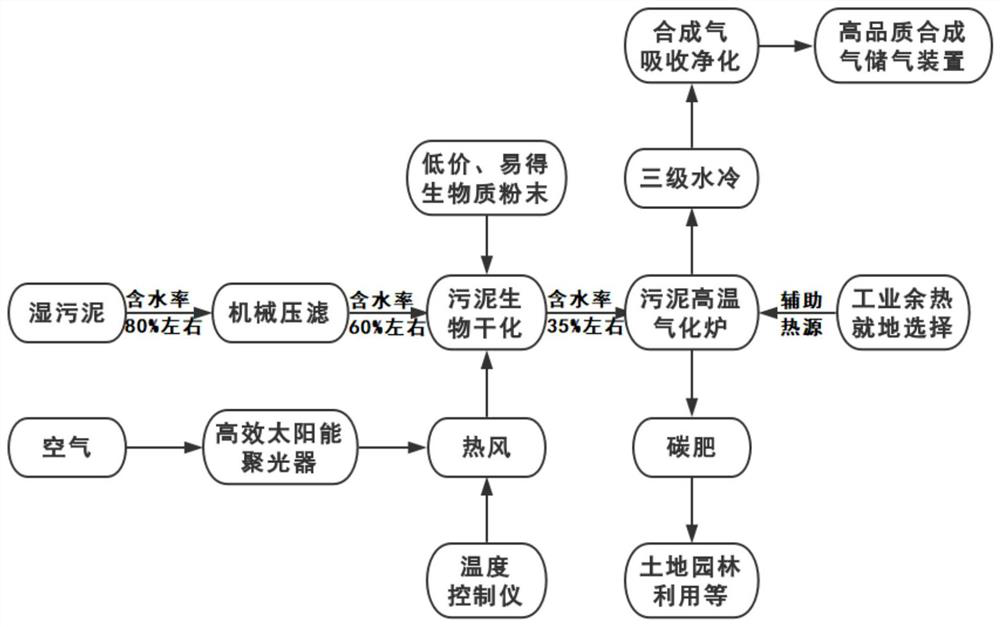

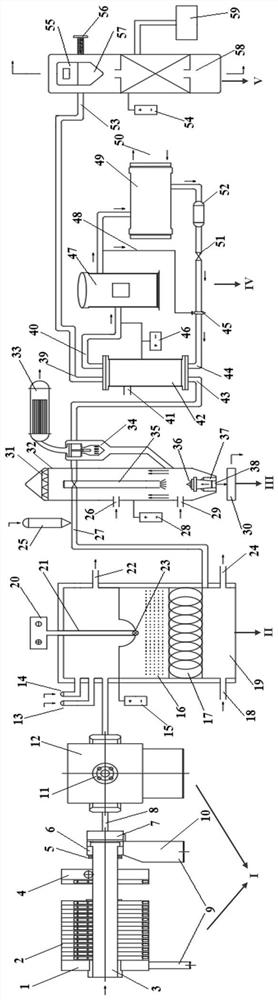

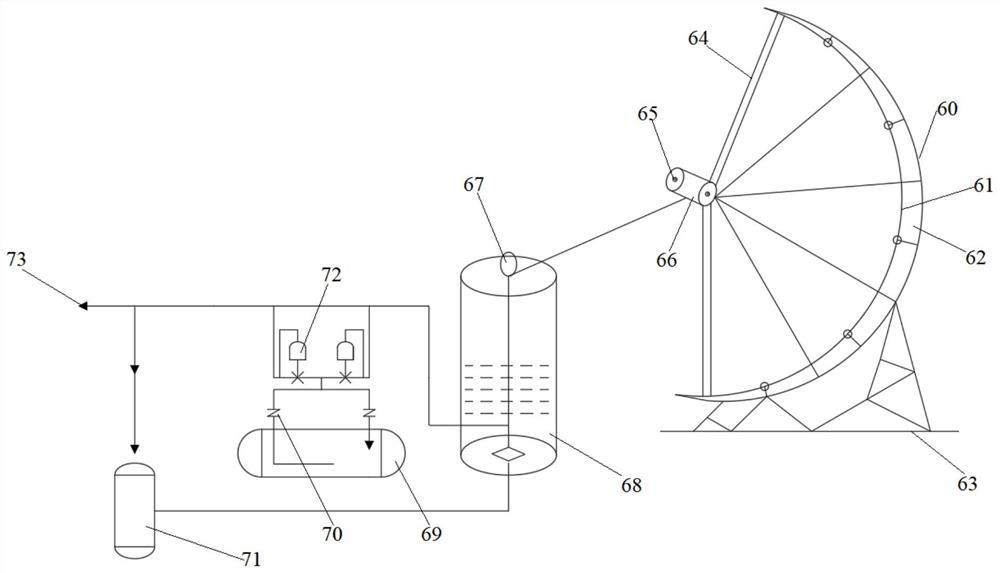

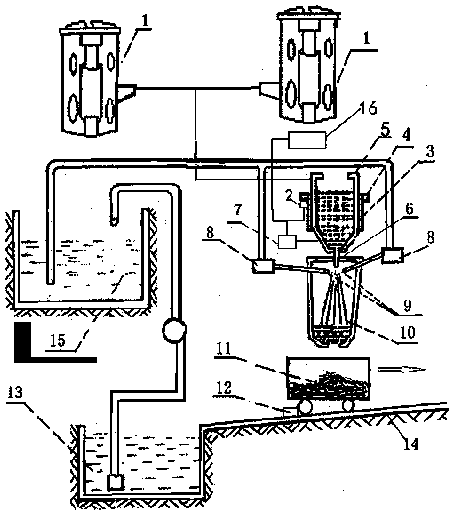

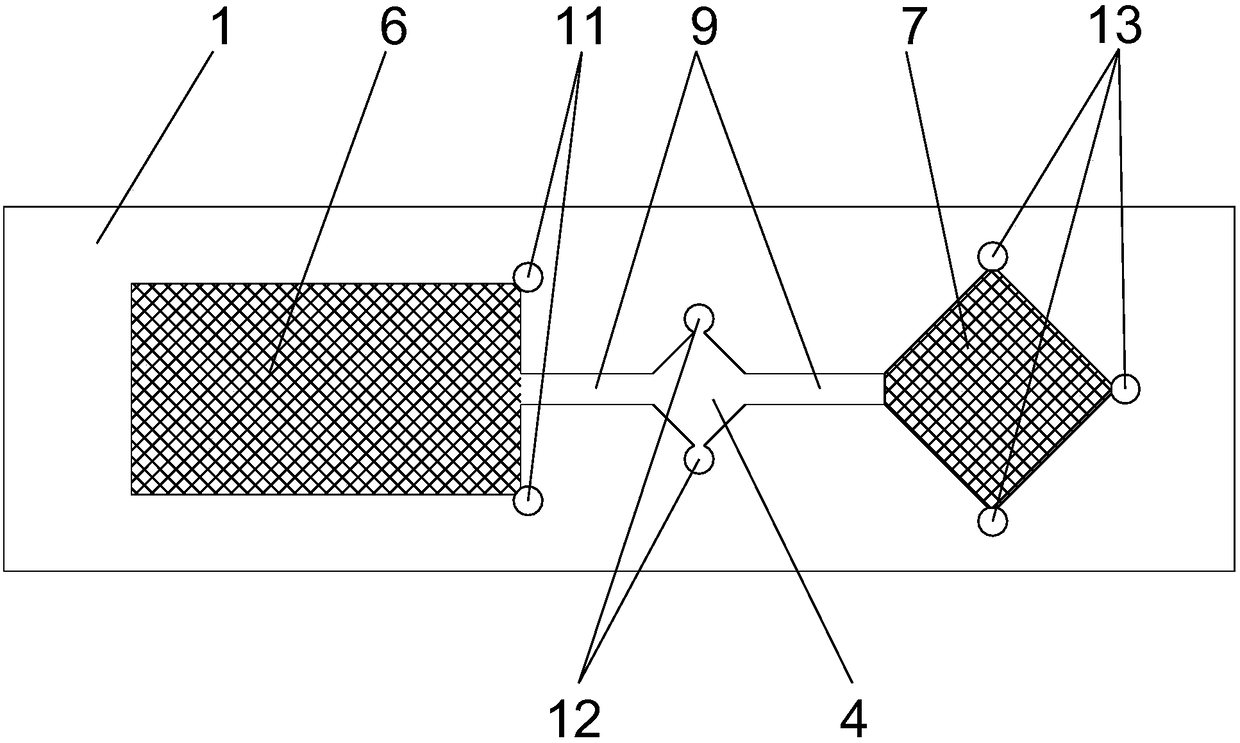

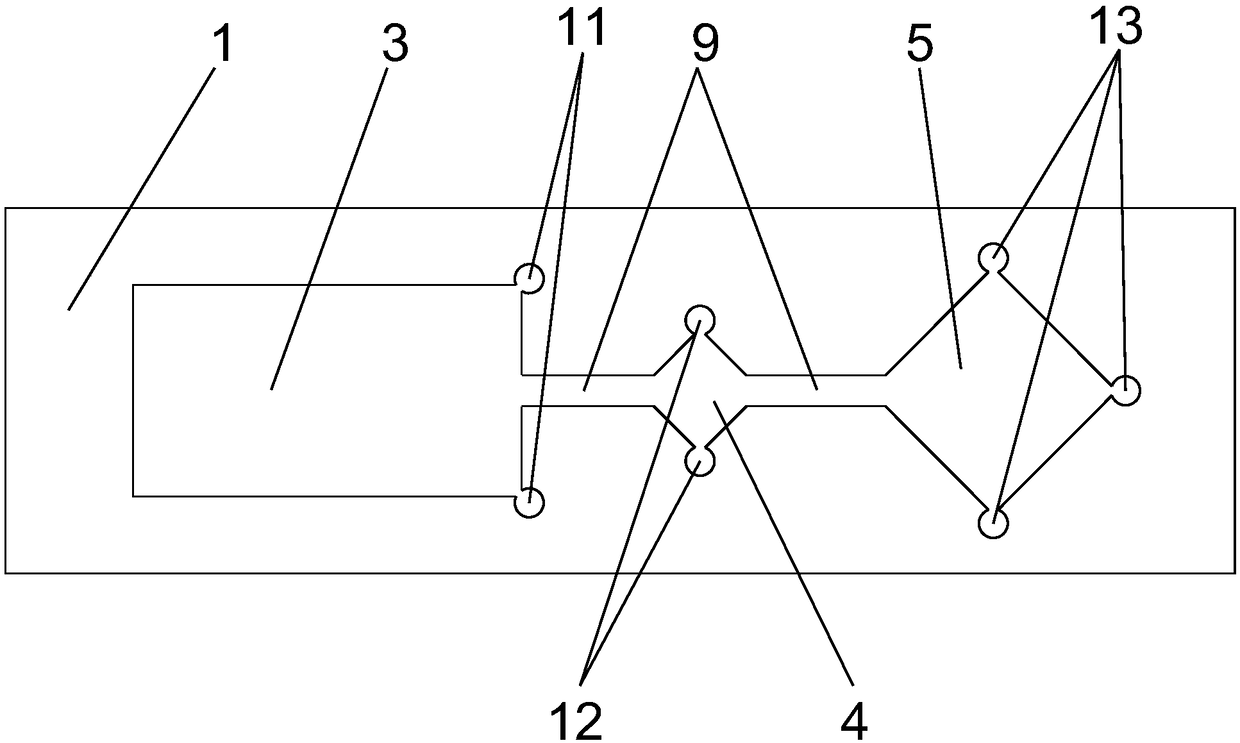

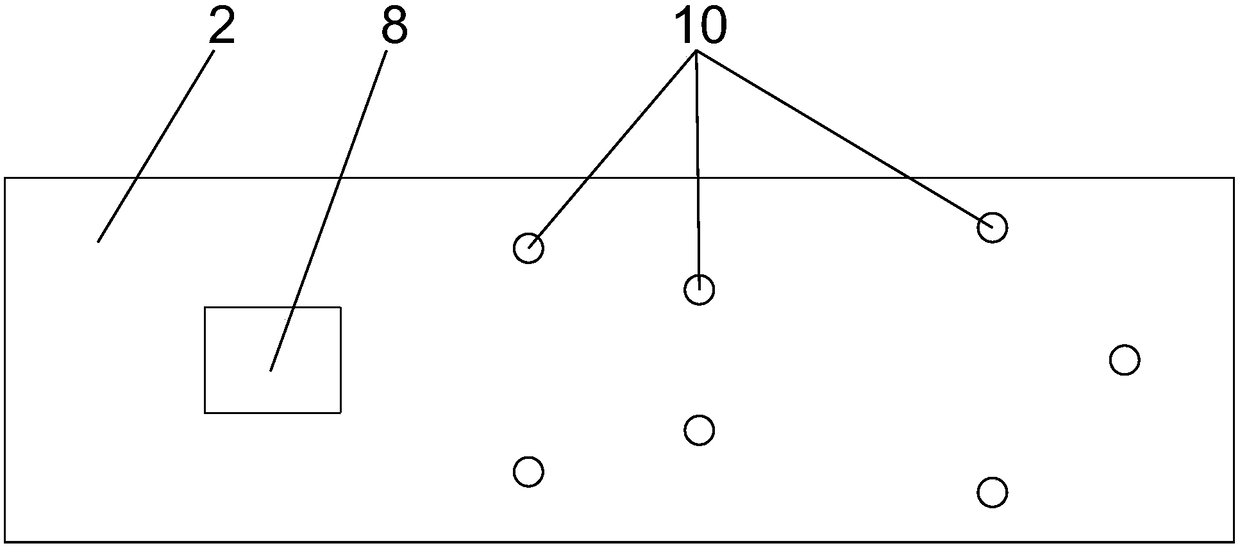

Solar enhanced sludge biological drying and gasified gas comprehensive treatment process and system

PendingCN112047596AAchieve reductionAchieve stabilizationSludge treatment by de-watering/drying/thickeningEnergy inputSludgeFiltration

The invention relates to a solar enhanced sludge biological drying and gasified gas comprehensive treatment process. The process comprises the following steps: dehydrating residual sludge with the water content of about 80% by using mechanical filter pressing until the water content is reduced to 55-65%; enabling a solar efficient condenser to provide a heat source to heat air and introduce hot air in order to enhance sludge biological drying through green energy; then, conditioning the wet sludge subjected to filter pressing by adopting cheap and easily available biomass powder, and biologically drying for further dehydration treatment to reduce the water content to 30-40%, wherein the addition of the biomass powder gives consideration to the advantages of conditioning the characteristicsof the sludge, improving the heat value of the sludge and the like; and carrying out secondary dehydration, feeding the dehydrated sludge into a high-temperature gasification furnace, and enabling high-temperature tar gas generated in the treatment process to be subjected to three-stage water cooling and adsorption filtration treatment to finally obtain high-quality synthetic gas. The invention further provides a solar enhanced sludge biological drying and gasified gas comprehensive treatment system. According to the invention, reduction, harmlessness, recycling and stabilization treatment ofsludge is realized.

Owner:ZHEJIANG UNIV OF TECH

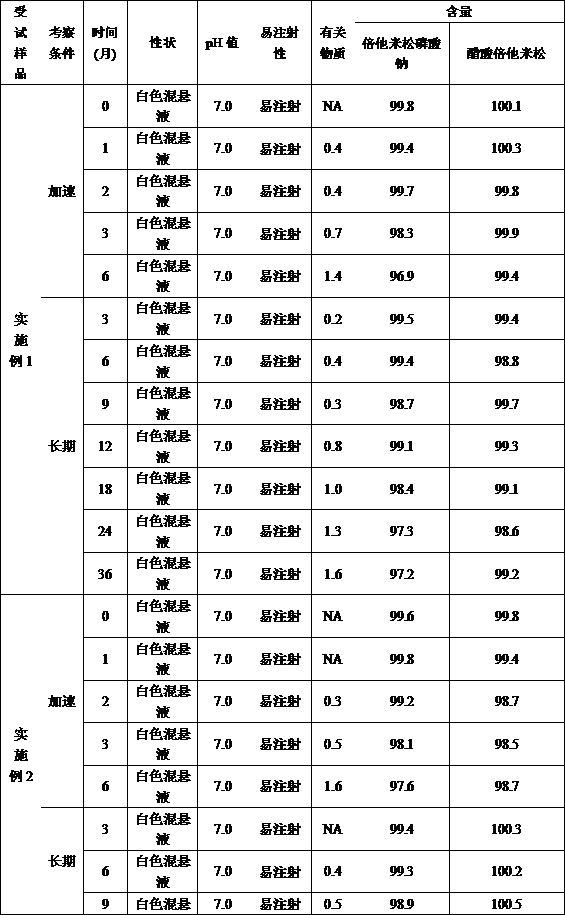

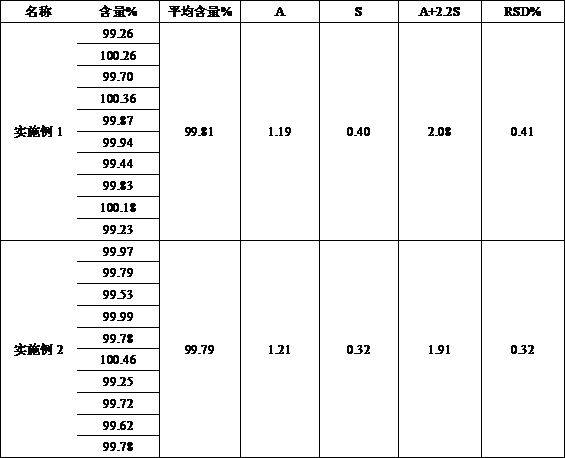

Betamethasone sodium phosphate and betamethasone acetate suspension injection and preparation method thereof

PendingCN113855630AStable physical and chemical propertiesGood efficacyOrganic active ingredientsAntipyreticBetamethasone Sodium PhosphateBetamethasone acetate phosphate

The invention discloses a betamethasone sodium phosphate and betamethasone acetate suspension injection composition. The suspension composition adopts a high-pressure homogenization process, can obtain a preparation with excellent stability, and is suitable for industrial production.

Owner:莱默(北京)药业科技有限公司

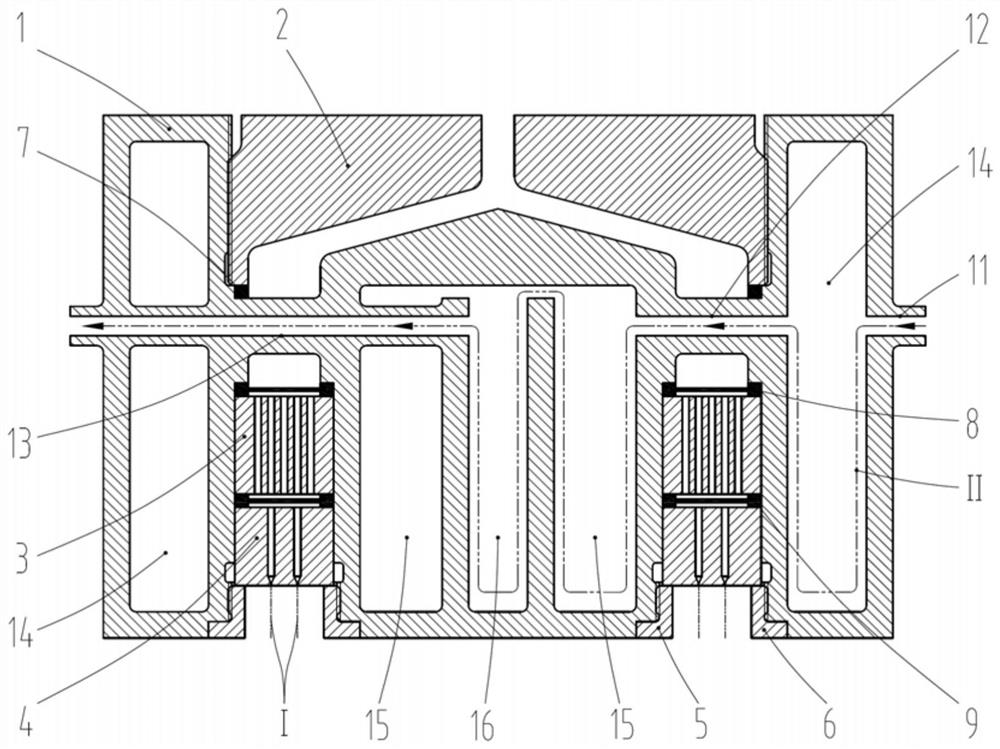

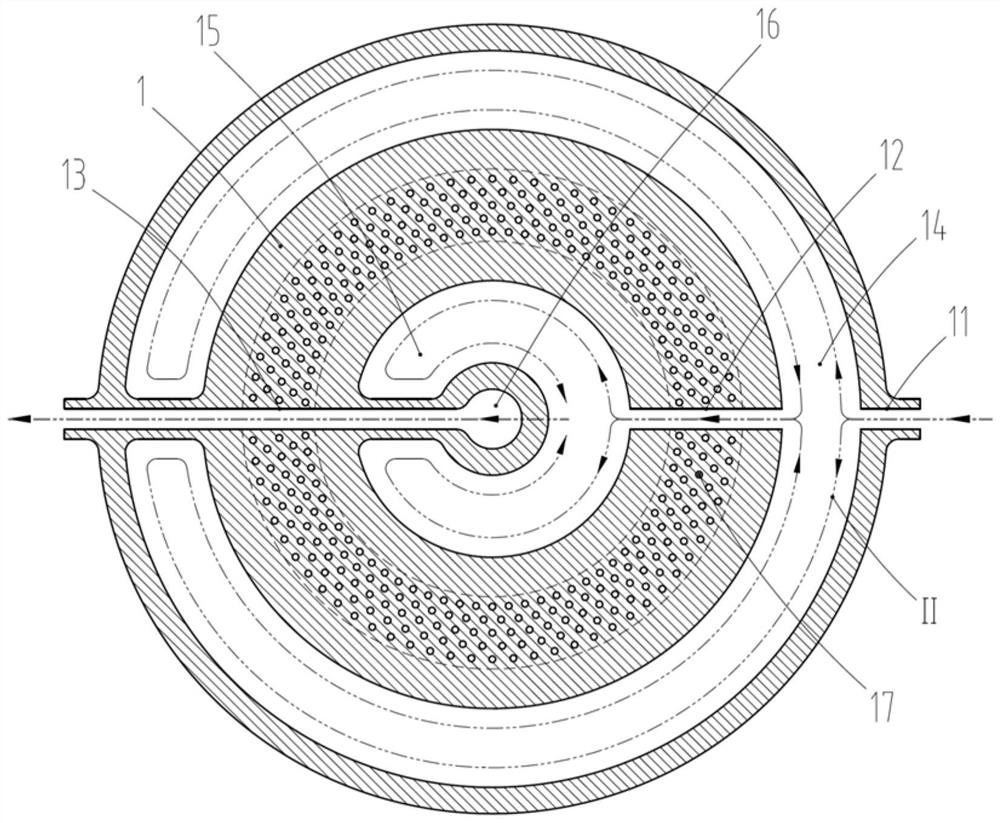

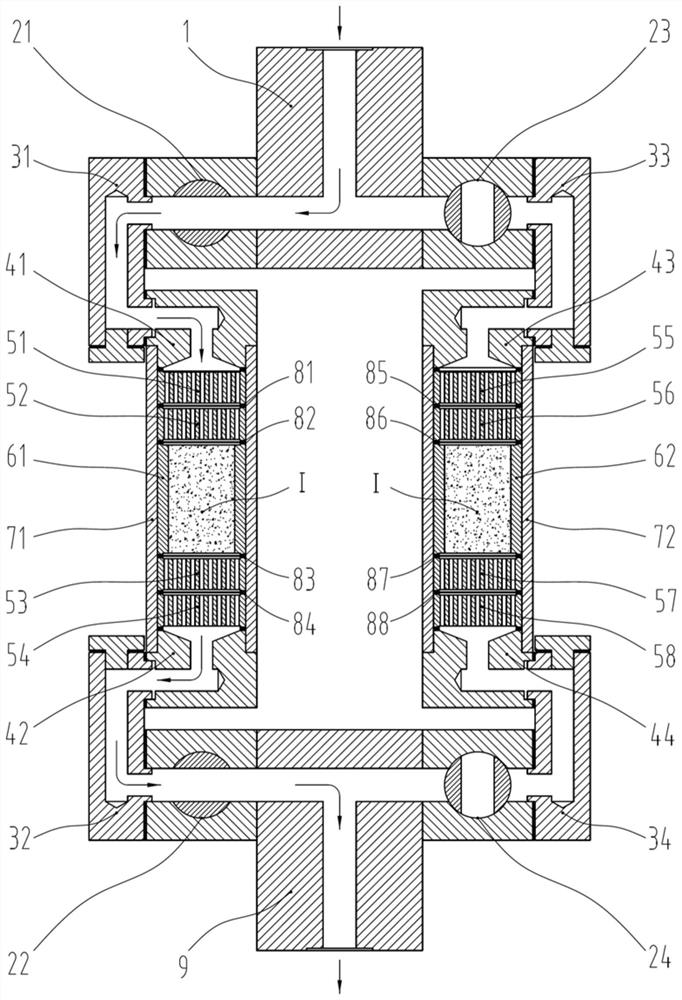

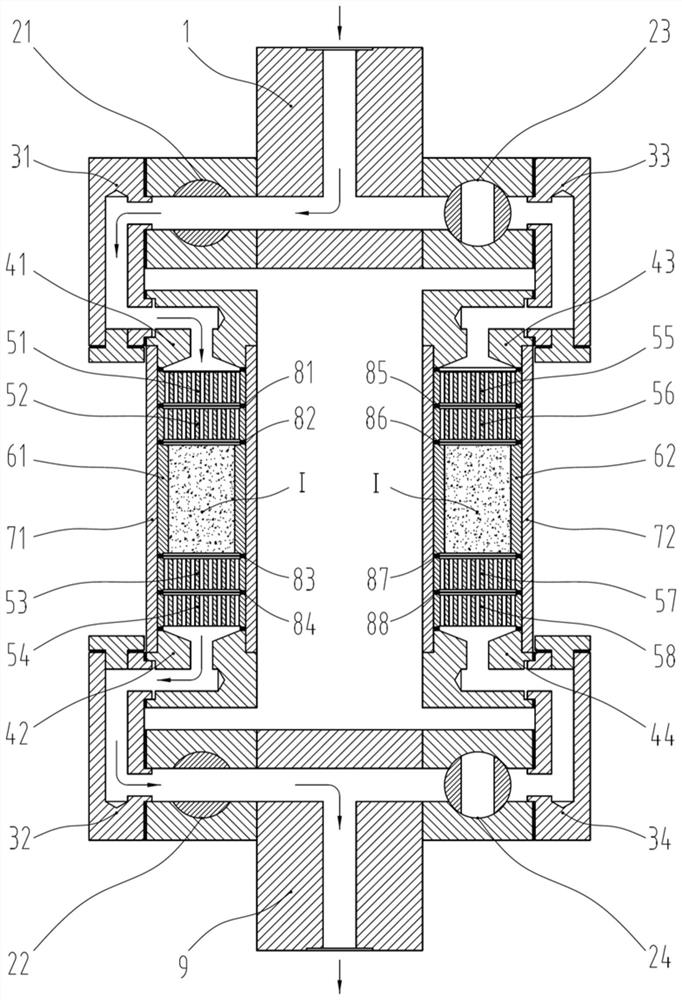

Inner and outer layer heat medium cyclic heating spinning component for preparing mesophase pitch based carbon fibers

ActiveCN111962168ASimple structureFully functionalSpinning solution de-aeratingSpinnerette packsFiberCarbon fibers

The invention discloses an inner and outer layer heat medium cyclic heating spinning component for preparing mesophase pitch based carbon fibers. A feed inlet plate is fixed to an upper inner cavity of a heat medium cyclic heating cavity through a screw thread; a mixed perforated plate is arranged at the top of a lower inner cavity of the heat medium cyclic heating cavity; a first edge filter screen is arranged between the mixed perforated plate and the heat medium cyclic heating cavity; a spinneret plate is arranged on the lower side of the mixed perforated plate; a second edge wrapping filter screen is arranged between the mixed perforated plate and the spinneret plate; an inner layer fixing sleeve and an outer layer fixing sleeve are arranged on the lower side of the spinneret plate; the inner layer fixing sleeve is fixed to the outer wall of the inner cavity of the heat medium cyclic heating cavity through the screw thread; and the outer layer fixing sleeve is fixed to the inner wall of an outer cavity of the heat medium cyclic heating cavity through the screw thread. The spinning component is reasonable and simple in structure and convenient to mount and dismount, the temperature uniformity of the asphalt melt in the spinning component is improved, meanwhile, the temperature control response of the spinning component is fast, the temperature control precision is high, andthe spinning property of the pitch melt and the product quality of the carbon fibers are improved.

Owner:SHAANXI TIANCE NEW MATERIAL TECH

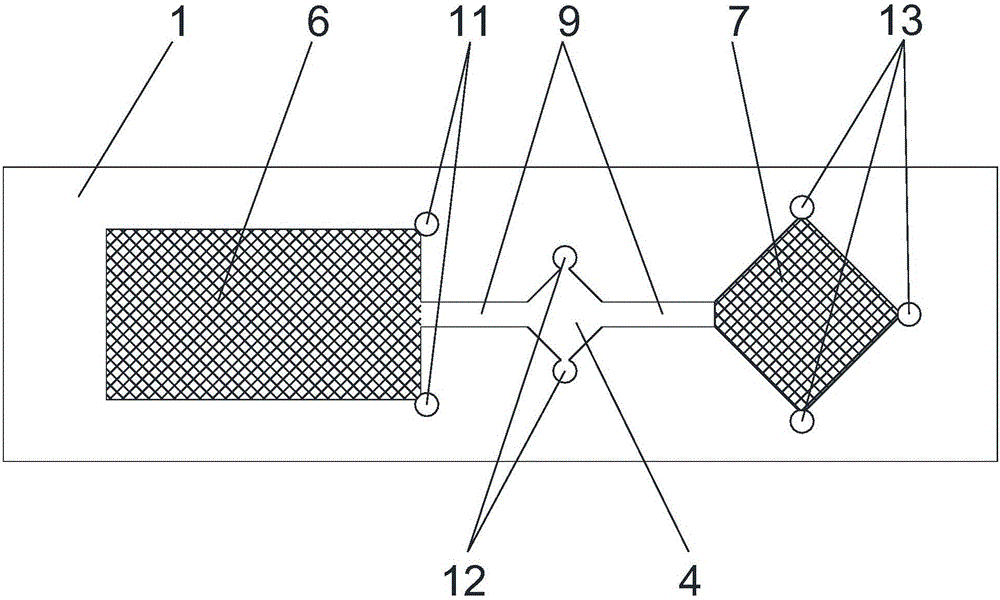

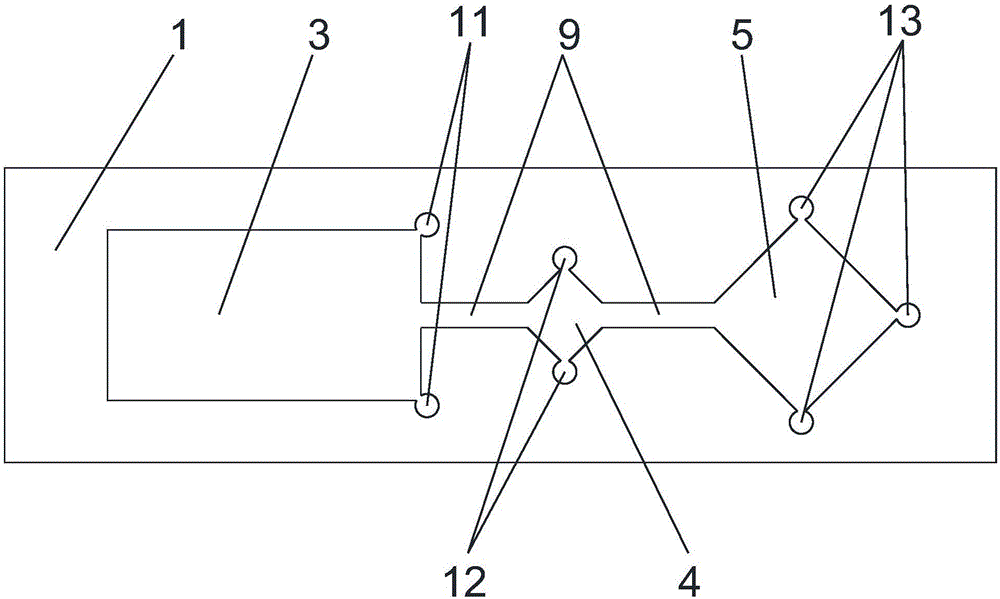

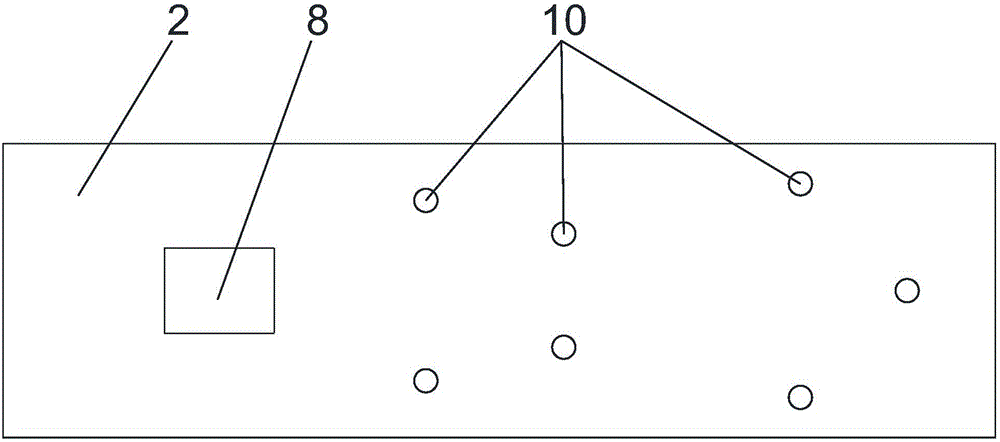

Kit for rapidly detecting ischemia modified albumin in blood

ActiveCN105973888AUniform physical and chemical propertiesMulti-buffer mixing spaceMaterial analysis by observing effect on chemical indicatorBORATE BUFFERCobalt

The invention discloses a kit for rapidly detecting ischemia modified albumin in blood. The kit comprises a detection chip and a reagent bottle filled with detection reagents, wherein the detection chip comprises a non-absorbent bottom plate and a non-absorbent cover plate; a sample cell, a mixing cell and a detection cell are sequentially arranged on the bottom plate; micro pipelines are formed between the sample cell and the mixing cell and between the mixing cell and the detection cell; a sample pad is filled in the sample cell; a cobalt standard substance is coated on the sample pad; a detection pad is filled in the detection cell; a cobalt indicator is coated on the detection pad; the cover plate is fixedly arranged above the bottom plate; a sample injection hole is formed in a position, which is positioned above the sample cell, of the cover plate; and the detection reagents refer to phosphate buffer, borate buffer or Tris-HCl buffer. According to the kit disclosed by the invention, based on the principle of an albumin cobalt binding test, sample separation and detection analysis processes are integrated into a device, so that IMA detection is more convenient.

Owner:西安良升生物科技有限公司

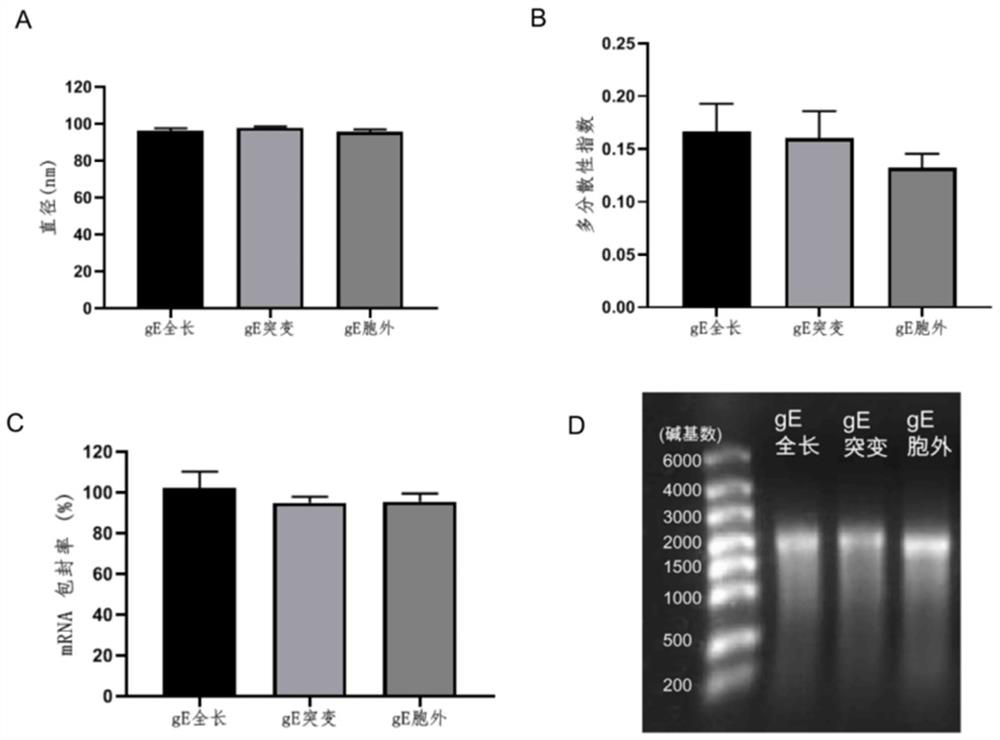

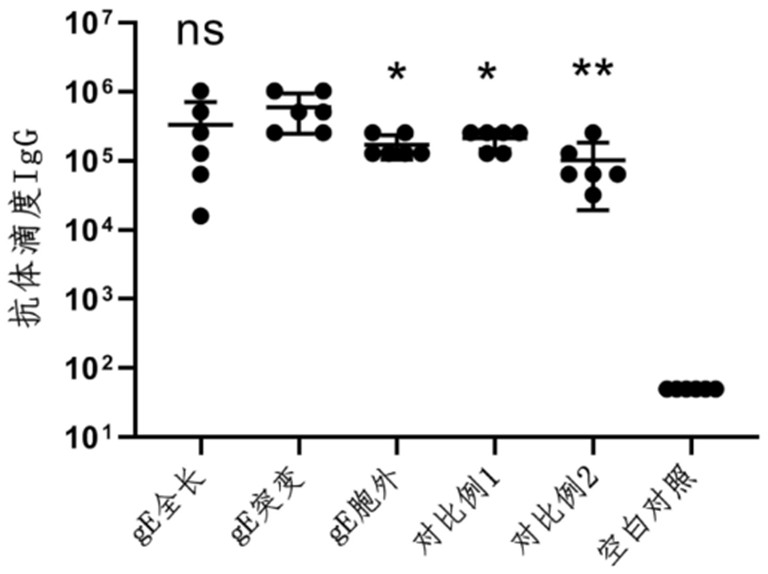

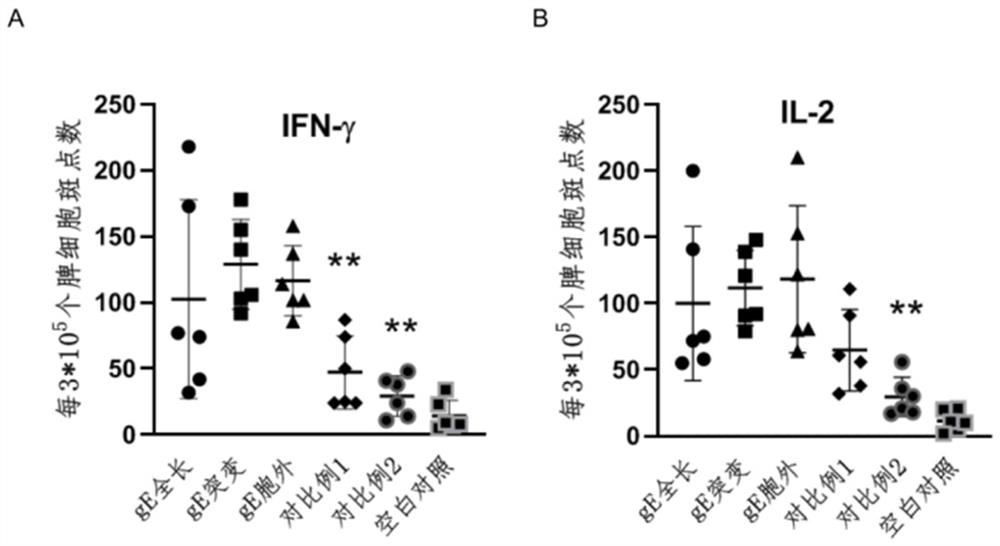

Varicella-herpes zoster mRNA vaccine composition, and preparation method and application thereof

PendingCN114081943AReduce manufacturing costSave uniformityNervous disorderViral antigen ingredientsChickenpoxHerpes zoster virus

The invention provides a varicella-herpes zoster mRNA vaccine composition, and a preparation method and application thereof. The vaccine composition comprises a messenger ribonucleic acid (mRNA) sequence for coding varicella-herpes zoster virus glycoprotein E, a derivative sequence of the messenger ribonucleic acid (mRNA) sequence and lipid nanoparticles (LNP), and the messenger ribonucleic acid (mRNA) sequence is prepared into particles with the diameter of 20-400 nanometers through microfluidic equipment. The vaccine composition can specifically enhance humoral immune response and cellular immune response against varicella-herpes zoster glycoprotein E, can be used as a varicella vaccine which does not cause latent infection of vaccine strains, and can also be used as a herpes zoster vaccine with unlimited productivity. All the components in the vaccine composition can be widely obtained, so that the vaccine cost is effectively reduced, and the vaccine yield is increased.

Owner:INST OF MEDICAL BIOLOGY CHINESE ACAD OF MEDICAL SCI

Composite interlaced yarn having variegated colour effect

The invention relates to a composite interlaced set yarn with dye effect, which is compositely made at a middle and low speed on a composite interlaced set yarn machine by adopting two or a plurality of sorts of yarn different in dry-hot shrinkage and yarn classes or color absorbing degrees. Due to the character differences in the nature of each component of the composite interlaced set yarn, the fabric surface of the products weaved by the invention can generate various mixed-color flash effects. If the invention is processed again by different dyeing processes, the invention can obtain dyeing effects of different characteristics, very natural star point-shaped, rain-shaped and strip-shaped dyeing effects. Simultaneously due to slight differences in nature among the components in selected materials, the physico-chemical properties of the product is uniform and the invention can not affect other characteristics except dyeing.

Owner:SHENGHONG GRP CO LTD

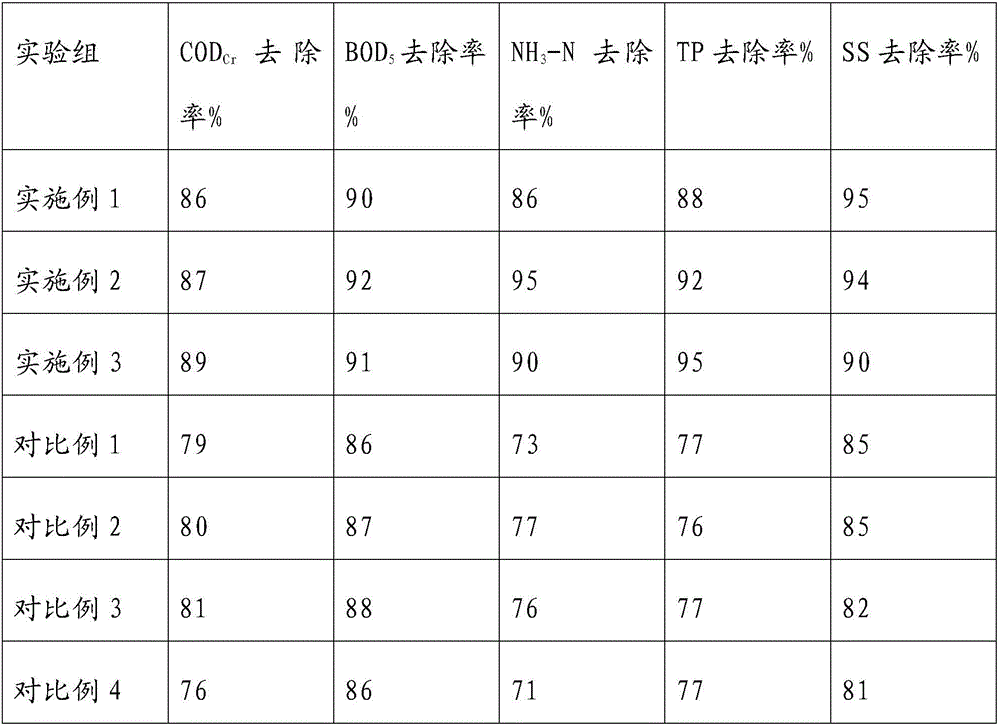

Low-permeability substrate and application of substrate in construction of artificial wetland

InactiveCN106673199ASolve efficiency problemsSolve the blockageBiological water/sewage treatmentConstructed wetlandPorosity

The invention discloses a low-permeability substrate and application of the substrate in construction of an artificial wetland. The low-permeability substrate comprises the following fillers with the particle sizes: the filler of which the particle sizes are smaller than 0.075mm, the filler of which the particle sizes are 0.075mm-0.6mm, the filler of which the particle sizes are 0.6mm-2mm, the filler of which the particle sizes are 2mm-6mm, and the filler of which the particle sizes are 6mm-10mm. According to the low-permeability substrate, the obtained filler has more uniform physical and chemical properties through multiple cleaning, screening, mixing and proportioning of a traditional artificial wetland filler, the uniformity coefficient is controlled to below 5, the porosity is controlled to be 30%-40%, the permeability is controlled to be 1.5*10<-4>m / s to 1.5*10<-3>m / s, the mean specific surface area of the filler reaches over 5,000-12,000m<2> / m<3> and is 15-20 times that of the traditional filler, so that the growth of microorganisms on the filler is promoted, the contact of the microorganisms and sewage is more uniform and sufficient, the synergistic effect of filler-plant-microorganisms is developed to the maximum extent, and the uniform treatment effect is achieved to solve the problems of treatment efficiency declination and blockage of the artificial wetland during long-term operation.

Owner:BEIJING SEN MIAO TIAN CHENG ENVIRONMENTAL PROTECTION TECH

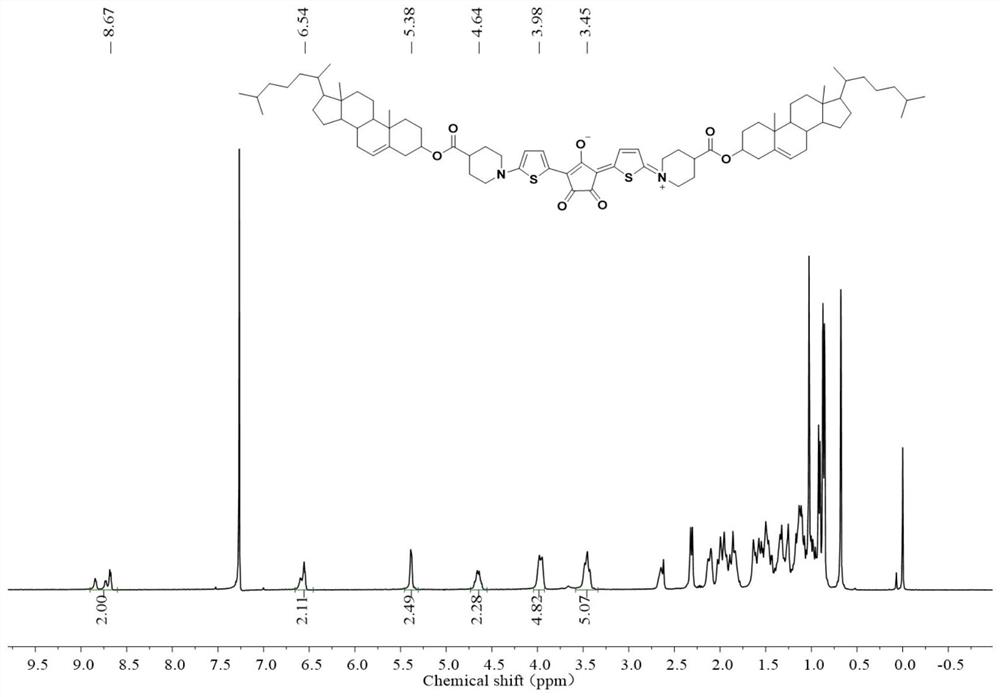

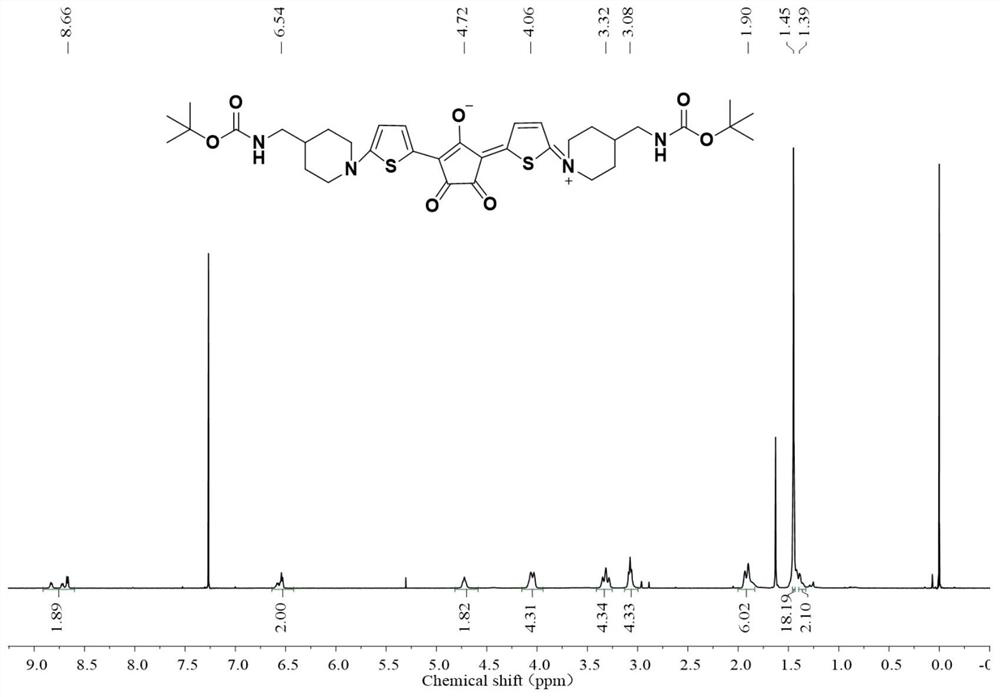

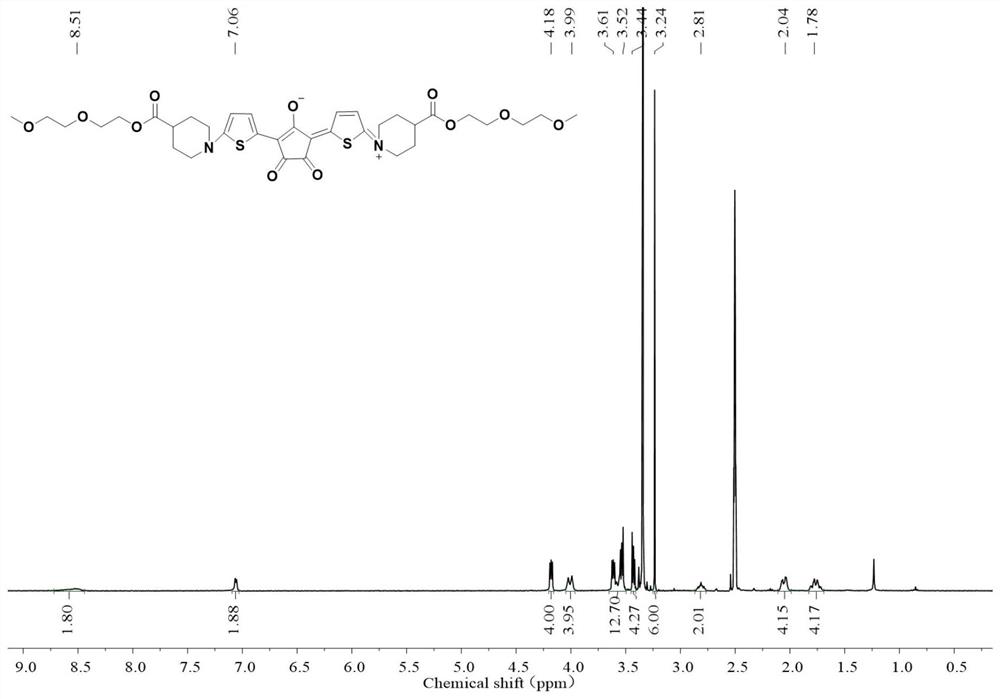

Near-infrared light stimulation response type functional macromolecule, intelligent nanometer material and preparation method of intelligent nanometer material

PendingCN111848596AStrong absorption capacityPrecise regulation of hydrophilicity and hydrophobicitySteroidsBiomedicinePhotothermal therapy

The invention relates to a near-infrared light stimulation response type functional macromolecule, an intelligent nanometer material and a preparation method of the intelligent nanometer material, belonging to a photo-thermal macromolecule, two synthesis methods and the preparation method of the nanometer material taking the photo-thermal macromolecule as a raw material. A piperidine-thiophene-croconic acid-thiophene-piperidine conjugated element is used as a main component, and a plurality of groups are used for modifying the photo-thermal macromolecule, so the overall properties of the macromolecule are regulated and controlled. A solvent replacement method and a self-nucleation method are adopted, and different solvent systems and temperatures are controlled, so various novel photo-thermal nanometer materials with various morphologies such as a spherical shape, a fibrous shape and a sheet shape are prepared. Structural parameters such as morphology, size and the like of the nanometer material can be effectively regulated and controlled through different photo-thermal macromolecule substituent elements, and the nanometer material has good biocompatibility and excellent photo-thermal performance. In the future, the nanometer material is expected to be applied to photothermal therapy, photodynamic therapy, photoacoustic imaging and the like in the field of biomedicine, and haspotential application value.

Owner:SHANGHAI UNIV

Production method of vanadium-titanium iron powder

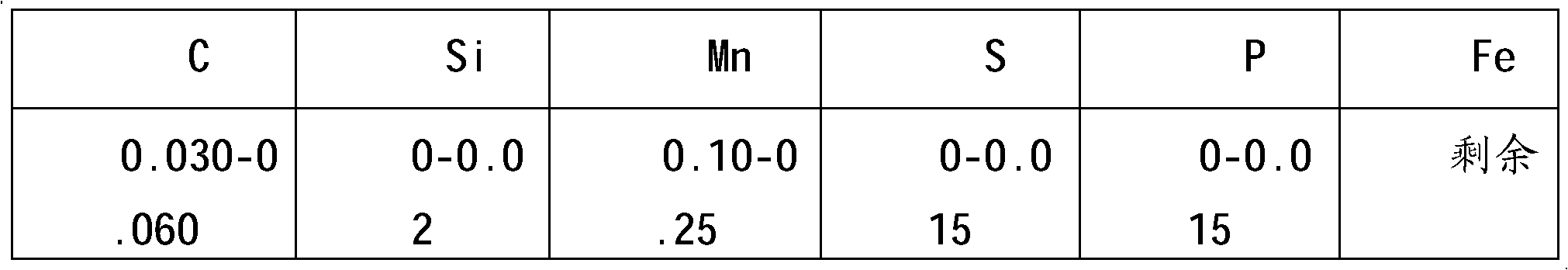

The invention provides a production method of vanadium-titanium iron powder. The production method includes the following steps that (1), waste steel is smelted in a medium frequency furnace, then steel is tempered with a vanadium-titanium alloy, and thus smelted vanadium-titanium molten steel is prepared from the chemical compositions of 0.1-0.5% of V, 0.06-0.6% of Ti, 0.4% of C, 0.40% or the less of Si, 0.4% or the less of Mn, 0.005% or the less of P and 0.005% or the less of S; (2) the smelted vanadium-titanium molten steel in the step (1) is injected into an atomized feeding tank, and thecompositions are constantly adjusted to be controlled as 0.1-0.5% of V, 0.06-0.6% of Ti, 0.15-0.4% of C, 0.4% or the less of Si, 0.4% or the less of Mn, 0.005% or the less of P and 0.001% or the lessof S, and the temperature is 1650-1680 DEG C; (3), the vanadium-titanium molten steel in the step (2) enters an atomizer for atomization; and (4), after atomization and hopper, the vanadium-titanium molten steel is sent to a magnetic separation drying line for magnetic separation, drying, annealing, screening and packaging to obtain atomized vanadium-titanium iron powder. According to the production method of the vanadium-titanium iron powder, production of the vanadium-titanium atomized iron powder with various performance standards can be achieved, the production process is simple, the quality of the obtained base powder is improved compared with the prior art, and a good raw material for downstream production is provided.

Owner:攀枝花市银江金勇工贸有限责任公司

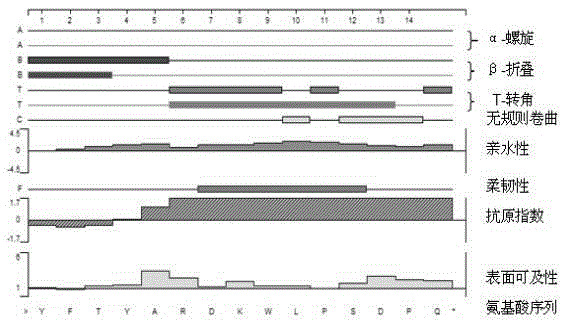

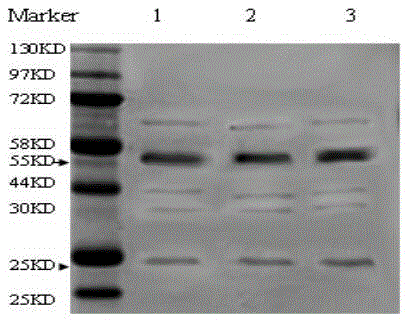

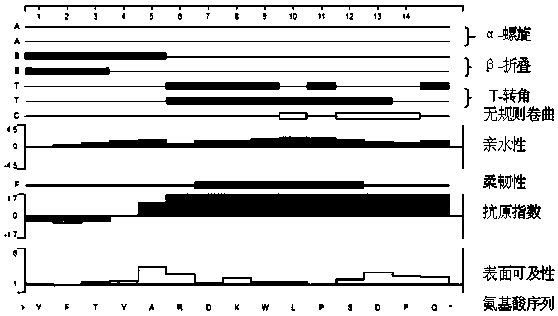

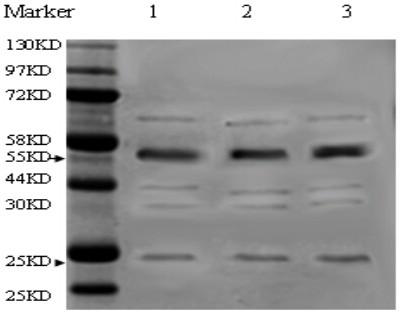

TRPC3 (Transient receptor potential cation channel, subfamily C, member 3) antigen peptide and anti-TRPC3 monoclonal antibody

InactiveCN105399798AEasy to predictMeet the requirements for the preparation of monoclonal antibodiesImmunoglobulins against animals/humansMicroorganism based processesDiseaseAntiendomysial antibodies

The invention discloses a TRPC3 (Transient receptor potential cation channel, subfamily C, member 3) antigen peptide and an anti-TRPC3 monoclonal antibody. The TRPC3 antigen peptide comprises 15 amino acids, and a specific sequence is represented as SEQ ID NO: 1. A preparation method of the anti-TRPC3 monoclonal antibody comprises steps as follows: the TRPC3 antigen peptide after being coupled with KLH (keyhole limpet hemocyanin) is taken as an antigen for immunization of a mouse, a hybridoma cell strain T-II is obtained through screening, and the anti-TRPC3 monoclonal antibody is obtained through secretion of the hybridoma cell strain T-II. The anti-TRPC3 monoclonal antibody can specifically recognize TRPC3 channel protein expressed by various tissue cells and can be applied to TRPC3 expression research of various tissue cells, thereby monitoring diseases related with TRPC3 molecules. Therefore, the anti-TRPC3 monoclonal antibody can be applied to preparation of diagnostic reagents for diseases related with TRPC3 molecule expression.

Owner:GUANGDONG PHARMA UNIV

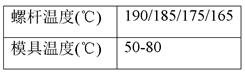

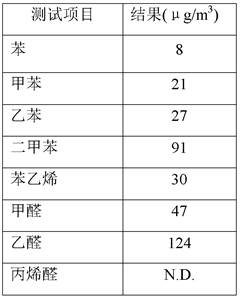

Cellulose reinforced polypropylene resin composite material as well as preparation method and application thereof

Owner:NIO TECH ANHUI CO LTD

Method for processing composite filament

InactiveCN101974809AAppropriate processing speedUniform physical and chemical propertiesTextiles and paperYarnColor effect

The invention relates to a method for processing a composite filament. The composite filament is prepared by compounding two or more than two yarns with different shrinkage rates, yarn kinds and dye absorption degrees on a network composite filament machine at medium-low speed. Because the interior components of the composite network filament have different properties, the surface of a fabric product made of the filament can produce various mixed color flash effects. If the fabric product is processed by different dyeing technologies, star-like, rain-like, strip-like and other mixed color effects with different characteristics can be obtained. Meanwhile, because the components selected as the raw materials have small property difference, various physical and chemical properties of the produce are uniform, and other characters except dyeing can not be influenced.

Owner:薛金礼

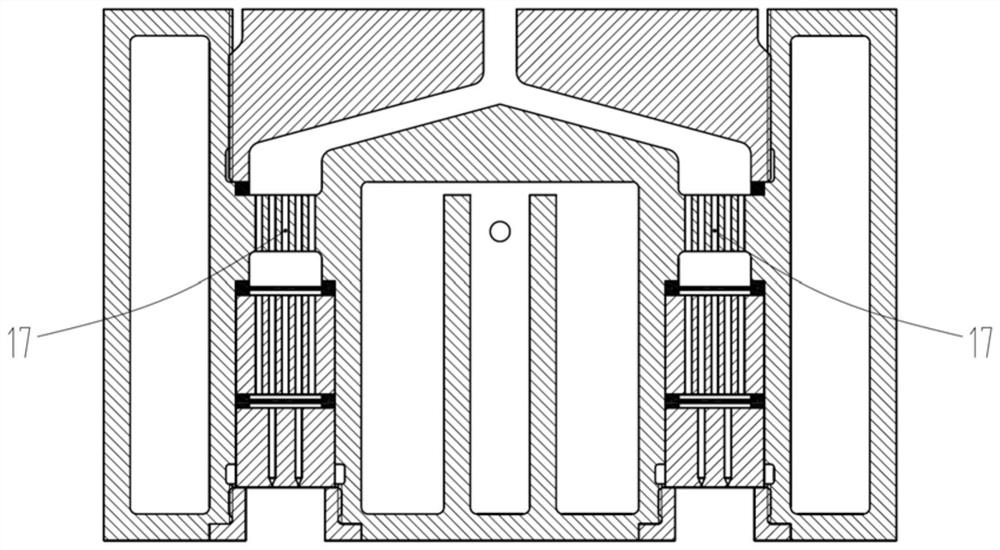

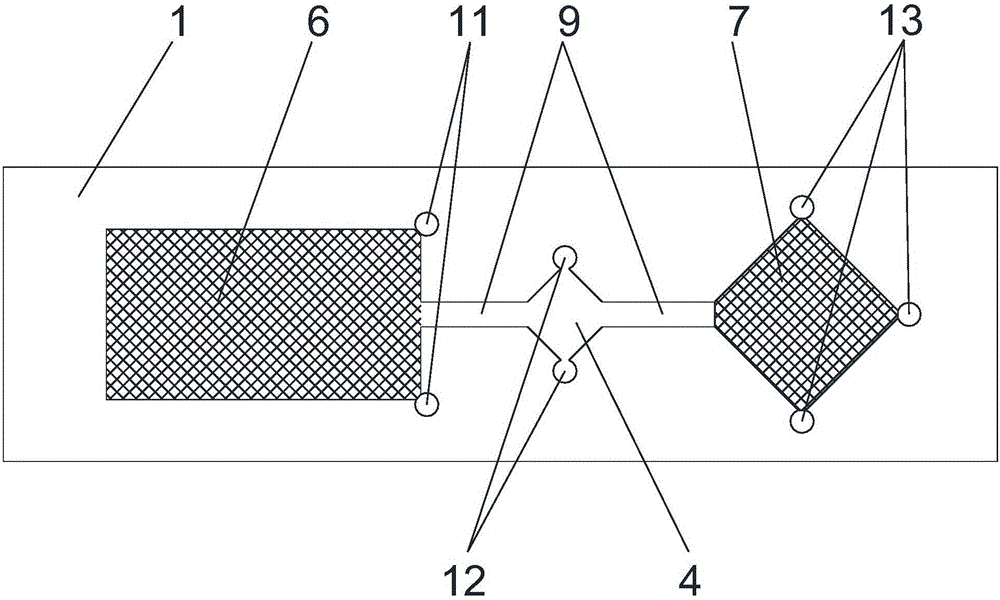

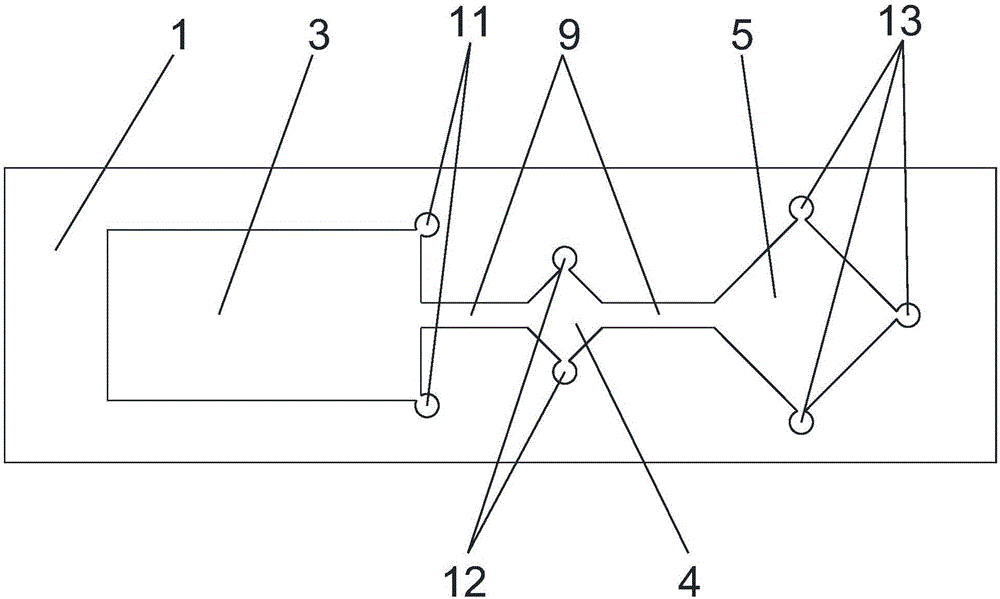

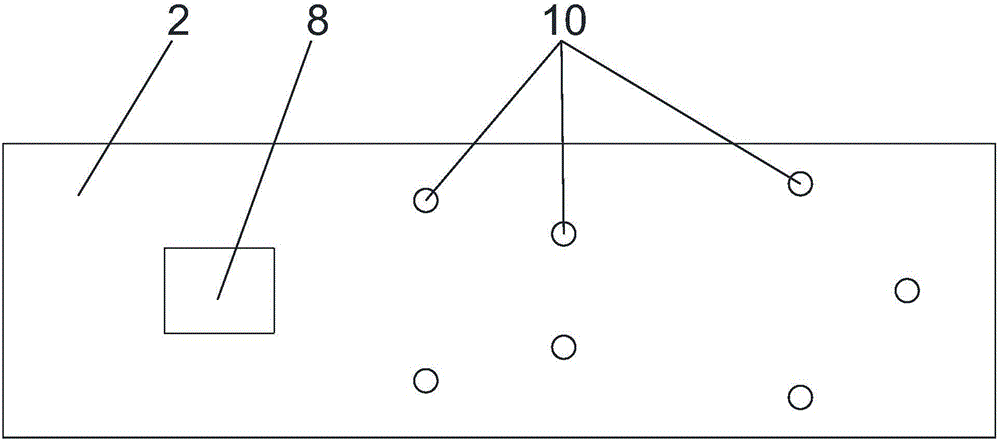

Dual-channel heat state switching mixing filter for preparing mesophase pitch based carbon fibers

The invention discloses a dual-channel heat state switching mixing filter for preparing mesophase pitch based carbon fibers. Before arriving at an assembly, molten polymers are already repeatedly mixed in multiple mixing flow channels in the filter, impurities and gel are repeatedly filtered in a filter screen and metal sand, it is guaranteed that components of the molten polymers are mixed evenlywhen the molten polymers arrive at an inlet of the spinning assembly, the symmetric arrangement structure is adopted, and the two same filter flow channels are arranged. The closing state of the flowchannels is controlled through four high-temperature electromagnetic ball valves, when too many impurities exist in one filter channel and blocking happens, the molten polymer flow channel is switched to the other filter channel through valve control, production continues, and production is not influenced by filtering and blocking.

Owner:SHAANXI TIANCE NEW MATERIAL TECH

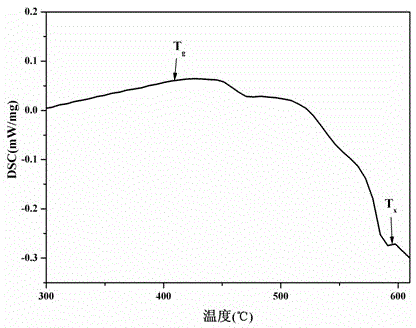

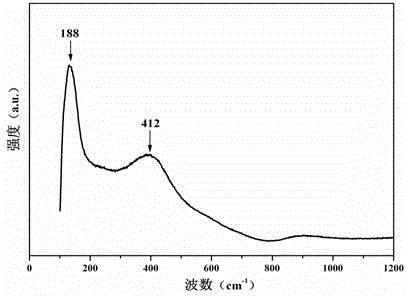

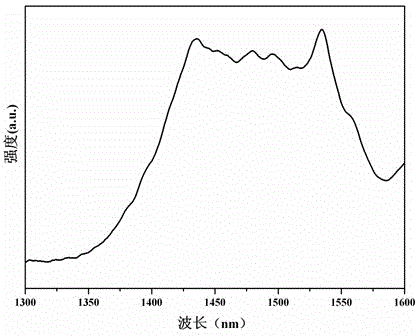

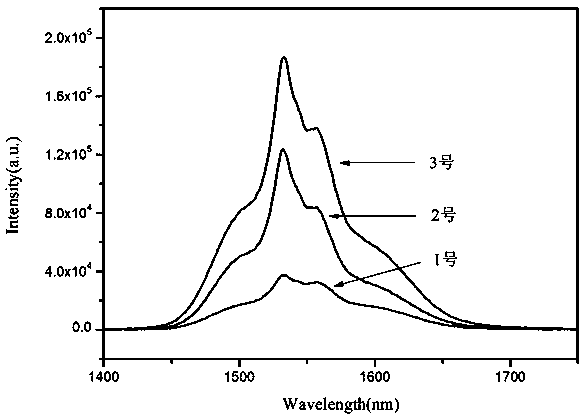

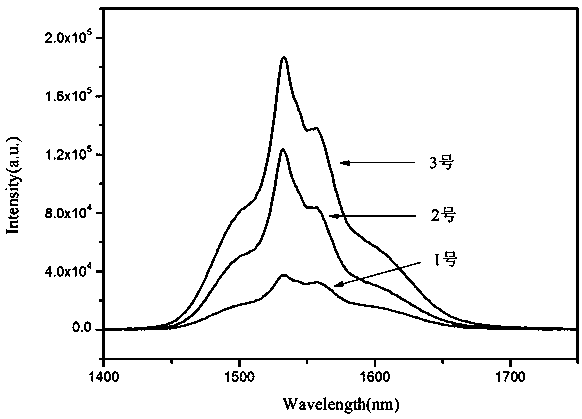

Near-infrared broadband luminescence erbium and thulium-co-doped bismuthate laser glass and preparation method thereof

The invention relates to near-infrared broadband luminescence erbium and thulium-co-doped bismuthate laser glass and a preparation method thereof. The glass comprises the following components in molar percentage: 53.6-59.8 mol% of Bi2O3, 10-20 mol% of B2O3, 10-20 mol% of SiO2, 10-20 mol% of Ga2O3, 0.8-1.2 mol% of Tm2O3 and 0.2-0.6 mol% of Er2O3. The glass which is prepared by utilizing a melting-cooling method is of glassy yellow and has uniform physical and chemical properties. The glass disclosed by the invention has the advantages of stable thermodynamic property and strong anti-devitrification ability. The Raman vibration spectrum of the glass shows that the strongest vibration peak is in the vicinity of 188-412cm-1. The probability of nonradiative transition of the energy level of rare earth ions is greatly reduced. The radiation bandwidth with the width of 165nm is obtained under pumping of a laser diode with 800nm wavelength and covered on an S plus C plus L wave band. The glass disclosed by the invention is suitable for preparation and application of near-infrared broadband luminescence rare earth ion-doped optical fiber materials.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

A chip for rapid detection of ischemia-modified albumin in blood

ActiveCN105973887BUniform physical and chemical propertiesMulti-buffer mixing spaceMaterial analysis by observing effect on chemical indicatorMedical unitHospitalized patients

The invention discloses a chip for rapidly detecting ischemia modified albumin in blood. The chip comprises a non-absorbent bottom plate and a non-absorbent cover plate, wherein a sample tank, a mixing tank and a detection tank are arranged on the bottom plate in sequence; micro-pipelines are arranged between the sample tank and the mixing tank and between the mixing tank and the detection tank; the sample tank is internally filled with a sample pad; the sample pad is coated with a cobalt standard product; the detection tank is internally filled with a detection pad; the detection pad is coated with a cobalt indicator; the cover plate is fixedly arranged above the bottom plate; and the cover plate is located above the sample tank and is provided with a sample feeding hole. The chip disclosed by the invention is simple in detection method, and a result is easy to judge; and the chip is suitable for being used in medical units including primary-level hospitals, emergency departments and the like or on bedsides of hospitalized patients, so that medical workers can rapidly judge dangers of the patients by layers and medical resources and health cost are saved.

Owner:西安良升生物科技有限公司

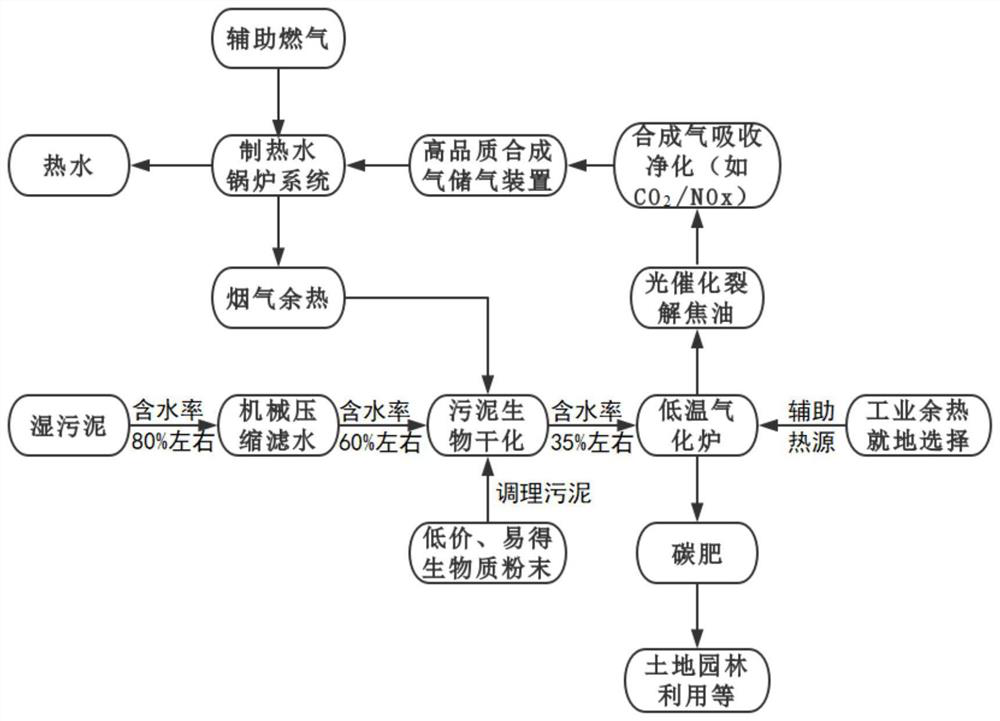

Comprehensive treatment process and system for preparing gas fertilizer by cooperation of biological drying and gasification of sludge

PendingCN112047597AAchieve reductionHarmlessWater treatment parameter controlSludge treatment by de-watering/drying/thickeningPhoto catalyticSludge

A comprehensive treatment process for preparing a gas fertilizer by cooperation of biological drying and gasification of sludge comprises the following steps: dehydrating excess sludge with water content of 80% by using mechanical filter pressing until the water content is reduced to 55-65%; carrying out biological drying and further dehydration treatment on the wet sludge subjected to conditioning and filter pressing by adopting cheap and easily available biomass powder to reduce the water content to 30-40%; and the addition of the biomass powder gives consideration to the advantages of conditioning the characteristics of the sludge, improving the heat value of the sludge and the like, the sludge subjected to secondary dehydration is fed into a low-temperature gasification furnace to finally obtain the carbon fertilizer, and high-temperature tar gas generated in the treatment process is subjected to photocatalytic cracking and adsorption purification to obtain high-quality synthetic gas. The invention further provides a comprehensive treatment system for preparing the gas fertilizer through cooperation of biological drying and gasification of the sludge. The comprehensive treatment process and system for preparing the gas fertilizer through cooperation of biological drying and gasification of the sludge are stable and reliable in operation, easy to operate, environment-friendly and energy-saving.

Owner:ZHEJIANG UNIV OF TECH

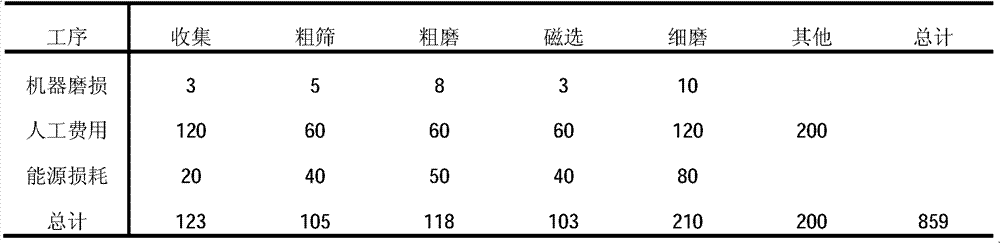

Recycled gas-shielded flux cored wire component and preparation method thereof

InactiveCN102152027BLow diffusible hydrogen contentReduce sensitivityWelding/cutting media/materialsSoldering mediaChemical compositionGranularity

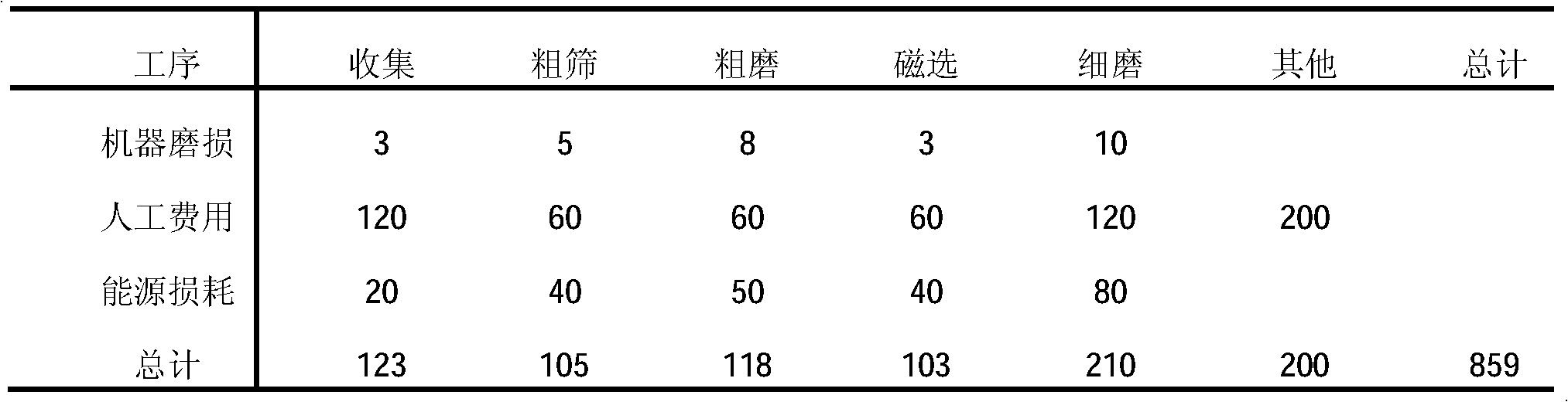

The invention discloses a recycled gas-shielded flux cored wire component and a preparation method thereof, which belong to the field of welding. The recycled gas-shielded flux cored wire component is characterized be comprising the components by the weight portions as follows: 35-65 percent of TiO2, 5-15 percent of MnO, 5-15 percent of MgO, 5-15 percent of SiO2, 1-15 percent of Fe2O3, and 1-15 percent of Al2O3. The invention is characterized in that the invention discloses a method for collecting, processing and recycling welding slag of rutile cored wires to replace rutile; through the steps of coarse screening, coarse grinding, magnetic separating and fine grinding, the granularity and chemical components of the welding slag are driven to satisfy requirements; and then the welding slagof the rutile cored wires can be used as a cored wire component to be added into gas-shielded flux cored wires to reach the purposes of replacing or partially replacing natural rutile, saving resources and reducing costs. As long as the powder components and granularity of the welding slag after processing and preparing are in the scope of the recycled gas-shielded flux cored wire component, the recycled gas-shielded flux cored wire component can be recycled for a plurality of times.

Owner:BEIJING UNIV OF TECH

Preparation of a dual-channel hot-state switching hybrid filter for mesophase pitch-based carbon fibers

The invention discloses a dual-channel hot-state switching mixing filter for preparing mesophase pitch-based carbon fibers, so that the molten polymer before reaching the component has been repeatedly mixed in multiple mixing flow channels inside the filter, and impurities and gels are in the filter screen and The metal sand is filtered multiple times to ensure that the molten polymer is evenly mixed when it reaches the inlet of the spinning assembly. It adopts a symmetrical arrangement structure and has two identical filter flow channels. Four high-temperature electromagnetic ball valves control the closed state of the flow channel. When there are too many impurities in one filter channel and blockage occurs, the molten polymer flow channel is switched to another filter channel through valve control, so that production can continue without filter blockage influences.

Owner:SHAANXI TIANCE NEW MATERIAL TECH

Chip for rapidly detecting ischemia modified albumin in blood

ActiveCN105973887AUniform physical and chemical propertiesMulti-buffer mixing spaceMaterial analysis by observing effect on chemical indicatorMedical unitHospitalized patients

The invention discloses a chip for rapidly detecting ischemia modified albumin in blood. The chip comprises a non-absorbent bottom plate and a non-absorbent cover plate, wherein a sample tank, a mixing tank and a detection tank are arranged on the bottom plate in sequence; micro-pipelines are arranged between the sample tank and the mixing tank and between the mixing tank and the detection tank; the sample tank is internally filled with a sample pad; the sample pad is coated with a cobalt standard product; the detection tank is internally filled with a detection pad; the detection pad is coated with a cobalt indicator; the cover plate is fixedly arranged above the bottom plate; and the cover plate is located above the sample tank and is provided with a sample feeding hole. The chip disclosed by the invention is simple in detection method, and a result is easy to judge; and the chip is suitable for being used in medical units including primary-level hospitals, emergency departments and the like or on bedsides of hospitalized patients, so that medical workers can rapidly judge dangers of the patients by layers and medical resources and health cost are saved.

Owner:西安良升生物科技有限公司

Method for preparing organic compound single-crystal nano structure

InactiveCN101210347BFlawlessHigh purityPolycrystalline material growthFrom condensed vaporsCrystal structureSingle crystal

The invention discloses a method for preparing single crystal nanostructure of an organic compound, which comprises the following steps of: (1) disposing a substrate and a quartz boat loaded with an organic compound powder into a quartz tube, connecting the quartz tube with a vacuum system and vacuuming the quartz tube to a pressure 10<-2> to 5 Pa; and (2) heating the quartz boat to the sublimation temperature of the organic compound and heating the substrate to a temperature lower than the sublimation temperature of the organic compound by 130 to 180 DEG C, keeping the vacuum degree in the quartz tube and growing the crystal nanostructure of the organic compound on the substrate. The invention is simple and easy and can obviate the use of a template and a catalyst. The obtained nanostructure has good crystallization, no defect, high purity and better test reproducibility.

Owner:INST OF CHEM CHINESE ACAD OF SCI

A kind of production process of medical ta3 plate

The invention relates to a production technology for medical TA3 sheet materials. The technology comprises the following steps: slabs are subjected to production and roll type hot rolling, strip coils are subjected to annealing, shot blasting, acid pickling, cold rolling, degreasing and cutting and splitting, the sheet materials are subjected to annealing and shot blasting, and the TA3 sheet materials are obtained. According to the invention, one-chip production is replaced by a roll type production; for medical TA3 sheet materials of 4.0-6.2 mm, 2-3 heating numbers and semi-finished product processing procedures between firing can be omitted; for TA3 sheet materials of 2.0-4.0 mm, 2-3 heating numbers can be omitted, and 2-3 rolling processes and semi-finished product processing procedures can be omitted, and the total processing procedures can be reduced by more than 30%; 4-6 tons of the TA3 sheet materials can be produced for one batch; the production technology has the advantages of low cost and high efficiency.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

trpc3 antigen polypeptide and anti-trpc3 monoclonal antibody

InactiveCN105399798BEasy to predictMeet the requirements for the preparation of monoclonal antibodiesImmunoglobulins against animals/humansMicroorganism based processesDiseaseTRPC3 channel

The invention discloses a TRPC3 (Transient receptor potential cation channel, subfamily C, member 3) antigen peptide and an anti-TRPC3 monoclonal antibody. The TRPC3 antigen peptide comprises 15 amino acids, and a specific sequence is represented as SEQ ID NO: 1. A preparation method of the anti-TRPC3 monoclonal antibody comprises steps as follows: the TRPC3 antigen peptide after being coupled with KLH (keyhole limpet hemocyanin) is taken as an antigen for immunization of a mouse, a hybridoma cell strain T-II is obtained through screening, and the anti-TRPC3 monoclonal antibody is obtained through secretion of the hybridoma cell strain T-II. The anti-TRPC3 monoclonal antibody can specifically recognize TRPC3 channel protein expressed by various tissue cells and can be applied to TRPC3 expression research of various tissue cells, thereby monitoring diseases related with TRPC3 molecules. Therefore, the anti-TRPC3 monoclonal antibody can be applied to preparation of diagnostic reagents for diseases related with TRPC3 molecule expression.

Owner:GUANGDONG PHARMA UNIV

A silver nanocrystal reinforced erbium-doped bismuthate laser glass for optical fiber amplifier and preparation method thereof

The invention provides silver nanocrystalline reinforced erbium-doped bismuthate laser glass for an optical fiber amplifier. The glass is prepared from the following raw materials according to molar percentage: 48 to 65mol% of Bi2O3, 15 to 25mol% of B2O3, 15 to 25mol% of SiO2, 0.5 to 1mol% of Er2O3, and 0 to 1mol% of Ag. The invention further provides a preparation method of the silver nanocrystalline reinforced erbium-doped bismuthate laser glass for the optical fiber amplifier. The glass disclosed by the invention has a broadband luminescent property of 1,450 to 1,700nm and has the maximum emission interface of 7.1*10<-21>cm<2>, covers a C+L communication waveband and is applicable to a near-infrared broadband optical fiber amplifier in the field of optical fiber communication.

Owner:LIANYUNGANG HONGYANG QUARTZ PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com