Dual-channel heat state switching mixing filter for preparing mesophase pitch based carbon fibers

A mesophase pitch and carbon fiber technology, which is applied in fiber treatment, filament forming treatment, spinning solution degassing, etc., to achieve the effect of changing the filtration type, reliable cooperation, and small space size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention is described in further detail:

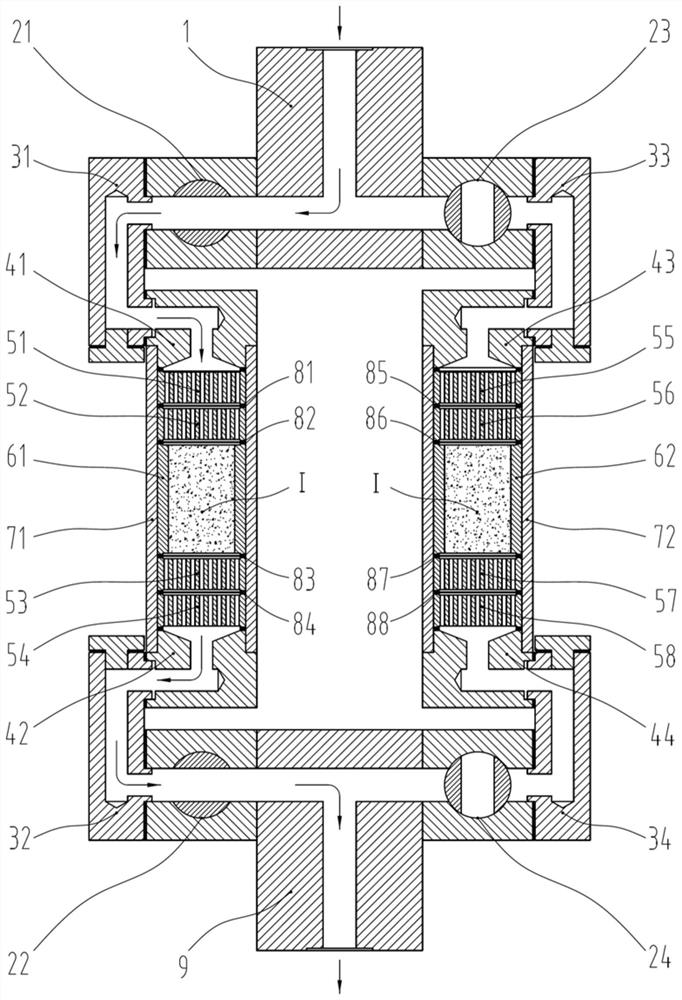

[0030] Such as figure 1 As shown, the dual-channel hot-state switching hybrid filter for preparing mesophase pitch-based carbon fibers includes an inlet three-way pipeline 1, and a first high-temperature electromagnetic ball valve 21 and a third high-temperature electromagnetic ball valve 23 are arranged behind the inlet three-way pipeline 1 , the back of the first high temperature electromagnetic ball valve 21 is arranged in sequence with the first flow channel reverse conversion pipeline 31, the first flow channel right-angle conversion pipeline 41, the first mixing and filtering pipeline 71, which are sequentially installed inside the first mixing and filtering pipeline 71 There is a first circular mixing perforated plate 51, a first circular filter screen 81, a second circular mixing perforated plate 52, a second circular filter screen 82, a first metal sand filli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com