Inner and outer layer heat medium cyclic heating spinning component for preparing mesophase pitch based carbon fibers

A mesophase pitch and cyclic heating technology, which is applied in the direction of spinneret assembly, fiber treatment, spinning solution degassing, etc., can solve the problems of reduced overall performance of carbon fiber bundles, discrete increase of carbon fiber diameter, and inconsistent performance of carbon fibers. Achieve the effects of fast temperature control response, high temperature control accuracy, and reduced temperature distribution gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

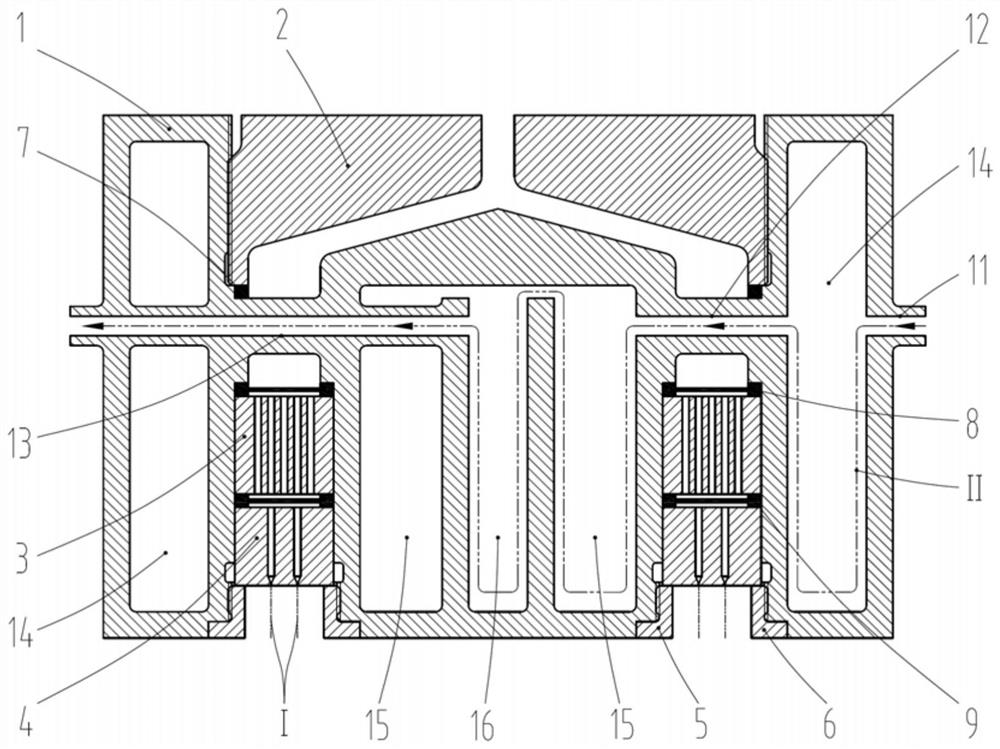

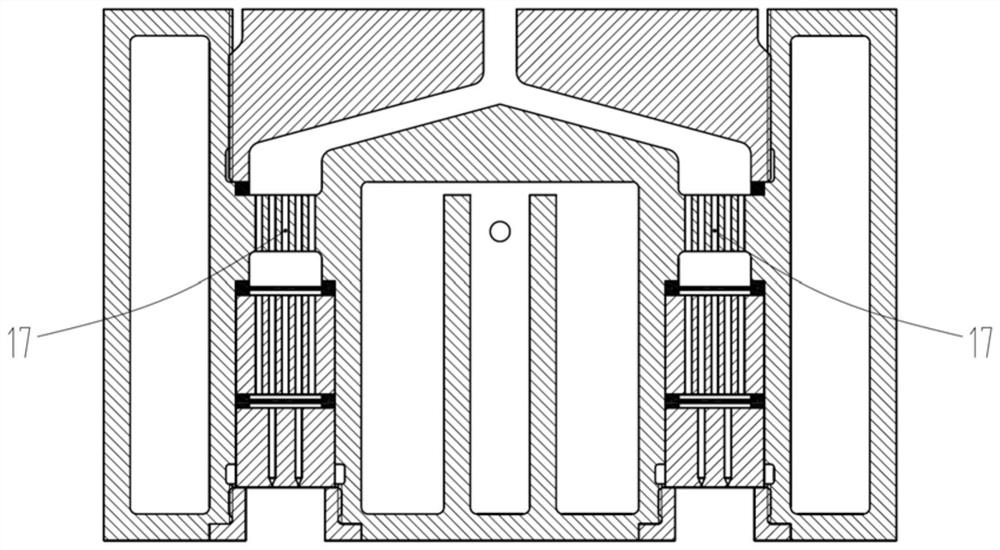

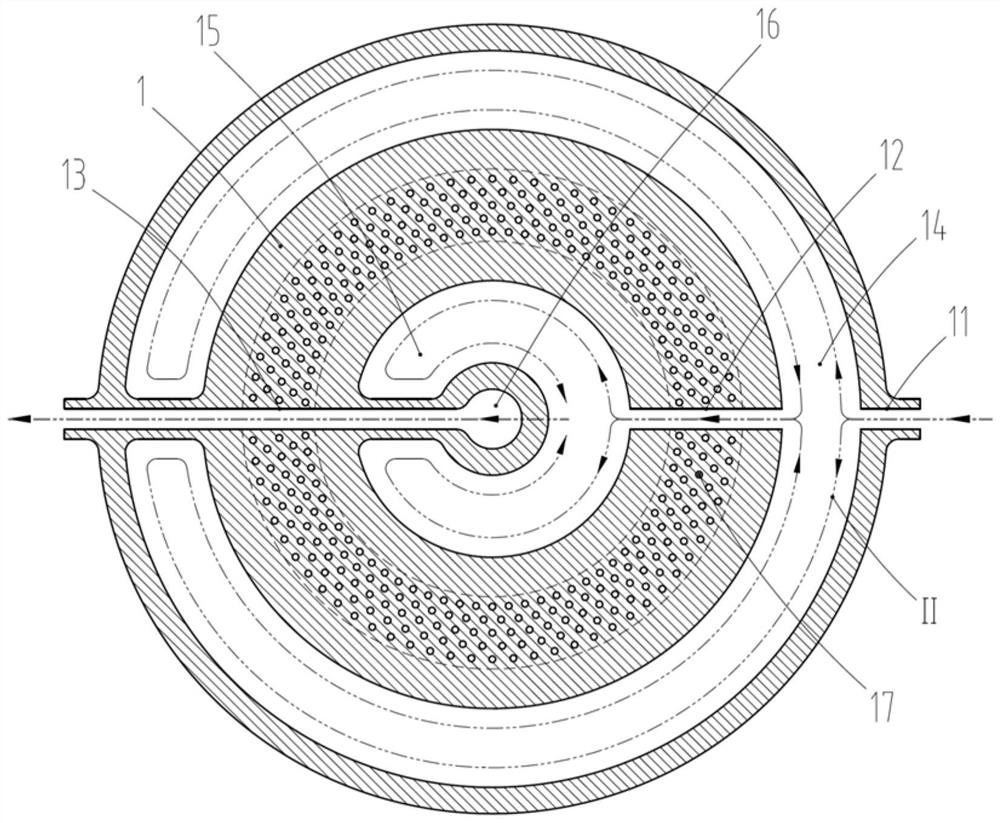

[0031] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0032] Such as Figure 1 to Figure 3 As shown, an inner and outer heat medium circulating heating spinning assembly for preparing mesophase pitch-based carbon fibers, including a heat medium circulating heating chamber 1, a raw material inlet plate 2, a mixing porous plate 3, a spinneret plate 4, and an inner layer fixing sleeve 5. The outer fixed sleeve 6, the sealing gasket 7, the first edging filter screen 8, and the second edging filter screen 9.

[0033] The raw material inlet plate 2 is fixed on the upper inner cavity of the heat medium circulation heating cavity 1 through threads, and the sealing gasket 7 is between the raw material entrance plate 2 and the heat medium circulation heating cavity 1 . The mixing perforated plate 3 is installed from the bottom of the heat medium circulation heating cavity 1 to the top of the lower inner chamber, and the first edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com