Production technology for medical TA3 sheet materials

A production process and plate technology, applied in the field of TA3 plate production technology, can solve the problems of fluctuation of finished plate performance, strict requirements on external dimensions, thickness tolerance and same plate difference, fluctuation of plate physical and chemical performance indicators, etc. Process reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

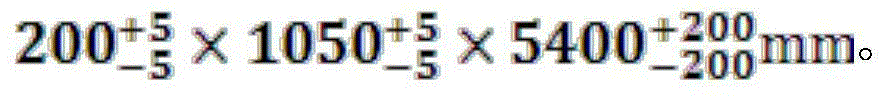

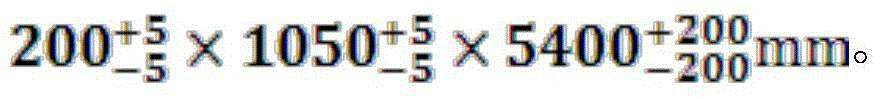

[0059] The first step, the production of the slab: select zero-grade small particle sponge titanium, use the German ALD vacuum consumable electric arc furnace for three times of melting, after three times of forging and face milling, the flaw detection level reaches A level, and the low-magnification structure is Fuzzy crystal TA3 slab, the nominal size of the slab is 200*1050*5500mm.

[0060] The second step, the coil hot rolling of the slab: put the slab into the walking heating furnace at room temperature, start timing when the temperature reaches 890°C, keep it warm for 300 minutes and then roll it out of the furnace, and pass 10 passes of rolling To 4.2mm, the deformation rate of each pass is as follows: 16%, 29.7%, 38.1%, 41%, 46.5%, 43.4%, 34.6%, 23.5%, 23%, 20%.

[0061] The third step, uncoiling and slitting of the strip: the hot-rolled strip is uncoiled and slit on the 1450mm finishing line. First, cut off the defective strips at the head and tail of the hot-rolled ...

Embodiment 2

[0065] The first step, the production of the slab: select zero-grade small particle sponge titanium, use the German ALD vacuum consumable electric arc furnace for three times of melting, after three times of forging and face milling, the flaw detection level reaches A level, and the low-magnification structure is Fuzzy crystal TA3 slab, the nominal size of the slab is 200*1050*5500mm.

[0066] The second step, the coil hot rolling of the slab: put the slab into the walking heating furnace at room temperature, start timing when the temperature reaches 890°C, keep it warm for 300 minutes and then roll it out of the furnace, and pass 10 passes of rolling To 4.5mm, the deformation rate of each pass is as follows: 16%, 29.7%, 38.1%, 41%, 46.5%, 43.4%, 34.6%, 23.5%, 23%, 15%.

[0067] The third step, the annealing of the coil: in the way of continuous annealing, put the TA3 coil into a 10m long continuous annealing furnace, raise the temperature of the furnace to 750°C, and the unco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com